Spring Fix For Tial BOV

#1

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,293

Total Cats: 475

I wrote this for HMT, but I know a few of yall run a Tial BOV and have spring problems with it. So this might help someone here.

Ok, here's everything you need to know about springs. Note: Some of these numbers are estimates so all the calculations are rough, not exact. Also some are arbitrary guesses and work because the change in the number is what matters, not the actual numbers. (IE- 9-7=2 or 6-4=2, still a difference of 2)

Background: Springs push and pull. A spring's stiffness, k, is measured in mass/unit length. So say a spring has a spring constant of k=60 lbs/in. That spring will require 60 lbs to compress (or stretch) it an inch. If you want to compress it 2", 120 lbs will be needed. The force, F, a spring applies is: F=-k*x where x is you much you compress it. The more you compress it, the more it pushes. This relationship is linear.

Natural length- how long the spring is with no forces acting on it. It's unstretched, uncompressed length.

Coil bind length- The length of the spring when you compress it until the coils finally hit each other.

When building a spring, there are several things that contribute to how stiff it is. How wide the spring is, how many coils it has, the diameter of the wire used to construct the spring, the alloy of the steel used, etc.

Now my BOV's spring was too stiff. Thing didn't want to open and I was getting compressor surge. So I needed a softer spring. Well, reading up everybody either buys a new one for $$$ or cuts their old one. I had a feeling cutting it wasn't the "right" way to do it. It's not.

To make a spring softer, you need to either:

Increase the number of coils

Increase the width of the spring (how big around it measures, outer diameter)

Decrease the diameter of the wire.

Of course if you buy a softer spring, it will be the same length and width as your original, but will made of a smaller diameter wire.

Cutting the spring actually makes the spring stiffer, not softer. The opposite of what you want. Making it shorter reduces the number of coils you have. Only reason it "helps" is because it doesn't get compressed as much as before as it's now shorter.

For example, my stock spring in my Tial Style BOV measures:

4.108" long

1.510" O.D.

Wire diameter of 0.140"

8 coils

When you install the spring, it gets compressed to about 2.00" long. When the valve opens, it gets compressed to about 1.50" long. Let's ASSume that the k value for my stock spring is 42 lbs/in. This is only an approximation, but a few different derivations based on other info suggest this number is correct.

So, stock spring is pushing on the piston with a force of F=-k*x. Our k is 42 and our x is 4.108-2.00"= ~2.11". F= (42) (2.11) = ~ 89 pounds.

My motor pulls about -10.6 PSI at idle. I guestimated (read, forgot to measure) the area of the piston as 8 in^2. So when I'm at idle, the force from the diaphragm is (-10.6) (eight) = ~85 lbs.

The net force acting on the piston at idle is 89-85= 4lbs. So it's staying shut with 4lbs to spare. Those 4lbs are the problem. Ideally, the piston would be on the verge of opening at idle such that the slightest pressure difference when I shift will cause it to open.

Let's backpedal and figure out what value k we need. Ideally the net force acting on the diaphragm at idle will be close to zero, and not negative (if it's negative, the BOV begins to open and leak). Rearranging our equation and solving for k I get k_ideal = 40.2. This should be the ideal k as to keep the piston shut, but neutral at idle.

So time to make your spring softer. How? I ground on the coils. This effectively reduces the diameter of the coils, which makes the spring softer. Did this with a right angle grinder. It's easy, just hold the spring and grind a little flat on the spring. Do a spot, then turn it a 1/4 turn and do that spot, wash, rinse, repeat. I had to wet the spring a few times as it gets too hot to hold.

So how much do you grind off? Here's how I did it. I measured the OD of the wire to be 0.140". Well, I ground a bit on both sides of the coil. Measured the diameter between the flats in several places and the average was 0.120". However, that's only on two sides of the wire. I would say the effective diameter is 0.130" (because it measures .120 between the flat sides, and .140 between the round sides). So that would make for a (130/140) = 7.2% softer spring. Or if my original k was 42, my new k would be 39. That's lower than k_ideal though. And sure enough, damn valve leaks at idle now. At least the math agrees with my real world results. :l Should have only ground one side of the spring apparently. Actually, doing the math I should have only removed .012", not .020". However it barely leaks and I should be able to shim it to stop leaking so no worries. But had I done this math before, I would have got it right or closer the first time.

CLIFFS:

Spring too stiff? Grind on the coils to make it softer. Don't cut the spring, that's makes it worse.

Pictures for you visual folks:

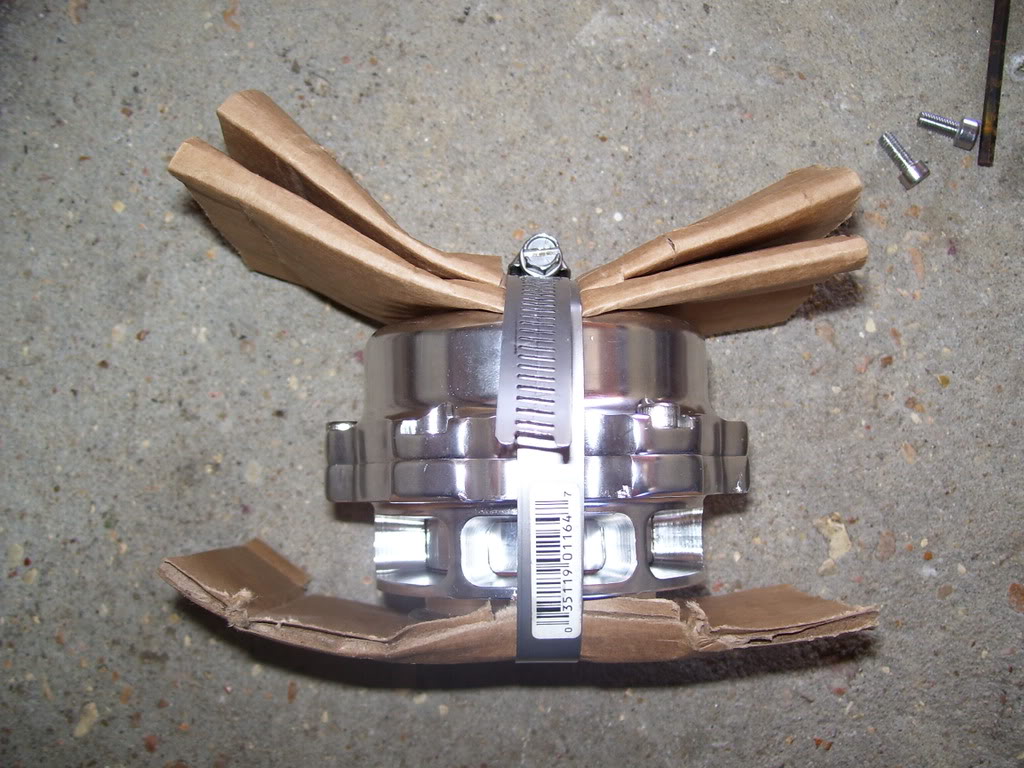

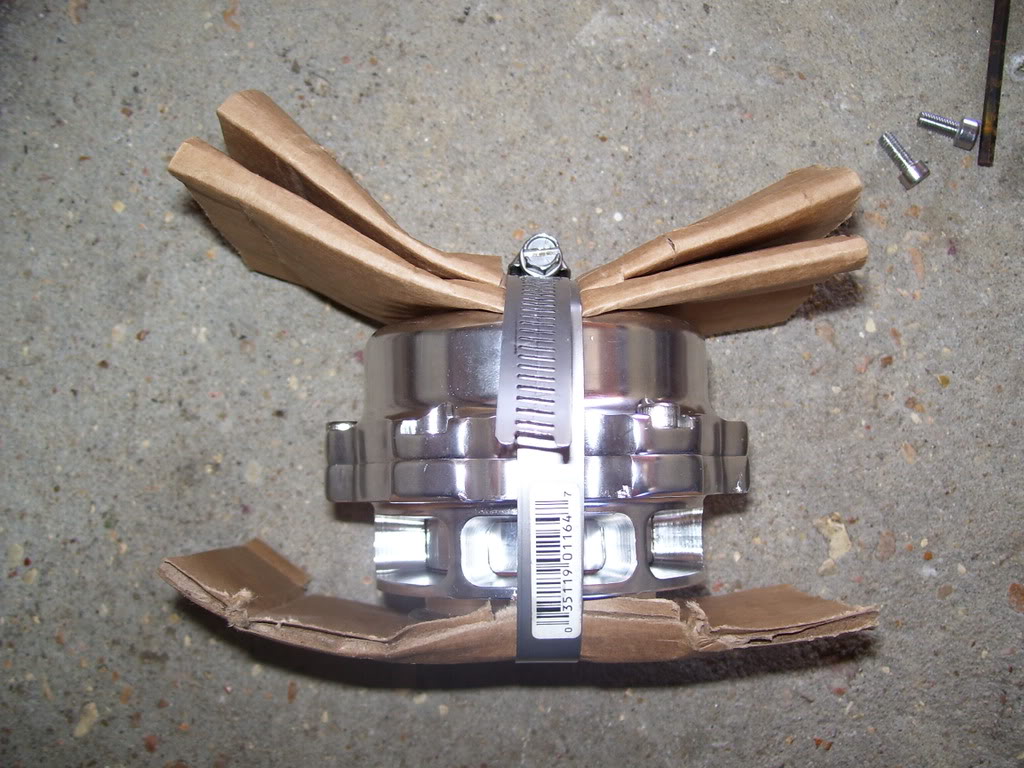

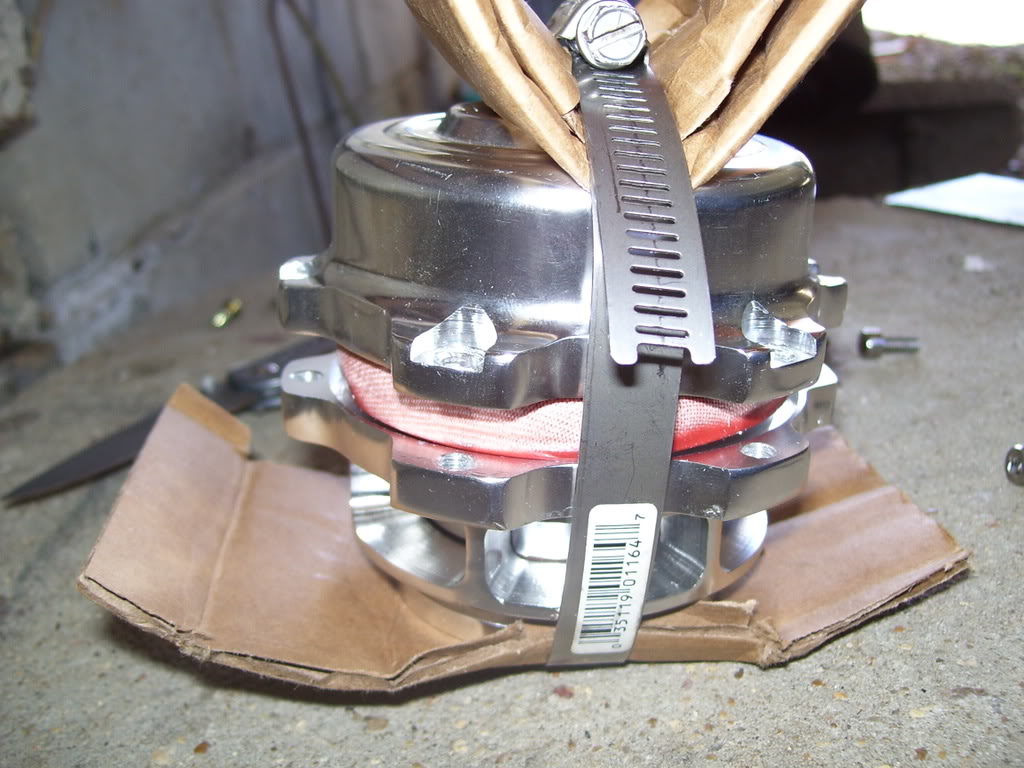

I didn't have a vise, so I found a big hose clamp and some cardboard...

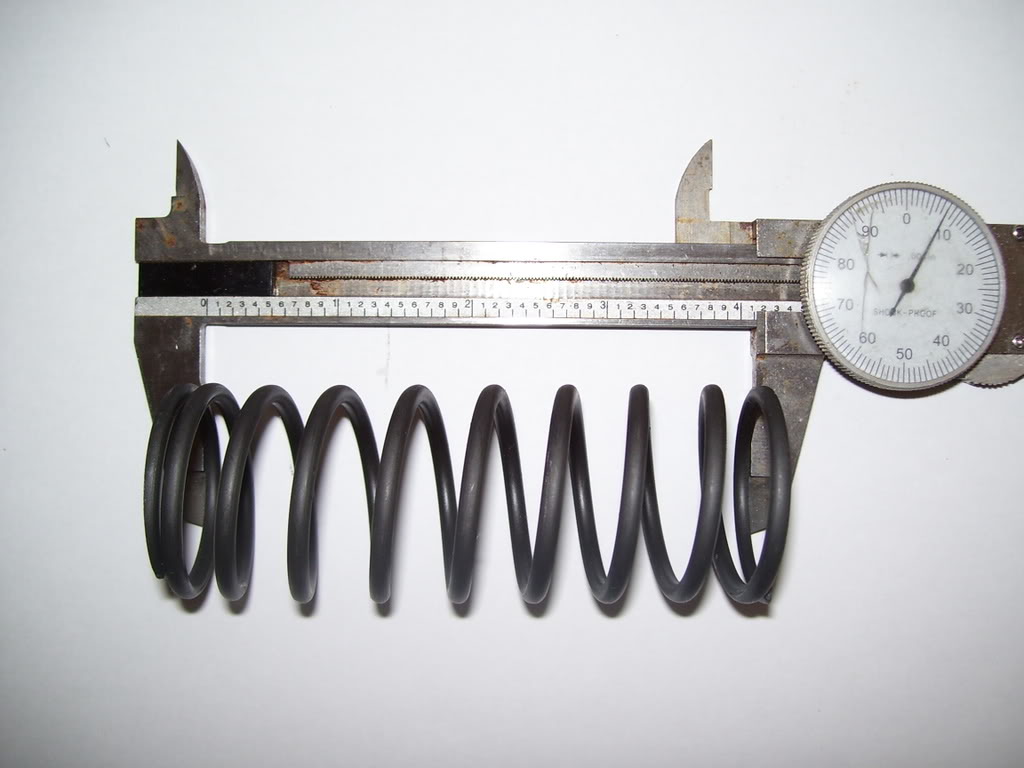

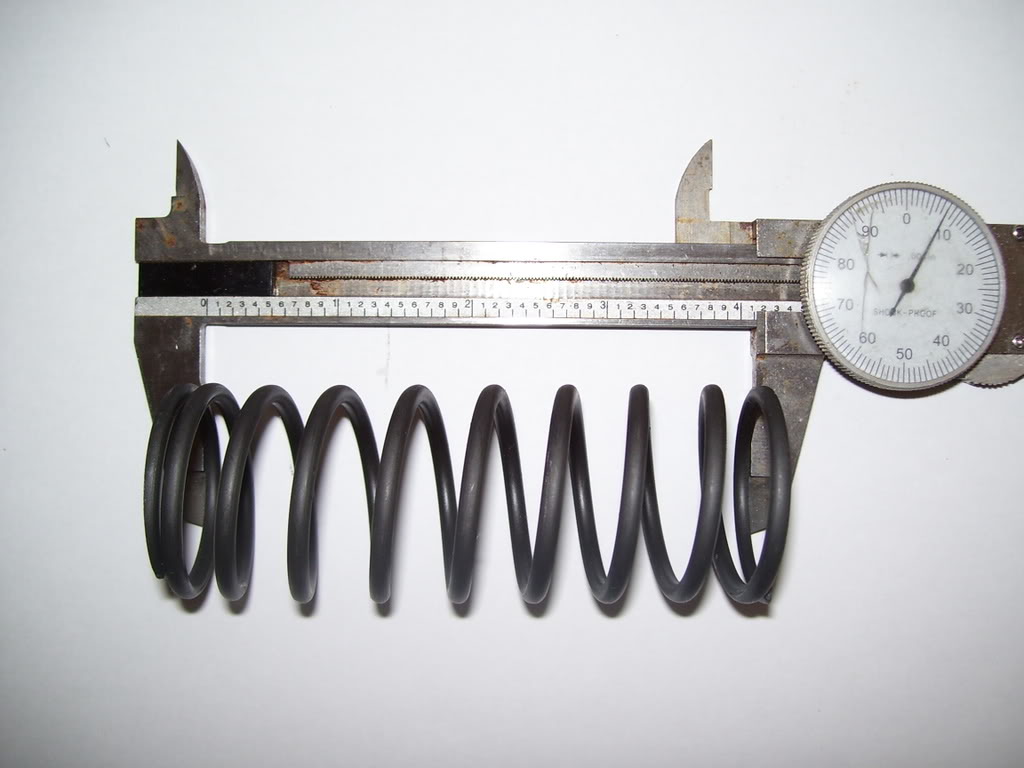

Measured the spring

Ground on that bitch

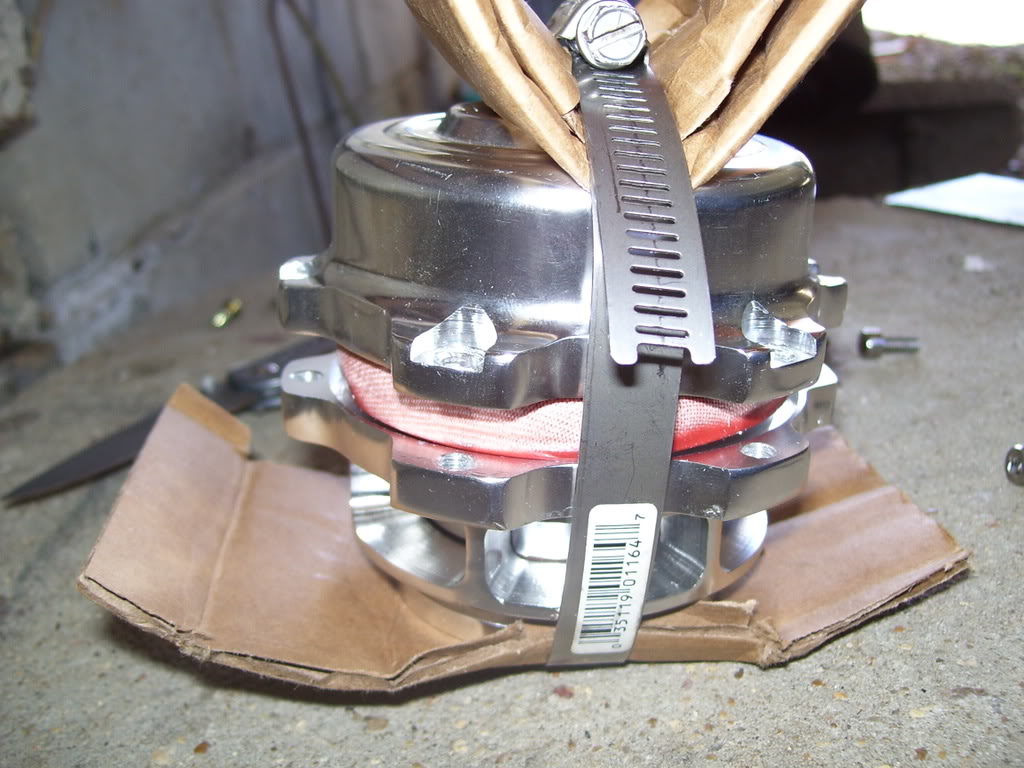

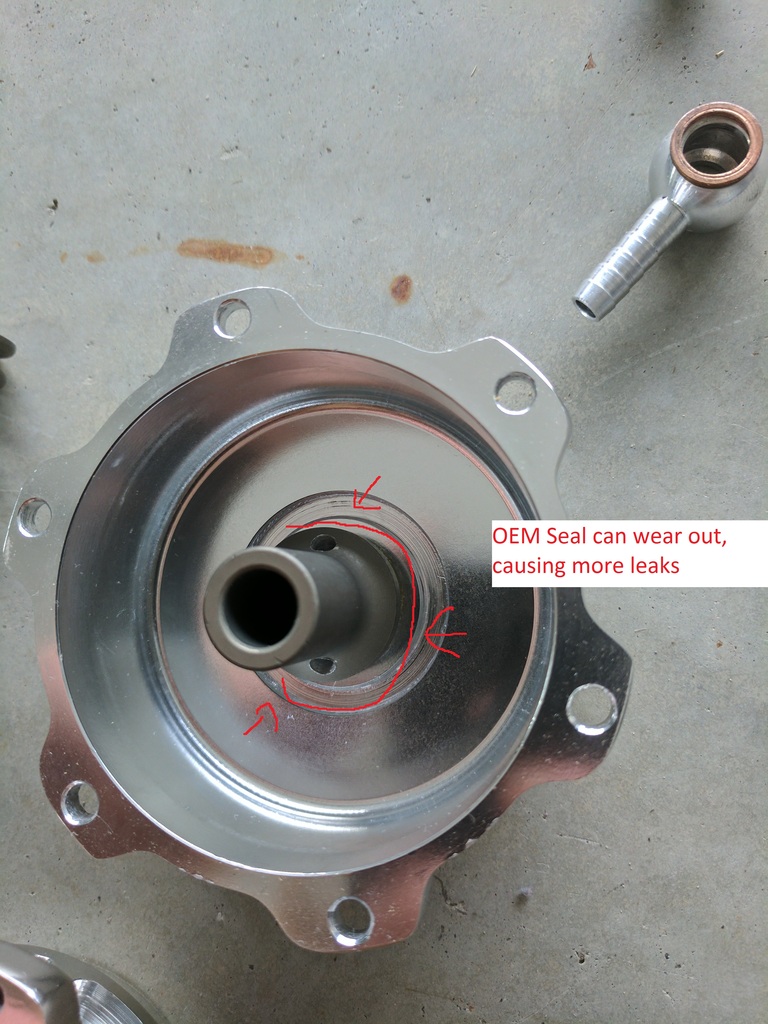

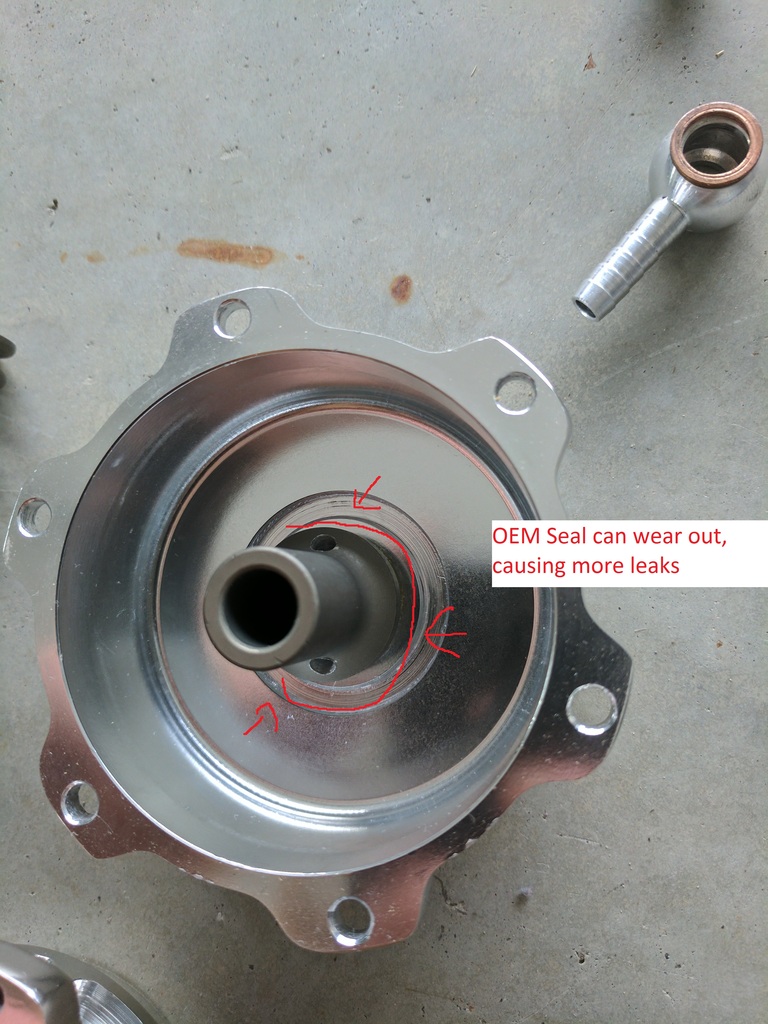

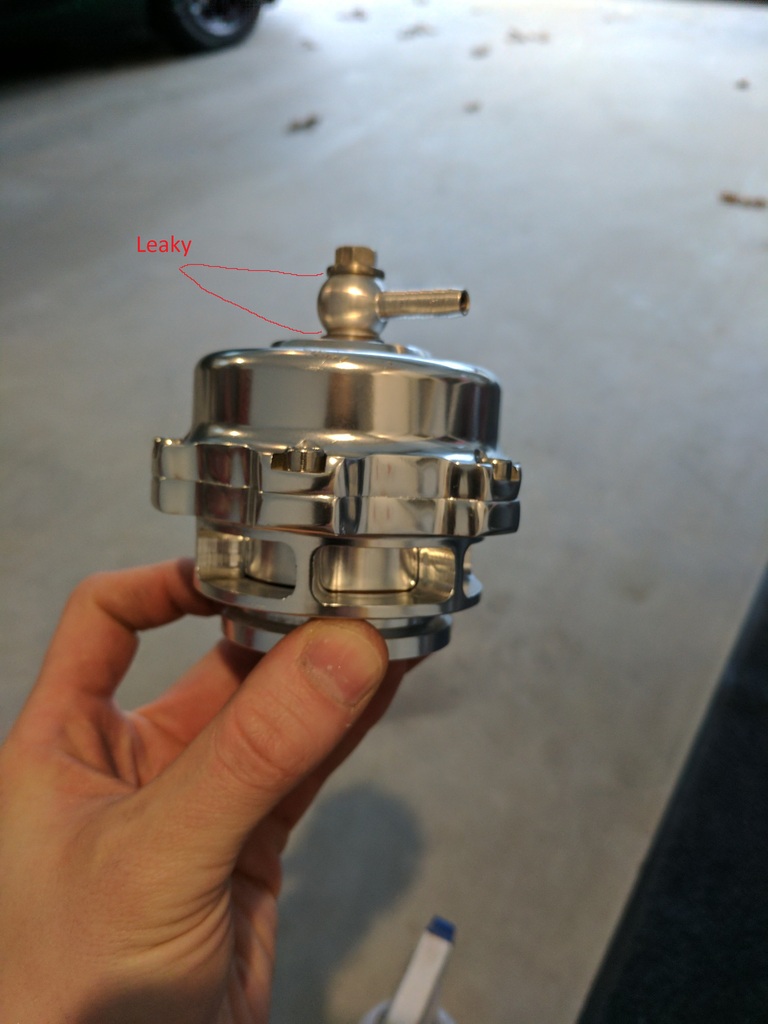

Pics of the BOV apart

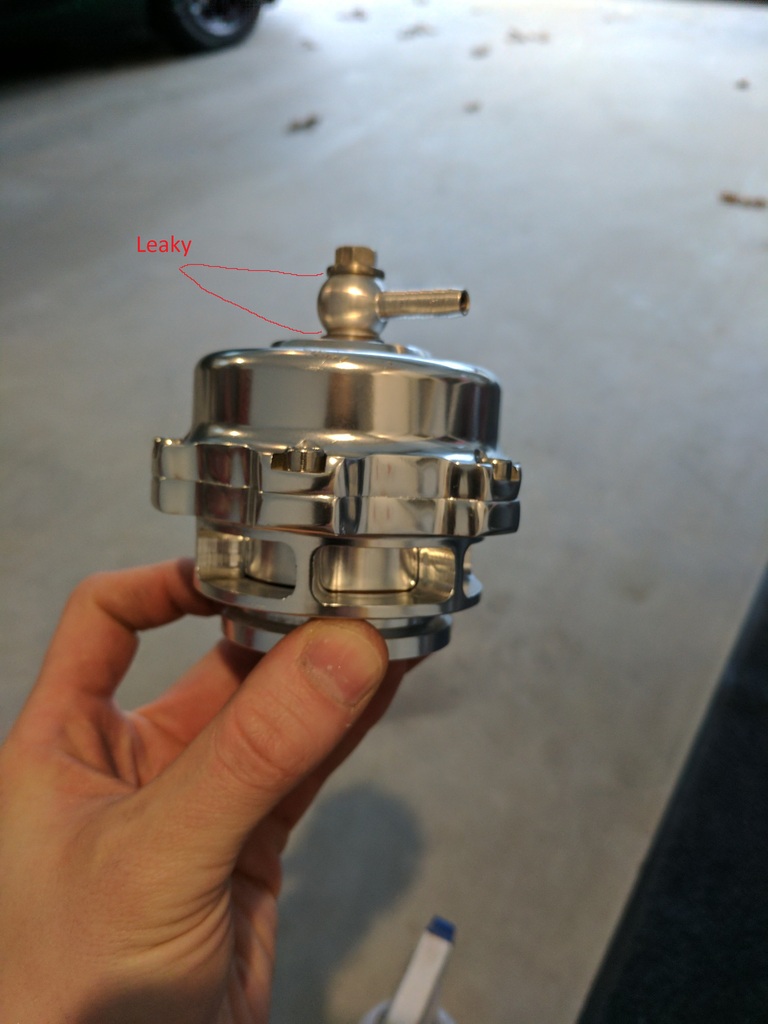

Back together

Marked the relation of the bolt to the banjo fitting. Blowing through it you can tell having it alligned it flows better.

Got it installed and it's a lot better. Blows off when I shift now! Granted it's leaking a bit at idle from me grinding a bit too much off of the spring though. But I should be able to shim it and get it to stop leaking. Hope this helps someone.

Ok, here's everything you need to know about springs. Note: Some of these numbers are estimates so all the calculations are rough, not exact. Also some are arbitrary guesses and work because the change in the number is what matters, not the actual numbers. (IE- 9-7=2 or 6-4=2, still a difference of 2)

Background: Springs push and pull. A spring's stiffness, k, is measured in mass/unit length. So say a spring has a spring constant of k=60 lbs/in. That spring will require 60 lbs to compress (or stretch) it an inch. If you want to compress it 2", 120 lbs will be needed. The force, F, a spring applies is: F=-k*x where x is you much you compress it. The more you compress it, the more it pushes. This relationship is linear.

Natural length- how long the spring is with no forces acting on it. It's unstretched, uncompressed length.

Coil bind length- The length of the spring when you compress it until the coils finally hit each other.

When building a spring, there are several things that contribute to how stiff it is. How wide the spring is, how many coils it has, the diameter of the wire used to construct the spring, the alloy of the steel used, etc.

Now my BOV's spring was too stiff. Thing didn't want to open and I was getting compressor surge. So I needed a softer spring. Well, reading up everybody either buys a new one for $$$ or cuts their old one. I had a feeling cutting it wasn't the "right" way to do it. It's not.

To make a spring softer, you need to either:

Increase the number of coils

Increase the width of the spring (how big around it measures, outer diameter)

Decrease the diameter of the wire.

Of course if you buy a softer spring, it will be the same length and width as your original, but will made of a smaller diameter wire.

Cutting the spring actually makes the spring stiffer, not softer. The opposite of what you want. Making it shorter reduces the number of coils you have. Only reason it "helps" is because it doesn't get compressed as much as before as it's now shorter.

For example, my stock spring in my Tial Style BOV measures:

4.108" long

1.510" O.D.

Wire diameter of 0.140"

8 coils

When you install the spring, it gets compressed to about 2.00" long. When the valve opens, it gets compressed to about 1.50" long. Let's ASSume that the k value for my stock spring is 42 lbs/in. This is only an approximation, but a few different derivations based on other info suggest this number is correct.

So, stock spring is pushing on the piston with a force of F=-k*x. Our k is 42 and our x is 4.108-2.00"= ~2.11". F= (42) (2.11) = ~ 89 pounds.

My motor pulls about -10.6 PSI at idle. I guestimated (read, forgot to measure) the area of the piston as 8 in^2. So when I'm at idle, the force from the diaphragm is (-10.6) (eight) = ~85 lbs.

The net force acting on the piston at idle is 89-85= 4lbs. So it's staying shut with 4lbs to spare. Those 4lbs are the problem. Ideally, the piston would be on the verge of opening at idle such that the slightest pressure difference when I shift will cause it to open.

Let's backpedal and figure out what value k we need. Ideally the net force acting on the diaphragm at idle will be close to zero, and not negative (if it's negative, the BOV begins to open and leak). Rearranging our equation and solving for k I get k_ideal = 40.2. This should be the ideal k as to keep the piston shut, but neutral at idle.

So time to make your spring softer. How? I ground on the coils. This effectively reduces the diameter of the coils, which makes the spring softer. Did this with a right angle grinder. It's easy, just hold the spring and grind a little flat on the spring. Do a spot, then turn it a 1/4 turn and do that spot, wash, rinse, repeat. I had to wet the spring a few times as it gets too hot to hold.

So how much do you grind off? Here's how I did it. I measured the OD of the wire to be 0.140". Well, I ground a bit on both sides of the coil. Measured the diameter between the flats in several places and the average was 0.120". However, that's only on two sides of the wire. I would say the effective diameter is 0.130" (because it measures .120 between the flat sides, and .140 between the round sides). So that would make for a (130/140) = 7.2% softer spring. Or if my original k was 42, my new k would be 39. That's lower than k_ideal though. And sure enough, damn valve leaks at idle now. At least the math agrees with my real world results. :l Should have only ground one side of the spring apparently. Actually, doing the math I should have only removed .012", not .020". However it barely leaks and I should be able to shim it to stop leaking so no worries. But had I done this math before, I would have got it right or closer the first time.

CLIFFS:

Spring too stiff? Grind on the coils to make it softer. Don't cut the spring, that's makes it worse.

Pictures for you visual folks:

I didn't have a vise, so I found a big hose clamp and some cardboard...

Measured the spring

Ground on that bitch

Pics of the BOV apart

Back together

Marked the relation of the bolt to the banjo fitting. Blowing through it you can tell having it alligned it flows better.

Got it installed and it's a lot better. Blows off when I shift now! Granted it's leaking a bit at idle from me grinding a bit too much off of the spring though. But I should be able to shim it and get it to stop leaking. Hope this helps someone.

#3

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,293

Total Cats: 475

LOL this is an old post of mine. I had completely forgotten about this.

FWIW, that BOV is still on my car, and still works great. It has not been taken apart since it was assembled for the spring mod in 2009.

FWIW, that BOV is still on my car, and still works great. It has not been taken apart since it was assembled for the spring mod in 2009.

#4

Senior Member

iTrader: (1)

Join Date: Apr 2011

Location: Jonesboro Arkansas

Posts: 553

Total Cats: 25

I was wondering why no one commented on this, looks like you put some thought into it. I had an 7psi spring and moved to the 6psi spring and I still have a very slight delay in release. So I'll try this out. I can't believe so many folks have issues with this Tial BOV.

#5

Senior Member

iTrader: (1)

Join Date: Apr 2011

Location: Jonesboro Arkansas

Posts: 553

Total Cats: 25

I guess I'm going to contribute to this is case anyone finds this thread like I did.

So my Tial 50mm BOV was delayed in release. I purchased a weaker spring from Tial and got a better response. I still had a 1 sec delay in response. Which caused some compressor surge. If I had a chia turbo I'd live with a tiny bit of surge. But since I'm running a GT3076R at 18psi, I thought this could cause some headaches.

I pulled the thing apart to lessen the spring like patsmx5, before I got too far along, I noticed the factory seal was broken. So I added some air to it from my compressor and did the hole soapy water thing. Come to find out this thing leaks like crazy where air comes in. So maybe folks, try this first. Then if needed go after the spring. This was a pretty major leak, I could see you losing a few psi from the seals leaking.

I used some Teflon tape to seal the threads and then used new washers and a hint of black rtv to seal the bad boy up. I'll report back if this helped.

So my Tial 50mm BOV was delayed in release. I purchased a weaker spring from Tial and got a better response. I still had a 1 sec delay in response. Which caused some compressor surge. If I had a chia turbo I'd live with a tiny bit of surge. But since I'm running a GT3076R at 18psi, I thought this could cause some headaches.

I pulled the thing apart to lessen the spring like patsmx5, before I got too far along, I noticed the factory seal was broken. So I added some air to it from my compressor and did the hole soapy water thing. Come to find out this thing leaks like crazy where air comes in. So maybe folks, try this first. Then if needed go after the spring. This was a pretty major leak, I could see you losing a few psi from the seals leaking.

I used some Teflon tape to seal the threads and then used new washers and a hint of black rtv to seal the bad boy up. I'll report back if this helped.

#6

I wrote this for HMT, but I know a few of yall run a Tial BOV and have spring problems with it. So this might help someone here.

Ok, here's everything you need to know about springs. Note: Some of these numbers are estimates so all the calculations are rough, not exact. Also some are arbitrary guesses and work because the change in the number is what matters, not the actual numbers. (IE- 9-7=2 or 6-4=2, still a difference of 2)

Background: Springs push and pull. A spring's stiffness, k, is measured in mass/unit length. So say a spring has a spring constant of k=60 lbs/in. That spring will require 60 lbs to compress (or stretch) it an inch. If you want to compress it 2", 120 lbs will be needed. The force, F, a spring applies is: F=-k*x where x is you much you compress it. The more you compress it, the more it pushes. This relationship is linear.

Natural length- how long the spring is with no forces acting on it. It's unstretched, uncompressed length.

Coil bind length- The length of the spring when you compress it until the coils finally hit each other.

When building a spring, there are several things that contribute to how stiff it is. How wide the spring is, how many coils it has, the diameter of the wire used to construct the spring, the alloy of the steel used, etc.

Now my BOV's spring was too stiff. Thing didn't want to open and I was getting compressor surge. So I needed a softer spring. Well, reading up everybody either buys a new one for $$$ or cuts their old one. I had a feeling cutting it wasn't the "right" way to do it. It's not.

To make a spring softer, you need to either:

Increase the number of coils

Increase the width of the spring (how big around it measures, outer diameter)

Decrease the diameter of the wire.

Of course if you buy a softer spring, it will be the same length and width as your original, but will made of a smaller diameter wire.

Cutting the spring actually makes the spring stiffer, not softer. The opposite of what you want. Making it shorter reduces the number of coils you have. Only reason it "helps" is because it doesn't get compressed as much as before as it's now shorter.

For example, my stock spring in my Tial Style BOV measures:

4.108" long

1.510" O.D.

Wire diameter of 0.140"

8 coils

When you install the spring, it gets compressed to about 2.00" long. When the valve opens, it gets compressed to about 1.50" long. Let's ASSume that the k value for my stock spring is 42 lbs/in. This is only an approximation, but a few different derivations based on other info suggest this number is correct.

So, stock spring is pushing on the piston with a force of F=-k*x. Our k is 42 and our x is 4.108-2.00"= ~2.11". F= (42) (2.11) = ~ 89 pounds.

My motor pulls about -10.6 PSI at idle. I guestimated (read, forgot to measure) the area of the piston as 8 in^2. So when I'm at idle, the force from the diaphragm is (-10.6) (eight) = ~85 lbs.

The net force acting on the piston at idle is 89-85= 4lbs. So it's staying shut with 4lbs to spare. Those 4lbs are the problem. Ideally, the piston would be on the verge of opening at idle such that the slightest pressure difference when I shift will cause it to open.

Let's backpedal and figure out what value k we need. Ideally the net force acting on the diaphragm at idle will be close to zero, and not negative (if it's negative, the BOV begins to open and leak). Rearranging our equation and solving for k I get k_ideal = 40.2. This should be the ideal k as to keep the piston shut, but neutral at idle.

So time to make your spring softer. How? I ground on the coils. This effectively reduces the diameter of the coils, which makes the spring softer. Did this with a right angle grinder. It's easy, just hold the spring and grind a little flat on the spring. Do a spot, then turn it a 1/4 turn and do that spot, wash, rinse, repeat. I had to wet the spring a few times as it gets too hot to hold.

So how much do you grind off? Here's how I did it. I measured the OD of the wire to be 0.140". Well, I ground a bit on both sides of the coil. Measured the diameter between the flats in several places and the average was 0.120". However, that's only on two sides of the wire. I would say the effective diameter is 0.130" (because it measures .120 between the flat sides, and .140 between the round sides). So that would make for a (130/140) = 7.2% softer spring. Or if my original k was 42, my new k would be 39. That's lower than k_ideal though. And sure enough, damn valve leaks at idle now. At least the math agrees with my real world results. :l Should have only ground one side of the spring apparently. Actually, doing the math I should have only removed .012", not .020". However it barely leaks and I should be able to shim it to stop leaking so no worries. But had I done this math before, I would have got it right or closer the first time.

CLIFFS:

Spring too stiff? Grind on the coils to make it softer. Don't cut the spring, that's makes it worse.

Pictures for you visual folks:

I didn't have a vise, so I found a big hose clamp and some cardboard...

Attachment 208387

Attachment 208388

Measured the spring

Attachment 208389

Ground on that bitch

Attachment 208390

Pics of the BOV apart

Attachment 208391

Attachment 208392

Attachment 208393

Attachment 208394

Attachment 208395

Attachment 208396

Back together

Attachment 208397

Attachment 208398

Marked the relation of the bolt to the banjo fitting. Blowing through it you can tell having it alligned it flows better.

Attachment 208399

Attachment 208400

Got it installed and it's a lot better. Blows off when I shift now! Granted it's leaking a bit at idle from me grinding a bit too much off of the spring though. But I should be able to shim it and get it to stop leaking. Hope this helps someone.

Ok, here's everything you need to know about springs. Note: Some of these numbers are estimates so all the calculations are rough, not exact. Also some are arbitrary guesses and work because the change in the number is what matters, not the actual numbers. (IE- 9-7=2 or 6-4=2, still a difference of 2)

Background: Springs push and pull. A spring's stiffness, k, is measured in mass/unit length. So say a spring has a spring constant of k=60 lbs/in. That spring will require 60 lbs to compress (or stretch) it an inch. If you want to compress it 2", 120 lbs will be needed. The force, F, a spring applies is: F=-k*x where x is you much you compress it. The more you compress it, the more it pushes. This relationship is linear.

Natural length- how long the spring is with no forces acting on it. It's unstretched, uncompressed length.

Coil bind length- The length of the spring when you compress it until the coils finally hit each other.

When building a spring, there are several things that contribute to how stiff it is. How wide the spring is, how many coils it has, the diameter of the wire used to construct the spring, the alloy of the steel used, etc.

Now my BOV's spring was too stiff. Thing didn't want to open and I was getting compressor surge. So I needed a softer spring. Well, reading up everybody either buys a new one for $$$ or cuts their old one. I had a feeling cutting it wasn't the "right" way to do it. It's not.

To make a spring softer, you need to either:

Increase the number of coils

Increase the width of the spring (how big around it measures, outer diameter)

Decrease the diameter of the wire.

Of course if you buy a softer spring, it will be the same length and width as your original, but will made of a smaller diameter wire.

Cutting the spring actually makes the spring stiffer, not softer. The opposite of what you want. Making it shorter reduces the number of coils you have. Only reason it "helps" is because it doesn't get compressed as much as before as it's now shorter.

For example, my stock spring in my Tial Style BOV measures:

4.108" long

1.510" O.D.

Wire diameter of 0.140"

8 coils

When you install the spring, it gets compressed to about 2.00" long. When the valve opens, it gets compressed to about 1.50" long. Let's ASSume that the k value for my stock spring is 42 lbs/in. This is only an approximation, but a few different derivations based on other info suggest this number is correct.

So, stock spring is pushing on the piston with a force of F=-k*x. Our k is 42 and our x is 4.108-2.00"= ~2.11". F= (42) (2.11) = ~ 89 pounds.

My motor pulls about -10.6 PSI at idle. I guestimated (read, forgot to measure) the area of the piston as 8 in^2. So when I'm at idle, the force from the diaphragm is (-10.6) (eight) = ~85 lbs.

The net force acting on the piston at idle is 89-85= 4lbs. So it's staying shut with 4lbs to spare. Those 4lbs are the problem. Ideally, the piston would be on the verge of opening at idle such that the slightest pressure difference when I shift will cause it to open.

Let's backpedal and figure out what value k we need. Ideally the net force acting on the diaphragm at idle will be close to zero, and not negative (if it's negative, the BOV begins to open and leak). Rearranging our equation and solving for k I get k_ideal = 40.2. This should be the ideal k as to keep the piston shut, but neutral at idle.

So time to make your spring softer. How? I ground on the coils. This effectively reduces the diameter of the coils, which makes the spring softer. Did this with a right angle grinder. It's easy, just hold the spring and grind a little flat on the spring. Do a spot, then turn it a 1/4 turn and do that spot, wash, rinse, repeat. I had to wet the spring a few times as it gets too hot to hold.

So how much do you grind off? Here's how I did it. I measured the OD of the wire to be 0.140". Well, I ground a bit on both sides of the coil. Measured the diameter between the flats in several places and the average was 0.120". However, that's only on two sides of the wire. I would say the effective diameter is 0.130" (because it measures .120 between the flat sides, and .140 between the round sides). So that would make for a (130/140) = 7.2% softer spring. Or if my original k was 42, my new k would be 39. That's lower than k_ideal though. And sure enough, damn valve leaks at idle now. At least the math agrees with my real world results. :l Should have only ground one side of the spring apparently. Actually, doing the math I should have only removed .012", not .020". However it barely leaks and I should be able to shim it to stop leaking so no worries. But had I done this math before, I would have got it right or closer the first time.

CLIFFS:

Spring too stiff? Grind on the coils to make it softer. Don't cut the spring, that's makes it worse.

Pictures for you visual folks:

I didn't have a vise, so I found a big hose clamp and some cardboard...

Attachment 208387

Attachment 208388

Measured the spring

Attachment 208389

Ground on that bitch

Attachment 208390

Pics of the BOV apart

Attachment 208391

Attachment 208392

Attachment 208393

Attachment 208394

Attachment 208395

Attachment 208396

Back together

Attachment 208397

Attachment 208398

Marked the relation of the bolt to the banjo fitting. Blowing through it you can tell having it alligned it flows better.

Attachment 208399

Attachment 208400

Got it installed and it's a lot better. Blows off when I shift now! Granted it's leaking a bit at idle from me grinding a bit too much off of the spring though. But I should be able to shim it and get it to stop leaking. Hope this helps someone.

I see the suggested use of a hose clamp for disassembly. How difficult will it be to disassemble and reassemble the BOV without a vice?

thanks for helping a newbie.

#9

It depends. A chu chu chu at low load throttle lifts, like cruising, isn't the end of the world. That noise when you're getting on it can be a problem.

Here the tial spring chart. Just match the vacuum reading on your boost gauge to the chart.

https://www.iraceautosports.com/wp-c...015/04/bov.jpg

the bov can be disabled without a vice as long as you keep pressure on the dome, although I highly recommend using one during reassembly to ensure you don't pinch the diaphragm

Here the tial spring chart. Just match the vacuum reading on your boost gauge to the chart.

https://www.iraceautosports.com/wp-c...015/04/bov.jpg

the bov can be disabled without a vice as long as you keep pressure on the dome, although I highly recommend using one during reassembly to ensure you don't pinch the diaphragm

#10

Thanks for your help. I get the sound when I let off the accelerator to shift while getting up to highway speed. I was advised this was not a problem other than not liking the sound. The car is still in hibernation, but ai will check the boost at idle as soon as our roads are ready for fun driving.

Thread

Thread Starter

Forum

Replies

Last Post

Godless Commie

Suspension, Brakes, Drivetrain

31

09-27-2013 11:44 PM