stock 1.6 oil return port question

#1

So I am currently getting my turbo kit together and I was reading the thread on here with the information regarding everything relating to turbo setups and in the thread.it.mentions that the stock 1.6L motor has an oil return port located by the oil filter. However I am trying to figure out why in the thread it mentions.using this can be a headache in the long run.

Any info on why this is problematic?

I did some research but.no one mentions specifically what the problem is so any help would be great.

Thanks

Colton

Any info on why this is problematic?

I did some research but.no one mentions specifically what the problem is so any help would be great.

Thanks

Colton

#2

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,181

Total Cats: 1,133

It's on the wrong side of the block. And because they're gravity fed, you need to keep it pointed downhill at all times. So you're either wrapping it around the back where you can't see it or in front with all the pulleys or belts.

#5

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,603

Total Cats: 564

Yeah, I ran this oil return location for waay too long. Needless to say my oil pan has been tapped and running correctly for a while now, and I would highly recommend you tap it right away so you don't burn oil.

#7

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

Most commonly, people around here use a 1/2" NPT thread, as adapter fittings are commonly available which will screw into this and then mate with a -10AN for the drain line itself.

#8

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,603

Total Cats: 564

I used this and a 3/8 brass npt barb.

http://www.bellengineering.net/produ...roducts_id=192

Applied JB weld to the threads, threaded it in, applied more jb weld on the outside. Worked like a charm

http://www.bellengineering.net/produ...roducts_id=192

Applied JB weld to the threads, threaded it in, applied more jb weld on the outside. Worked like a charm

#9

I used this and a 3/8 brass npt barb.

BEGi Oil Pan Drill Bit and Tap Set BEGi

Applied JB weld to the threads, threaded it in, applied more jb weld on the outside. Worked like a charm

BEGi Oil Pan Drill Bit and Tap Set BEGi

Applied JB weld to the threads, threaded it in, applied more jb weld on the outside. Worked like a charm

#11

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,181

Total Cats: 1,133

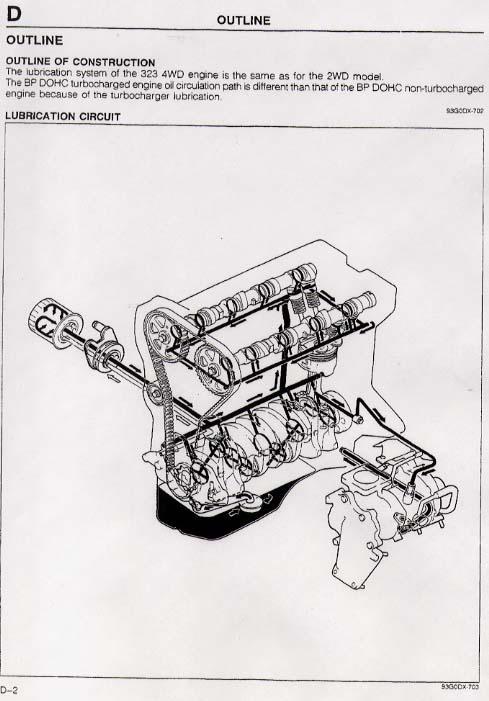

Just to back up Mazda on this one, you have to remember our engine came from a FWD turbo application, so the engine was sideways in the bay, unlike ours. And that capped drain was for a catch can IIRC, not the turbo.

#13

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

#15

Elite Member

iTrader: (13)

Join Date: Dec 2006

Location: Taos, New mexico

Posts: 6,603

Total Cats: 564

If they came turbo they would be much more expensive, not as many would be around, the motors would beaten up and more expensive, more ricers would have miatas, etc.

I kind of like the little known fact that our B6/BP motors are basically boost ready and strong as ****.

#16

While I agree it is a shame, its also a blessing. Keep in mind how cheap these cars are now days, and how cheap replacement motors/chassis are when you wreck them.

If they came turbo they would be much more expensive, not as many would be around, the motors would beaten up and more expensive, more ricers would have miatas, etc.

I kind of like the little known fact that our B6/BP motors are basically boost ready and strong as ****.

If they came turbo they would be much more expensive, not as many would be around, the motors would beaten up and more expensive, more ricers would have miatas, etc.

I kind of like the little known fact that our B6/BP motors are basically boost ready and strong as ****.

Iron block ftw!

Thread

Thread Starter

Forum

Replies

Last Post

Andifer

Miata parts for sale/trade

8

09-23-2015 05:43 PM

itsMikey

Insert BS here

0

09-05-2015 02:56 PM