Bosch integrated pressure/temp sensors

#22

Awesome. On my last purchase from Haltech I grabbed a few of the m10-->NPT fittings. Next order from priority mazda, I will grab a sensor. I will install on a turbo oil feed tee. I have one that has 2 ports, so use one for sensor and one for turbo oil and jsut cap that off until I am ready to turbo stuff.

#23

Awesome. On my last purchase from Haltech I grabbed a few of the m10-->NPT fittings. Next order from priority mazda, I will grab a sensor. I will install on a turbo oil feed tee. I have one that has 2 ports, so use one for sensor and one for turbo oil and jsut cap that off until I am ready to turbo stuff.

I have been playing with this sensor for the last week or so, unfortunately the temp pin does not output a linear 0-5v curve. I am currently working on trying to find a tiny arduino board to convert the log curve to linear so i can have my MS read it and output the values properly.

#24

I have been playing with this sensor for the last week or so, unfortunately the temp pin does not output a linear 0-5v curve. I am currently working on trying to find a tiny arduino board to convert the log curve to linear so i can have my MS read it and output the values properly.

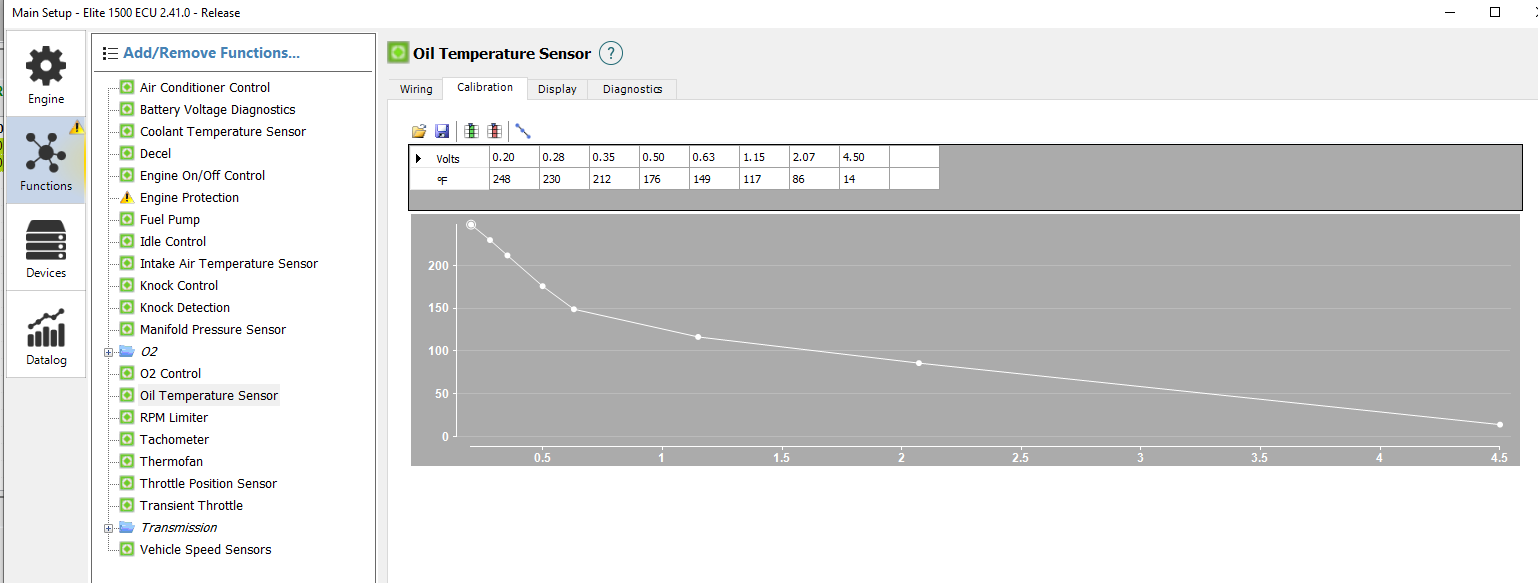

Is there a way to make a curve in tunerstudio? for haltech you can select a calibration with those curves and it will work.

#25

I have been playing with this sensor for the last week or so, unfortunately the temp pin does not output a linear 0-5v curve. I am currently working on trying to find a tiny arduino board to convert the log curve to linear so i can have my MS read it and output the values properly.

E.g. like this?

#26

ie: I have a GM iat sensor with a known curve, I can choose for the bosch sensor to match the same configuration as the GM IAT curve, if it lined up.

#27

Well that's no fun.

In which case I'd grab one of these sweet new teensy 4s (https://www.pjrc.com/store/teensy41.html , seriously these are such insane value), a 5v to 3v logic level shifter, and just hook the teensy up to the MS3 with CAN. That way you can have whatever calibration or filtering you want + error handling and room to add more sensors down the line on the teensy (or SPI devices like thermocouple amp, GPS, etc. -- https://github.com/mantonakakis1/MegaCAN) and just broadcast it to the MS3. With whats out there in the community it should be pretty spoon feedy, but for sure some amount of coding involved. Talk about something you can't do with a Haltech (sadly.....)

In which case I'd grab one of these sweet new teensy 4s (https://www.pjrc.com/store/teensy41.html , seriously these are such insane value), a 5v to 3v logic level shifter, and just hook the teensy up to the MS3 with CAN. That way you can have whatever calibration or filtering you want + error handling and room to add more sensors down the line on the teensy (or SPI devices like thermocouple amp, GPS, etc. -- https://github.com/mantonakakis1/MegaCAN) and just broadcast it to the MS3. With whats out there in the community it should be pretty spoon feedy, but for sure some amount of coding involved. Talk about something you can't do with a Haltech (sadly.....)

#28

Well that's no fun.

In which case I'd grab one of these sweet new teensy 4s (https://www.pjrc.com/store/teensy41.html , seriously these are such insane value), a 5v to 3v logic level shifter, and just hook the teensy up to the MS3 with CAN. That way you can have whatever calibration or filtering you want + error handling and room to add more sensors down the line on the teensy (or SPI devices like thermocouple amp, GPS, etc. -- https://github.com/mantonakakis1/MegaCAN) and just broadcast it to the MS3. With whats out there in the community it should be pretty spoon feedy, but for sure some amount of coding involved. Talk about something you can't do with a Haltech (sadly.....)

In which case I'd grab one of these sweet new teensy 4s (https://www.pjrc.com/store/teensy41.html , seriously these are such insane value), a 5v to 3v logic level shifter, and just hook the teensy up to the MS3 with CAN. That way you can have whatever calibration or filtering you want + error handling and room to add more sensors down the line on the teensy (or SPI devices like thermocouple amp, GPS, etc. -- https://github.com/mantonakakis1/MegaCAN) and just broadcast it to the MS3. With whats out there in the community it should be pretty spoon feedy, but for sure some amount of coding involved. Talk about something you can't do with a Haltech (sadly.....)

#29

Gotcha gotcha.

Looks like MS uses a 10-bit ADC but given this is diy hardware in an environment with a good deal of noise you might be better off going with a 12 or 14 bit ADC/DAC combo and oversampling + filtering the input.

You could always grab 2 demo boards from the ADC/DAC mfg (i.e. analog devices, stmicro, ti, etc) but those are usually pretty expensive and likely overkill. Best easy-mode would be to get some 12-bit adc/dacs from adafriut/sparkfun and run them off the 5v rail from the ECU. They should be 3.3v and 5v tolerant, but not sure if you can use 3.3v logic if you're powering it off a 5v to get the ADC/DAC range you need. Either way a logic level shifter is cheap and easy.

https://www.adafruit.com/product/1083

https://www.adafruit.com/product/935

https://www.adafruit.com/product/757

Should be easy code attached in the docs depending on if you want to use an mcu that supports circuit python (the new hotness these days it would seem) or just arduino IDE c code. Regardless that adc will run at ~3 kHz, probably best to run it quick and just take a large moving average before your lookup table or calibration curve.

If you wanted to go totally overkill with ton of expandability, these lil fpga boards are cheap for what you get, super robost/reliable compared to normal MCUs, and the system gives lots of option for future expansion, but also learning curve.

https://store.digilentinc.com/arty-a...lopment-board/

https://store.digilentinc.com/pmod-gps-gps-receiver/

https://store.digilentinc.com/pmod-a...a-d-converter/

https://store.digilentinc.com/pmod-s...tronic-switch/

Looks like MS uses a 10-bit ADC but given this is diy hardware in an environment with a good deal of noise you might be better off going with a 12 or 14 bit ADC/DAC combo and oversampling + filtering the input.

You could always grab 2 demo boards from the ADC/DAC mfg (i.e. analog devices, stmicro, ti, etc) but those are usually pretty expensive and likely overkill. Best easy-mode would be to get some 12-bit adc/dacs from adafriut/sparkfun and run them off the 5v rail from the ECU. They should be 3.3v and 5v tolerant, but not sure if you can use 3.3v logic if you're powering it off a 5v to get the ADC/DAC range you need. Either way a logic level shifter is cheap and easy.

https://www.adafruit.com/product/1083

https://www.adafruit.com/product/935

https://www.adafruit.com/product/757

Should be easy code attached in the docs depending on if you want to use an mcu that supports circuit python (the new hotness these days it would seem) or just arduino IDE c code. Regardless that adc will run at ~3 kHz, probably best to run it quick and just take a large moving average before your lookup table or calibration curve.

If you wanted to go totally overkill with ton of expandability, these lil fpga boards are cheap for what you get, super robost/reliable compared to normal MCUs, and the system gives lots of option for future expansion, but also learning curve.

https://store.digilentinc.com/arty-a...lopment-board/

https://store.digilentinc.com/pmod-gps-gps-receiver/

https://store.digilentinc.com/pmod-a...a-d-converter/

https://store.digilentinc.com/pmod-s...tronic-switch/

#30

Gotcha gotcha.

Looks like MS uses a 10-bit ADC but given this is diy hardware in an environment with a good deal of noise you might be better off going with a 12 or 14 bit ADC/DAC combo and oversampling + filtering the input.

You could always grab 2 demo boards from the ADC/DAC mfg (i.e. analog devices, stmicro, ti, etc) but those are usually pretty expensive and likely overkill. Best easy-mode would be to get some 12-bit adc/dacs from adafriut/sparkfun and run them off the 5v rail from the ECU. They should be 3.3v and 5v tolerant, but not sure if you can use 3.3v logic if you're powering it off a 5v to get the ADC/DAC range you need. Either way a logic level shifter is cheap and easy.

https://www.adafruit.com/product/1083

https://www.adafruit.com/product/935

https://www.adafruit.com/product/757

Should be easy code attached in the docs depending on if you want to use an mcu that supports circuit python (the new hotness these days it would seem) or just arduino IDE c code. Regardless that adc will run at ~3 kHz, probably best to run it quick and just take a large moving average before your lookup table or calibration curve.

If you wanted to go totally overkill with ton of expandability, these lil fpga boards are cheap for what you get, super robost/reliable compared to normal MCUs, and the system gives lots of option for future expansion, but also learning curve.

https://store.digilentinc.com/arty-a...lopment-board/

https://store.digilentinc.com/pmod-gps-gps-receiver/

https://store.digilentinc.com/pmod-a...a-d-converter/

https://store.digilentinc.com/pmod-s...tronic-switch/

Looks like MS uses a 10-bit ADC but given this is diy hardware in an environment with a good deal of noise you might be better off going with a 12 or 14 bit ADC/DAC combo and oversampling + filtering the input.

You could always grab 2 demo boards from the ADC/DAC mfg (i.e. analog devices, stmicro, ti, etc) but those are usually pretty expensive and likely overkill. Best easy-mode would be to get some 12-bit adc/dacs from adafriut/sparkfun and run them off the 5v rail from the ECU. They should be 3.3v and 5v tolerant, but not sure if you can use 3.3v logic if you're powering it off a 5v to get the ADC/DAC range you need. Either way a logic level shifter is cheap and easy.

https://www.adafruit.com/product/1083

https://www.adafruit.com/product/935

https://www.adafruit.com/product/757

Should be easy code attached in the docs depending on if you want to use an mcu that supports circuit python (the new hotness these days it would seem) or just arduino IDE c code. Regardless that adc will run at ~3 kHz, probably best to run it quick and just take a large moving average before your lookup table or calibration curve.

If you wanted to go totally overkill with ton of expandability, these lil fpga boards are cheap for what you get, super robost/reliable compared to normal MCUs, and the system gives lots of option for future expansion, but also learning curve.

https://store.digilentinc.com/arty-a...lopment-board/

https://store.digilentinc.com/pmod-gps-gps-receiver/

https://store.digilentinc.com/pmod-a...a-d-converter/

https://store.digilentinc.com/pmod-s...tronic-switch/

Thanks for this well thought out reply. I was looking into the logic level shifters, but am concerned as most have a minimum voltage of ~1.5 on the low side and slightly more on the high side, this will drastically reduce the resolution capable of the sensor. I was hoping to find a cheap diy type mcu that is very small and operates at 5v logic level, and is capable of 10bit. The problem will be finding something that has that and a adc/dac onboard. sample rate is not overly a concern for this application i dont think, as even at 1khz i would be getting readings at 1/sec which should be adequate for temp/pressure for logging and visual display on a gauge.

Edit:

this breadkout board you linked may be the ticket! https://www.adafruit.com/product/935

#31

Yeah those adafruit boards will work with any arduino or teensy type MCU and, while slightly more expensive than some, they generally have good support/docs. All the analog input/output is handled by those 12-bit ICs, the MCU is only communicating digitally so no worries there.

The logic level shifter is needed as to get the 0-5V range you want you need to power the ADC/DAC ICs with 5V as well (which is fine even if your MCU doesn't have it because MS3 has a 5V rail). But, while they are both 1.8-5V logic tolerant ICs, I think they expect logic to be at the same level as VDD (5V), so the level shifter is just to translate the digital communication between the ICs (5V) and the MCU (3.3V/1.8V) over the I2C bus.

Good luck!

The logic level shifter is needed as to get the 0-5V range you want you need to power the ADC/DAC ICs with 5V as well (which is fine even if your MCU doesn't have it because MS3 has a 5V rail). But, while they are both 1.8-5V logic tolerant ICs, I think they expect logic to be at the same level as VDD (5V), so the level shifter is just to translate the digital communication between the ICs (5V) and the MCU (3.3V/1.8V) over the I2C bus.

Good luck!

Last edited by Spaceman Spiff; 04-23-2021 at 03:15 PM.

#32

Adafruit makes a M4 Feather that has a SAME51 with built in canbus plus transceiver as well as a DAC. Use a unity gain opamp as a buffer followed by a resistor divider to reduce 5v to 3.3v linearly, look at what rusefi is doing. You cannot use just a resistor divider as that's all a temp sensor is in the first place. Put all this on a stupid simple PCB that has input power filtering/clamping/polarity protection, maybe canbus filter if you care. Also, add the pullups, lowpass filters, etc...

Or forget the DAC and just pipe the data straight into the megasquirt over canbus. If you want to do the same on haltech, PM me and I'll tell you were to stick data, in what format.

Adafruit's code for canbus is kinda crap, but if you search github for my name you should find a ATSAME arduino canbus library that works.

Ms3 has three non-linear comp curves, maybe one more if you can use analog MAF. Most installs would have no issue using the stock CLT/IAT and as many of these sensors as you can manage.

Or forget the DAC and just pipe the data straight into the megasquirt over canbus. If you want to do the same on haltech, PM me and I'll tell you were to stick data, in what format.

Adafruit's code for canbus is kinda crap, but if you search github for my name you should find a ATSAME arduino canbus library that works.

Ms3 has three non-linear comp curves, maybe one more if you can use analog MAF. Most installs would have no issue using the stock CLT/IAT and as many of these sensors as you can manage.

#34

The canbus controller on the SAME51 is incredible. I think there are enough buffers to be able to store each and every MS incoming broadcast message to a dedicated receive buffer. It uses SRAM directly, the very moment a message hits a buffer it's sitting waiting in SRAM for the CPU.

I don't know how teensy does it, but I can't bootload it so I don't give a hoot.

That feather has two of those canbus peripherals, only one transceiver and the available IO might be used somewhere else anyway, probably usb. Could easily port whatever format you are running to the megasquirt format, then forgo the ADC-DAC-ADC loop. Probably have to make a fully custom board then, but you can since it's not a teensy.

I don't know how teensy does it, but I can't bootload it so I don't give a hoot.

That feather has two of those canbus peripherals, only one transceiver and the available IO might be used somewhere else anyway, probably usb. Could easily port whatever format you are running to the megasquirt format, then forgo the ADC-DAC-ADC loop. Probably have to make a fully custom board then, but you can since it's not a teensy.

#35

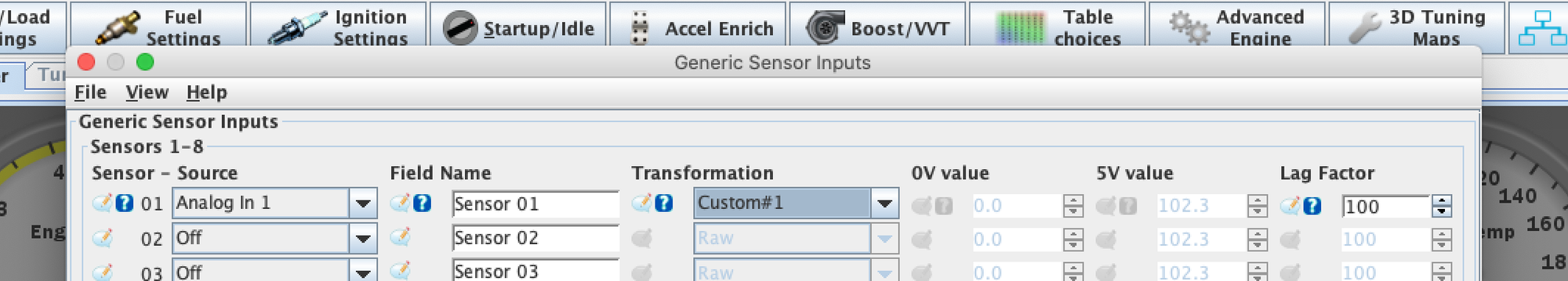

Unfortunately, Generic Sensor Inputs on MS can only be 0-5v linear or match existing curves used for MAT/CLT/IAT sensors already configured and used elsewhere.

ie: I have a GM iat sensor with a known curve, I can choose for the bosch sensor to match the same configuration as the GM IAT curve, if it lined up.

ie: I have a GM iat sensor with a known curve, I can choose for the bosch sensor to match the same configuration as the GM IAT curve, if it lined up.

Set it...

...and forget it.

#36

Much as I hate to tell someone not to put ten more computers in their car, if you're using a recent firmware release on MS3, there is also an additional "Custom#1" thermistor calibration you can use for whatever you like. You can even specify transformations that don't neatly fit the three-parameter NTC curve generator.

#37

Update

9956-21-000 2006-2020 Mazda Brake Hose Gasket $1.98 ordered these washers

https://www.haltech.com/product/ht-0...-bspt-adaptor/ these adapters

PY8V-18-541B 2016-2020 Mazda Oil Pressure Sensor $57.49 this sensor

mazda parts from mazdapartsfactor/werner mazda in NH. Cheaper than priority, no messed up orders so far.

ordering trapezoid connector and wiring from Corsa Technic later this week

https://www.corsa-technic.com/item.php?item_id=1506

Have a bunch of stuff to do to my car as soon as the snow starts flying, after the valve seals, the knock sensor and running this off the turbo oil feed and connecting to the Haltech will be the next things on the list.

9956-21-000 2006-2020 Mazda Brake Hose Gasket $1.98 ordered these washers

https://www.haltech.com/product/ht-0...-bspt-adaptor/ these adapters

PY8V-18-541B 2016-2020 Mazda Oil Pressure Sensor $57.49 this sensor

mazda parts from mazdapartsfactor/werner mazda in NH. Cheaper than priority, no messed up orders so far.

ordering trapezoid connector and wiring from Corsa Technic later this week

https://www.corsa-technic.com/item.php?item_id=1506

Have a bunch of stuff to do to my car as soon as the snow starts flying, after the valve seals, the knock sensor and running this off the turbo oil feed and connecting to the Haltech will be the next things on the list.

#38

Update again.

Using the haltech adapter, the washers I bought were superfluous. the sensor bottoms in the adapter and the washer is loose. So the washer is not needed. Put a thin smear of permatex sealant on the top of the threads, will see if it leaks when i get round to oiling it up and starting this thing

Using the haltech adapter, the washers I bought were superfluous. the sensor bottoms in the adapter and the washer is loose. So the washer is not needed. Put a thin smear of permatex sealant on the top of the threads, will see if it leaks when i get round to oiling it up and starting this thing

#39

This is an old-*** thread, but are you supposed to run shielded wires for these sensors or something?

I have what I think is the same or a derivative of the same sensor in my K24 BRZ and the oil temperature immediately spikes 30-40f when wide open throttle. I am guessing there is some kind of interference at this point, sensor is in the stock pressure sensor location.

I have what I think is the same or a derivative of the same sensor in my K24 BRZ and the oil temperature immediately spikes 30-40f when wide open throttle. I am guessing there is some kind of interference at this point, sensor is in the stock pressure sensor location.

#40

Yuba, I can't speak to your problem, perhaps by now you've figured it out and want to share what the root of issue was?

msmola2002, I'm wondering how the sensor has been doing with your sealing method. I'm eyeing a $45 cheapo version of this sensor on Aliexpress. I'm hoping that if the sensor leaks, it would tell me so with a low pressure warning

I have seen the similar Lowdoller-branded sensor posted recently with a 1/8" NPT thread, if adapting m10 doesn't work well maybe I'll have to go that route.

msmola2002, I'm wondering how the sensor has been doing with your sealing method. I'm eyeing a $45 cheapo version of this sensor on Aliexpress. I'm hoping that if the sensor leaks, it would tell me so with a low pressure warning

I have seen the similar Lowdoller-branded sensor posted recently with a 1/8" NPT thread, if adapting m10 doesn't work well maybe I'll have to go that route.