PSA: EFR Turbo Oil Drain Information. Read this before designing your oil drain

#1

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

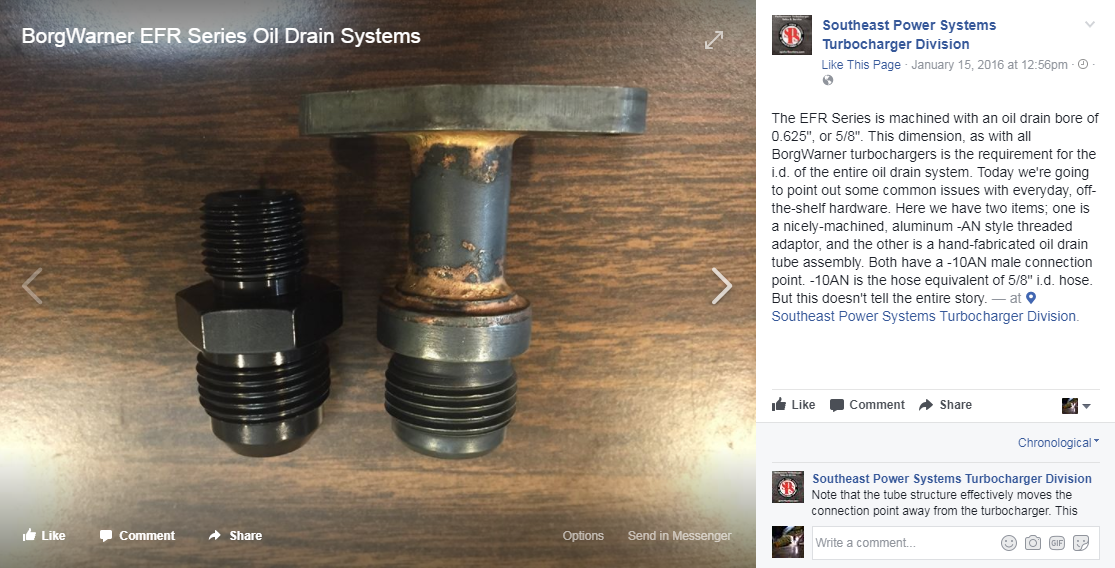

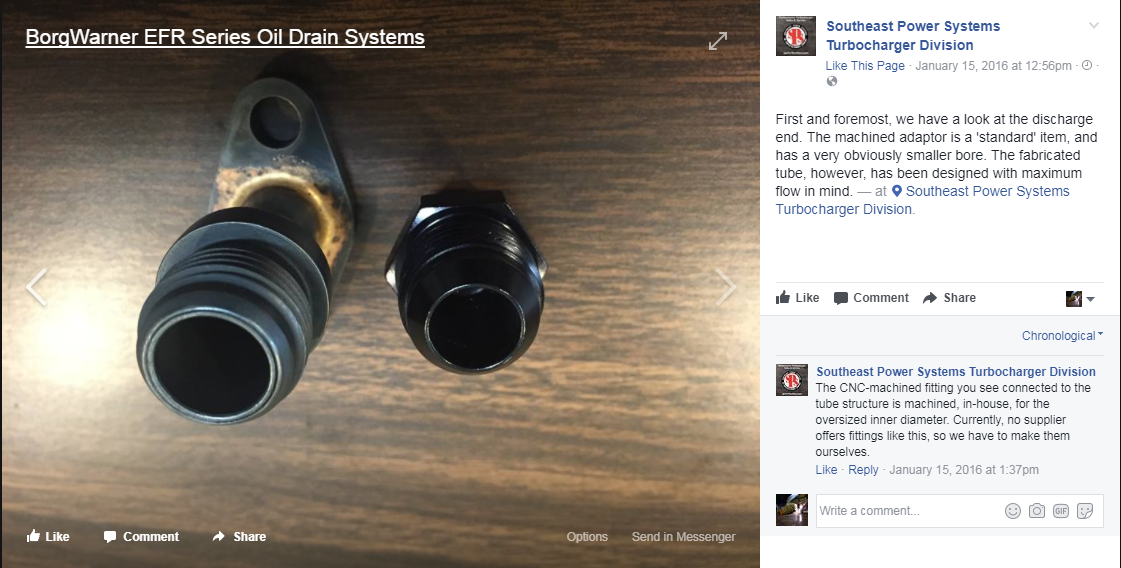

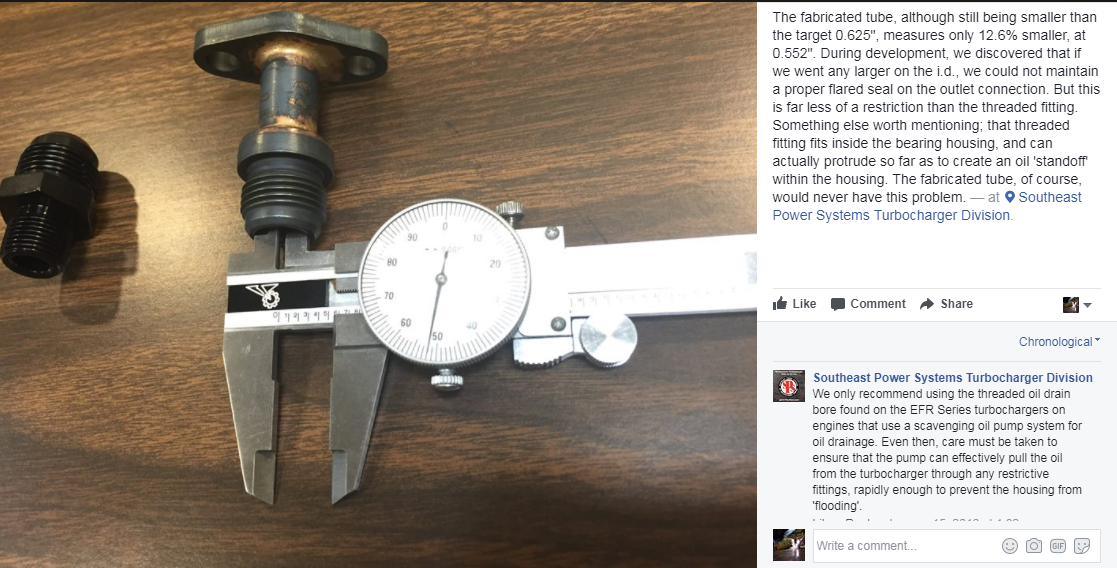

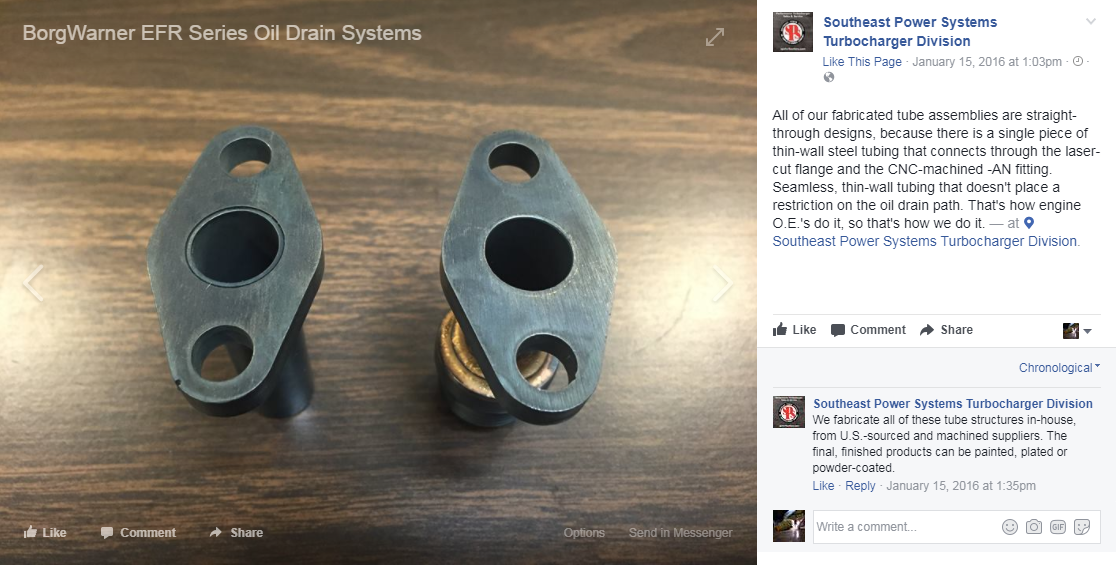

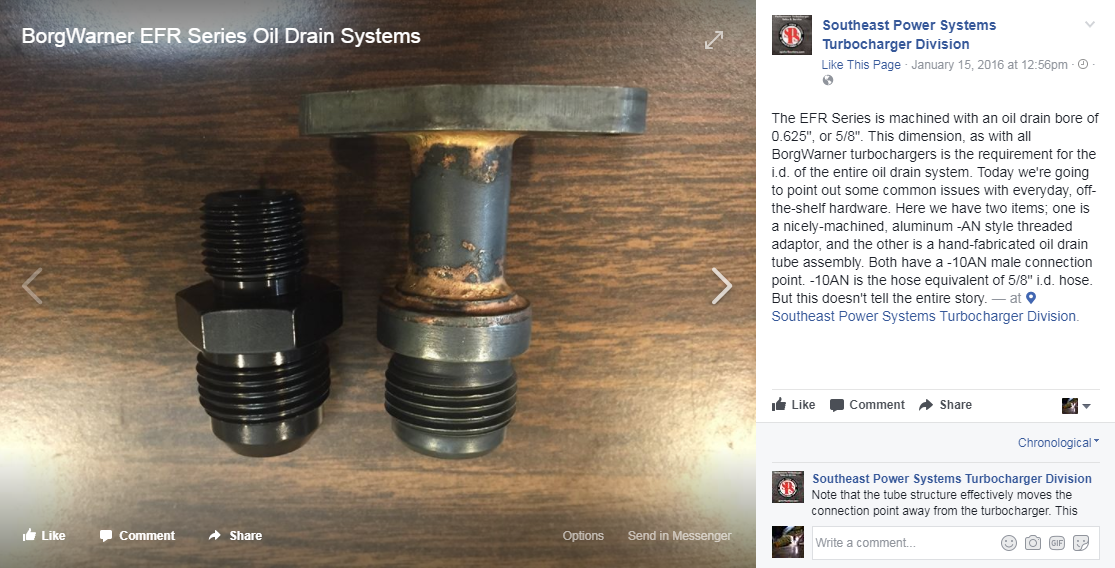

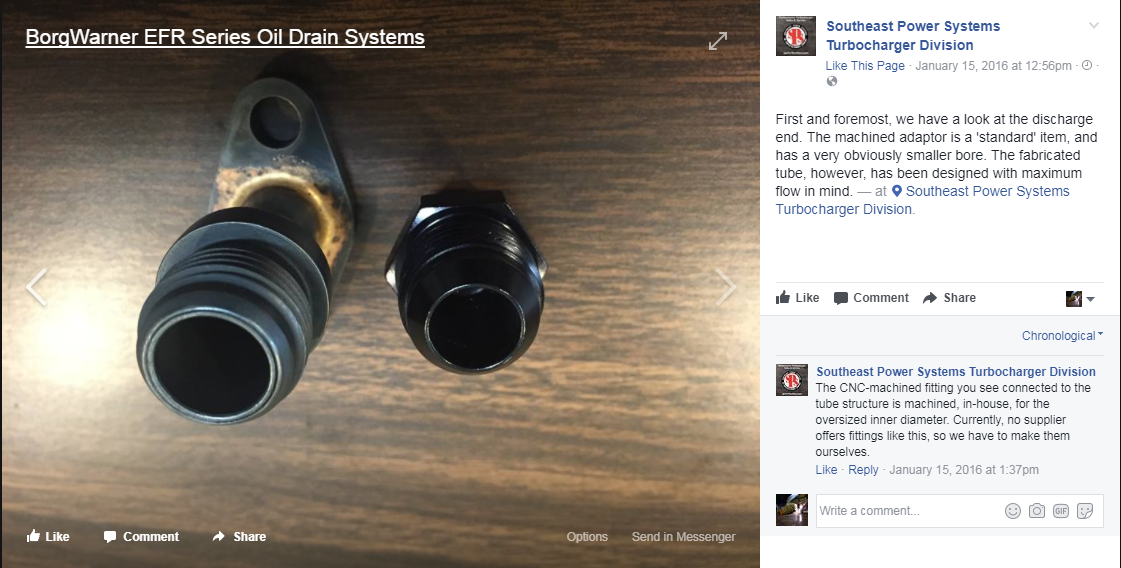

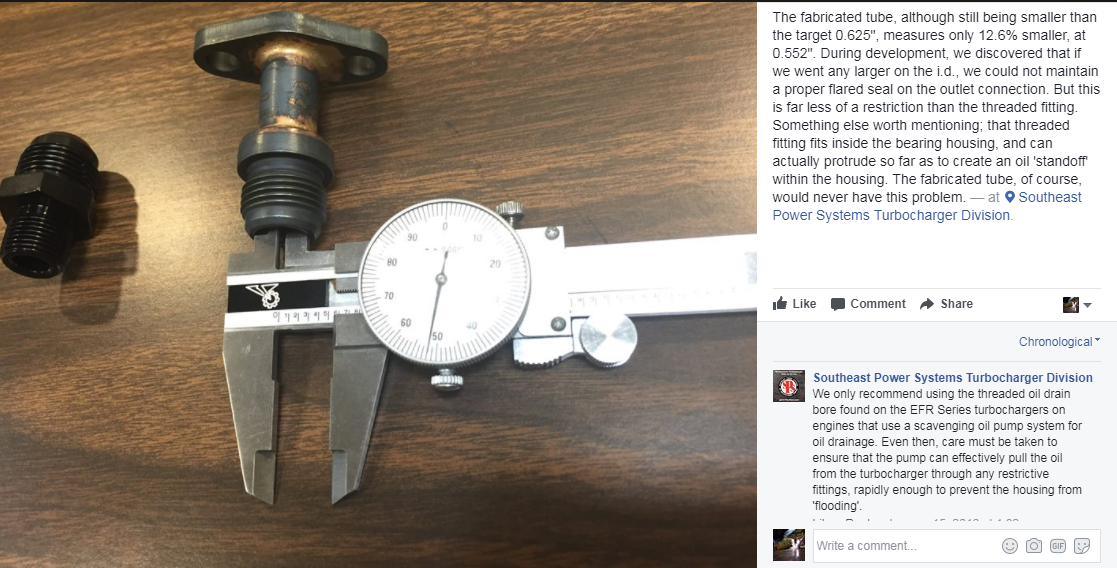

Spoke with Mike Franke from Southeast Power Systems today about what I now believe to be a drain issue on my setup. And he sent me a bunch of good information about the requirements for EFR oil drains. Thought I would share that information with you guys and hopefully help someone out in the future.

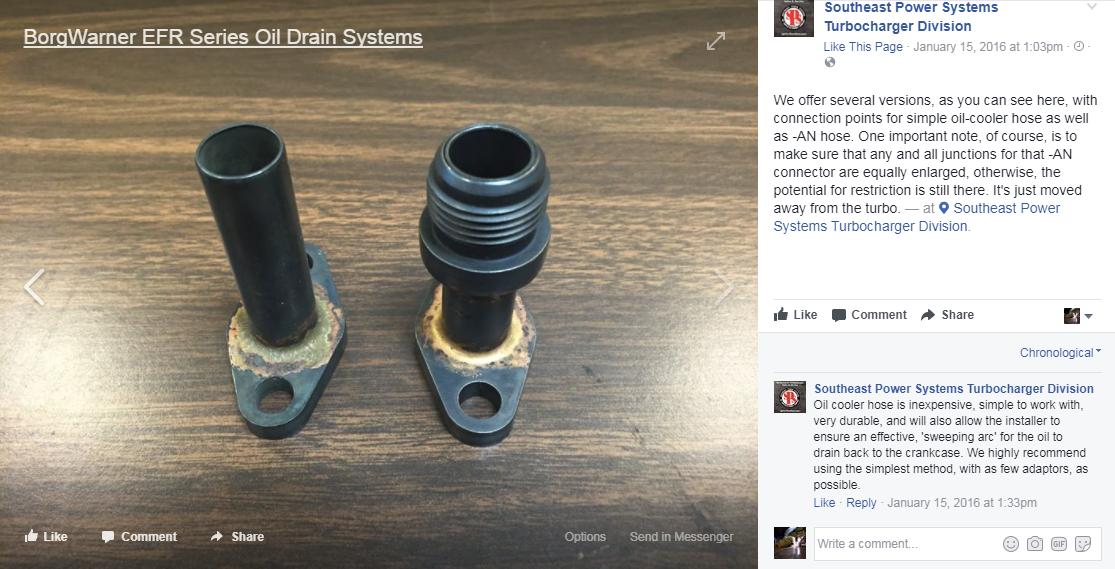

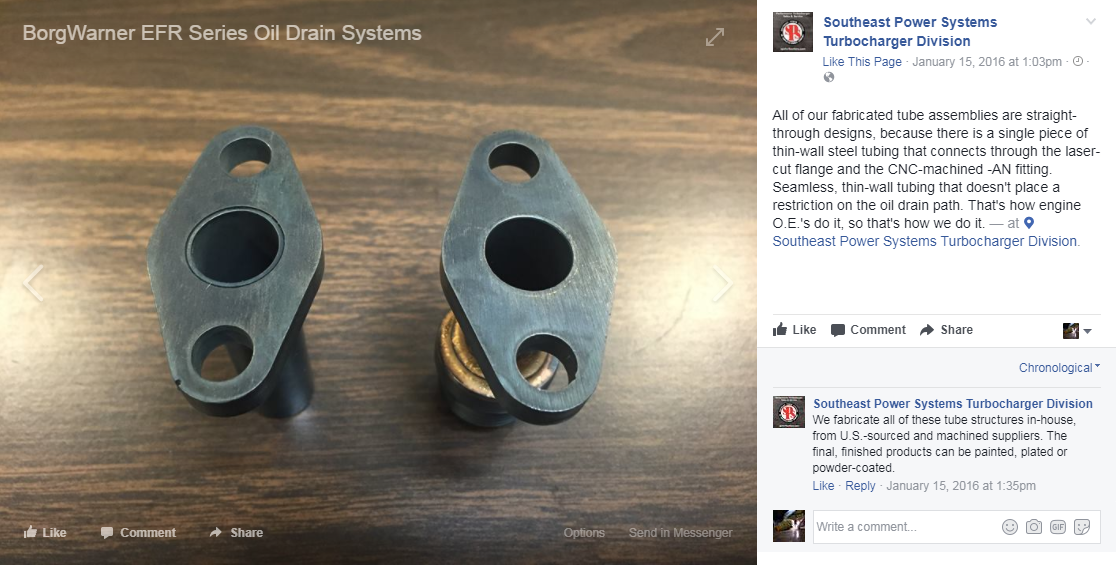

I'll start with a Facebook post from them. And will scrape the screenshots too.

Also here are links to both a very technical document on turbo oil systems, and a general guidelines for EFR.

https://drive.google.com/open?id=0B7...VxbHRxSWRzOXNZ

https://drive.google.com/file/d/0B7v...ew?usp=sharing

And a note on turbo seals. Turbo seals are just like piston rings, they are not meant to hold positive oil pressure into the turbo, they are instead meant to keep gasses from outside (exhaust or intake) from entering the CHRA. So if you end up with a backed up oil drain, your oil feed pressurizes the oil inside the CHRA and will push it out the seals. My specific issue is seeing smoke after hard driving, and then idling. I believe that this is because when I'm driving hard, there is a lot of pressure in the turbine housing and compressor housing, which means the oil is the low pressure area of the system. But when I stop driving hard, there is little pressure in the turbine housing, which means the oil cavity is now the high pressure system. And it leaks into the turbine housing. Of course this is all speculation right now, and I will come update this when I make a change and figure out if that was my real issue.

TL R is the following: EFR's can be particular about their oil draining, we knew this. I didn't know how particular. A properly designed system must be the same size as the turbo outlet, and stay that size or bigger to the oil pan. Oil leaving the turbine housing is not all liquid, but frothy too, and only has gravity too pull it down. You might be getting away with smaller drains, but if you have standard AN fittings most likely they are too small.

R is the following: EFR's can be particular about their oil draining, we knew this. I didn't know how particular. A properly designed system must be the same size as the turbo outlet, and stay that size or bigger to the oil pan. Oil leaving the turbine housing is not all liquid, but frothy too, and only has gravity too pull it down. You might be getting away with smaller drains, but if you have standard AN fittings most likely they are too small.

I'll start with a Facebook post from them. And will scrape the screenshots too.

Facebook Post

Also here are links to both a very technical document on turbo oil systems, and a general guidelines for EFR.

https://drive.google.com/open?id=0B7...VxbHRxSWRzOXNZ

https://drive.google.com/file/d/0B7v...ew?usp=sharing

And a note on turbo seals. Turbo seals are just like piston rings, they are not meant to hold positive oil pressure into the turbo, they are instead meant to keep gasses from outside (exhaust or intake) from entering the CHRA. So if you end up with a backed up oil drain, your oil feed pressurizes the oil inside the CHRA and will push it out the seals. My specific issue is seeing smoke after hard driving, and then idling. I believe that this is because when I'm driving hard, there is a lot of pressure in the turbine housing and compressor housing, which means the oil is the low pressure area of the system. But when I stop driving hard, there is little pressure in the turbine housing, which means the oil cavity is now the high pressure system. And it leaks into the turbine housing. Of course this is all speculation right now, and I will come update this when I make a change and figure out if that was my real issue.

TL

R is the following: EFR's can be particular about their oil draining, we knew this. I didn't know how particular. A properly designed system must be the same size as the turbo outlet, and stay that size or bigger to the oil pan. Oil leaving the turbine housing is not all liquid, but frothy too, and only has gravity too pull it down. You might be getting away with smaller drains, but if you have standard AN fittings most likely they are too small.

R is the following: EFR's can be particular about their oil draining, we knew this. I didn't know how particular. A properly designed system must be the same size as the turbo outlet, and stay that size or bigger to the oil pan. Oil leaving the turbine housing is not all liquid, but frothy too, and only has gravity too pull it down. You might be getting away with smaller drains, but if you have standard AN fittings most likely they are too small.

#6

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

lol. thats the other thing that Mike talked about. Crankcase venting. Any pressure at all in the crankcase will be detrimental. Even if its as ghetto as running a hose from your dipstick tube to your catch can, it can help.

#7

Ah crum, I've been using the treadstone one, and it seems it's too small. Now I'm questioning my bung....

EFR & Garrett GT Oil Drain Return Flange, -10AN- TREADSTONE PERFORMANCE

EFR & Garrett GT Oil Drain Return Flange, -10AN- TREADSTONE PERFORMANCE

#10

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

If you are not having issues I would not worry. Either way oil blowby is not a fatal issue, and will usually clear itself up. There are extreme cases when enough blowby causes carbon buildup and housing contact, but that is rare.

#12

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Yep. I followed your thread as well. I didn't remember seeing the 2 documents but I might be wrong. Didn't you also have an issue with the pickup tube blocking the drain?

#13

My car has puffed blue smoke from dead stops although the leakdown and compression numbers are ****. I have two -10 AN ports on the valve cover to help facilitate venting, but I could never track down why I still see the occasional blue. This occurred on my previous build that blew also. Common denominator, oil pan, exhaust setup and oil drain.

At the time I was referencing the Full-Race/BW tech doc stating ~minimum -8AN. I thought I was in the clear with -10AN and built accordingly. Not good enough as things have evolved lol...

At the time I was referencing the Full-Race/BW tech doc stating ~minimum -8AN. I thought I was in the clear with -10AN and built accordingly. Not good enough as things have evolved lol...

#14

I think I included some pictures and references from the report he gave me after inspecting my turbo but I can't remember. Those may also have been loaded on photo bucket so I am not sure if they are even still up. I did have my oil pickup tube blocking my drain. I have since fixed that issue but I also had leaking valve seals which I just replaced this week. I have driven the car twice and seen no smoke but I need to clean out the intake pipes of excess oil and put It through the paces to be sure. I'll submit my findings to this thread and my build thread so it's easier for people to find.

#15

Hi, Everyone.

I had forgotten that I do have a profile here, and, as Aidan mentioned, I'm pretty familiar with the EFR Series, having been involved in the development as far back as 2008. If anyone needs any assistance with issues like this, please feel free to reach out to me.

I am available by email, and I use the same profile name on all major I/M programs, and am online during office hours, from 8-5 Eastern, Monday through Friday.

I had forgotten that I do have a profile here, and, as Aidan mentioned, I'm pretty familiar with the EFR Series, having been involved in the development as far back as 2008. If anyone needs any assistance with issues like this, please feel free to reach out to me.

I am available by email, and I use the same profile name on all major I/M programs, and am online during office hours, from 8-5 Eastern, Monday through Friday.

#17

I just wanted to add myself in here, I have a 3/8" bung into the oil pan and have been having the idle smoking issue periodically as well. PCV and check valve are both good, no extra oil or fluids in the catch can and nothing on the hotside vent filter. I do occasionally see some on the dipstick tube though. I'll replace that O ring tonight.

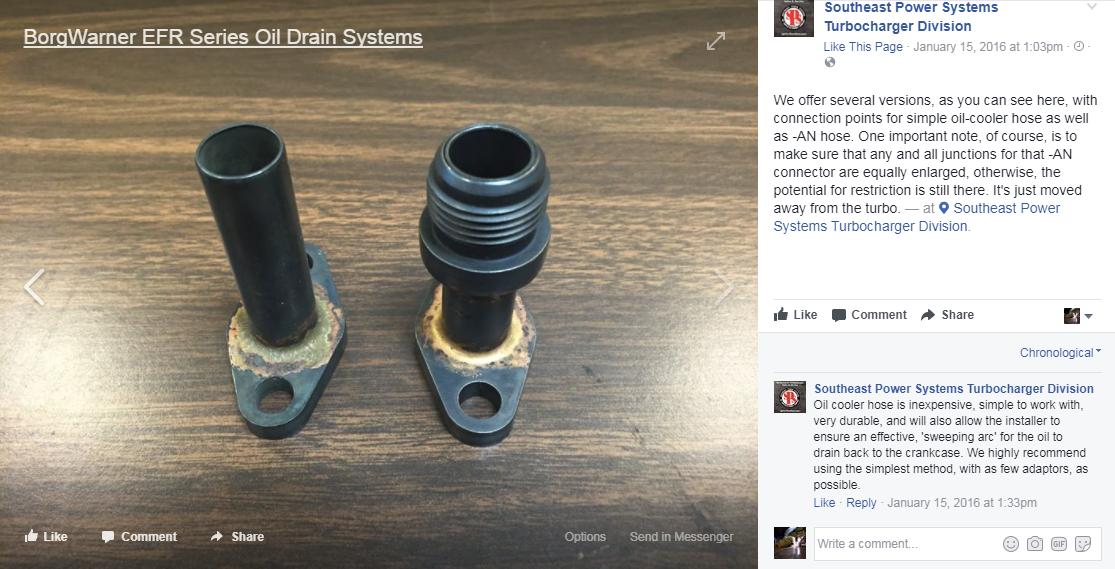

#19

If the fitting you'll be using inside that bung can be machined to an inner diameter closer to, or equal to, the inner diameter of the remainder of your oil drain structure, this can be easily overcome. Since many of us use either brass or aluminum fittings for this, that's sometimes very easy, especially if the fitting is 'straight' in design. This is also a really good reason to avoid 45- or 90-degree fittings for oil drain systems, as it's quite difficult to make those larger in i.d.. It's much better to let the hose or tube structure to act as the 'bend' for the drain system, as you can get a more gradual declining angle that way.

Keep in mind, as well, that most all turbo manufacturers (BorgWarner among them) require no more than a total declination of 45 degrees for the entire oil drain path, so add up your angles and make sure you don't exceed that, and, in a perfect world, you should come in well below it for best results.

Remember that you can rotate the bearing housing within the structure to allow a more gradual angle, as well. Just don't overdo it; 5 degrees in either direction is as far as I would suggest.

The real key, there, though, is the inner diameter of the entire drain structure, so I always suggest looking really closely at any fittings or adaptors that you're using, and if you can avoid stacking up fittings, generally, you're going to be in better shape.

When in doubt, it's also a good idea to have a look at virtually any O.E. oil drain system, gasoline or diesel, as you'll never find adaptors or threaded fittings in these systems.

My personal preference, across the board, is to set up tubular systems, either as complete assemblies, or partial, with oil cooler hose junctions, as you can hold a larger i.d. throughout, and, in most cases, they're less expensive than having a fancy -AN line made up that's going to be full of hidden restrictions anyhow.

Please let me know if this is helpful.

#20

I like the welded tubular fitting with the custom machined threaded portion made by Southeast Power Systems. But this also begs the question, if the BorgWarner EFR series turbos are "Clean-sheet concepts. Loaded with innovations. Engineered For Racing." then why on earth do they require custom machined fittings to function properly? Why can't they simply use readily available off the shelf hardware to get the job done? Yes, any competent race shop can fabricate the necessary hardware components. But it's not necessarily the wisest use of anyone's time.