Who is interested

#21

Senior Member

Thread Starter

iTrader: (2)

Join Date: Feb 2006

Location: Mesa, AZ

Posts: 999

Total Cats: 0

well i am glad to see all of the intrest.. i think i may do stainless and mild, i know there are guys out there like me that are just cheap, and want something that is going to work, and be cheap, but maybe not the best u can get.

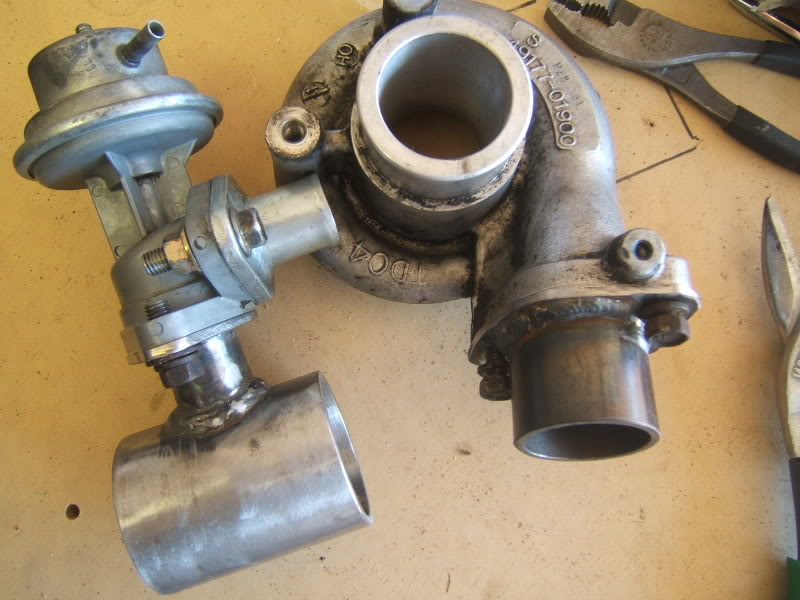

from all of this intrest i think i should be able to justify a batch of 10 or so sets, im going to do 5 dsm, and 5 t3/t4. The dsm desing im working on installing on my car right now, has the turbo hanging down like it does on a stock dsm, this way no clocking is needed, and if u wanted to, you could use the factory dsm o2 housing, i am using the dsm o2 housing insted of a down pipe. id say we will end up going ahead and making down pipes, and manifolds.

Thanx for all of your imput guys!

from all of this intrest i think i should be able to justify a batch of 10 or so sets, im going to do 5 dsm, and 5 t3/t4. The dsm desing im working on installing on my car right now, has the turbo hanging down like it does on a stock dsm, this way no clocking is needed, and if u wanted to, you could use the factory dsm o2 housing, i am using the dsm o2 housing insted of a down pipe. id say we will end up going ahead and making down pipes, and manifolds.

Thanx for all of your imput guys!

#25

Former Vendor

iTrader: (8)

Join Date: Mar 2005

Location: Broken Arrow,Ok

Posts: 1,185

Total Cats: 57

Loki- No matter how you look at it, the process to take the material and create it into a flange cost money. Yes, you could possibly get a large piece of 1/2 plate and the a length of straight tubing needed for $40, but no matter how you look at it, there is cost to create a part from the plate.

-Michael-

-Michael-

#27

Senior Member

Thread Starter

iTrader: (2)

Join Date: Feb 2006

Location: Mesa, AZ

Posts: 999

Total Cats: 0

it hasnt been mocked up on the car yet, but as soon as i do, i will take lots of pics

as far as cost of machining, my dad's normal shop rate is 30 bucks an hour.. so if he makes 10 flanges, the cost of machining shouldnt be to bad

as far as cost of machining, my dad's normal shop rate is 30 bucks an hour.. so if he makes 10 flanges, the cost of machining shouldnt be to bad

#29

Senior Member

iTrader: (1)

Join Date: Mar 2006

Location: Tucson "it's 110º" Arizona

Posts: 1,017

Total Cats: 0

Do you mean to say the D/P will be easier to fab up using the factory o2 housing?

Or are you going to dump it there?

#32

Senior Member

Thread Starter

iTrader: (2)

Join Date: Feb 2006

Location: Mesa, AZ

Posts: 999

Total Cats: 0

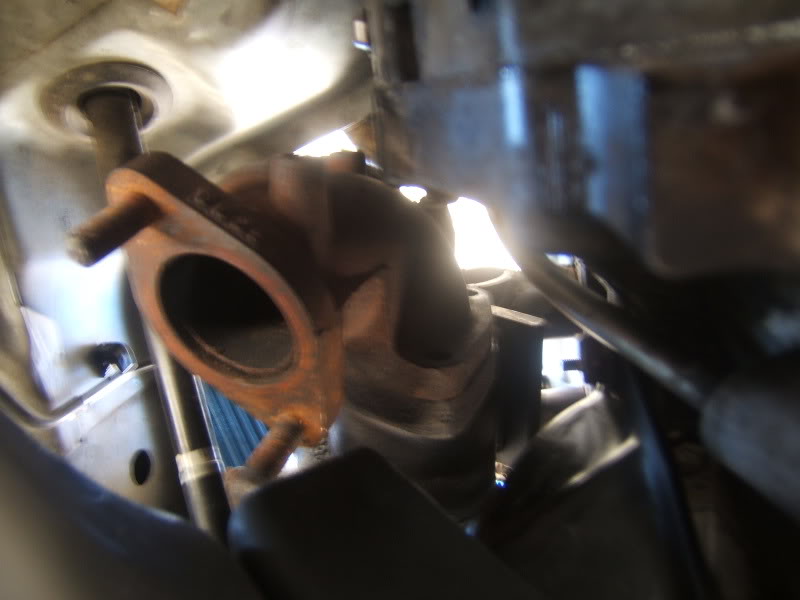

as far as the oil drain goes, it should be able to run down at a 45 degree angle, then a 90 into the oil pan.. as long as you dont have a/c

for the compressor housing to fit, the main coolant feed, and the heater core line that runs under the manifold, will have to be relocated as well.. i know that corky bell makes a part for doing this and its not that costly.

for the compressor housing to fit, the main coolant feed, and the heater core line that runs under the manifold, will have to be relocated as well.. i know that corky bell makes a part for doing this and its not that costly.

#33

Senior Member

Thread Starter

iTrader: (2)

Join Date: Feb 2006

Location: Mesa, AZ

Posts: 999

Total Cats: 0

I made a mount for my 5 dollar recirculating valve from a volvo i think, and a spout for the end of my compressor housing to attatch the intake pipe to.

#37

I personally wouldn't buy a manifold with welds like that. I can make something just as good easily and the only reason I would buy something like that is if I didn't have the time to make my own flanges and get everything all put together. Your designs are fine but if you want to sell a product like that you might want to look into powdercoating/ceramic coating to hide the welds.

Then again if someone is building up a project and just want's to get on the road and you have a cheap manifold/DP combo for sale. I wouldn't give a damn what it looked like or what coating it had on it. Long as you can build a good strong product that won't have structural problems I'm sure you could sell 10 of them. Do look into Tig though, it would increase sales in the end for sure.

Then again if someone is building up a project and just want's to get on the road and you have a cheap manifold/DP combo for sale. I wouldn't give a damn what it looked like or what coating it had on it. Long as you can build a good strong product that won't have structural problems I'm sure you could sell 10 of them. Do look into Tig though, it would increase sales in the end for sure.