To SSM Ahead of Schedule

#42

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Yeah. I wish that was in the cards for this year. Next year hopefully. Same with power steering. After driving this car and the CSP car on hoosiers I KNOW it will make me faster. We're working on PS for the CSP car and maybe ABS this winter. Did you the the NB2 abs?

#45

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

I know I know. I've already made 2 sets of RS3s last season into octagon shapes. Its more about down time and finding a unit than the cost. And I need to double check the rules on the wiring aspect for SSM. It'll be real easy if I can just cut and splice, but if I have to do it like you have to in SP... Thats a **** load of work.

#47

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Good call. And thankfully the NB2 ABS box doesnt have a prop valve. Thankfully 16.1.I changed 1 letter so the entire windshild washing system is free, so we could put the module in the stock location and run some other washer bottle or completely remove it. But we could have used SP udbd for that anyways.

#49

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

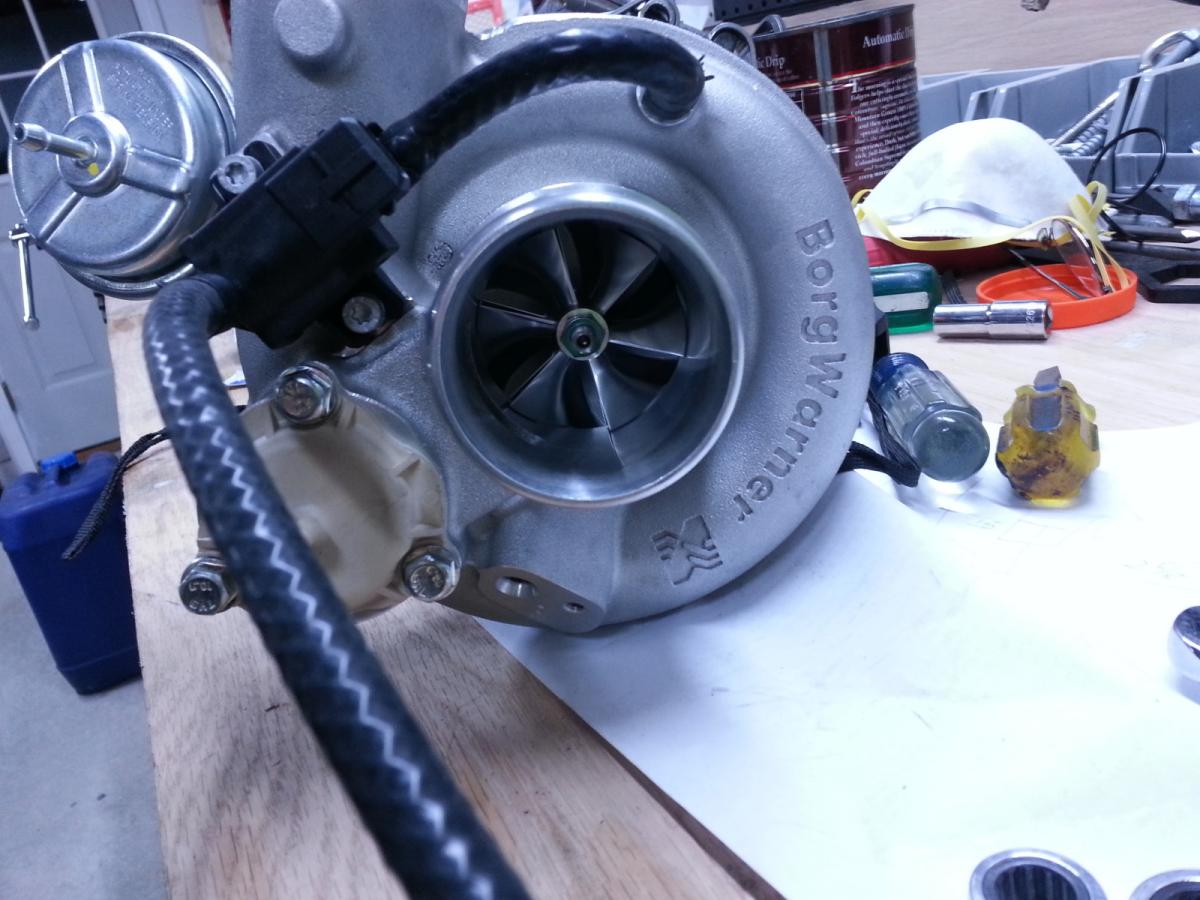

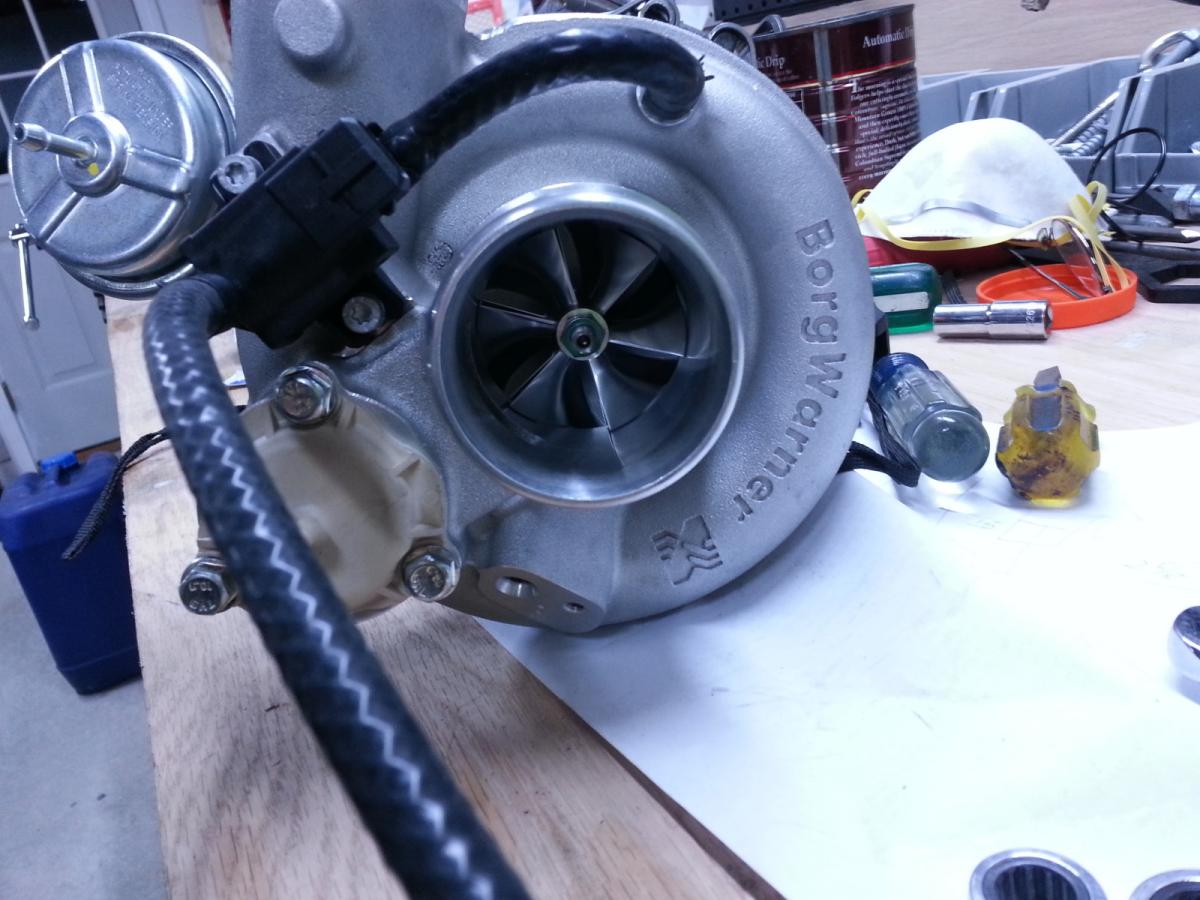

This just arrived at my house.

More good news. My time off accruals just updated in the payroll software. I will be going to nationals.

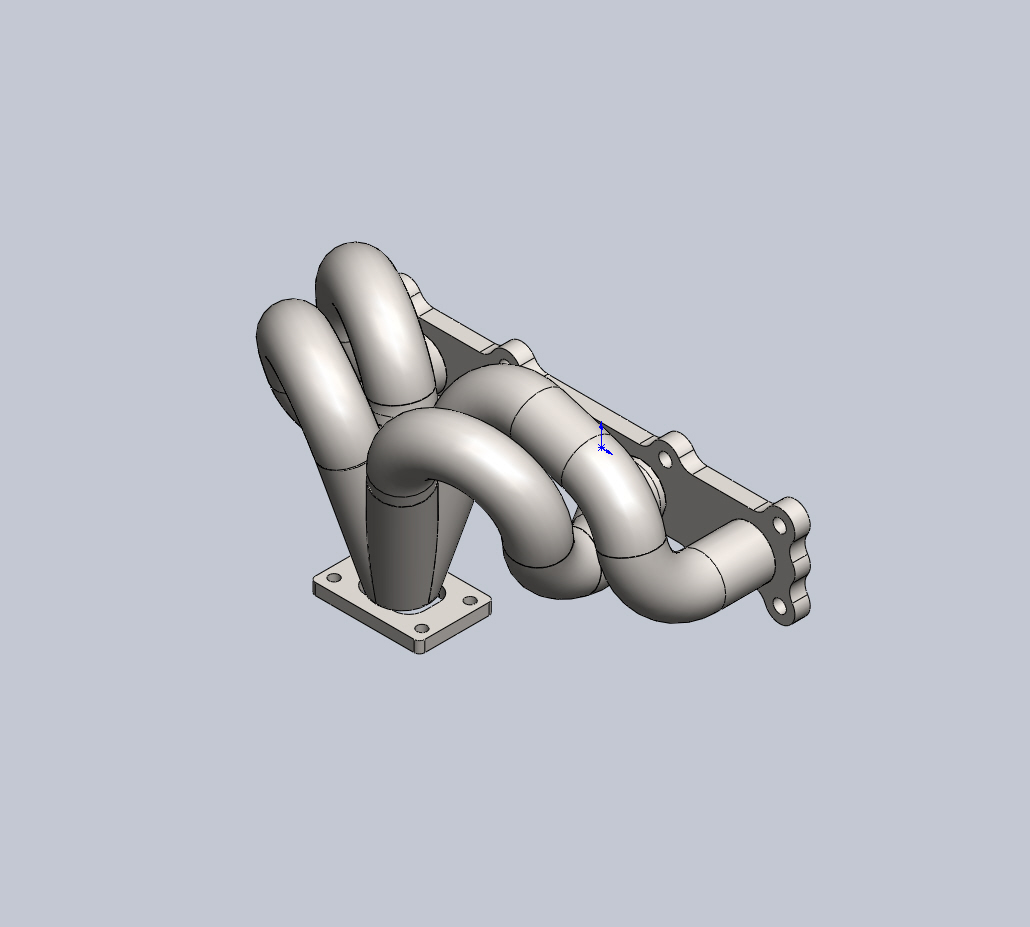

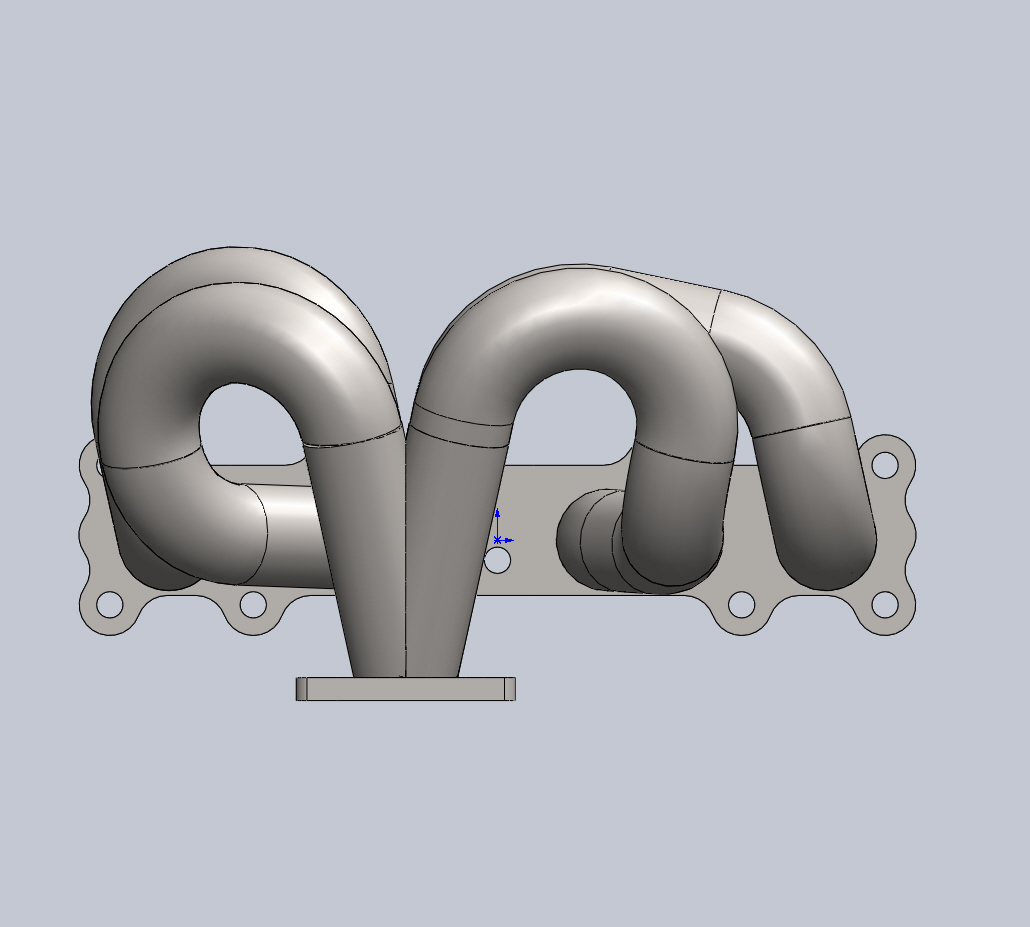

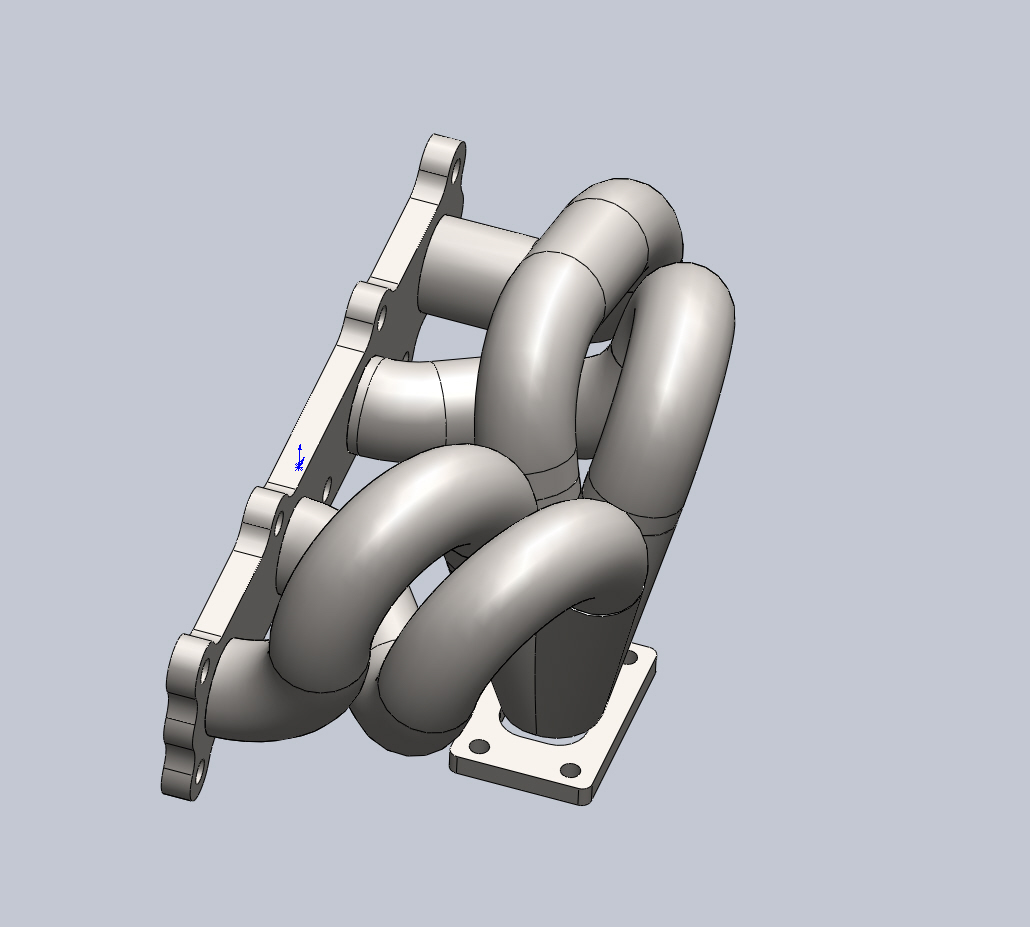

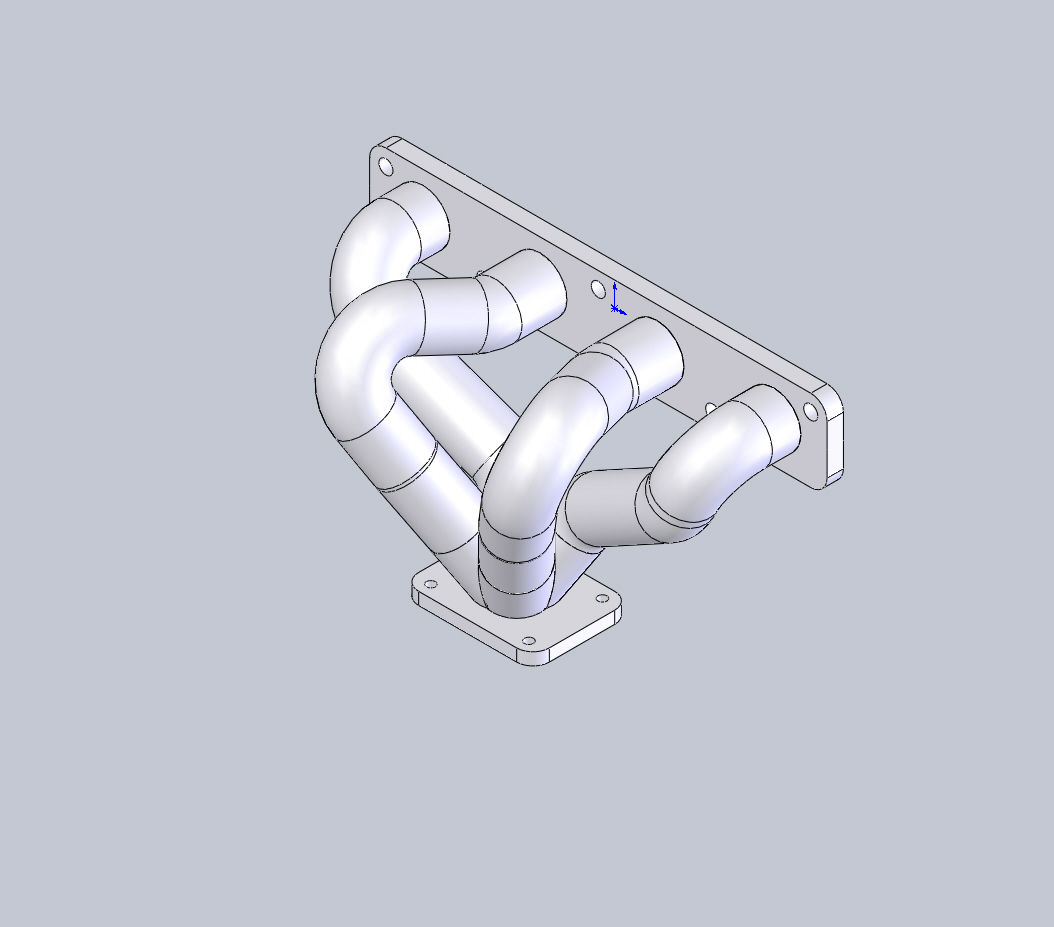

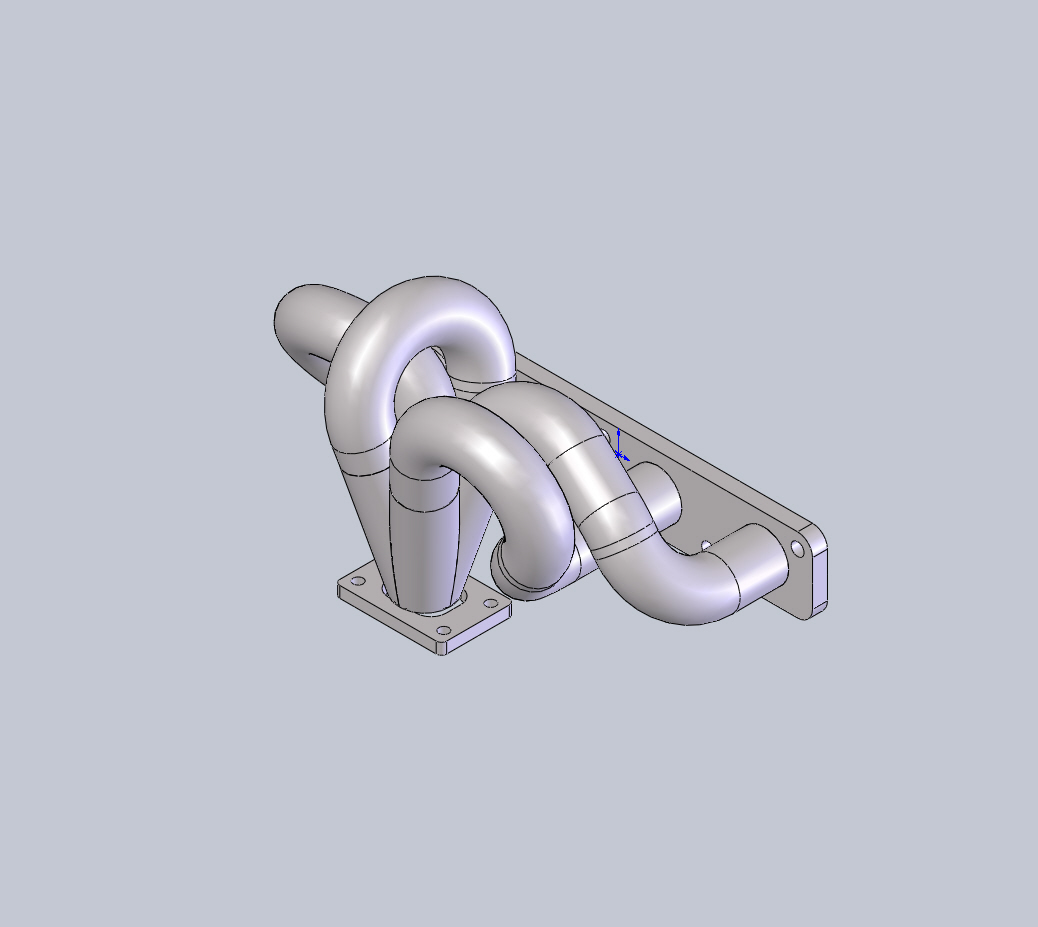

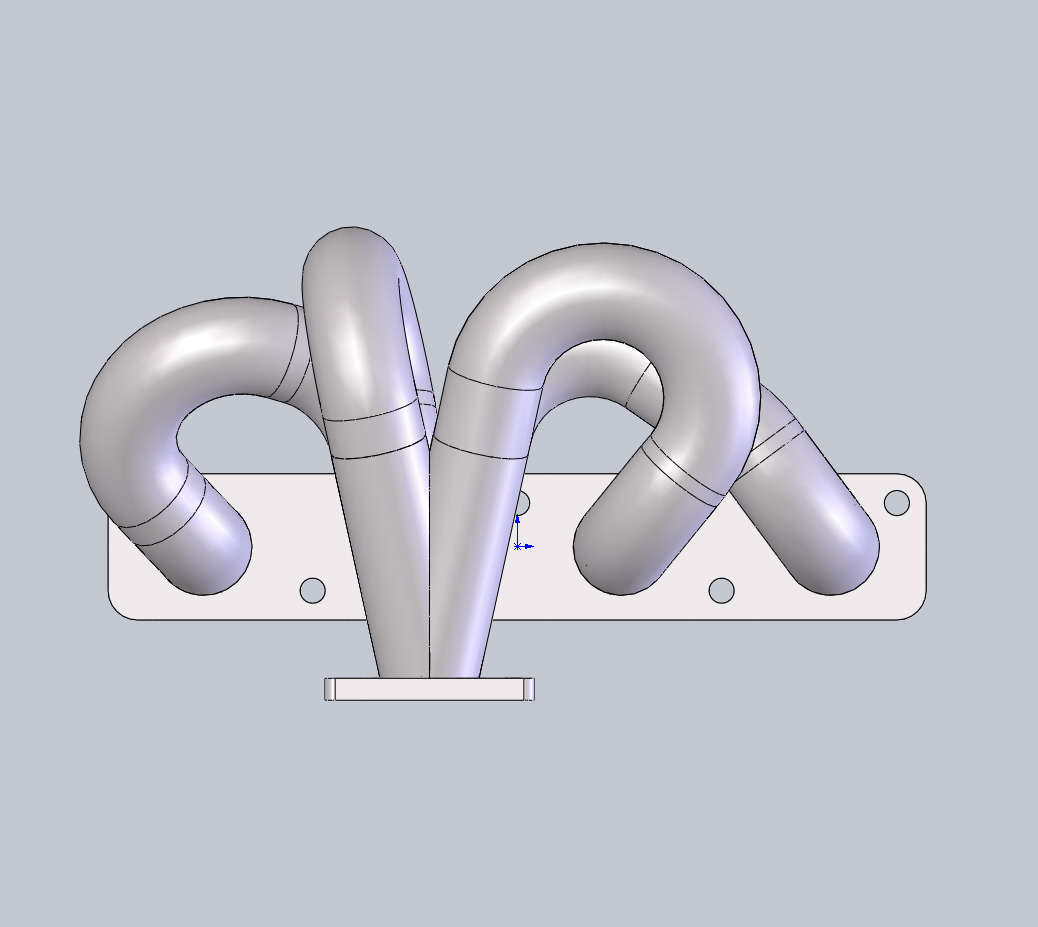

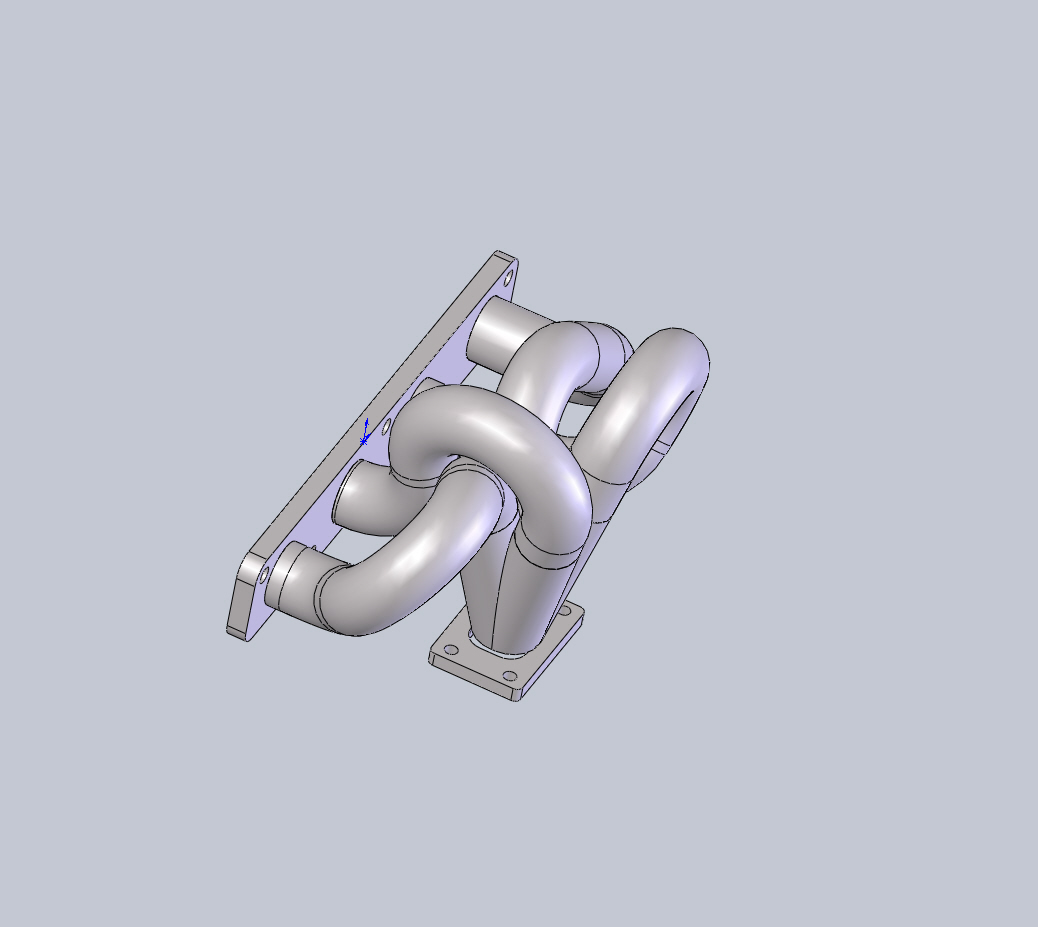

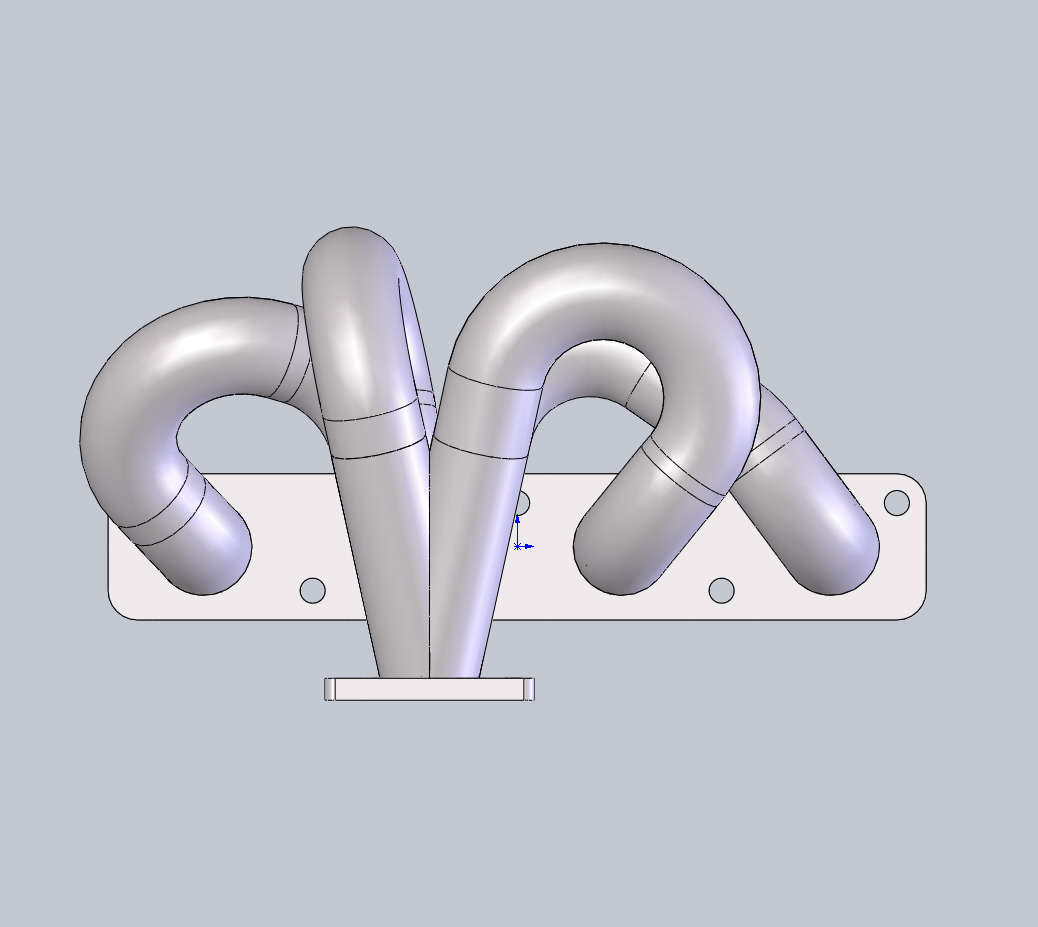

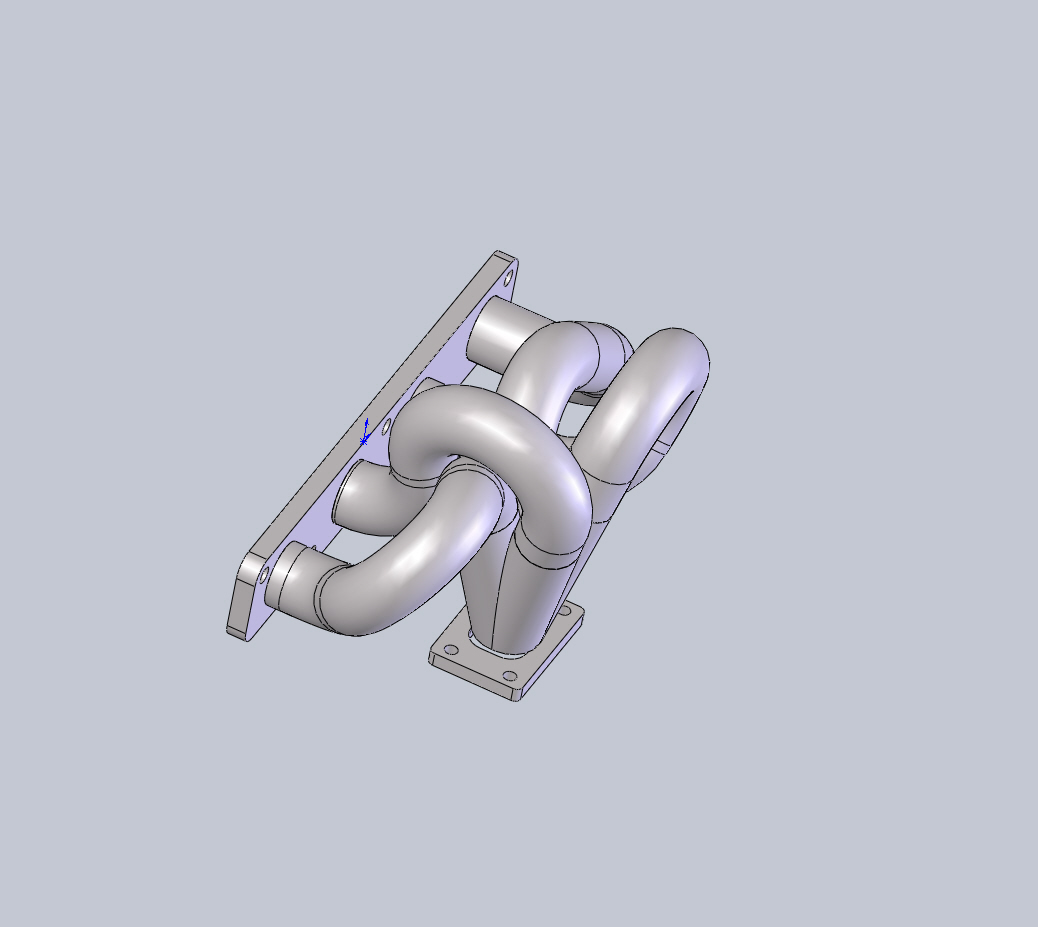

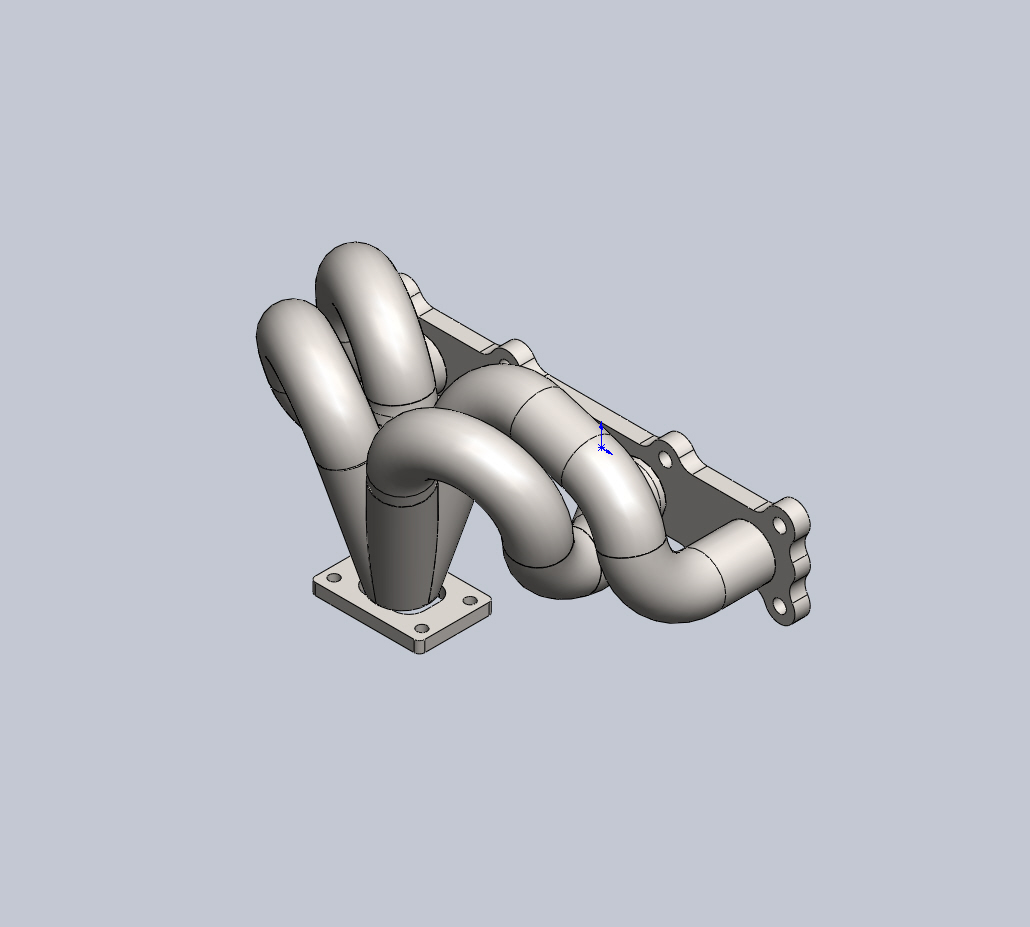

And what the turbo manifold is starting to maybe shape up into.

More good news. My time off accruals just updated in the payroll software. I will be going to nationals.

And what the turbo manifold is starting to maybe shape up into.

Last edited by Leafy; 01-09-2013 at 03:49 PM.

#50

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

So, I've come to accept the fact that there is no ******* way I'm going to get a vacuform machine to work this year for the fenders, doing research it seems that I would need an industrial amount of electricity (like 3 phase 220 for single phase 480) to make the oven work for such a large piece of material. And even if I could make some sort of oven that would work like with propane, I dont have the time now. So I can either, cut the stock fenders and have it look like crap. Try again to pull them, even though I already pulled them as far as I could once and it wasnt very far. I could pull them off and spend another 200 bucks in resin and many many hours making my own out of fiber glass or I could buy these. I need to email them and find out what the weight and strength difference is between them. I know after a couple cone strikes on the fiber glass ones the paint will crack, even if I tell the painter to put ALL the flex in it... and the ricer in me wants bare CF/kevlar weave.

#52

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

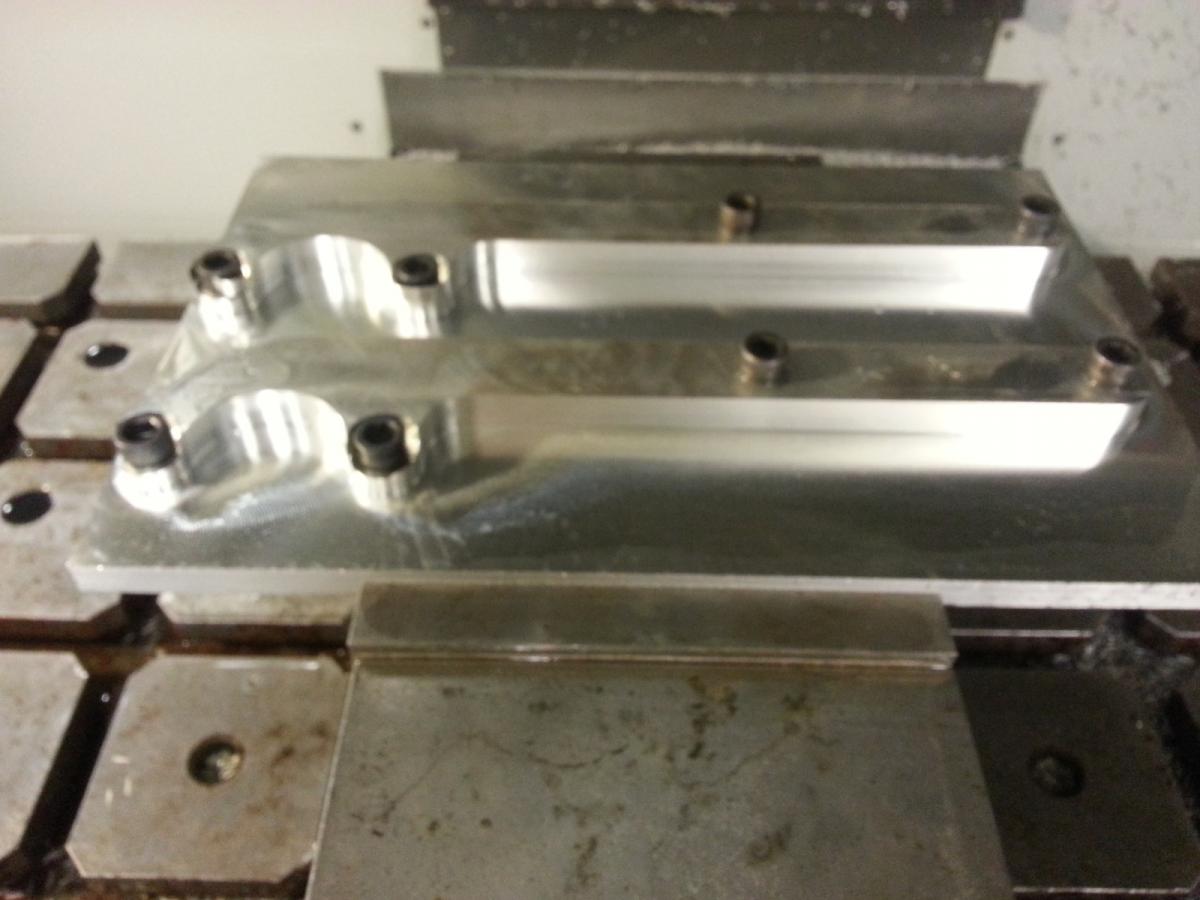

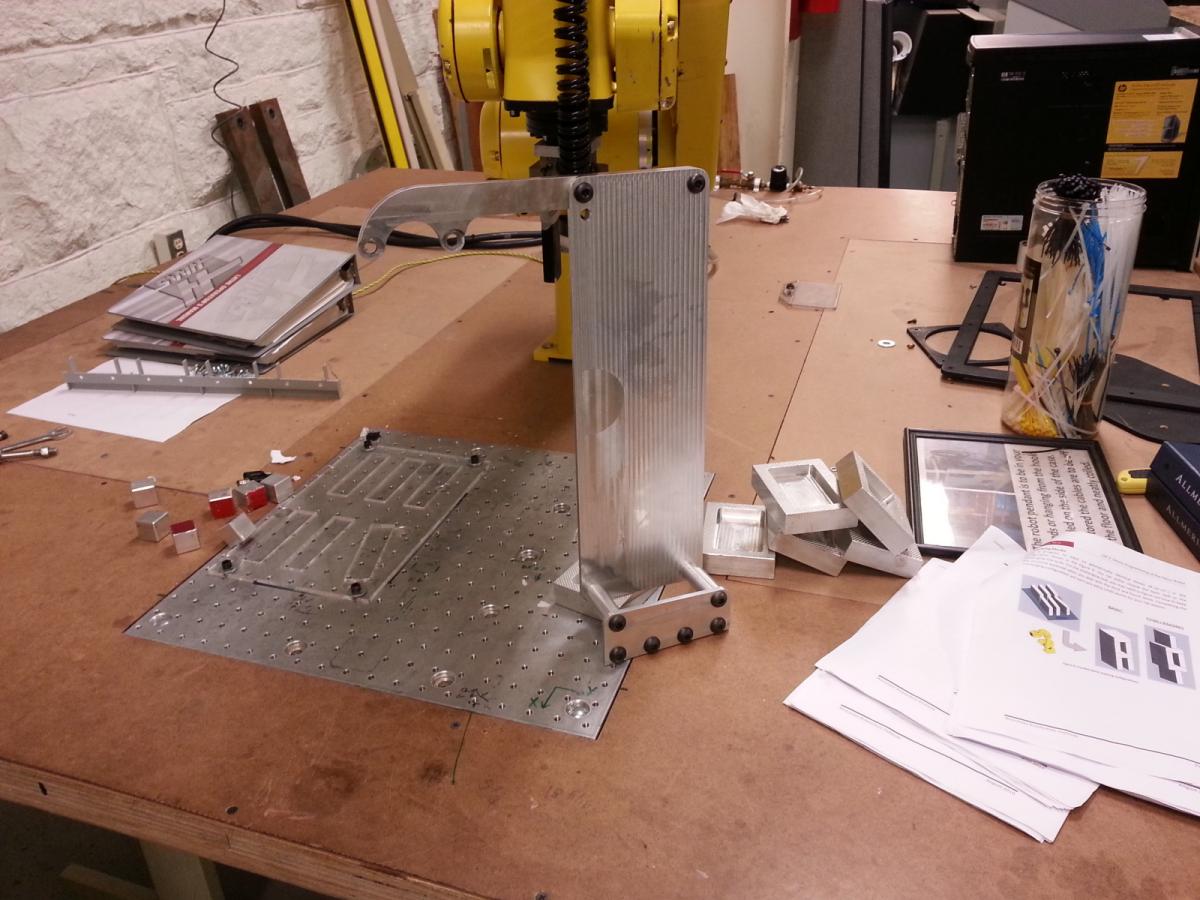

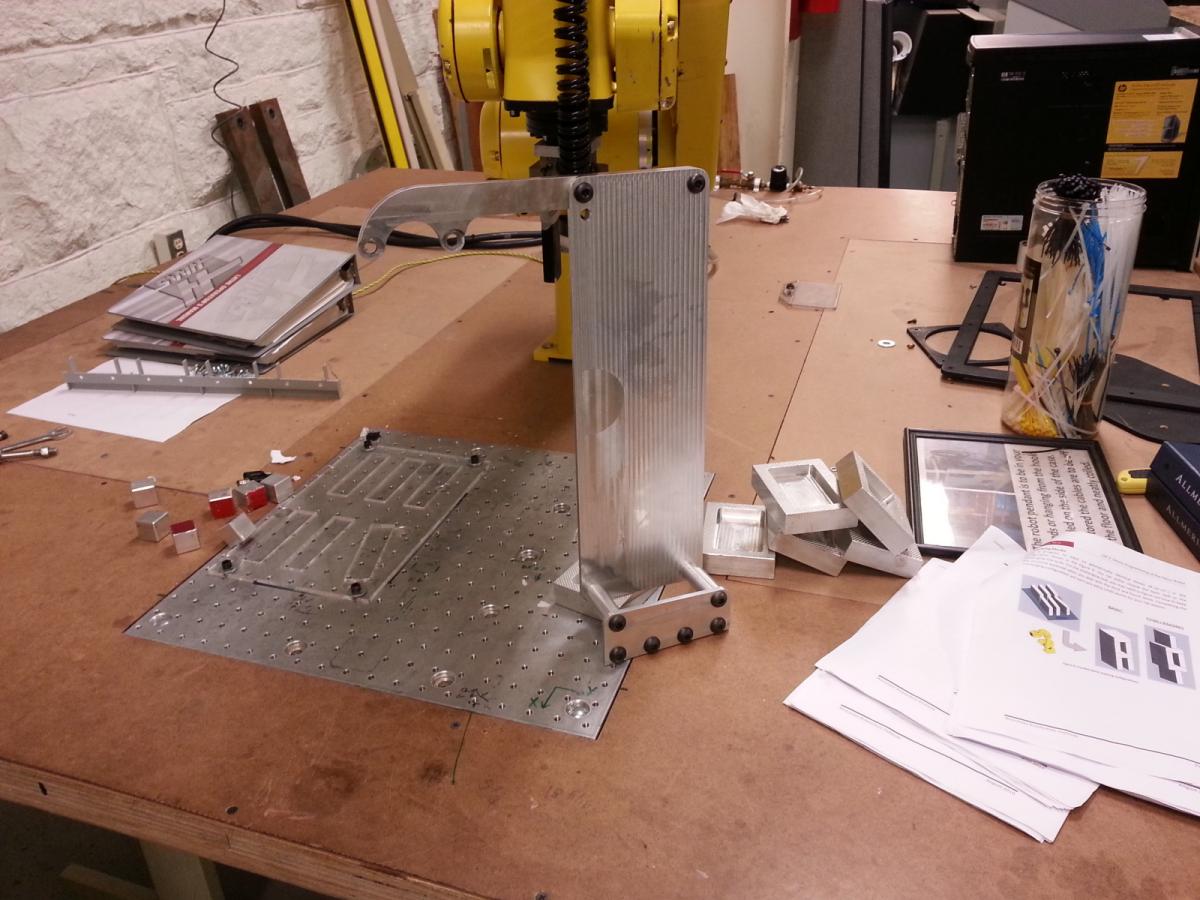

Just got back from the shop and showered. Current state of the wing below. Machines part of the wing supports.

Also the mobile site wouldn't let me paste, had to switch to desktop version. Or maybe I cannot brain at 5am before bed.

Also the mobile site wouldn't let me paste, had to switch to desktop version. Or maybe I cannot brain at 5am before bed.

#53

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Ended up doing a **** load of sanding on them, 2 reasons. For some reason the gelcoat didn't want to cure spots that I most recently resined, but didnt sand. And the gelcoat made ALL of the imperfections pop like mad. Thankfully it also made it easy to smooth it out since the gelcoat is a lot easier to sand than the resin. I did end up making a couple holes in the glass trying to get it smooth so I had to re resin again in a couple spots, I also found some more holes last night when I was packing up the shop at 2am. So tonight's game plan is to woof down dinner after work, resin the holes in the top element, sand the couple resin spots in the main element, go to a meeting at 7. Sand the lower element, and then see if I have enough time to gelcoat them again.

I did finish the wing supports. They were too damn shiny, kept washing out the pictures unless I got the angle just right.

I did finish the wing supports. They were too damn shiny, kept washing out the pictures unless I got the angle just right.

#54

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Welp, just heard from track speed, engine wont be shipping this month. I have in the last hour sent ~$1800 to full race and ~#200 to cx racing. Waiting to hear from doc race and bmc racing, so they can take another couple hundred bucks each from me.

#55

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Well, Full race was out of 6758s, so is threadstone, southeat power systems, and a host of other companies, I almost bought soviets 6258. Then I tried calling AWE again to see if they'd pick up, low and behold they had 2 of them. So I made that order there, but I'm still getting the bpv cover, wastegate actuator, and vband stuff from full race.

#56

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Mwhahahahahaha

And I've got the placement done. Pulled the exhaust manifold and drained the coolant so that I could get it where I wanted. Getting close to pulling the engine.

And I've got the placement done. Pulled the exhaust manifold and drained the coolant so that I could get it where I wanted. Getting close to pulling the engine.

Last edited by Leafy; 02-02-2013 at 07:53 PM.

#57

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

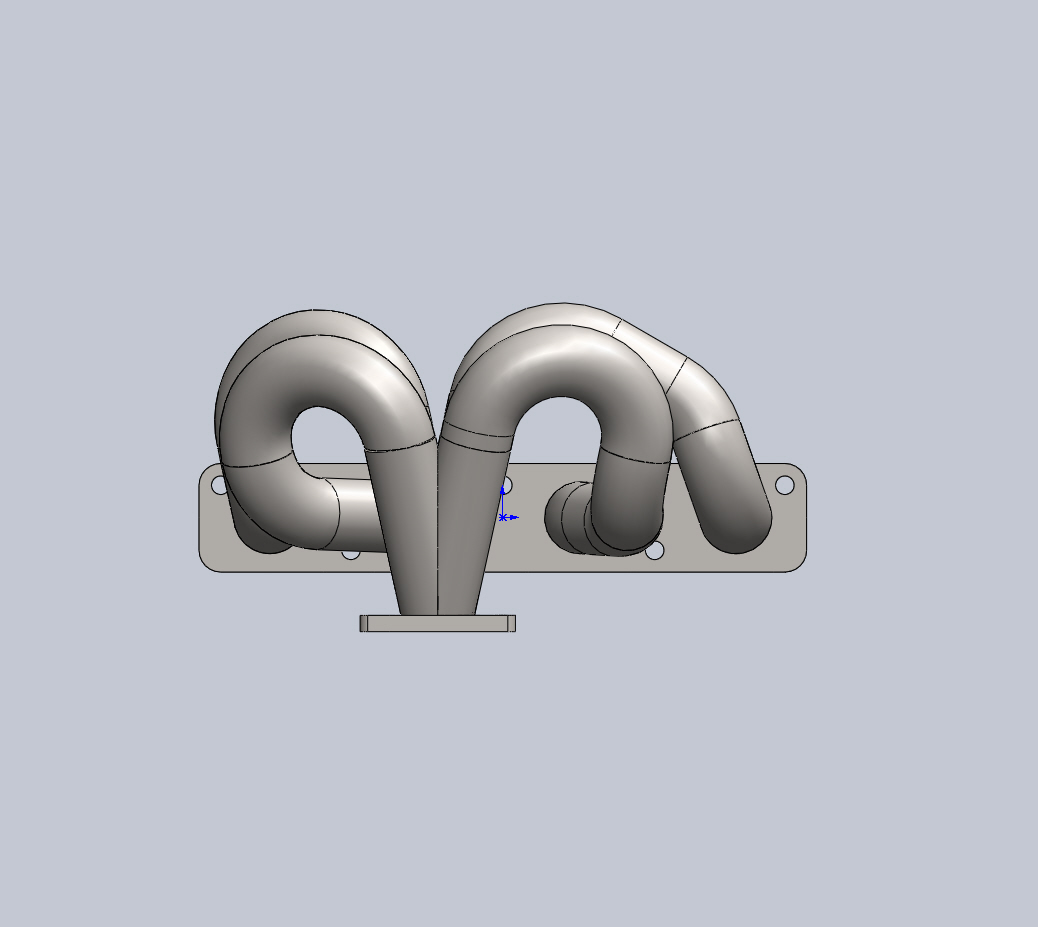

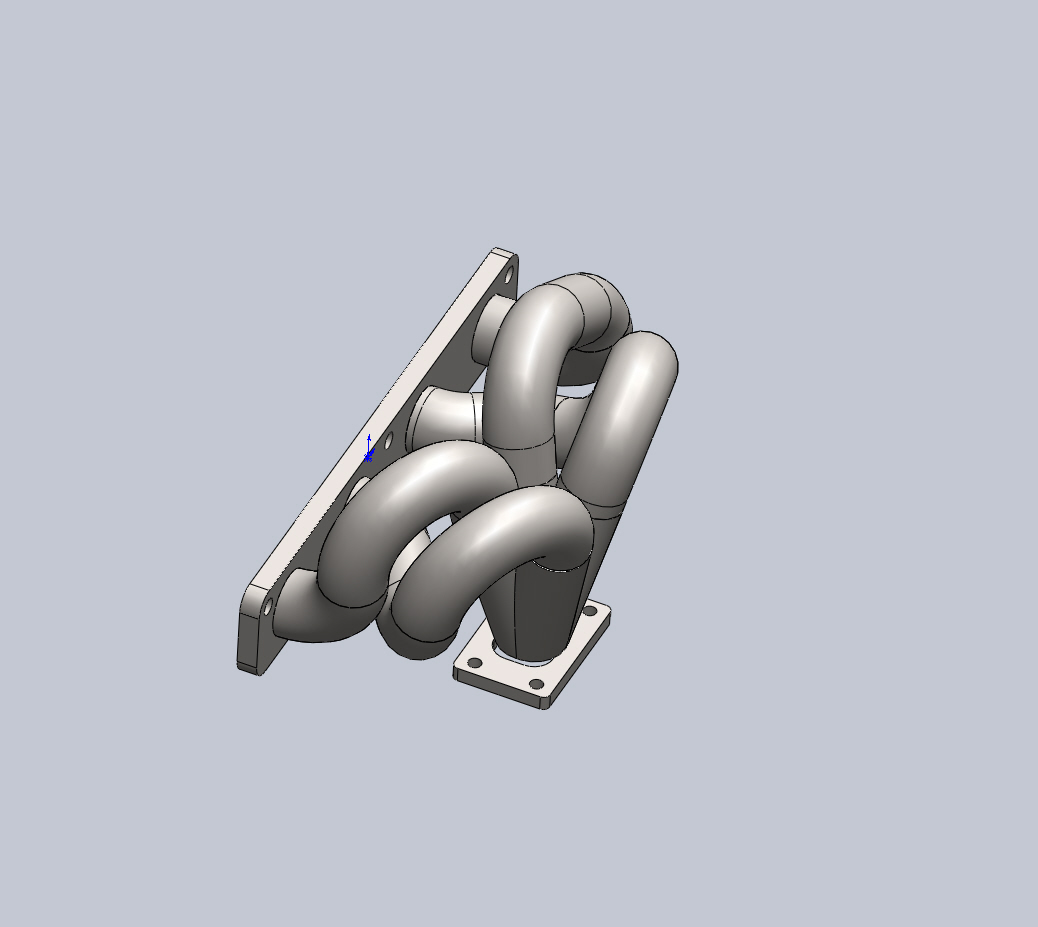

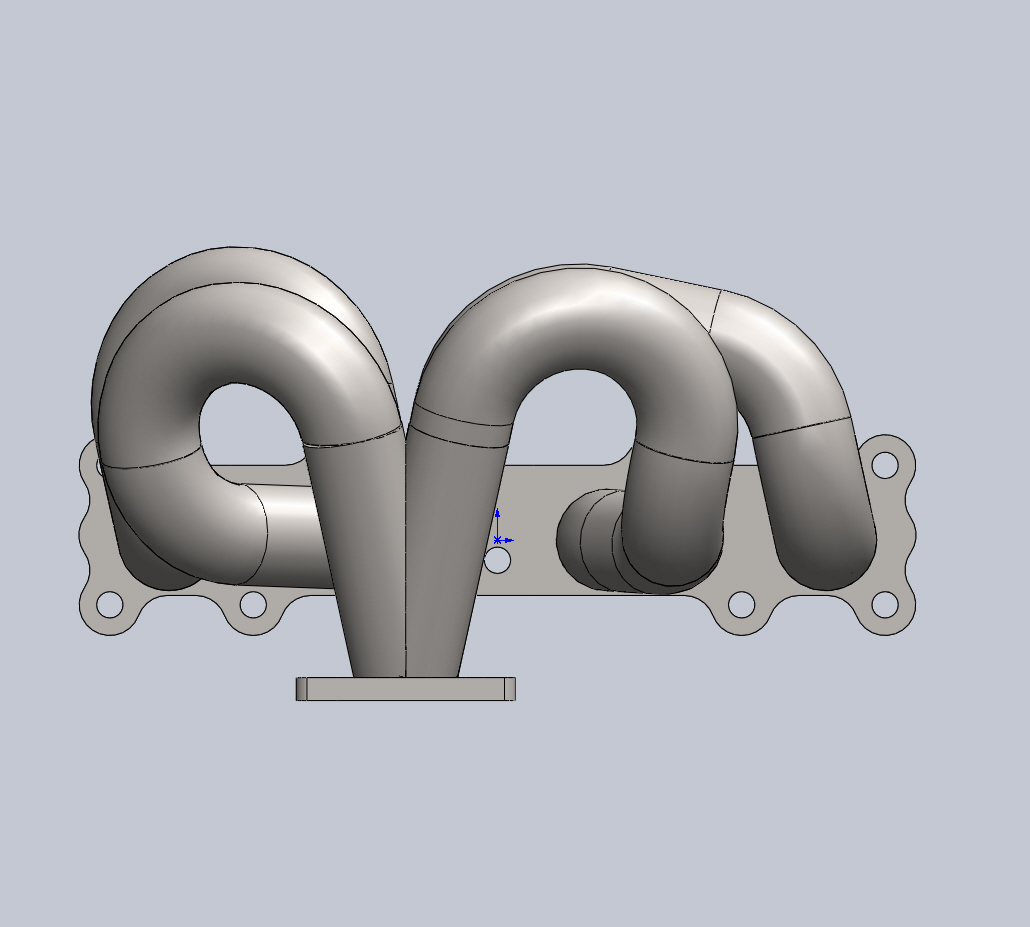

Put my actual measurements of where I want the turbo into the cad model. **** me right?

I'm working on something less retarded right after I finish this post.

Getting better, 2-4 are 12" long, 1 is 10" long And I cant figure out how to make them even, 2 inches shouldnt be that big of a deal.

Cylinder 4 kind of looks stupid, but I cant get anything better that still clears cylinder 3 and is 12".

I'm working on something less retarded right after I finish this post.

Getting better, 2-4 are 12" long, 1 is 10" long And I cant figure out how to make them even, 2 inches shouldnt be that big of a deal.

Cylinder 4 kind of looks stupid, but I cant get anything better that still clears cylinder 3 and is 12".

Last edited by Leafy; 02-04-2013 at 01:34 PM.

#59

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

I know. Especially because BMC race hasnt gotten back to me yet. I think I'm just going to have to take that 1/2 304 plate thats been sitting in my apartment and make my own flange.

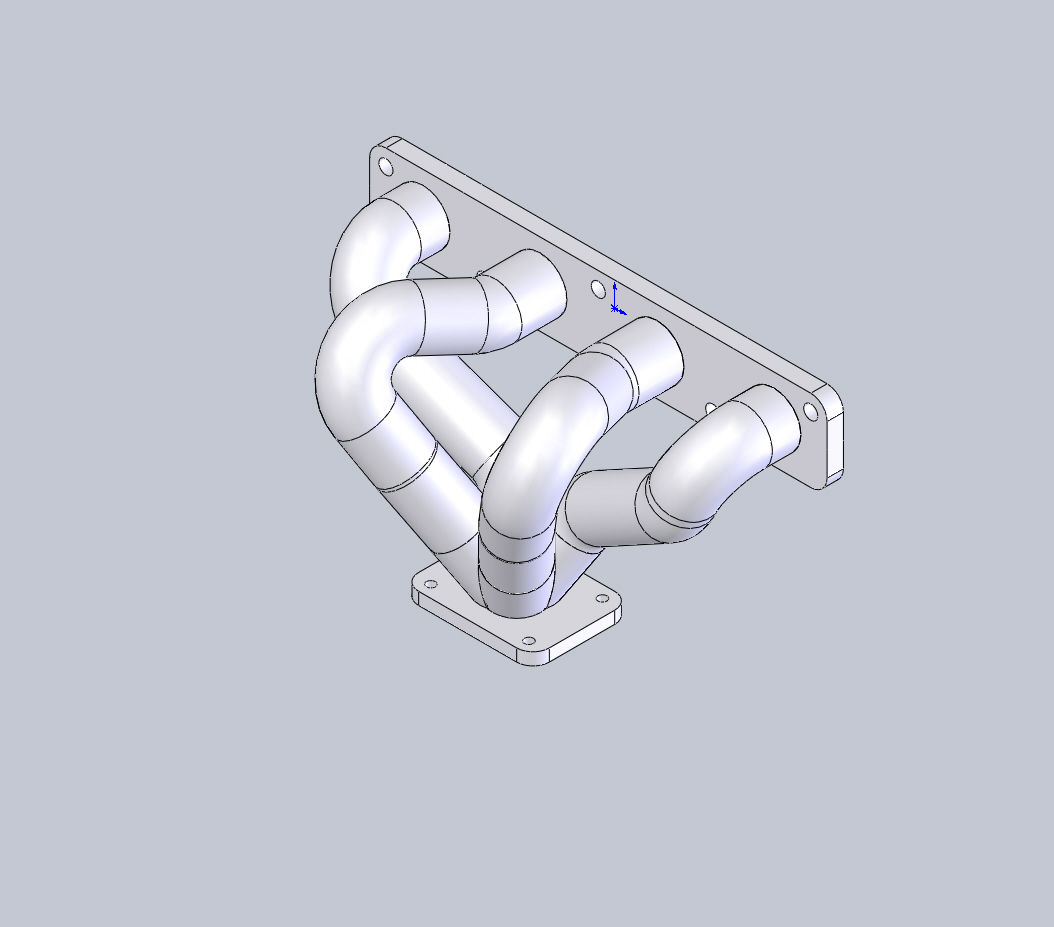

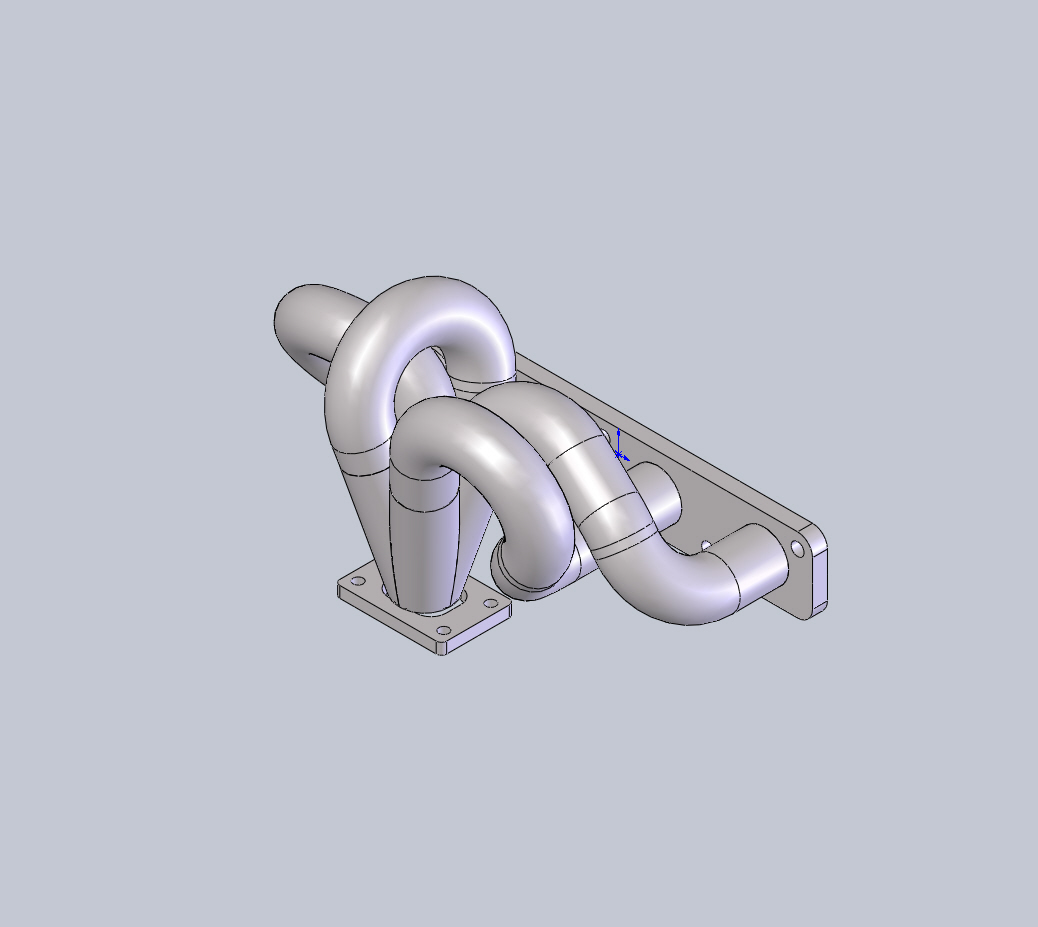

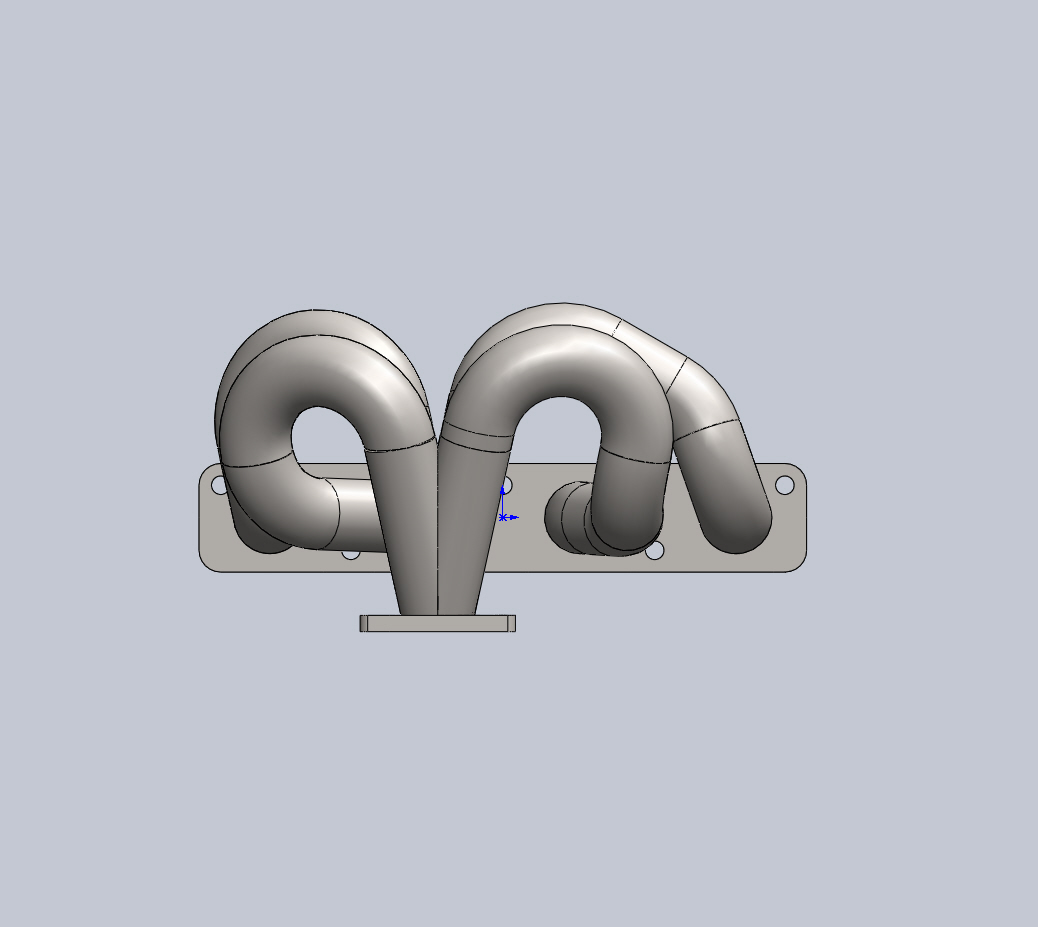

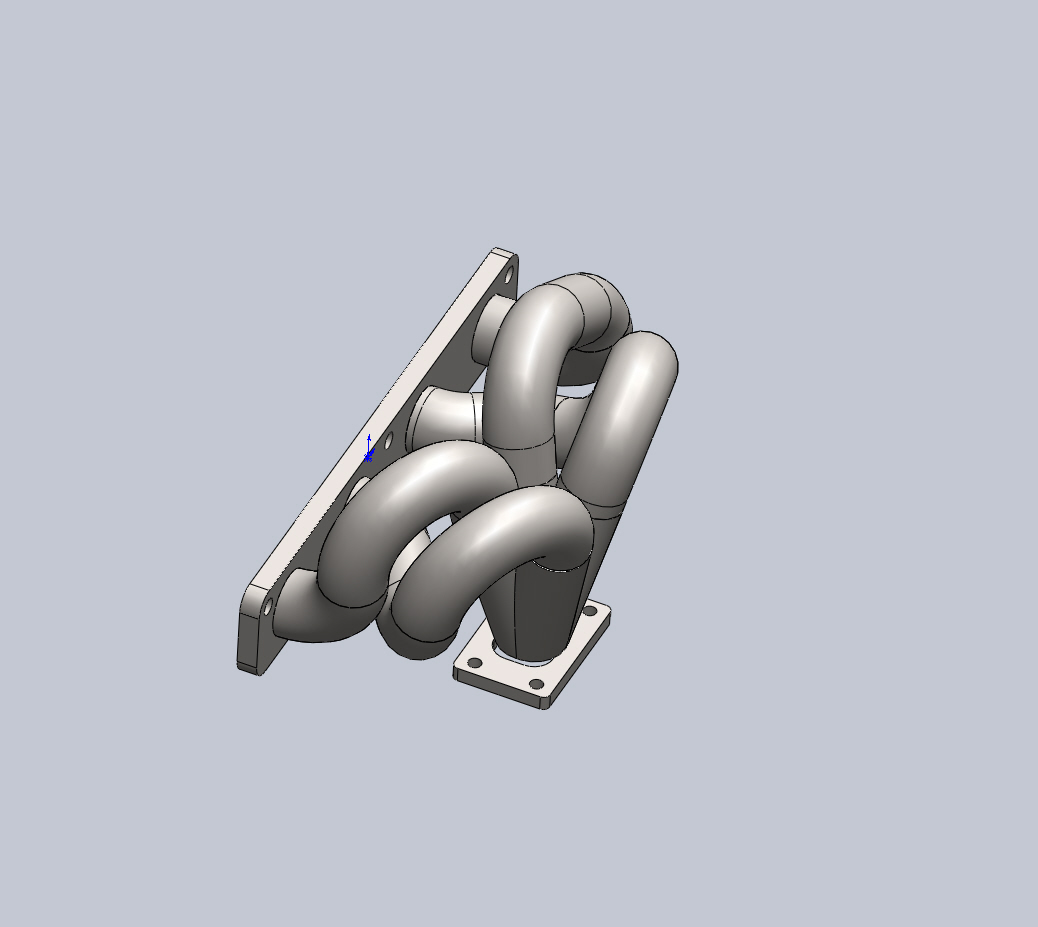

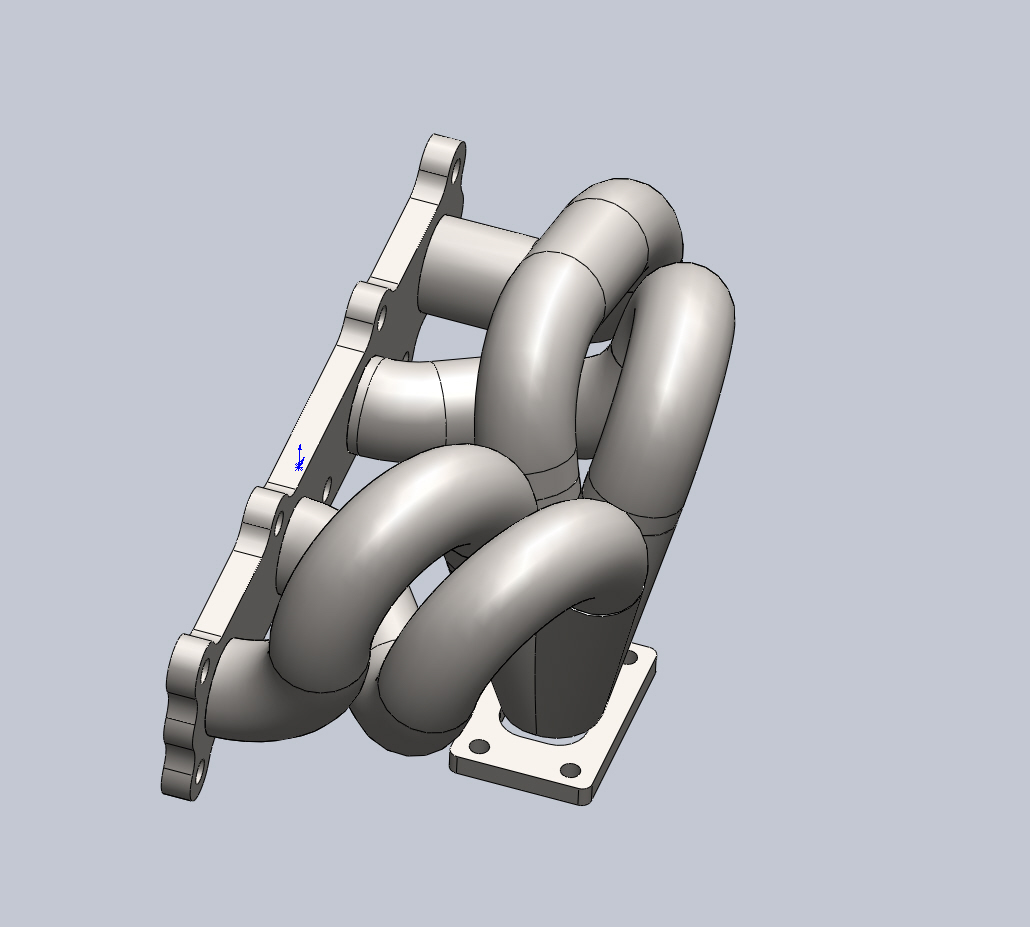

And here's the newest version I integrated my actual manifold flange into this one rather than the mockup flange. And cleaned up cylinder 4 so that it takes less bends to make. Its going to take 9 90's 3 180's and a little over 5" of straight.

And here's the newest version I integrated my actual manifold flange into this one rather than the mockup flange. And cleaned up cylinder 4 so that it takes less bends to make. Its going to take 9 90's 3 180's and a little over 5" of straight.