To SSM Ahead of Schedule

#261

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

-10 feed -6 return? Thats like opposite from stock isnt it? The rack has a M14 Banjo bolt on the high pressure side and a M16x1.5 inverted flare fitting on the LP side. The face of the rack looks like it got a cleanup machining pass on the LP side so I just need to scotch bright the scale off it to run a banjo fitting there (already ordered). I'll be running -6 AN on both sides unless it proves to be a problem, with the option to add a PS cooler if needed. The volvo pump has the reservoir built into it, so I shouldnt need another, thanks for the offer though. I do plan on paying someone to fabricate the HP line because its going to need crimped connections, I already have an in at a hydraulic shop. That reminds me I should call that junk yard about the pump today.

On a track car, I dont think having PS would be too big of a deal. But running the 275's on a track car I might want a steering damper rather than PS. The two issues I'm resolving by going to PS is, the manual rack ratio is too slow for how fast the car is, and the kickback from the tires even with the slow rack is enough that the wheel has been ripped out of my hands. A damper would take care of the ripping issue as much as PS will, but with my car in auto-x, a lot of times my speed in elements is limited by how fast I can turn the wheel, so every bit there helps.

On a track car, I dont think having PS would be too big of a deal. But running the 275's on a track car I might want a steering damper rather than PS. The two issues I'm resolving by going to PS is, the manual rack ratio is too slow for how fast the car is, and the kickback from the tires even with the slow rack is enough that the wheel has been ripped out of my hands. A damper would take care of the ripping issue as much as PS will, but with my car in auto-x, a lot of times my speed in elements is limited by how fast I can turn the wheel, so every bit there helps.

#262

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

I will clarify.

-10an from the reservoir to the pump (feed)

-6an from the stock "cooling" lines to the reservoir (return)

I left the high pressure lines from the pump to the rack and the low pressure cooling loop. Doing it again (which I might) I would get a small oil cooler with -6an fittings and run a new return line right off the rack to the cooler then back to the reservoir.

For me the only reason I am considering leaving PS is because I want to be able to be able to have anyone drive the car and enjoy the experience... instead of fighting a crazy setup. (im thinking of my wife in specific, but the idea is the same either way)

-10an from the reservoir to the pump (feed)

-6an from the stock "cooling" lines to the reservoir (return)

I left the high pressure lines from the pump to the rack and the low pressure cooling loop. Doing it again (which I might) I would get a small oil cooler with -6an fittings and run a new return line right off the rack to the cooler then back to the reservoir.

For me the only reason I am considering leaving PS is because I want to be able to be able to have anyone drive the car and enjoy the experience... instead of fighting a crazy setup. (im thinking of my wife in specific, but the idea is the same either way)

#263

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

That makes sense. I wouldnt really think without the PS that it would be too crazy. What makes my car physically difficult to drive is having to go hand over hand a lot, and the kickback from the big tires. The wheel isnt that hard to turn with the manual rack and I wouldnt think it would be much worse with a depowered rack. Heck the hohos are easier to turn when stopped than the RS3s.

On the pump front. Called the $30 pump junk yard. They want a $20 core charge, seriously what junk yard has a ******* core charge? And they're 35 miles away and would make me pull it. The JY 2 miles away has one for $75 and they're pulling it for me. I'm glad there's like a billion of these pumps in junk yards in case it ever dies.

On the pump front. Called the $30 pump junk yard. They want a $20 core charge, seriously what junk yard has a ******* core charge? And they're 35 miles away and would make me pull it. The JY 2 miles away has one for $75 and they're pulling it for me. I'm glad there's like a billion of these pumps in junk yards in case it ever dies.

Last edited by Leafy; 01-21-2014 at 10:15 AM.

#264

Used pumps off EBAY $34 shipped. So $75 seems a little pricy.

1999 2000 2001 2002 2003 2004 2005 Mazda Miata MX 5 Power Steering Pump | eBay

1999 2000 2001 2002 2003 2004 2005 Mazda Miata MX 5 Power Steering Pump | eBay

#265

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Used pumps off EBAY $34 shipped. So $75 seems a little pricy.

1999 2000 2001 2002 2003 2004 2005 Mazda Miata MX 5 Power Steering Pump | eBay

1999 2000 2001 2002 2003 2004 2005 Mazda Miata MX 5 Power Steering Pump | eBay

#267

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

I'll check when I get back to my apartment. I'm taking a lot of weight out of the back this winter because the new fuel pump setup should be able to run on only a couple gallons of gas rather than a full tank like I ran all year.

#268

I need to learn more about tanks and pickups. A friend with multiple CSP national championships says he has started events with the needle hovering empty. Never had a problem. I never know if I should run low for less weight, run several gallons giving me tank slap, or run full. That's why my prepared cars run 2-3 gal fuel cells. Eliminates the decision.

#269

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Stock style pickups work. Non-stock style blow. I was running the bosch044, now I have the wally400E85 using the wally stock style pickup. The effects are worse and worse the more grip you make. The 044 was pretty much fine on street tires with no aero. But on 275 hoho and with aero it needed no less than 6 gallons in the tank or it was going to fuel starve.

And I know that at least 2 top national CSP cars have broken baffles in the tank from the fuel sloshing at high G loads.

And I know that at least 2 top national CSP cars have broken baffles in the tank from the fuel sloshing at high G loads.

#270

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Keep forgetting to check that weight distribution.

I just picked up the pump today. It feels like its only 10-15 pounds with the factory volvo isolation bracket on it. I dont think its going to be easy to fit in the engine bay. With all the other ****. The trunk is sounding like a better idea.

I just picked up the pump today. It feels like its only 10-15 pounds with the factory volvo isolation bracket on it. I dont think its going to be easy to fit in the engine bay. With all the other ****. The trunk is sounding like a better idea.

#272

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

So update from the weekend, in no particular order.

Went to take the intake manifold back off because I realized I needed to make new fuel lines... ahhh... Yeah I'm putting the brace on, **** this.

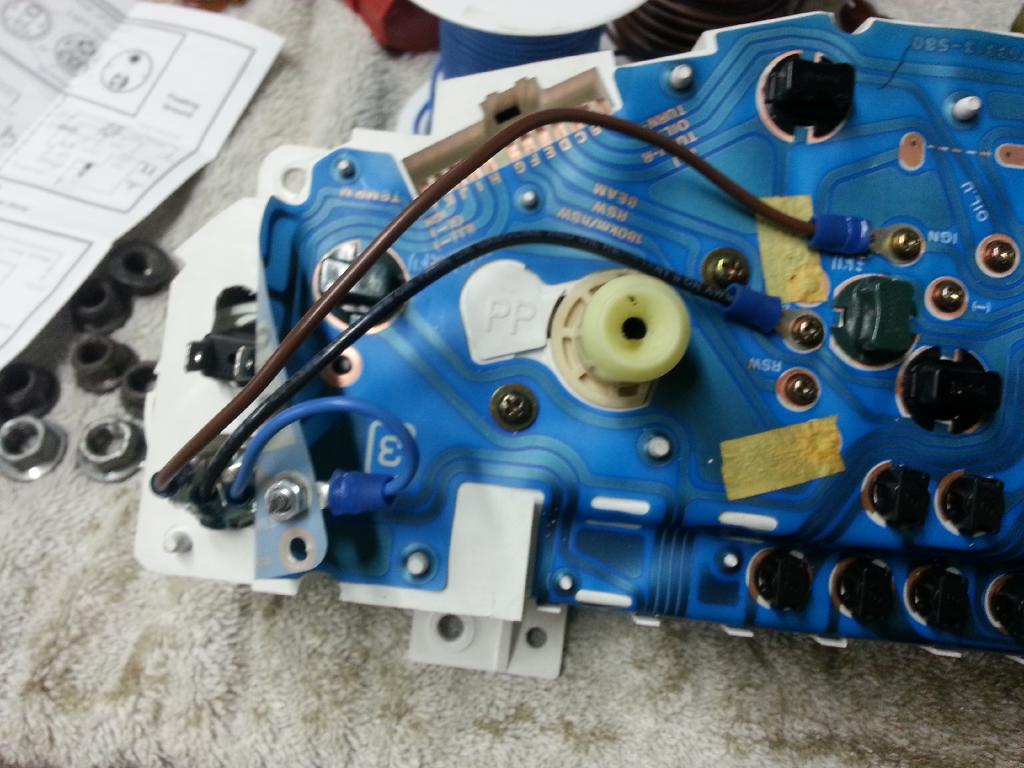

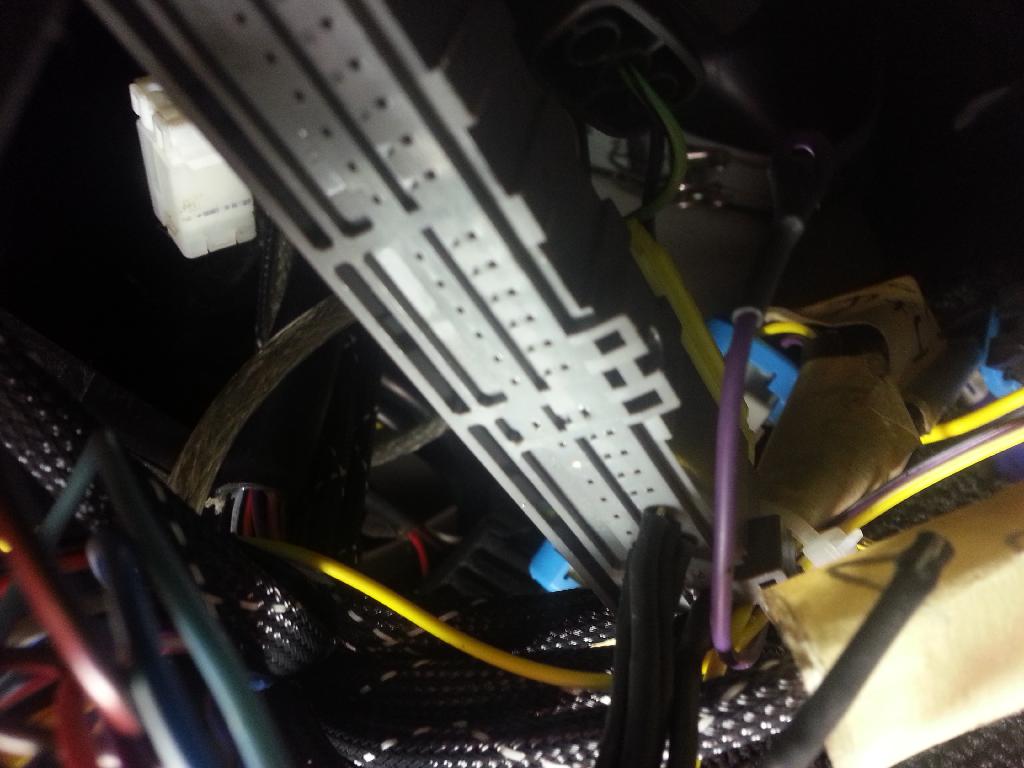

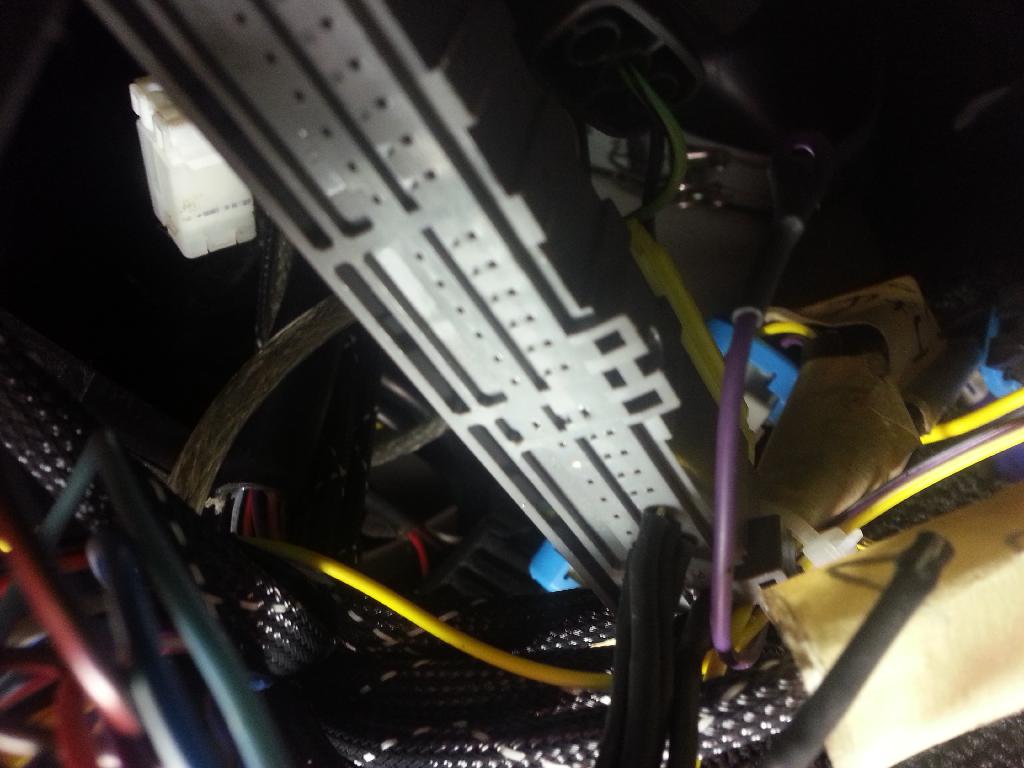

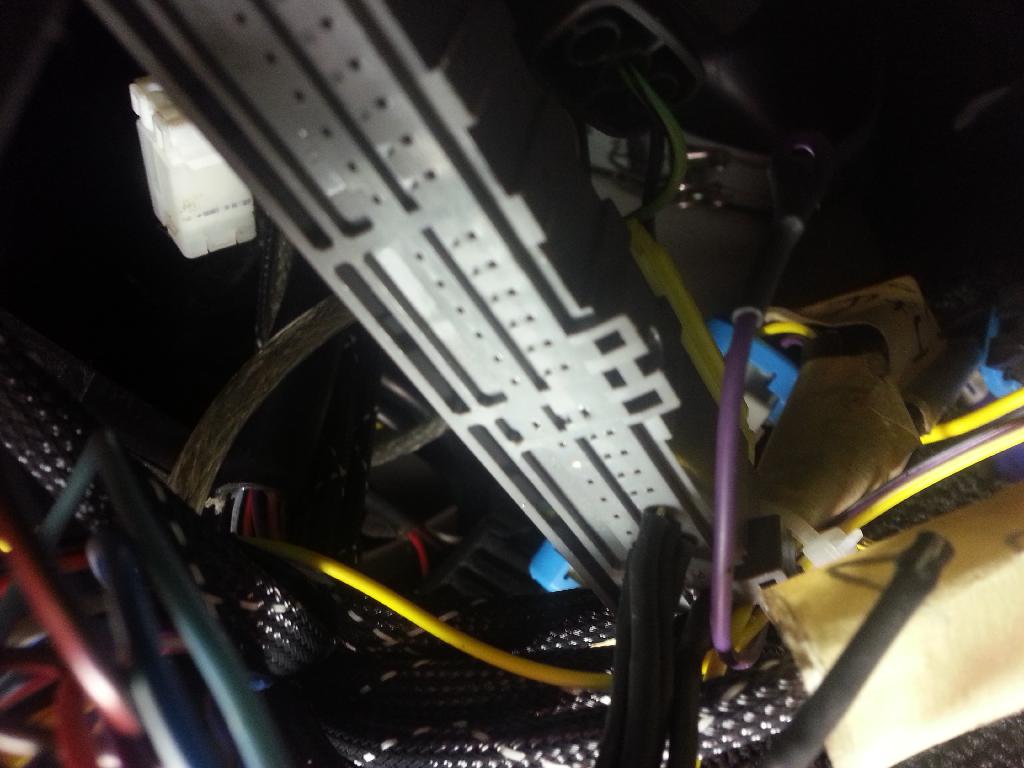

Pictures of the gauge mod, I decided to just tie the gauge light into the wires in the dash rather than try to solder to the flex board.

Had to clearance the dash a bit.

What I didnt take pictures of. The new fuse and relay panel in the engine bay, came out pretty ok. Its not done yet because I ran out of 12-10gauge female spade terminals and relay sockets. That will get finished next weekend. I drilled and partially wired for the new fuel pump wiring in the tank. I didnt finish because the metripac connector for the wally pump I bought from ballenger apparently wasnt fuel rated and the seal swelled up and broke. Not a big deal for gasoline use, but once I run on E85 the connector needs to be sealed. I bought the listed mating part from racetronix which should be the real deal. I also need to ground the fuel pump wiring. Once thats done I can put the interior back together besides the center console.

I got the brake system all sealed up, the front sider pins were basically siezed again, so I lubed those bitches up. Next year I would really like to get a lightweight brake setup.

Got the front bodywork back on. The fenders and bumper have never lined up this well as long as I owned the car. My dad spent some time drilling out broken bolts and getting stuff to line up.

And a bought a whole shitload of stuff last night.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

oil

coolant

RB Race front sway bar and 949 endlinks (my current bar setup is staying in my dads car)

Things that need to happen

Engine, radiator, back in

Finish wiring oil temp gauge

finish fuel pump wiring

finish abs wiring

power steering wiring

design and make a new splitter

install new headlight setup

bleed brakes and clutch

mount aero catches

Mount FPR somewhere new since the ABS **** is in the way now

make a new turbo oil feed line and drain line

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

put running lights on the trailer

fix the brakes on the trailer

put seats back in, now with 90-93 style belts

put rest of interior back together

redo the fuel lines in the engine bay

mount power steering pump, and do hoses

install intake tube

make a working crank case vent setup

pray the fuel pump wiring doesnt blow up the car

pray the rest of the wiring works

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

Went to take the intake manifold back off because I realized I needed to make new fuel lines... ahhh... Yeah I'm putting the brace on, **** this.

Pictures of the gauge mod, I decided to just tie the gauge light into the wires in the dash rather than try to solder to the flex board.

Had to clearance the dash a bit.

What I didnt take pictures of. The new fuse and relay panel in the engine bay, came out pretty ok. Its not done yet because I ran out of 12-10gauge female spade terminals and relay sockets. That will get finished next weekend. I drilled and partially wired for the new fuel pump wiring in the tank. I didnt finish because the metripac connector for the wally pump I bought from ballenger apparently wasnt fuel rated and the seal swelled up and broke. Not a big deal for gasoline use, but once I run on E85 the connector needs to be sealed. I bought the listed mating part from racetronix which should be the real deal. I also need to ground the fuel pump wiring. Once thats done I can put the interior back together besides the center console.

I got the brake system all sealed up, the front sider pins were basically siezed again, so I lubed those bitches up. Next year I would really like to get a lightweight brake setup.

Got the front bodywork back on. The fenders and bumper have never lined up this well as long as I owned the car. My dad spent some time drilling out broken bolts and getting stuff to line up.

And a bought a whole shitload of stuff last night.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

oil

coolant

RB Race front sway bar and 949 endlinks (my current bar setup is staying in my dads car)

Things that need to happen

Engine, radiator, back in

Finish wiring oil temp gauge

finish fuel pump wiring

finish abs wiring

power steering wiring

design and make a new splitter

install new headlight setup

bleed brakes and clutch

mount aero catches

Mount FPR somewhere new since the ABS **** is in the way now

make a new turbo oil feed line and drain line

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

put running lights on the trailer

fix the brakes on the trailer

put seats back in, now with 90-93 style belts

put rest of interior back together

redo the fuel lines in the engine bay

mount power steering pump, and do hoses

install intake tube

make a working crank case vent setup

pray the fuel pump wiring doesnt blow up the car

pray the rest of the wiring works

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

#273

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

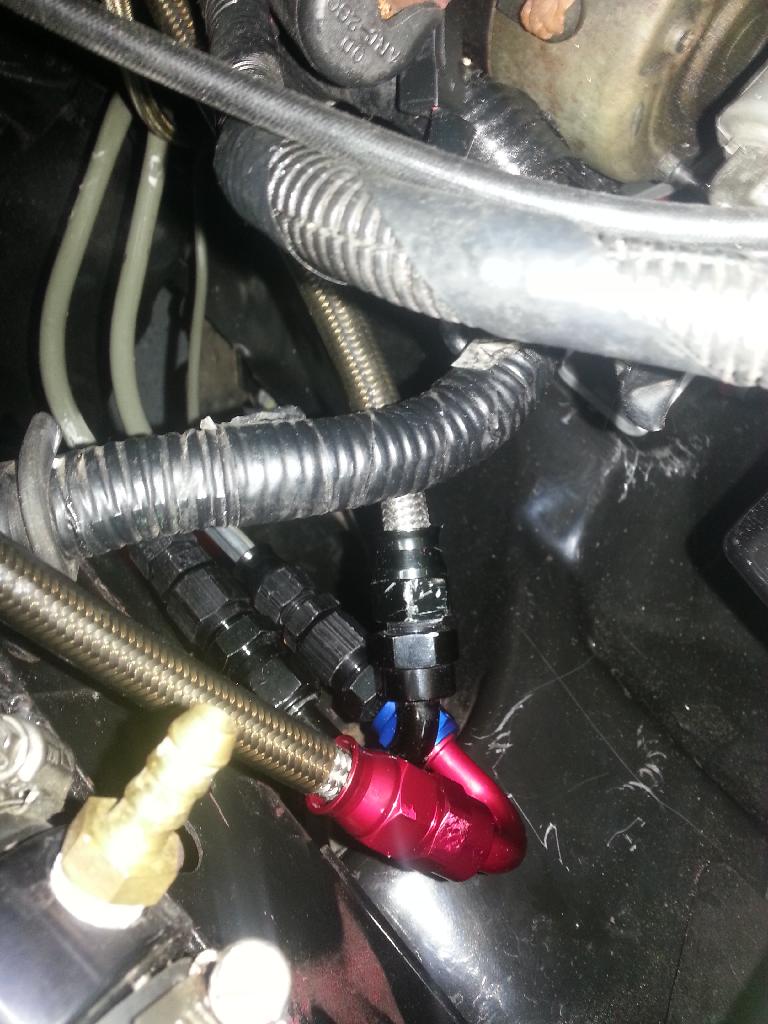

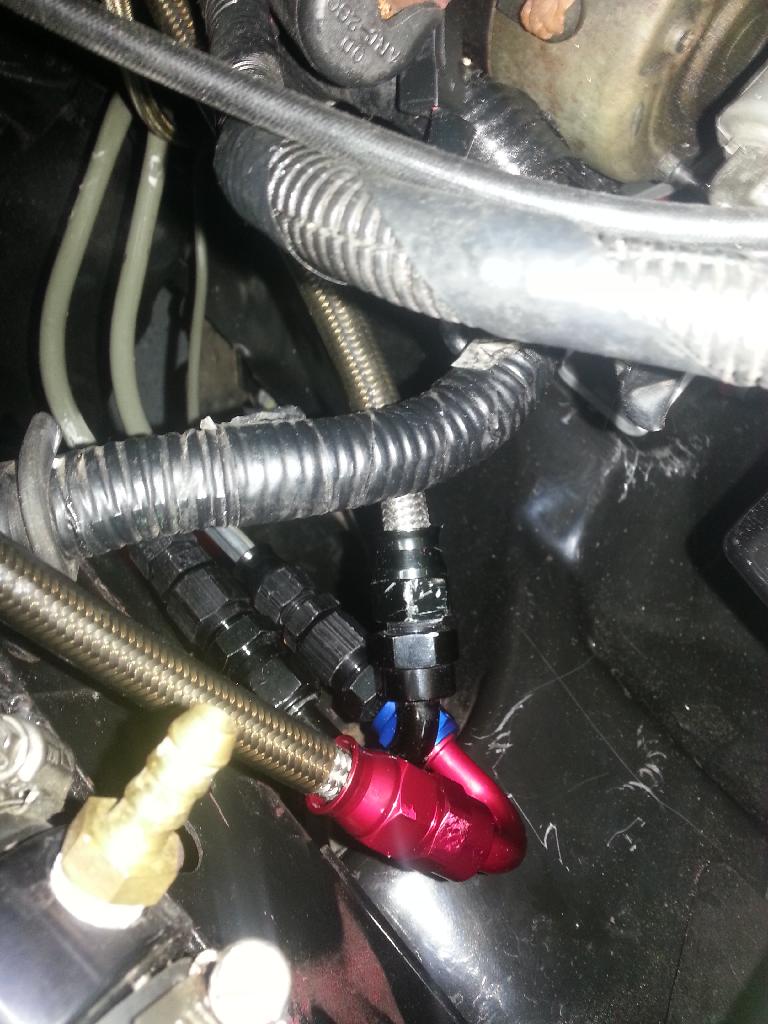

Got more work done. Finished up the in tank wiring for the pump, the relay socket didnt come so I couldnt finish the wiring completely.

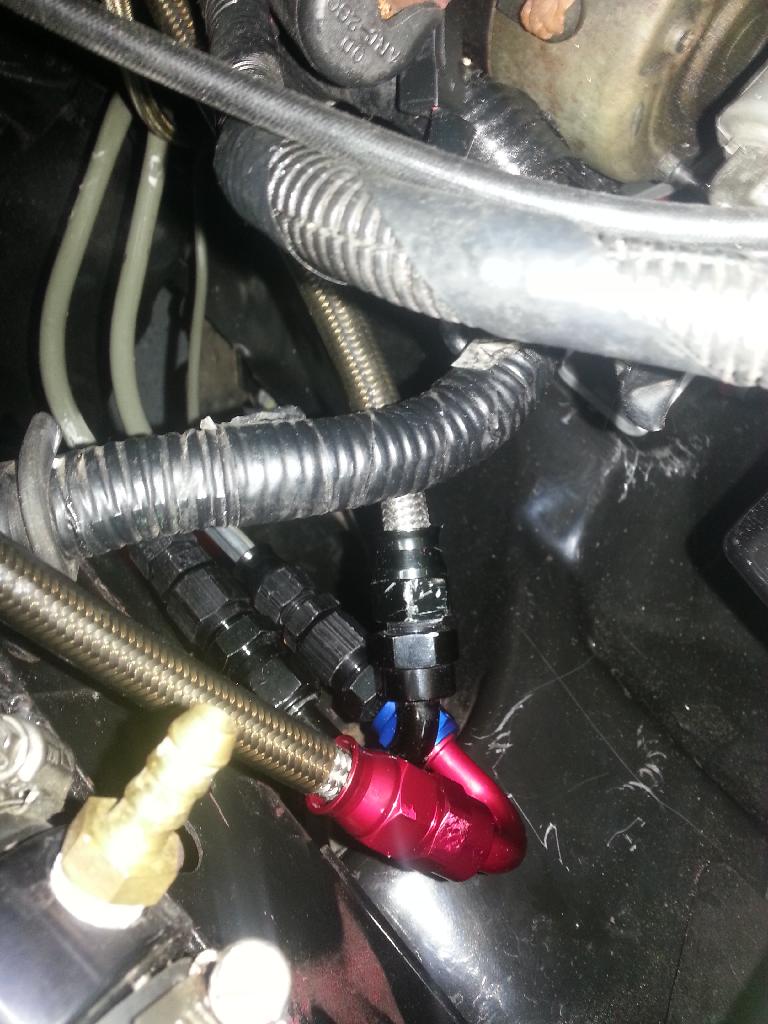

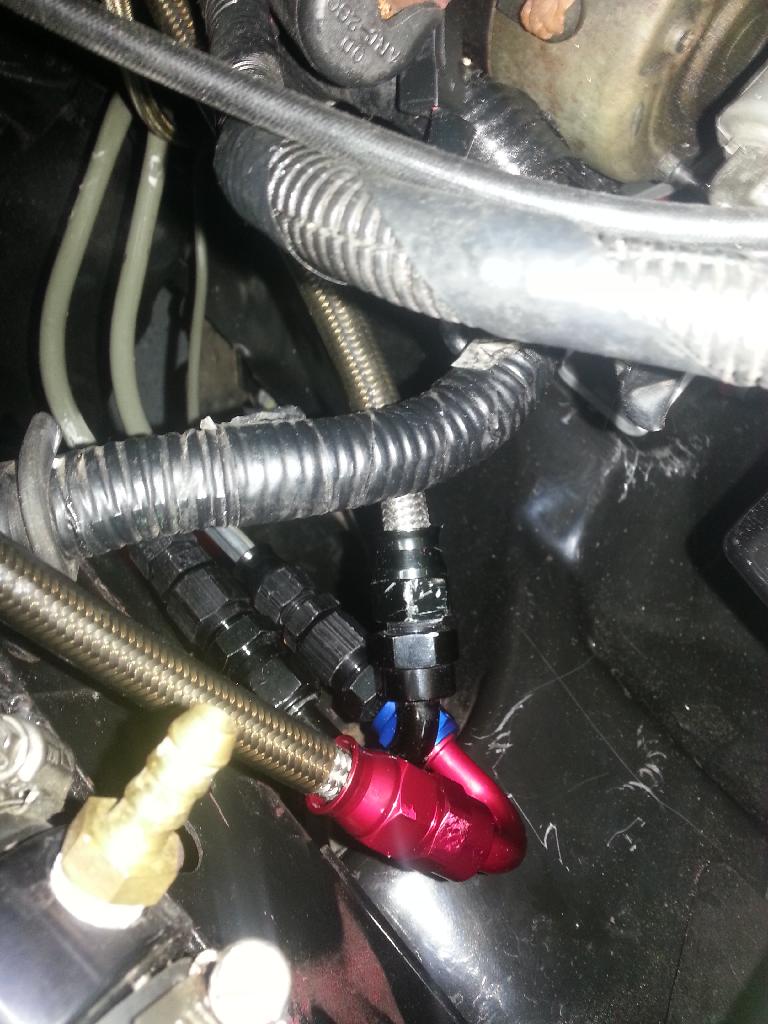

Made up new oil lines for the turbo. Had to reajust the hardline for the feed once the engine was in the car.

Wrote myself a little note. Every ******* time I forget to put that god damn plate on.

I broke one of the tranny bolts when torquing them, and of course their M12 and my local hardware stores only go up to M10 for JIS bolts, cant find em online either, looks like I'm buying from mazda and paying $12 to ship a $3 bolt.

Got the engine in, radiator in, started making up the fuel lines, figured out how I'm mounting the fpr. Getting the engine is was a pain in the dick this time, because I accidentally put the chains as 2 different lengths on the load leveler, had to pull it back out and fix that before I could get it to drop back in. Decided that there's no ******* way the power steering pump is going to fit in the engine bay, its going in the spot where the jack was in the trunk. Almost died last night from the heater being dirty, still feel shitty. Also finished up the work on the trailer. And I got the passenger seat and belt in, the drivers side belt threads are all fucked up, I had to order an M12x1.25 tap I only had M12x1.5 on hand.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

coolant

RB Race front sway bar and 949 endlinks (my current bar setup is staying in my dads car)

tranny bolt

Things that need to happen

finish fuel pump wiring

finish abs wiring

power steering wiring

design and make a new splitter

install new headlight setup

bleed brakes and clutch

mount aero catches

Mount FPR somewhere new since the ABS **** is in the way now

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

put seats back in, now with 90-93 style belts

put rest of interior back together

redo the fuel lines in the engine bay

mount power steering pump, and do hoses

install intake tube

make a working crank case vent setup

pray the fuel pump wiring doesnt blow up the car

pray the rest of the wiring works

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

Made up new oil lines for the turbo. Had to reajust the hardline for the feed once the engine was in the car.

Wrote myself a little note. Every ******* time I forget to put that god damn plate on.

I broke one of the tranny bolts when torquing them, and of course their M12 and my local hardware stores only go up to M10 for JIS bolts, cant find em online either, looks like I'm buying from mazda and paying $12 to ship a $3 bolt.

Got the engine in, radiator in, started making up the fuel lines, figured out how I'm mounting the fpr. Getting the engine is was a pain in the dick this time, because I accidentally put the chains as 2 different lengths on the load leveler, had to pull it back out and fix that before I could get it to drop back in. Decided that there's no ******* way the power steering pump is going to fit in the engine bay, its going in the spot where the jack was in the trunk. Almost died last night from the heater being dirty, still feel shitty. Also finished up the work on the trailer. And I got the passenger seat and belt in, the drivers side belt threads are all fucked up, I had to order an M12x1.25 tap I only had M12x1.5 on hand.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

coolant

RB Race front sway bar and 949 endlinks (my current bar setup is staying in my dads car)

tranny bolt

Things that need to happen

finish fuel pump wiring

finish abs wiring

power steering wiring

design and make a new splitter

install new headlight setup

bleed brakes and clutch

mount aero catches

Mount FPR somewhere new since the ABS **** is in the way now

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

put seats back in, now with 90-93 style belts

put rest of interior back together

redo the fuel lines in the engine bay

mount power steering pump, and do hoses

install intake tube

make a working crank case vent setup

pray the fuel pump wiring doesnt blow up the car

pray the rest of the wiring works

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

#274

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

It runs.

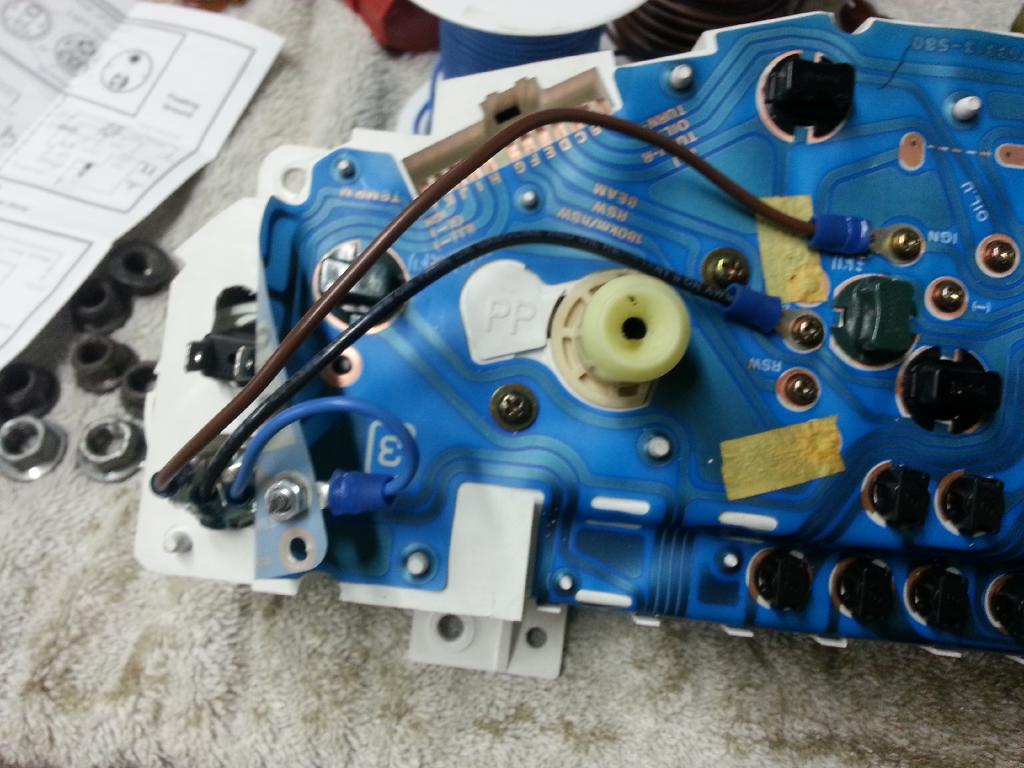

And doesnt leak any liquids yet. It does have a massive vac leak at the intake manifold flange and the vband for the turbo to downpipe connection is leaking but I can fix that without crying an wanting to burn the car down. I did have some struggles. The ground pin for the ecu on the patch harness sheared off on the big gray connector. I managed to have enough pin left to jam it back in and make it work for now. Its temporary thats probably going to become permanent.

You see the blurry wire in the foreground and the 1 silver dot on the gray connector? Yeah there was much I invented new cuss words to describe my pleasure with trackspeed and wishing I had just bought a megasquirt.

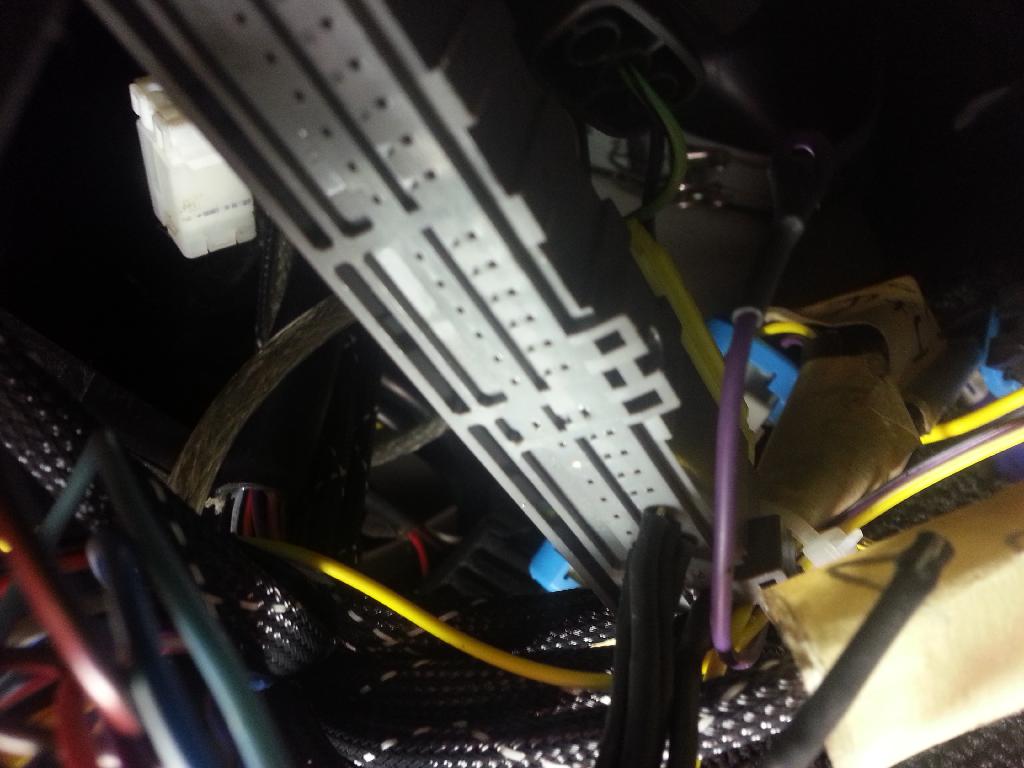

I also finished the fuel lines. The stupid POS AEM FPR is kind of leaking now. I cranked down on the bolts that hold the body together and it stopped for now. But on a good note, the car didnt catch on fire and explode from the fuel pump wiring.

AN Fittings direct ran out of black 135* -6AN hose ends. No one will ever see it.

The volvo pump fits not that I yanked the jack bracket out and hammered the floor.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

Things that need to happen

power steering wiring

design and make a new splitter

install new headlight setup

mount aero catches

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

mount power steering pump, and do hoses

make a working crank case vent setup

Fix intake and exhaust leak

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

And doesnt leak any liquids yet. It does have a massive vac leak at the intake manifold flange and the vband for the turbo to downpipe connection is leaking but I can fix that without crying an wanting to burn the car down. I did have some struggles. The ground pin for the ecu on the patch harness sheared off on the big gray connector. I managed to have enough pin left to jam it back in and make it work for now. Its temporary thats probably going to become permanent.

You see the blurry wire in the foreground and the 1 silver dot on the gray connector? Yeah there was much I invented new cuss words to describe my pleasure with trackspeed and wishing I had just bought a megasquirt.

I also finished the fuel lines. The stupid POS AEM FPR is kind of leaking now. I cranked down on the bolts that hold the body together and it stopped for now. But on a good note, the car didnt catch on fire and explode from the fuel pump wiring.

AN Fittings direct ran out of black 135* -6AN hose ends. No one will ever see it.

The volvo pump fits not that I yanked the jack bracket out and hammered the floor.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

Things that need to happen

power steering wiring

design and make a new splitter

install new headlight setup

mount aero catches

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

mount power steering pump, and do hoses

make a working crank case vent setup

Fix intake and exhaust leak

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

#275

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

It runs.

And doesnt leak any liquids yet. It does have a massive vac leak at the intake manifold flange and the vband for the turbo to downpipe connection is leaking but I can fix that without crying an wanting to burn the car down. I did have some struggles. The ground pin for the ecu on the patch harness sheared off on the big gray connector. I managed to have enough pin left to jam it back in and make it work for now. Its temporary thats probably going to become permanent.

You see the blurry wire in the foreground and the 1 silver dot on the gray connector? Yeah there was much I invented new cuss words to describe my pleasure with trackspeed and wishing I had just bought a megasquirt.

I also finished the fuel lines. The stupid POS AEM FPR is kind of leaking now. I cranked down on the bolts that hold the body together and it stopped for now. But on a good note, the car didnt catch on fire and explode from the fuel pump wiring.

AN Fittings direct ran out of black 135* -6AN hose ends. No one will ever see it.

The volvo pump fits not that I yanked the jack bracket out and hammered the floor.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

Things that need to happen

power steering wiring

design and make a new splitter

install new headlight setup

mount aero catches

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

mount power steering pump, and do hoses

make a working crank case vent setup

Fix intake and exhaust leak

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

And doesnt leak any liquids yet. It does have a massive vac leak at the intake manifold flange and the vband for the turbo to downpipe connection is leaking but I can fix that without crying an wanting to burn the car down. I did have some struggles. The ground pin for the ecu on the patch harness sheared off on the big gray connector. I managed to have enough pin left to jam it back in and make it work for now. Its temporary thats probably going to become permanent.

You see the blurry wire in the foreground and the 1 silver dot on the gray connector? Yeah there was much I invented new cuss words to describe my pleasure with trackspeed and wishing I had just bought a megasquirt.

I also finished the fuel lines. The stupid POS AEM FPR is kind of leaking now. I cranked down on the bolts that hold the body together and it stopped for now. But on a good note, the car didnt catch on fire and explode from the fuel pump wiring.

AN Fittings direct ran out of black 135* -6AN hose ends. No one will ever see it.

The volvo pump fits not that I yanked the jack bracket out and hammered the floor.

So new list

Things left to buy in order to race march 30th

PS pressure line

plywood for splitter, cheap AL angle and channel from home deopt

Catch can

Things that need to happen

power steering wiring

design and make a new splitter

install new headlight setup

mount aero catches

align car

pick through pile of hoosiers and mount up the best looking non-corded ones

mount power steering pump, and do hoses

make a working crank case vent setup

Fix intake and exhaust leak

Optional

corner weight car

buy another set of takeoff hoosiers

vacuum interior

wash exterior

cry

canards

make new and improved intake tube

do the correct crank case vent setup

#276

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

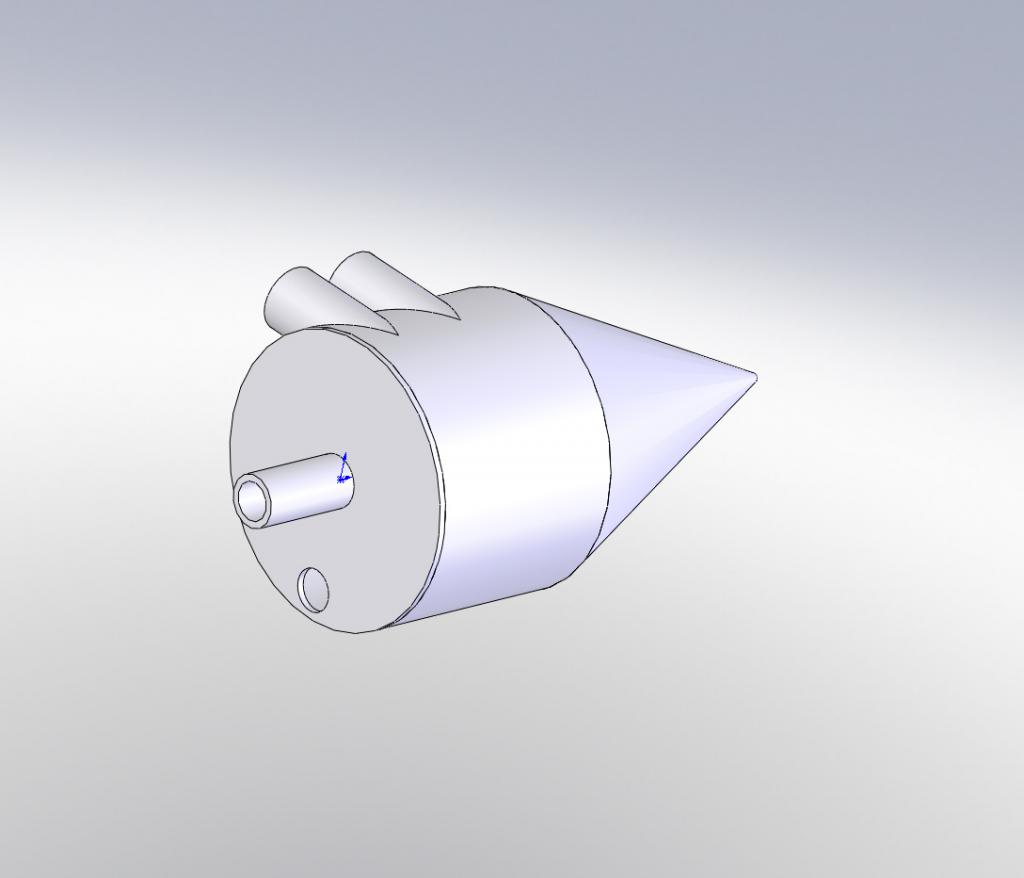

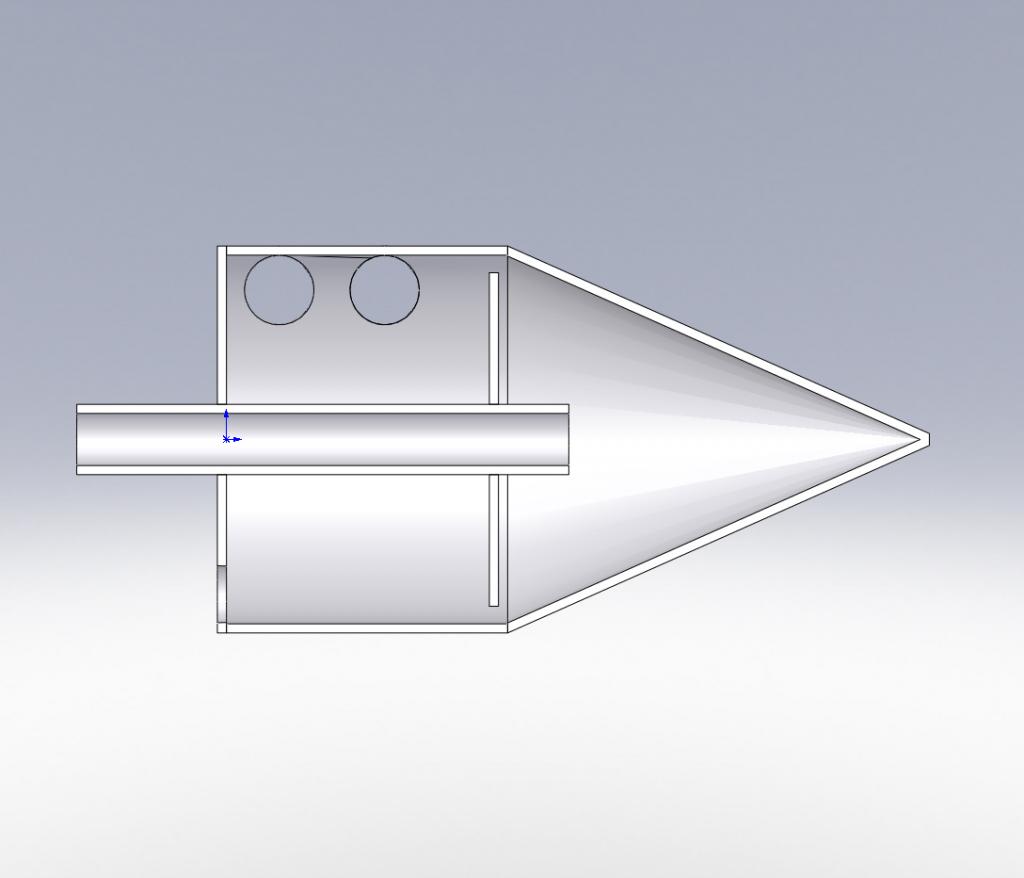

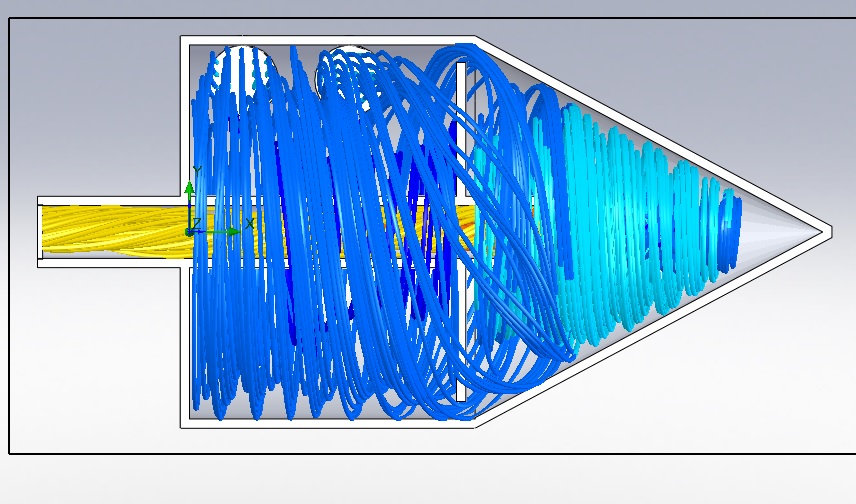

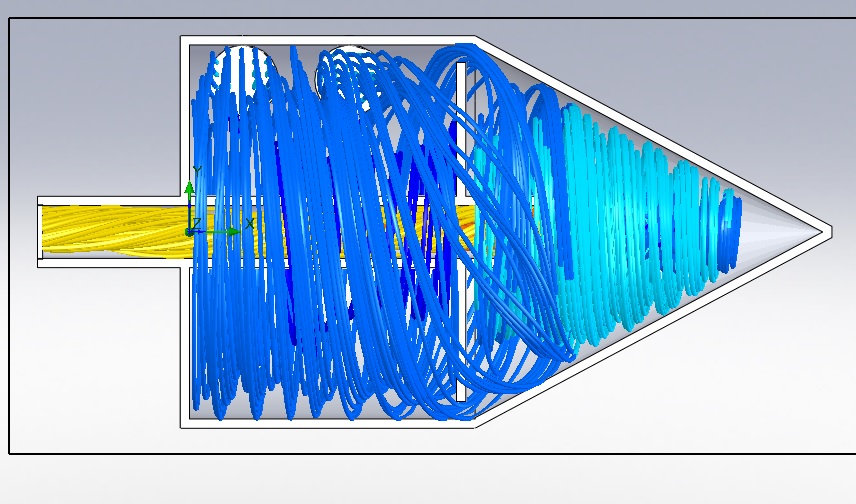

What do you do when no one makes an AOS in a size that fits your tiny engine bay at a price you like? Design your own. Its 3" diameter and 5" long right now I need to mock it up in the engine bay to see if I want to squeeze another stage in there to add scrubble. I should probably make pretty and useless colors in it with cfd or something.

#278

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Air oil separator. We'll see if that design even works first. I think it will Denso says its great DANA says its only ok. Crank case vents connect to the two ports on the top side, exits on the long nipple out the middle of the flat side. Air spins a lot in the round section, speeds up at the disk, tumbles in the cone and then goes out the tube with hopefully all the oil falling out. Thats the theory. Small hole at the bottom of the side is the drain, a valve will thread in there.

#279

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Well the air seems to take a predictable path. And I cant seem to make it any better by messing with the size and location of the separator plate or the size of the cone. I really wanted to get the air to tumble in the cone, but staying attached and swirling should work fine. At least the simulation thinks the air is going to swirl rather than take the short cut. If this isnt effective enough I can still add a 2nd chamber at the exit packed with scrubble and some baffles.

I just realized that I had 2 -10 inlets and 1 -8 outlet, kind of fucked that up, increased the outlet to -12. Also made the cone section easier to make.

I just realized that I had 2 -10 inlets and 1 -8 outlet, kind of fucked that up, increased the outlet to -12. Also made the cone section easier to make.

Last edited by Leafy; 02-19-2014 at 09:58 AM.