oil drill issue

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: Apr 2007

Location: Odenton, MD

Posts: 713

Total Cats: 0

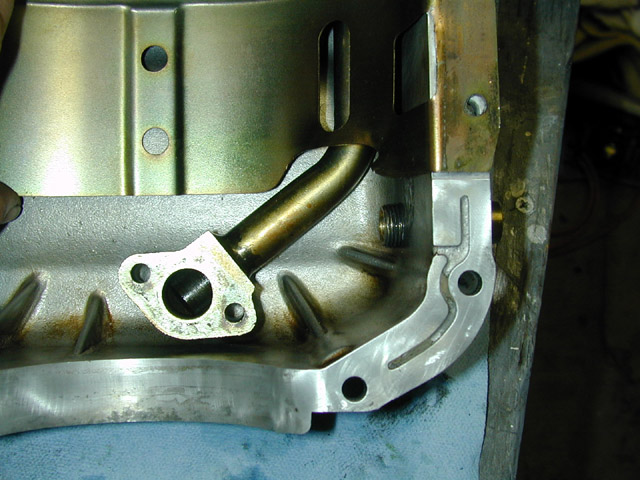

Hey everyone, idrilled my oil pan today. I did it just to the left of the motor mount. I got through fine, but when i pulled it out i felt in and i found some kind of metal shield. Is that the pickup? It doesnt seem like i damaged it, but i dont see how i can tap it now. any suggestions?

#3

Senior Member

Thread Starter

iTrader: (3)

Join Date: Apr 2007

Location: Odenton, MD

Posts: 713

Total Cats: 0

i already checked it out and the pickup looks good still, but i cant get the tap to turn. it wont catch. any suggestions for gettings it to catch. I don't think the hole is a completely 11/16th cause i didnt go in far enough, and my rotozip wont fit in there...

#4

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,499

Total Cats: 4,080

yes just gotta work at it, it's not catching cause the dirll bit is like .1" too small for the tap. so keep trying. possibly go back with teh drill and try ti slightly widen the hole, very slightly.

otherwise keep at it.

otherwise keep at it.

#8

Senior Member

Thread Starter

iTrader: (3)

Join Date: Apr 2007

Location: Odenton, MD

Posts: 713

Total Cats: 0

well it's tough to get to it with a hammer but i'll try. I bought the correct drill bit so i'll try t o bore it out a little with it, and than go a little deeper. Than i'll try tapping it again,. I really dont want to pull the motor... or drop the pan.

#12

I would definatly bend it in. If you are 1000000000000% sure that there is no little tube of metal in the way feel with your finger first please. Then drill through the sheild, having a hole in the sheild is not bad having a hole in the oil pick up means

A. Pull the motor

B. Hope you are a lucky jewish bastard like Loki i beleive and JB weld the hole shut.

C. Pull the subframe

None of those apeal to me and i don't think they would apeal to you either. So do some recon and make the call Tom. GL.

A. Pull the motor

B. Hope you are a lucky jewish bastard like Loki i beleive and JB weld the hole shut.

C. Pull the subframe

None of those apeal to me and i don't think they would apeal to you either. So do some recon and make the call Tom. GL.

#15

Senior Member

Thread Starter

iTrader: (3)

Join Date: Apr 2007

Location: Odenton, MD

Posts: 713

Total Cats: 0

ill try to take a few pics. i went outsdie today and felt around. It is a smooth surface with a slope to it, and towards the bottom it has a sudden drop off. My assumption is that i was a hole in the shield like in your pics Koto. I'm thinking since this isnt my DD in the winter i should just pull the motor/trans and do my clutch at the same time. Thoughts on this? It should take a day to pull and a day to replace/drill/clutch. Probably will same me alot of trouble knowing that i am 100% safe. Koto how long it take you to remove it? Did you drop the motor or pull out of the bay?