DIY downpipe opinions

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Indianapolis

Posts: 610

Total Cats: 12

I will need to fabricate my own downpipe. I have a 1.6L with Artech short manifold and external wastegate. I believe the hole on the exhaust flange on my sr20t25 is 2.25". I already have a 2.5" exhaust and I will use it.

Would you guys make the downpipe 2.25"(for 3-4 inches) to 3" to 2.5" or just stick with 2.25" outlet to 2.5" and connect it to my current 2.5" exhaust?

Would going to 3" tubing for maybe 2 feet and then back to 2.5" exhaust give me more power or just more turbulence?

Would you guys make the downpipe 2.25"(for 3-4 inches) to 3" to 2.5" or just stick with 2.25" outlet to 2.5" and connect it to my current 2.5" exhaust?

Would going to 3" tubing for maybe 2 feet and then back to 2.5" exhaust give me more power or just more turbulence?

#2

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

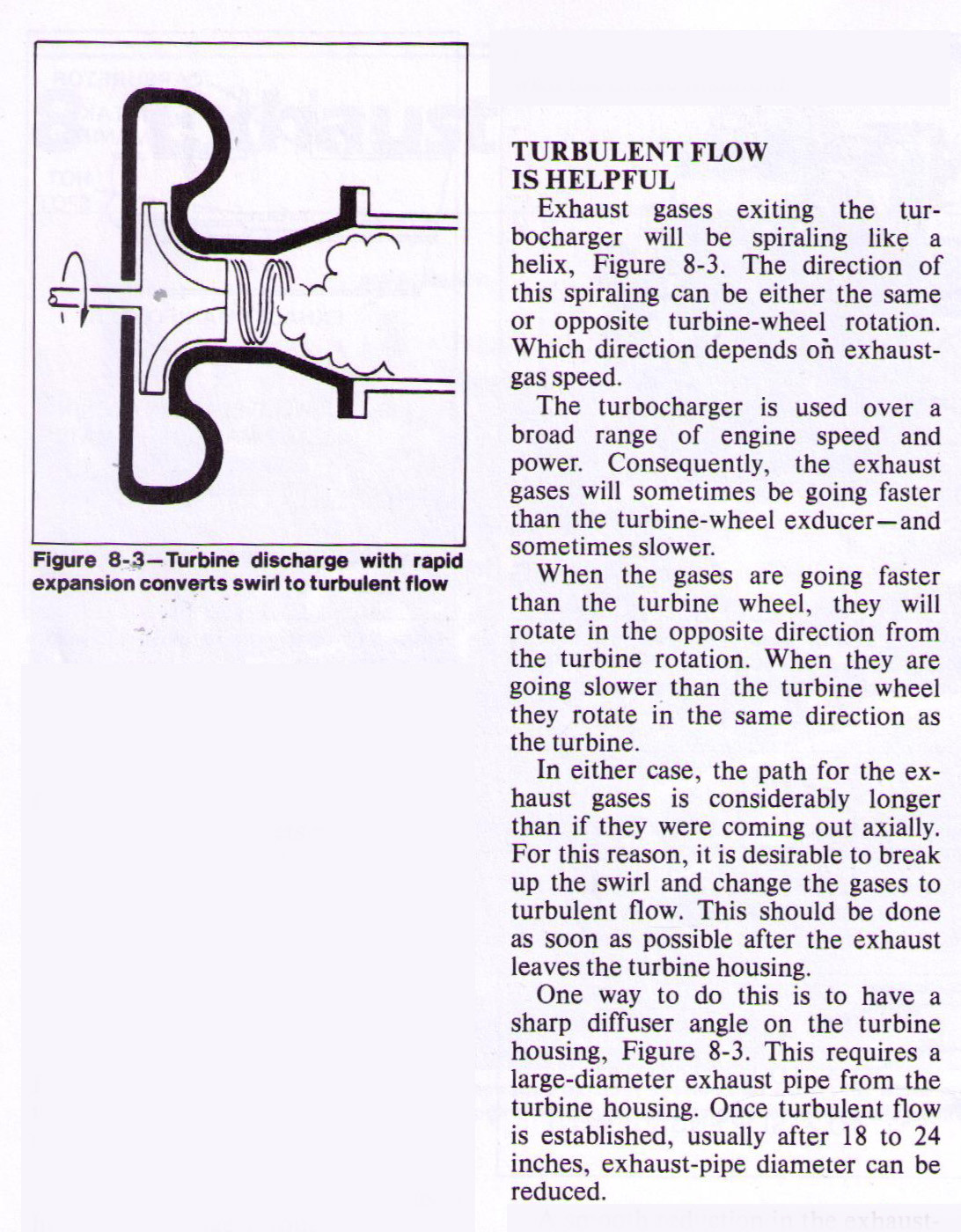

Turbulence can be used for good. Namely removing the rotation of the exhaust gasses out of the turbine outlet.

If you could step to 3" straight out of the turbo and then gradually reduce to 2.5", that would be good. But if you have to have it 2.5" out of the turbo for clearance, then I would just keep it 2.5" the whole way.

If you could step to 3" straight out of the turbo and then gradually reduce to 2.5", that would be good. But if you have to have it 2.5" out of the turbo for clearance, then I would just keep it 2.5" the whole way.

#3

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Indianapolis

Posts: 610

Total Cats: 12

Sounds good.

How does this look?

Weld this cone to the flange and go straight to 3" 2.25" to 3.00" Stainless, 16 Gauge, Transition Cone Columbia River Mandrel Bending

Then use this to go back to 2.5"

2.50" to 3.00" Cone, 4.1" Length, 16 gauge, 304 Stainless Columbia River Mandrel Bending

How does this look?

Weld this cone to the flange and go straight to 3" 2.25" to 3.00" Stainless, 16 Gauge, Transition Cone Columbia River Mandrel Bending

Then use this to go back to 2.5"

2.50" to 3.00" Cone, 4.1" Length, 16 gauge, 304 Stainless Columbia River Mandrel Bending

#6

Senior Member

Thread Starter

iTrader: (3)

Join Date: Oct 2008

Location: Indianapolis

Posts: 610

Total Cats: 12

But it may be easier to just use a 2.5" and sell the whole thing after I swap in the 1.8 in the future.

#7

Turbulence can be used for good. Namely removing the rotation of the exhaust gasses out of the turbine outlet.

If you could step to 3" straight out of the turbo and then gradually reduce to 2.5", that would be good. But if you have to have it 2.5" out of the turbo for clearance, then I would just keep it 2.5" the whole way.

If you could step to 3" straight out of the turbo and then gradually reduce to 2.5", that would be good. But if you have to have it 2.5" out of the turbo for clearance, then I would just keep it 2.5" the whole way.

#9

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

First good post in this thread:

GRADUALLY step up to 2.5" or 3"

stepping up to 3" after the turbo and then transitioning back to 2.5" is stupid.

it takes only the most basic understanding of the most basic common sense concepts to understand why.

GRADUALLY step up to 2.5" or 3"

stepping up to 3" after the turbo and then transitioning back to 2.5" is stupid.

it takes only the most basic understanding of the most basic common sense concepts to understand why.

#13

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

that's silly.

that will cause the gases to expand slow and cool and increase back pressure potential.

I'd much rather have a 2.25" outlet for 18-20" then step that up to 3" gradually. That way the exhaust stays hot, and the velocity is maintained and then the volume is increased where the exhaust gasses cool and expand and need the space.*

*im an art student.

that will cause the gases to expand slow and cool and increase back pressure potential.

I'd much rather have a 2.25" outlet for 18-20" then step that up to 3" gradually. That way the exhaust stays hot, and the velocity is maintained and then the volume is increased where the exhaust gasses cool and expand and need the space.*

*im an art student.

#15

that's silly.

that will cause the gases to expand slow and cool and increase back pressure potential.

I'd much rather have a 2.25" outlet for 18-20" then step that up to 3" gradually. That way the exhaust stays hot, and the velocity is maintained and then the volume is increased where the exhaust gasses cool and expand and need the space.*

that will cause the gases to expand slow and cool and increase back pressure potential.

I'd much rather have a 2.25" outlet for 18-20" then step that up to 3" gradually. That way the exhaust stays hot, and the velocity is maintained and then the volume is increased where the exhaust gasses cool and expand and need the space.*

OP says:

"Would going to 3" tubing for maybe 2 feet and then back to 2.5" exhaust give me more power or just more turbulence?"

Will my 3" version have better spool up and make more power than your version? Yes it will. I did it on my 86 5KTQ. Built the down pipe first, then later finished the exhaust. Noticeable difference with that change only.

""""""""""""""""""""LISTEN TO ME NOW, BELIEVE ME LATER"""""""""""""""""""""

-JB

Last edited by Braineack; 09-26-2014 at 09:15 AM.

#17

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

what exactly is silly about it? that there is actually theory behind my statement?

My DP was 2.5" off the turbo (matching the outlet) and stepped up to 2.75" after about 18". Then went to 3" at the cat. I was making better spool and TQ than every other 1.6L I've ever seen posted here; and I was using a bigger shittier turbo than most members. I still have yet to see a better 1.6L dyno in the last 6 years.

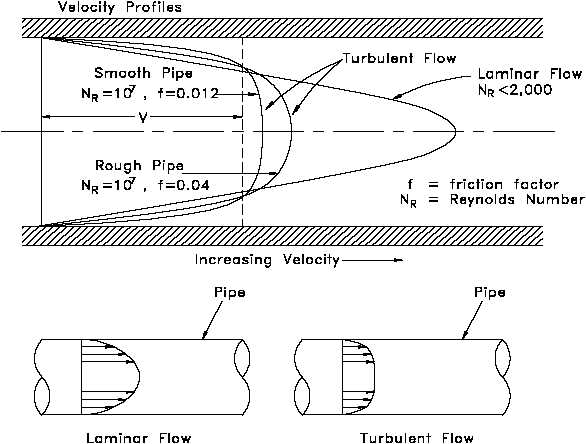

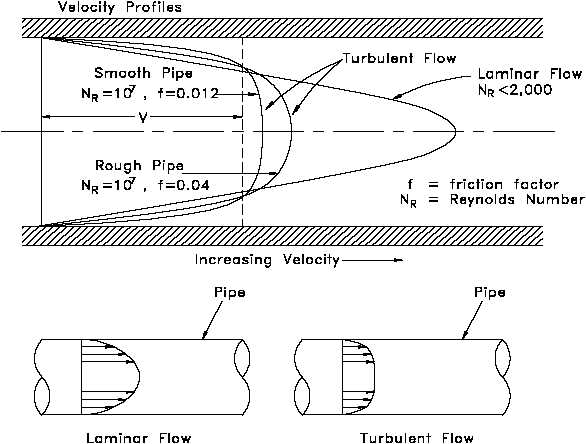

I honestly don't believe that had I just had a 3" DP that my results would be any better. It was engineered to evacuate exhaust gasses as quickly and efficiently as possible, reducing back pressure, which increased performance by inducing a steady decrease in exhaust gas velocity.

If you allow the exhaust gasses to become turbulent, cool & expand quickly right off the turbo, then you're inducing backpressure. So there's less torque being used to push pistons downward and instead energy is being wasted pushing the gasses out of the turbo. Imagine designing a highway and suggesting that it makes sense to put several on-ramps in one location, and then reduce the lanes from 4 to 2. That's like installing a HVAC unit and installing 2" pipes to your top floor. That's like designing an intake manifold with small runners that get bigger as the reach the head. That's like designing a water slide that everyone enters at the same time, and then funnels into an area where only one person can exit at a time, and everyone piles onto each other while waiting, backing up to the entrance and falling off the platform to their deaths.

Building a DP to go from 3" back down to 2.5" is just completely retarded in every way. If the exhaust is always remain 2.5" then it makes sense to keep the DP 2.5", if you ever upgrade later then there's only just improvement to be had. If you make your 3" to 2.5" DP and then upgrade to a 3" exhaust, then you've designed in a roughly 2 sq.in. flow area bottleneck for no good reason (sorry: because 2manyhobyz says so is not a good reason until he provides reasoning).

I saw a HUGE increase in power, spool, and boost creep when I used my same 2.5 to 2.75" DP with a 2.5" cat and exhaust and then upgraded to a 3" cat and exhaust. HUGE. like insane difference. I cant find the dyno right now, but iirc I went from 180rwhp to 230rwhp at 13psi with no other changes to the setup (same boost level, spark advance, etc).

Or we can listen to people suggesting that energy loss, turbulence, and backpressure are the keys to exhaust design.

but then I might post something like this:

We are talking about the down pipe. The first 24" of volume that the exhaust gas has to fill.

I honestly don't believe that had I just had a 3" DP that my results would be any better. It was engineered to evacuate exhaust gasses as quickly and efficiently as possible, reducing back pressure, which increased performance by inducing a steady decrease in exhaust gas velocity.

If you allow the exhaust gasses to become turbulent, cool & expand quickly right off the turbo, then you're inducing backpressure. So there's less torque being used to push pistons downward and instead energy is being wasted pushing the gasses out of the turbo. Imagine designing a highway and suggesting that it makes sense to put several on-ramps in one location, and then reduce the lanes from 4 to 2. That's like installing a HVAC unit and installing 2" pipes to your top floor. That's like designing an intake manifold with small runners that get bigger as the reach the head. That's like designing a water slide that everyone enters at the same time, and then funnels into an area where only one person can exit at a time, and everyone piles onto each other while waiting, backing up to the entrance and falling off the platform to their deaths.

Building a DP to go from 3" back down to 2.5" is just completely retarded in every way. If the exhaust is always remain 2.5" then it makes sense to keep the DP 2.5", if you ever upgrade later then there's only just improvement to be had. If you make your 3" to 2.5" DP and then upgrade to a 3" exhaust, then you've designed in a roughly 2 sq.in. flow area bottleneck for no good reason (sorry: because 2manyhobyz says so is not a good reason until he provides reasoning).

I saw a HUGE increase in power, spool, and boost creep when I used my same 2.5 to 2.75" DP with a 2.5" cat and exhaust and then upgraded to a 3" cat and exhaust. HUGE. like insane difference. I cant find the dyno right now, but iirc I went from 180rwhp to 230rwhp at 13psi with no other changes to the setup (same boost level, spark advance, etc).

Or we can listen to people suggesting that energy loss, turbulence, and backpressure are the keys to exhaust design.

but then I might post something like this:

Last edited by Braineack; 09-26-2014 at 10:47 AM.

#20

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

I hope that's a joke and you just have it installed backwards.

That v-band outlet on the turbo looks 2.5" so what you should have done is stepped it up to 3" initially to fill it with a lot of turbulent exhaust gasses that slow/cool rapidly then step down to 2.5" so it creates extra backpressure since you need more flow area to allow the slowed exhaust piling up behind itself to reach the outlet.

That v-band outlet on the turbo looks 2.5" so what you should have done is stepped it up to 3" initially to fill it with a lot of turbulent exhaust gasses that slow/cool rapidly then step down to 2.5" so it creates extra backpressure since you need more flow area to allow the slowed exhaust piling up behind itself to reach the outlet.