DIY SS Bottom Mount Manifold

#62

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Wayne, a spacer is fine. That's not a cheated cut. A cheater cut is an angled cut not perpendicular to the center axis of the pipe (if that makes sense). I'm sure you noticed the pipe you cut at an angle ended up with a bigger, ovaled diameter that didn't quite match up to the other pipe.

#63

Elite Member

Thread Starter

iTrader: (8)

Join Date: Aug 2007

Location: Bellingham, Wa

Posts: 2,712

Total Cats: 4

Ahh I see. A good display of my ignorance. Makes sense now.

I'm gonna go price cutoff wheels as well as get my gas bottle filled up. Hoping to get this manifold all tacked up today and start on the downpipe as well.

I'm gonna go price cutoff wheels as well as get my gas bottle filled up. Hoping to get this manifold all tacked up today and start on the downpipe as well.

#64

Elite Member

Thread Starter

iTrader: (8)

Join Date: Aug 2007

Location: Bellingham, Wa

Posts: 2,712

Total Cats: 4

More pictures.

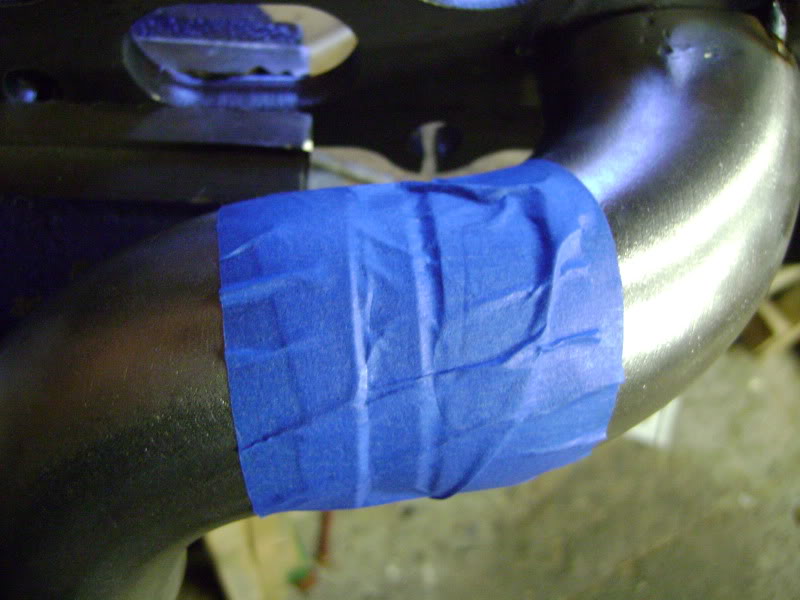

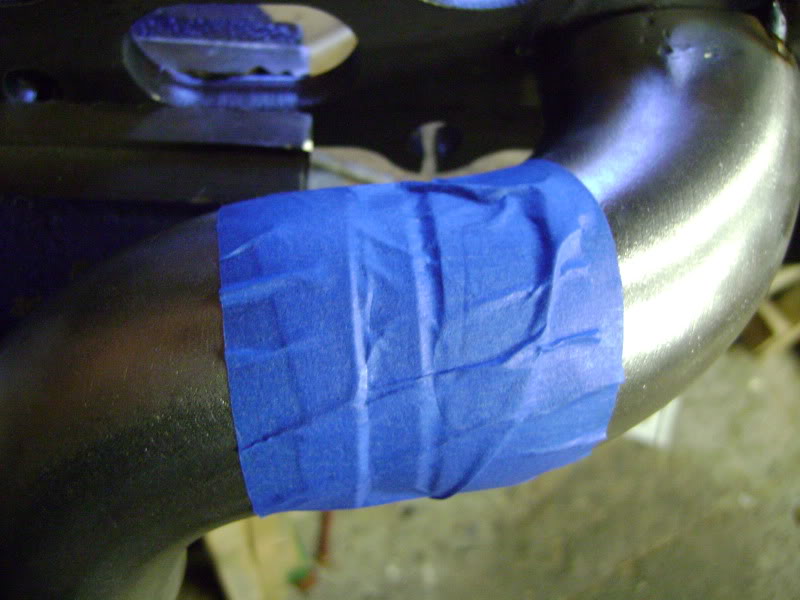

Made more progress today. The meat and potatoes of the manifold are all tacked and taped up ready for me to pull the car in and tear it apart to test fit everything.

I can tell already i'm going to need more angle.

You can see the spacer I cut underneath the tape in this one.

One of my main concerns so far is that i've already drilled my turbine housing to the bigger M10 studs, but this weirtech flange is drilled/tapped for M8 and doesn't look like there is a substantial amount of metal around the holes to safely drill it out even more. I plan on through-bolting this when I get it all figured out instead of studs.

I took the advice of Artech and Tim and picked up cutoff wheels for the angle grinder. Holy hell do I feel stupid for using a ******* hacksaw...

As soon as I can get someone over to help me move this big piece of **** out of the middle of the garage i'll be able to pull the car in and really get to work.

Made more progress today. The meat and potatoes of the manifold are all tacked and taped up ready for me to pull the car in and tear it apart to test fit everything.

I can tell already i'm going to need more angle.

You can see the spacer I cut underneath the tape in this one.

One of my main concerns so far is that i've already drilled my turbine housing to the bigger M10 studs, but this weirtech flange is drilled/tapped for M8 and doesn't look like there is a substantial amount of metal around the holes to safely drill it out even more. I plan on through-bolting this when I get it all figured out instead of studs.

I took the advice of Artech and Tim and picked up cutoff wheels for the angle grinder. Holy hell do I feel stupid for using a ******* hacksaw...

As soon as I can get someone over to help me move this big piece of **** out of the middle of the garage i'll be able to pull the car in and really get to work.

#68

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Drilling out to use a 3/8-24 bolt is the good idea and like Rev. Greg said there's lots of room. If you need some fancy 12point ARP nuts I can get some. Makes getting a wrench (box end) on there easier.

Overall, looking great!

Overall, looking great!

#74

Elite Member

Thread Starter

iTrader: (8)

Join Date: Aug 2007

Location: Bellingham, Wa

Posts: 2,712

Total Cats: 4

they have 3/8-24 316ss for sure. Just not Monel. I think through-bolting the SS bolts with Tim's nuts (and some washers of course) with safety wire will keep my junk pretty tight at the track.

#78

Elite Member

Thread Starter

iTrader: (8)

Join Date: Aug 2007

Location: Bellingham, Wa

Posts: 2,712

Total Cats: 4

Got my old stuff out. Boy am I glad i'll never be putting that pain in the *** begi manifold and downpipe on again. I forgot just how big of a pain in the *** it is to install/remove.

I quickly mocked up the new manifold (forgot to take a picture) and as I suspected, i'll need to rotate the collector out a little so turbo not hit block but other than that its going to be a marvelous fit. I'm going to be so glad to easily reach every nut/bolt on the new setup. Downpipe routing is going to be a breeze as well.

Gotta go play cribbage at the bar with some friends cause i'm 90 years old and its what we do on wednesdays. Will get pics up tomorrow.

I quickly mocked up the new manifold (forgot to take a picture) and as I suspected, i'll need to rotate the collector out a little so turbo not hit block but other than that its going to be a marvelous fit. I'm going to be so glad to easily reach every nut/bolt on the new setup. Downpipe routing is going to be a breeze as well.

Gotta go play cribbage at the bar with some friends cause i'm 90 years old and its what we do on wednesdays. Will get pics up tomorrow.

#79

Elite Member

Thread Starter

iTrader: (8)

Join Date: Aug 2007

Location: Bellingham, Wa

Posts: 2,712

Total Cats: 4

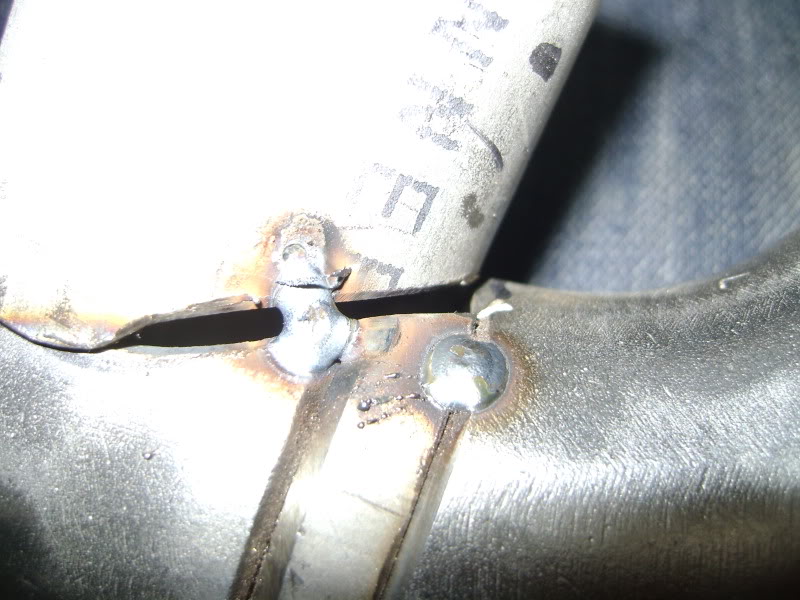

Manifold build phail.

Not so bad from this side.

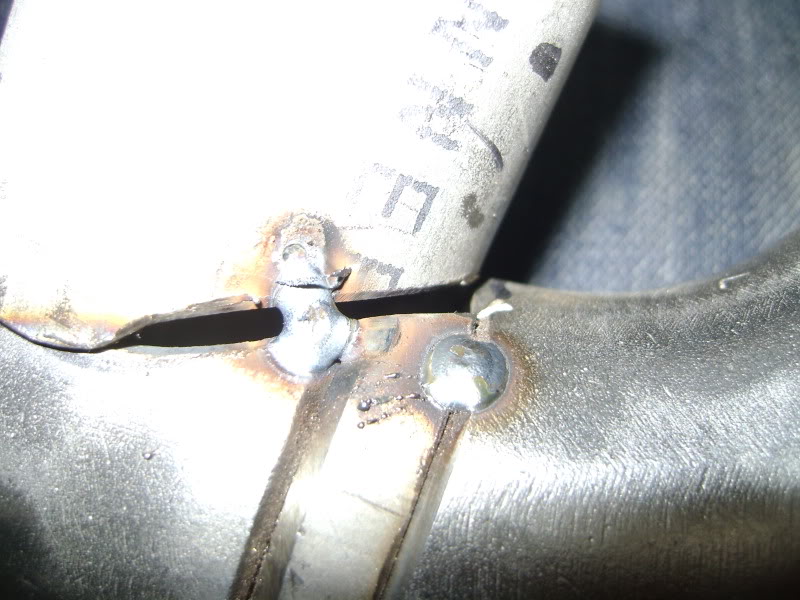

Horrid from this side.

Gappage.

Not even sure why I tacked it together. I guess to get motivation to order more pipe and try again. since it looks decent from one side.

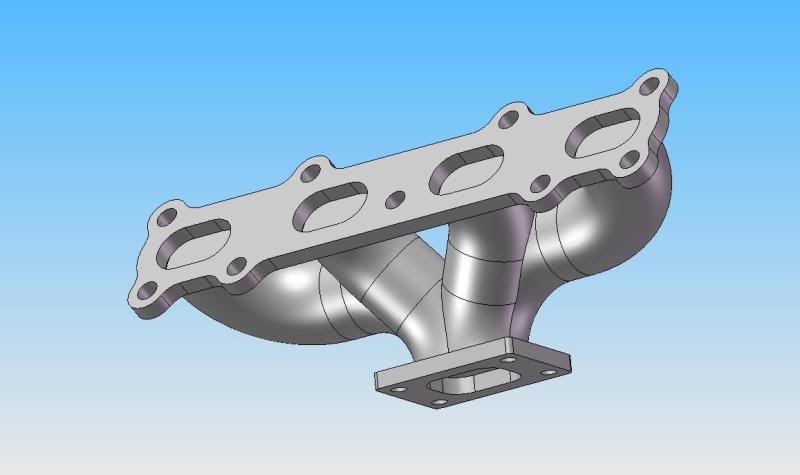

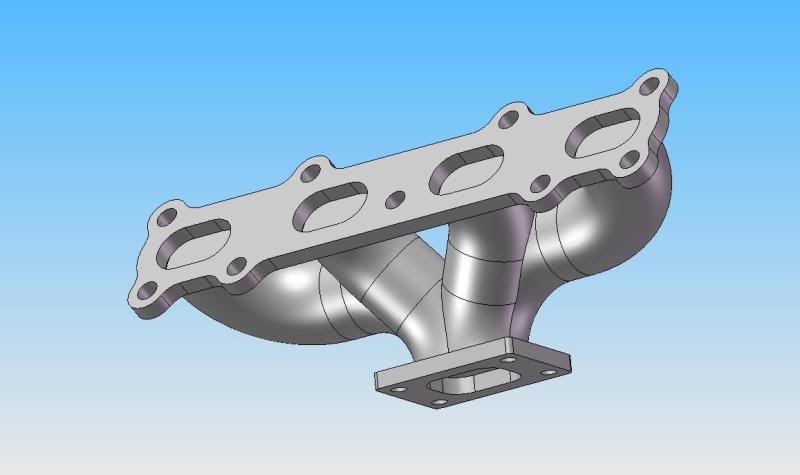

I guess my options at this point are to order more pipe and try to cope it again with more patience this time or order all mild bends and completely start from scratch like this:

I think making a 4 into 1 collector would be easier than trying to cope pipe into the center 2 runners. My biggest mistake was cutting with the dremel instead of a hole saw :(

I started hurrying last night to try and get it done in time to take to Sbk to weld for me tonight. Oh well, i learned some things.

Not so bad from this side.

Horrid from this side.

Gappage.

Not even sure why I tacked it together. I guess to get motivation to order more pipe and try again. since it looks decent from one side.

I guess my options at this point are to order more pipe and try to cope it again with more patience this time or order all mild bends and completely start from scratch like this:

I think making a 4 into 1 collector would be easier than trying to cope pipe into the center 2 runners. My biggest mistake was cutting with the dremel instead of a hole saw :(

I started hurrying last night to try and get it done in time to take to Sbk to weld for me tonight. Oh well, i learned some things.