Fed up with loose studs, help me decide on new manifold/turbo

#1

So, I've got my turbo loose for the 500th time now. BEGI log manifold, GT2560R, time-serts in the manifold threads, your inco studs, rebond, stage8, the works.

Couple of sessions and the lower stud backs out. Basically I thing there is not enough beef in the manifold. Especially after all the harassment it has seen.

A new log from BEGI would be the drop in cure, but close to $500 doesn't make it a no brainer. Still the GT2560 and a log and studs.

I'm kinde done with this kit now. Tempted to go for the AbsurdFlow kit that is on sale now, but the GT30xx is not for me. The v-bands are win.

The new EFRs sound like heaven, but the TSE kit doesn't ship yet and kinda curious about using studs. Proper bracing will be critical.

So, long story short; what would _you_ do and what options did I miss other than the BEGI v-band kit?

Couple of sessions and the lower stud backs out. Basically I thing there is not enough beef in the manifold. Especially after all the harassment it has seen.

A new log from BEGI would be the drop in cure, but close to $500 doesn't make it a no brainer. Still the GT2560 and a log and studs.

I'm kinde done with this kit now. Tempted to go for the AbsurdFlow kit that is on sale now, but the GT30xx is not for me. The v-bands are win.

The new EFRs sound like heaven, but the TSE kit doesn't ship yet and kinda curious about using studs. Proper bracing will be critical.

So, long story short; what would _you_ do and what options did I miss other than the BEGI v-band kit?

#10

Elite Member

iTrader: (14)

Join Date: Sep 2009

Location: Birmingham, AL

Posts: 2,101

Total Cats: 180

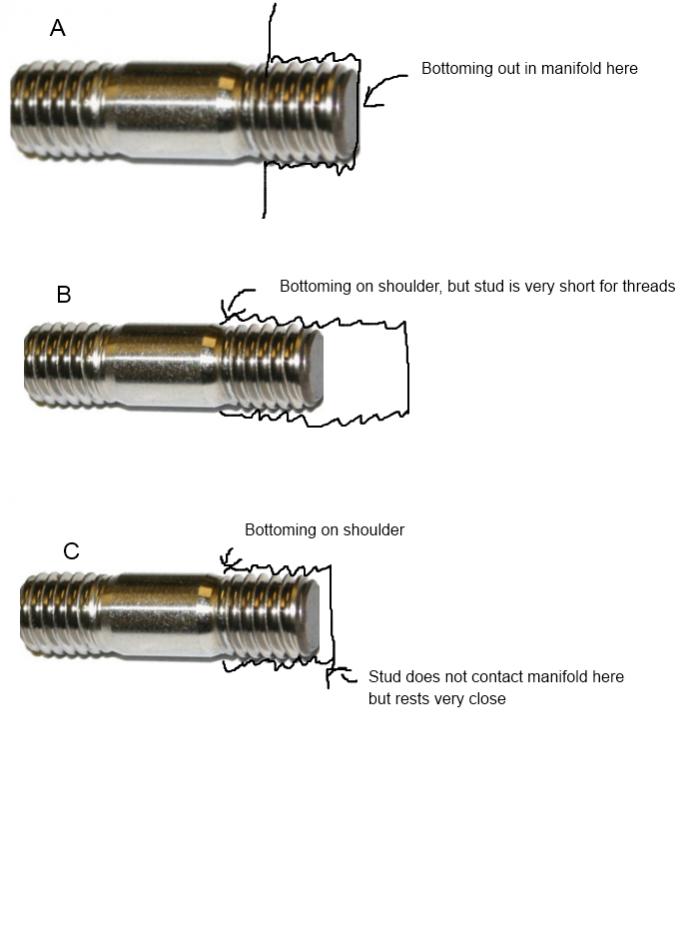

Mounting depth 14mm? I had the TSE Inco kit back out too, but found it was due to lack of mounting depth (even with resbond). Drilled, tapped, and time-serted manifold for proper stud depth and never had an issue after. Were you able to thread the stud in all the way down to the shank? Here's where my fail started... notice stud shank/collor not threaded to base of manifold

Last edited by GeneSplicer; 01-08-2013 at 08:57 AM.

#12

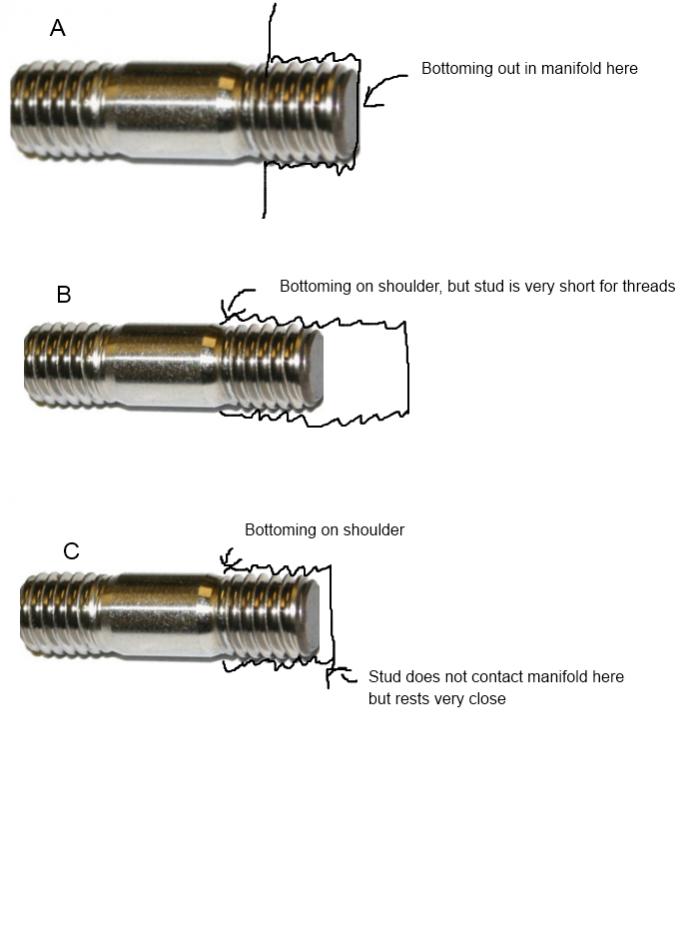

Is it doing something like A where the shoulder doesn't bottom,

B where the shoulder bottoms but the stud is too short,

or are you in situation C where both the stud & manifold just don't have enough threads?

I think GeneSplicer on the right track with his suggestion.

A should be easy to fix, just shorten the stud a little. B you'd need longer studs to engage more threads. C I dunno, I've never really heard of it being a problem unless you're using a super esoteric stud/manifold combination.

B where the shoulder bottoms but the stud is too short,

or are you in situation C where both the stud & manifold just don't have enough threads?

I think GeneSplicer on the right track with his suggestion.

A should be easy to fix, just shorten the stud a little. B you'd need longer studs to engage more threads. C I dunno, I've never really heard of it being a problem unless you're using a super esoteric stud/manifold combination.

#14

It seems like a manual way to get more threads in your manifold without having to buy a new one. No idea if this would work, but hey, it's an idea.

#16

With locking hardware on both sides and resbond, the studs would have to somehow loosen themselves from the nuts on the top and bottom and the manifold. This is all speculation, there's probably not enough room on the back side of the manifold for nuts anyways (maybe half-size nuts?).

#17

I think just on the nuts for the top side of the studs. If they poke through enough on the back end I was thinking maybe he could fit them on there too.

With locking hardware on both sides and resbond, the studs would have to somehow loosen themselves from the nuts on the top and bottom and the manifold. This is all speculation, there's probably not enough room on the back side of the manifold for nuts anyways (maybe half-size nuts?).

With locking hardware on both sides and resbond, the studs would have to somehow loosen themselves from the nuts on the top and bottom and the manifold. This is all speculation, there's probably not enough room on the back side of the manifold for nuts anyways (maybe half-size nuts?).

#18

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

We already have a thread for this.

https://www.miataturbo.net/prefabbed...warning-35874/

Start posting there or I'm going to start banning you troglodyte, mouth-breathing neckbeards.

https://www.miataturbo.net/prefabbed...warning-35874/

Start posting there or I'm going to start banning you troglodyte, mouth-breathing neckbeards.

#19

We already have a thread for this.

https://www.miataturbo.net/prefabbed...warning-35874/

Start posting there or I'm going to start banning you troglodyte, mouth-breathing neckbeards.

https://www.miataturbo.net/prefabbed...warning-35874/

Start posting there or I'm going to start banning you troglodyte, mouth-breathing neckbeards.

So, one stud failed - well, the time-sert failed and that allowed the stud to move out. The other three are fine and were still tights. I'm going to remove the time-sert and insert a new one, reseat the studs, drill through manifold and studs and insert dowel pins to lock them in place.

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-26-2018 11:00 PM