Recommend the best BOV for my boost levels.

#101

So I got my Forge today. STOKED. Put it on. Massive compressor surge.... Opened it up... sent me the yellow spring instead of lighter green one. Ugh. Called. New one is on its way.

This brings me to the question: what spring do you guys use on the idle side, to keep it closed during idle? I have red, yellow, blue, green, and the stock one in it which is very light. Idle did seem to be much different as soon as I installed the new valve over the old China one so I'm assuming its either sealing a lot better or leaking a lot better, but don't know how to test it hahaha.

This brings me to the question: what spring do you guys use on the idle side, to keep it closed during idle? I have red, yellow, blue, green, and the stock one in it which is very light. Idle did seem to be much different as soon as I installed the new valve over the old China one so I'm assuming its either sealing a lot better or leaking a lot better, but don't know how to test it hahaha.

Basically, you want to find the lightest spring that keeps the BOV closed at peak vacuum (full decel, NOT idle). This design can never open under full boost if you have a spring installed, speaking in a general sense (Don't run an unshimmed green at 50PSI, although that may not be enough to open it), and the weaker the spring you have, the faster/better the response from the BOV is.

You should have 3 shims with those 4 springs to help you fine tune the point where the BOV does not open under peak vacuum. Personally, I run a yellow without shims but am considering a 3 shim green. I'd be moderately surprised if an unshimmed green was okay - yellow is their second weakest spring included FWIW. Are you certain it is compressor surge you are hearing? The green is ridiculously wimpy as a spring, and my yellow setup has no problem opening under ~4 PSI (Wastegate unhooked for engine break in....No issues with operation here).

Last edited by blaen99; 10-12-2014 at 11:12 AM.

#105

Sorry for the crappy pics, work has been crazy and I'm trying to fit everything in best I can.

Did ya'll see the video I posted? This valve has me completely confused, it looks like its opening just fine.

Griz, interesting what you're saying about pulling air out of the intercooler.

Underhood of the car revving at idle it almost definitely sounds like its the compressor. Could it be the small idle spring that is somehow an issue?

blaen99, thats interesting. The yellow spring was ultra heavy for me, it seemed like. I'm thinking about swapping it back just to mess around, because I could get it to open at full boost, but now that I think about it I think it didn't open much less than the green does.

I have to get something to close the boost gauge line, then I'm going to try and bring the BOV straight to the TB across the front of the engine (at least for testing) so its ultra short. Then go from there.

I will change the location of it like Griz suggests, but unfortunately don't have enough time to get into that right now. I'll have to run with the old BOV for now and wait until snow files to do it.

But, as always, thanks everyone!

Did ya'll see the video I posted? This valve has me completely confused, it looks like its opening just fine.

Griz, interesting what you're saying about pulling air out of the intercooler.

Underhood of the car revving at idle it almost definitely sounds like its the compressor. Could it be the small idle spring that is somehow an issue?

blaen99, thats interesting. The yellow spring was ultra heavy for me, it seemed like. I'm thinking about swapping it back just to mess around, because I could get it to open at full boost, but now that I think about it I think it didn't open much less than the green does.

I have to get something to close the boost gauge line, then I'm going to try and bring the BOV straight to the TB across the front of the engine (at least for testing) so its ultra short. Then go from there.

I will change the location of it like Griz suggests, but unfortunately don't have enough time to get into that right now. I'll have to run with the old BOV for now and wait until snow files to do it.

But, as always, thanks everyone!

#107

Or maybe I am misunderstanding and what you mean is that upon throttle lift at full boost you could get it to open?

So maybe to simplify...

With engine off and BOV in your hand, how much pressure does it take to open push open the valve with your finger? Heavy, light?

With BOV in your hand but vacuum line connected to your source, how much pressure does it take to push the BOV open? Harder? Easier?

With BOV back connected to charge pipes and connected to vacuum source, does is it open or closed at idle?

With BOV still connected and a twist of the throttle, does it stay closed until you lift the throttle?

Under what circumstances can you get it to open? Under what circumstances does it stay closed?

#111

Vlad, others,

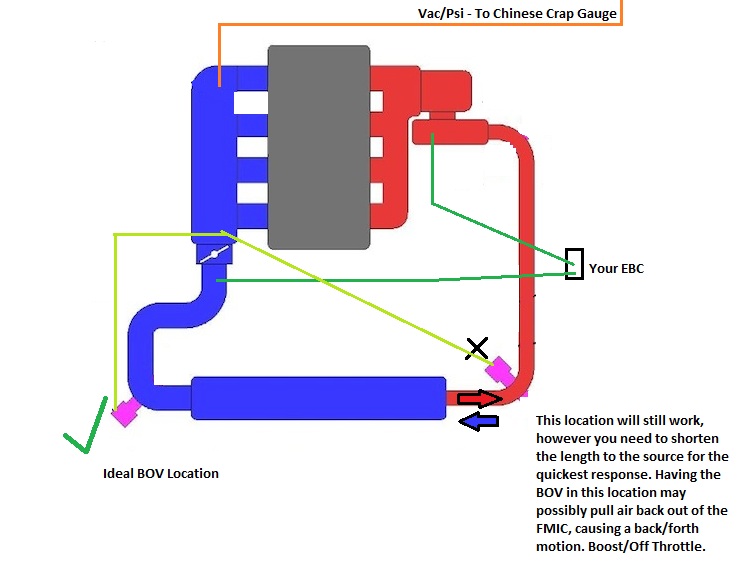

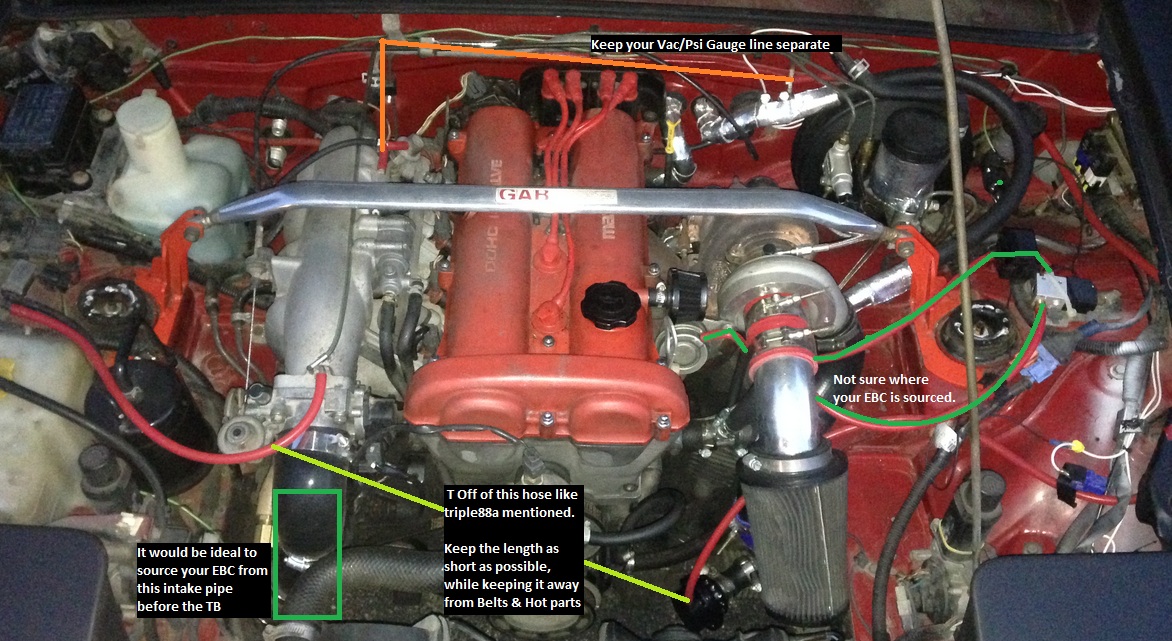

In reference to the above image with the green box showing the ideal EBC source is this still correct for EBC? I know this is the ideal place for engines NOT running EBC but when you are running EBC is it just ACCEPTABLE to run the EBC signal from the turbo outlet on the front of the housing or is it PREFERRABLE?

Currently my EBC signal is sourced before the throttle plate as is shown above, however with my new charge pipes I was going to just run the EBC signal from the housing.

What is the story? Preferred vs acceptable?

In reference to the above image with the green box showing the ideal EBC source is this still correct for EBC? I know this is the ideal place for engines NOT running EBC but when you are running EBC is it just ACCEPTABLE to run the EBC signal from the turbo outlet on the front of the housing or is it PREFERRABLE?

Currently my EBC signal is sourced before the throttle plate as is shown above, however with my new charge pipes I was going to just run the EBC signal from the housing.

What is the story? Preferred vs acceptable?

#112

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

This was discussed in another thread. Lots of oppinions.

I remain convinced that for EBC, go housing, solenoid, waste gate. Simplest routing and fastest response. Signal to ECU, naturally, remains line from the manifold.

I remain convinced that for EBC, go housing, solenoid, waste gate. Simplest routing and fastest response. Signal to ECU, naturally, remains line from the manifold.

#113

OP, see link - JoePerez - boost sag? no you dont need ebc

And I quote, "Hey, I want you to do whatever it takes to maintain a constant pressure at point B in the system, and to hell with what's going on over at the compressor."

Point being, EBC or not... It should not have to be used to band-aid low boost response. As "B" being a prime location, the turbo will have the quickest spool up to the given pressure (say 6psi @ wastegate). And EBC is only a controller to increase that boost level. (Same low end response, higher psi output till it lets off and cracks open the wastegate)

And I quote, "Hey, I want you to do whatever it takes to maintain a constant pressure at point B in the system, and to hell with what's going on over at the compressor."

Point being, EBC or not... It should not have to be used to band-aid low boost response. As "B" being a prime location, the turbo will have the quickest spool up to the given pressure (say 6psi @ wastegate). And EBC is only a controller to increase that boost level. (Same low end response, higher psi output till it lets off and cracks open the wastegate)

#114

I will re-read the thread but nowhere have I seen anything that mentions EBC.

I will agree that position B is the correct location for manual boost control OR for straight wastegate. However with EBC you are getting your "control" from the ecu which sees the pressure in the manifold and bases it's corrections on that. Pressure in the charge pipes or the compressor outlet will always be higher than straight wastegate pressure by the time the EBC is opening to start modulating wastegate activity.

I am still unconvinced.

I will agree that position B is the correct location for manual boost control OR for straight wastegate. However with EBC you are getting your "control" from the ecu which sees the pressure in the manifold and bases it's corrections on that. Pressure in the charge pipes or the compressor outlet will always be higher than straight wastegate pressure by the time the EBC is opening to start modulating wastegate activity.

I am still unconvinced.

#115

Vlad, others,

In reference to the above image with the green box showing the ideal EBC source is this still correct for EBC? I know this is the ideal place for engines NOT running EBC but when you are running EBC is it just ACCEPTABLE to run the EBC signal from the turbo outlet on the front of the housing or is it PREFERRABLE?

Currently my EBC signal is sourced before the throttle plate as is shown above, however with my new charge pipes I was going to just run the EBC signal from the housing.

What is the story? Preferred vs acceptable?

In reference to the above image with the green box showing the ideal EBC source is this still correct for EBC? I know this is the ideal place for engines NOT running EBC but when you are running EBC is it just ACCEPTABLE to run the EBC signal from the turbo outlet on the front of the housing or is it PREFERRABLE?

Currently my EBC signal is sourced before the throttle plate as is shown above, however with my new charge pipes I was going to just run the EBC signal from the housing.

What is the story? Preferred vs acceptable?

Lets say you have no EBC, and a 6psi wastegate.

When you source the wastegate to the compressor housing, you're only seeing 6psi at the compressor housing. And over in front of the TB, it actually could be 4-5psi due to loss. As explained in Joe's thread, at a higher volume it becomes increasingly difficult to "See" 6psi on your boost gauge (Because it literally isn't there, the turbo is letting off early bc it already sees the 6psi at the compressor housing).

When you source before the TB to the wastegate, the turbo will spin up freely until it gets the 6psi and hold steady. This is compensating for any pressure loss inside your FMIC & pipes. Your boost readout will be closer to what the motor is actually getting.

Now, take the same layout. Program your EBC to do NOTHING. You're still at 6psi before the TB.

Program your EBC to hold (Past 6psi), taper off/maintain (@ 12psi). You now have the same result as before, just at a higher pressure. (still no care about what psi the compressor housing has, it could be at 15psi... but who cares, you're tuned for 12psi which the motor & driver see)

Increase boost as needed.

Which reminds me, OP your boost may spike past your normal 9psi or w/e simply due to how your EBC is tuned. I'd try running wastegate only before trying the new EBC source before the TB.

I will re-read the thread but nowhere have I seen anything that mentions EBC.

I will agree that position B is the correct location for manual boost control OR for straight wastegate. However with EBC you are getting your "control" from the ecu which sees the pressure in the manifold and bases it's corrections on that. Pressure in the charge pipes or the compressor outlet will always be higher than straight wastegate pressure by the time the EBC is opening to start modulating wastegate activity.

I am still unconvinced.

I will agree that position B is the correct location for manual boost control OR for straight wastegate. However with EBC you are getting your "control" from the ecu which sees the pressure in the manifold and bases it's corrections on that. Pressure in the charge pipes or the compressor outlet will always be higher than straight wastegate pressure by the time the EBC is opening to start modulating wastegate activity.

I am still unconvinced.

And while your last sentence is true, I feel like that is a bandaid method or may be more difficult to tune. Logically that just tells me your final psi at the TB becomes a variable that you're trying to control/compensate with the EBC. The EBC would be tuned for "that car's" setup. If you lets say install a new bigger FMIC, you potentially could have pressure loss and you're stuck having to retune the EBC because you're not meeting your said #psi anymore. If my EBC is tuned off the "B" reference point and I buy a new larger FMIC... I still don't need to care about what the turbo is doing at the compressor housing because it is compensating for B to reach 12psi. Its just now 12psi with a much larger FMIC, no further EBC tuning required.

Last edited by Girz0r; 10-14-2014 at 03:45 PM.

#117

I'm not reading all that crap. Too lazy. for EBC source doesn't matter much cause you can eliminate "sag" with the settings.

I am still clueless on what OP is doing or how he managed to not only complicate the easiest thing known to mankind, but also confuse half the forum that is attempting to help him. I'm bowing out cause the thread is getting too stupid.

Blaen, I have no idea what the crap your'e talking about with the "tune for decel" crap. No one "tunes" the bov for decel, stop overcomplicating this crap just like OP.

OP,

Source from a vacuum fitting on the mani. Stop running tentacle raep lines all over the bay that are all tee'd off each other. Stop being ridiculously stupid and complicating the simplest thing known to mankind.

-if vacuum source is not crap

-if lines are not 4 miles long and tee;ing off each other

-if regular 5-15psi spring is installed

The bov should work just fine. Period.

Please stop posting when you're busy and distracted and re-visit this thread when you can actually not have ADD, and do basic troubleshooting. I bet you $5 that when you find the issue, it will be one of those "omg I'm so stupid" situations.

I am still clueless on what OP is doing or how he managed to not only complicate the easiest thing known to mankind, but also confuse half the forum that is attempting to help him. I'm bowing out cause the thread is getting too stupid.

Blaen, I have no idea what the crap your'e talking about with the "tune for decel" crap. No one "tunes" the bov for decel, stop overcomplicating this crap just like OP.

OP,

Source from a vacuum fitting on the mani. Stop running tentacle raep lines all over the bay that are all tee'd off each other. Stop being ridiculously stupid and complicating the simplest thing known to mankind.

-if vacuum source is not crap

-if lines are not 4 miles long and tee;ing off each other

-if regular 5-15psi spring is installed

The bov should work just fine. Period.

Please stop posting when you're busy and distracted and re-visit this thread when you can actually not have ADD, and do basic troubleshooting. I bet you $5 that when you find the issue, it will be one of those "omg I'm so stupid" situations.

#119

Dang, this really got intense while I was gone.

The EBC works fine, I just haven't tuned it that much yet. Honestly I don't really care about it at this point but I appreciate the input.

I don't have any vacuum fittings around the house so I'll try and pick some up today and make all of you happy when it ends up being something stupid and I look like an idiot. Thats usually how most threads end for me

BTW... did the video ever work? It might answer lots of questions.

http://vid745.photobucket.com/albums...5F589251FE.mp4

The EBC works fine, I just haven't tuned it that much yet. Honestly I don't really care about it at this point but I appreciate the input.

I don't have any vacuum fittings around the house so I'll try and pick some up today and make all of you happy when it ends up being something stupid and I look like an idiot. Thats usually how most threads end for me

BTW... did the video ever work? It might answer lots of questions.

http://vid745.photobucket.com/albums...5F589251FE.mp4

#120

Dang, this really got intense while I was gone.

The EBC works fine, I just haven't tuned it that much yet. Honestly I don't really care about it at this point but I appreciate the input.

I don't have any vacuum fittings around the house so I'll try and pick some up today and make all of you happy when it ends up being something stupid and I look like an idiot. Thats usually how most threads end for me

BTW... did the video ever work? It might answer lots of questions.

http://vid745.photobucket.com/albums...5F589251FE.mp4

The EBC works fine, I just haven't tuned it that much yet. Honestly I don't really care about it at this point but I appreciate the input.

I don't have any vacuum fittings around the house so I'll try and pick some up today and make all of you happy when it ends up being something stupid and I look like an idiot. Thats usually how most threads end for me

BTW... did the video ever work? It might answer lots of questions.

http://vid745.photobucket.com/albums...5F589251FE.mp4

Please just go outside, take a picture of your engine bay, and post the picture of how you have your BOV hooked up. Something's wrong with how you have it hooked up if it operates how you say.

@Vlad: Sure, you can do it that way, if you want to potentially take in unmetered air. I would just tune for idle if I had a stock or junkyard engine, but with a TSE engine, I'm not taking any chances. For a BOV like the Forge, all the spring's real job is to keep it shut during vacuum - although Forge may label their weakest spring as a "5-15psi spring", even the weakest spring should be enough to keep the BOV shut under boost in any situation Miata owners run into. Of course, assuming the BOV is properly hooked up, which I seriously doubt it is if it works as the OP says.

TL;DR: Stronger spring = keeps it shut under vacuum easier, opens under boost harder. Find weakest spring that keeps it shut at desired vacuum, done.