Trackspeed's '02SE "Acamas" - EFR6758, TSE motor, 500whp or bust

#41

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

Thanks. I was thinking about reducing maxDC% a little. It seems to want to stabilize in the mid 30s, so I'll set it at 60% on the way home. I really want to avoid the initial values table, because those values are going to change as the target boost changes. If it comes to that, I'll enter some numbers there, but I want to see if I can do it without.

#42

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

From what I remember the initial values table is a 3d table that's rpm on one axis, target boost on the other, and DC on the Z. You can basically copy your open loop table over to it. (You did tune open loop first like everyone says right  )

)

One last tidbit. Not sure if this applies to 1.3.4 (they may not have fixed it) but on 1.4 you can set min duty to something above what makes your turbo spool fastest (0% = wastegate closed) and it will hold at 0 until the delta is reached. It used to hold at your min percentage before. So really your min and max should be reasonable close together. The PID algorithm will have a much easier time working in a smaller range. You can be more aggressive and get better response.

)

)One last tidbit. Not sure if this applies to 1.3.4 (they may not have fixed it) but on 1.4 you can set min duty to something above what makes your turbo spool fastest (0% = wastegate closed) and it will hold at 0 until the delta is reached. It used to hold at your min percentage before. So really your min and max should be reasonable close together. The PID algorithm will have a much easier time working in a smaller range. You can be more aggressive and get better response.

#43

The initial value table is important, you want it to put the DC close to the desired value when the EBC algorithm first kicks in. It has to use *some* value as the initial duty cycle, and if that value is way too high then boost will spike before it can control it, if it's way too low then it can drop the boost fast enough to drop it below the delta. That leads to a really violent oscillation as it kicks in and out of EBC mode.

And yes, it's a 3d map based on target MAP and RPM. It changes if you change the VE of the engine.

--Ian

And yes, it's a 3d map based on target MAP and RPM. It changes if you change the VE of the engine.

--Ian

#44

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

But Sav mentioned changing with target boost. Don't need to worry about that because it is a 3d table.

1.4 uses a bias table where it is based off of the table the entire time. Though IMO it doesn't work well yet and needs some sort of temperature modifier. Also might just be my setup.

1.4 uses a bias table where it is based off of the table the entire time. Though IMO it doesn't work well yet and needs some sort of temperature modifier. Also might just be my setup.

#45

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

One last tidbit. Not sure if this applies to 1.3.4 (they may not have fixed it) but on 1.4 you can set min duty to something above what makes your turbo spool fastest (0% = wastegate closed) and it will hold at 0 until the delta is reached. It used to hold at your min percentage before. So really your min and max should be reasonable close together. The PID algorithm will have a much easier time working in a smaller range. You can be more aggressive and get better response.

I am tuning on 1.3.4 right now, but I will switch over to 1.4.0 at some point soon.

Will input a min/max DC%, take a guess at initial targets (based on datalogs, it wants ~35% for 160kpa), and take some pulls on the way home tonight.

#46

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Start with open loop at 100% and spool. Lower by 10 until you spool slower then back up 5% etc. Thats your max. I then give it a 5% buffer to be safe.

#47

Max and min are the duty cycles at which the hardware valve is fully closed and open. That is, if you pulse a given solenoid at 1%, that's probably not enough for it to open at all, so 1% and 0% are equal. Similarly, it's going to saturate before it gets to 99%. Mine are set to 10 and 70.

By setting the max and min duty cycles you're telling the PID algorithm the range that it has two work on. Imagine min/max are 10/70, but you have them set to 0/100. As the RPMS climb, the PID algorithm is going to wind its output value all the way up to 100 trying to make boost before the turbo is physically able to do so. Once it *does* hit the target RPM, it's now going to have to work its way back down to 70 before the changes will have any effect on the boost level, which will slow down the response time. It will also also build up a lot of I contribution, so it's probably going to undershoot before getting back to where it wants to be.

IIRC, you can tune the values sitting still, just increase the DC on the valve until it starts/stop making noise.

--Ian

By setting the max and min duty cycles you're telling the PID algorithm the range that it has two work on. Imagine min/max are 10/70, but you have them set to 0/100. As the RPMS climb, the PID algorithm is going to wind its output value all the way up to 100 trying to make boost before the turbo is physically able to do so. Once it *does* hit the target RPM, it's now going to have to work its way back down to 70 before the changes will have any effect on the boost level, which will slow down the response time. It will also also build up a lot of I contribution, so it's probably going to undershoot before getting back to where it wants to be.

IIRC, you can tune the values sitting still, just increase the DC on the valve until it starts/stop making noise.

--Ian

#51

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

aidandj has given about the best closed loop EBC advice I have seen recently. Ken and James did some talking about EBC tuning at the MegaMeet 2 weeks ago. You should get upgraded to 1.4.0 firmware sooner rather then later. Drop the delta value to around 50 to start, then lower it once you get closed loop working well. Start with open loop and get relatively close values in that table. Then move them over to the bias table. It helps out a ton to have those close values close to make EBC work better.

#52

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

aidandj has given about the best closed loop EBC advice I have seen recently. Ken and James did some talking about EBC tuning at the MegaMeet 2 weeks ago. You should get upgraded to 1.4.0 firmware sooner rather then later. Drop the delta value to around 50 to start, then lower it once you get closed loop working well. Start with open loop and get relatively close values in that table. Then move them over to the bias table. It helps out a ton to have those close values close to make EBC work better.

#53

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Its different. I don't think 1.4 is perfect, but it is very very easy to get "close". I talked a bit about it with Savington at MRLS. IMO 1.4 gets you really close really easily, but the bias table is weighted too much in the equation. I have a thread open on msextra where a temperature modifier has been discussed, but i think the bias table just needs less weight.

I have a vm setup with the build tools and am going to try and change it and if it helps a lot I will suggest it to Ken. Currently I don't know enough about the code to ask him to change it, but changing it myself and getting good results will help.

I am also trying to hit 3x my internal wastegate spring with EBC, So tuning is extra hard for me.

PID tuning is the same in 1.4 you just need a very solid bias table. (Which is easy to get)

Once 1.4 is perfected it will be better than 1.3.4, and way easier to tune. You can get very close to perfect using just basic mode.

Here is some info about the new method of boost control

Setup mode is really cool. You put it in setup mode and it uses all of your closed loop boost control settings, except it doesn't use PID. So it uses your target delta, and then treats the bias table as open loop. This way you can tune your bias table starting with the RPM you hit your target delata, instead of just open loop where you have to hold the wastegate closed manually.

So you run setup mode. Find your bias table, then turn on simple mode. Raise the sensitivity of the slider until you get a little bit of oscillation, then use advanced mode to tune out the oscillation. You shouldn't need much P because you are using the bias table to get close to your values, and the PID is for minor corrections.

Somehow forgot to add the link to my thread over on MSextra. Its a really good read.

Megasquirt Support Forum (MSEXTRA) ? Tuning Boost Control With Bias Table (View topic)

Ex of my bias table:

It is not very finely tuned because I have been messing with it a lot lately. But you can see how I don't even start it until 3400. My wastegate does a weird thing where it needs a lot more duty randomly at around 5250, you I have a hump there, and then PID doesnt have to take care of it.

I have a vm setup with the build tools and am going to try and change it and if it helps a lot I will suggest it to Ken. Currently I don't know enough about the code to ask him to change it, but changing it myself and getting good results will help.

I am also trying to hit 3x my internal wastegate spring with EBC, So tuning is extra hard for me.

PID tuning is the same in 1.4 you just need a very solid bias table. (Which is easy to get)

Once 1.4 is perfected it will be better than 1.3.4, and way easier to tune. You can get very close to perfect using just basic mode.

Here is some info about the new method of boost control

The current beta stuff I like to think of it as a ve table of sorts. We tune for an afr (boost duty) open loop style then once were close we turn on O2 correction ( slider and pid) to maintain and correct for day to day changes. Since the code is using the bias table it always has a new reference to base boost duty on so the code doesn't have to work so hard

So you run setup mode. Find your bias table, then turn on simple mode. Raise the sensitivity of the slider until you get a little bit of oscillation, then use advanced mode to tune out the oscillation. You shouldn't need much P because you are using the bias table to get close to your values, and the PID is for minor corrections.

Somehow forgot to add the link to my thread over on MSextra. Its a really good read.

Megasquirt Support Forum (MSEXTRA) ? Tuning Boost Control With Bias Table (View topic)

Ex of my bias table:

It is not very finely tuned because I have been messing with it a lot lately. But you can see how I don't even start it until 3400. My wastegate does a weird thing where it needs a lot more duty randomly at around 5250, you I have a hump there, and then PID doesnt have to take care of it.

Last edited by aidandj; 10-27-2015 at 04:59 PM.

#55

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

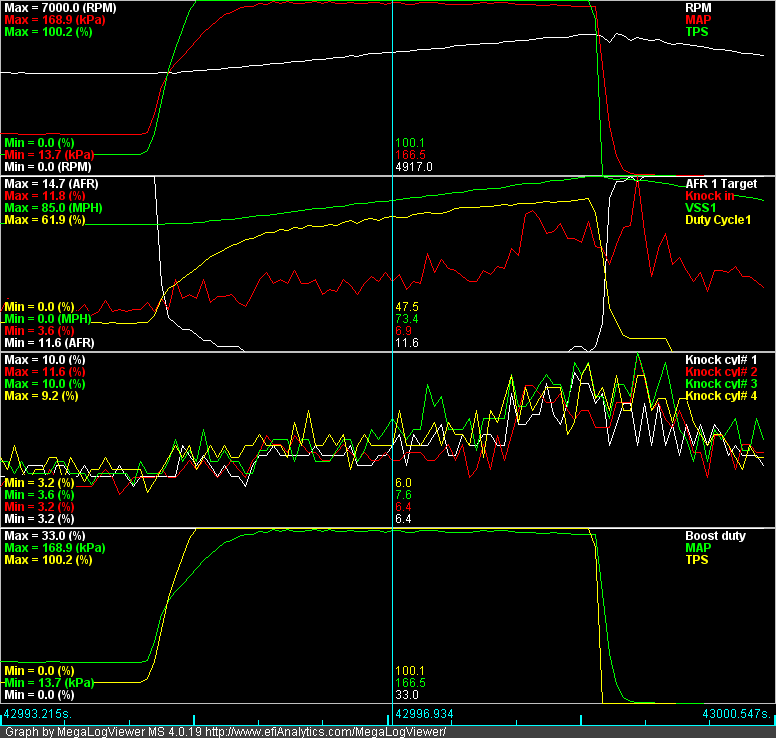

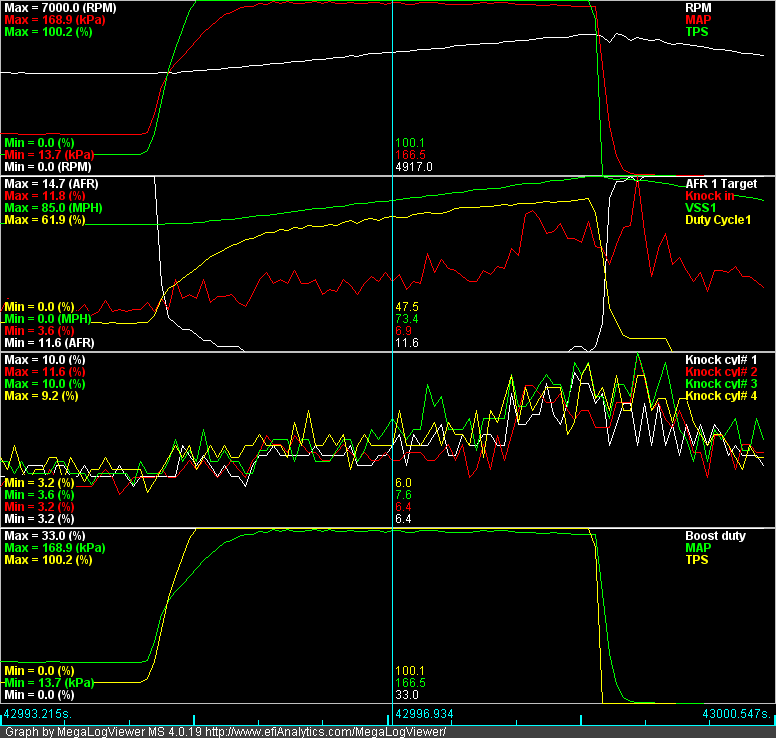

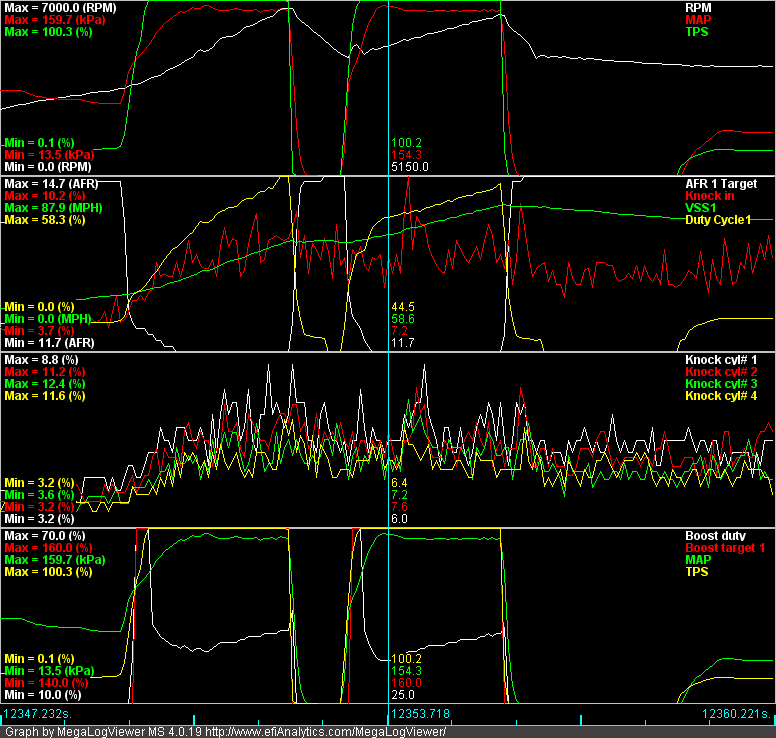

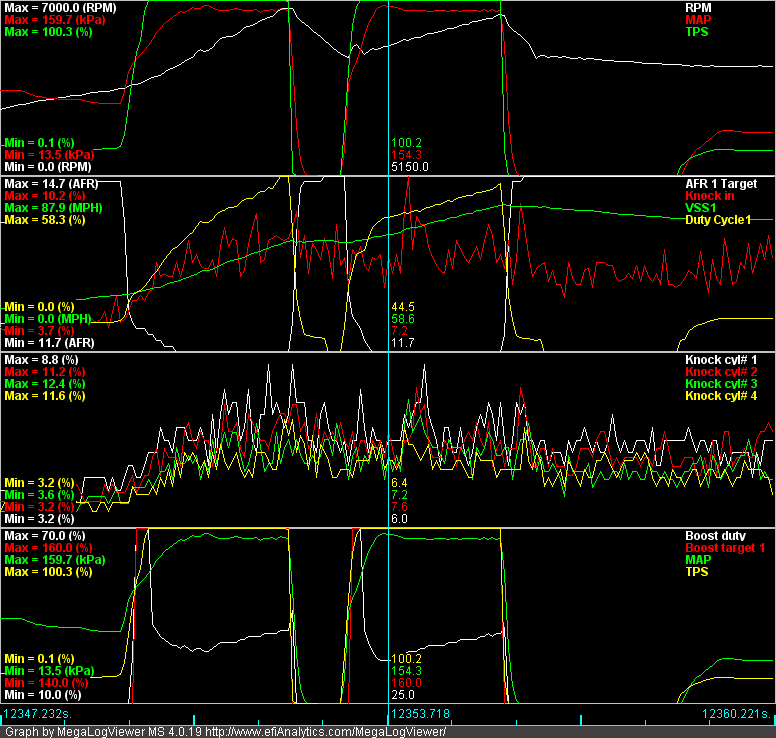

OL tuning went fast. This IWG is a beast. This is 33% across the board. A little overshoot the whole way through. 30% was too low so I settled at 32.

On to closed loop basic, target of 160kpa. 250 is too little P to reach the target, but too much to not oscillate the valve:

350 still isn't enough P to reach target quickly, but there's enough I to force it up to target boost at higher RPM:

I'm thinking I will go back to 250 and start tuning the advanced PID numbers from there.

On to closed loop basic, target of 160kpa. 250 is too little P to reach the target, but too much to not oscillate the valve:

350 still isn't enough P to reach target quickly, but there's enough I to force it up to target boost at higher RPM:

I'm thinking I will go back to 250 and start tuning the advanced PID numbers from there.

#56

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Sounds like you got it.

When you switch to 1.4 just put your open loop table into the bias table. Then do basic again. I have a feeling with how good the BW IWG is you won't even need to touch advanced PID tuning.

Test it on a "cold" (forgot you were in cali ) morning on the way to work too. Thats when PID has to work the hardest against your bias table.

) morning on the way to work too. Thats when PID has to work the hardest against your bias table.

I want that turbo. Very jealous.

When you switch to 1.4 just put your open loop table into the bias table. Then do basic again. I have a feeling with how good the BW IWG is you won't even need to touch advanced PID tuning.

Test it on a "cold" (forgot you were in cali

) morning on the way to work too. Thats when PID has to work the hardest against your bias table.

) morning on the way to work too. Thats when PID has to work the hardest against your bias table.I want that turbo. Very jealous.

#59

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

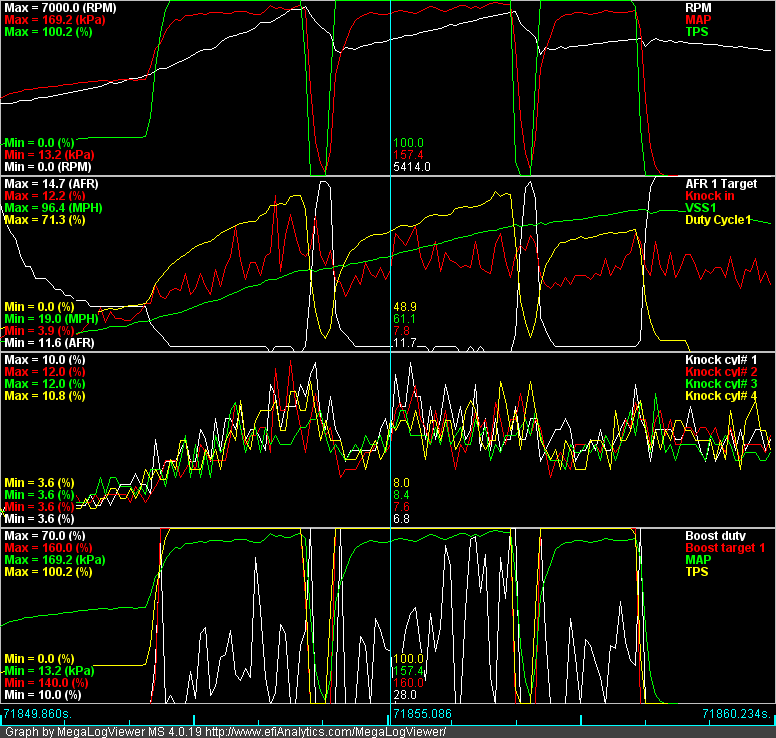

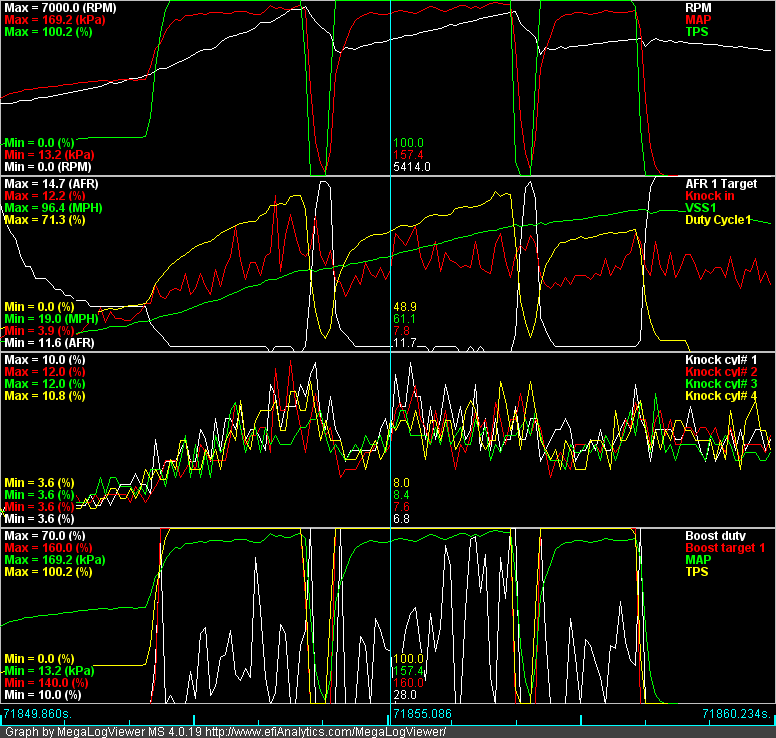

I'm close, but it's still not there. Turning Advanced PID mode on smoothed out the oscillations in the duty cycle curve, but it would still dip down to 10-11% as the boost came on, which was preventing it from ever reaching peak. At this point, I'm up to 400 on the slider, down to P5 I5 D0 on the advanced settings, and I've raised the initial duty from 32% to 37%, and it still doesn't want to overshoot. I have so much P in it at this point that I'm wondering if I've missed something.

#60

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

You say P is 5. That's barely any P.

https://en.wikipedia.org/wiki/PID_co...portional_term

Basically only 5% of your current error is being applied to the corrections. So its barely being corrected at all.

See how each step boost duty increases a little bit? Adding P will make it increase more.

This **** gets confusing. I still don't have a good way to tune it all. When you find one let me know

https://en.wikipedia.org/wiki/PID_co...portional_term

Basically only 5% of your current error is being applied to the corrections. So its barely being corrected at all.

See how each step boost duty increases a little bit? Adding P will make it increase more.

This **** gets confusing. I still don't have a good way to tune it all. When you find one let me know