Bottom End Build With SuperMiata VVT Head First Start – Observations and Questions

#1

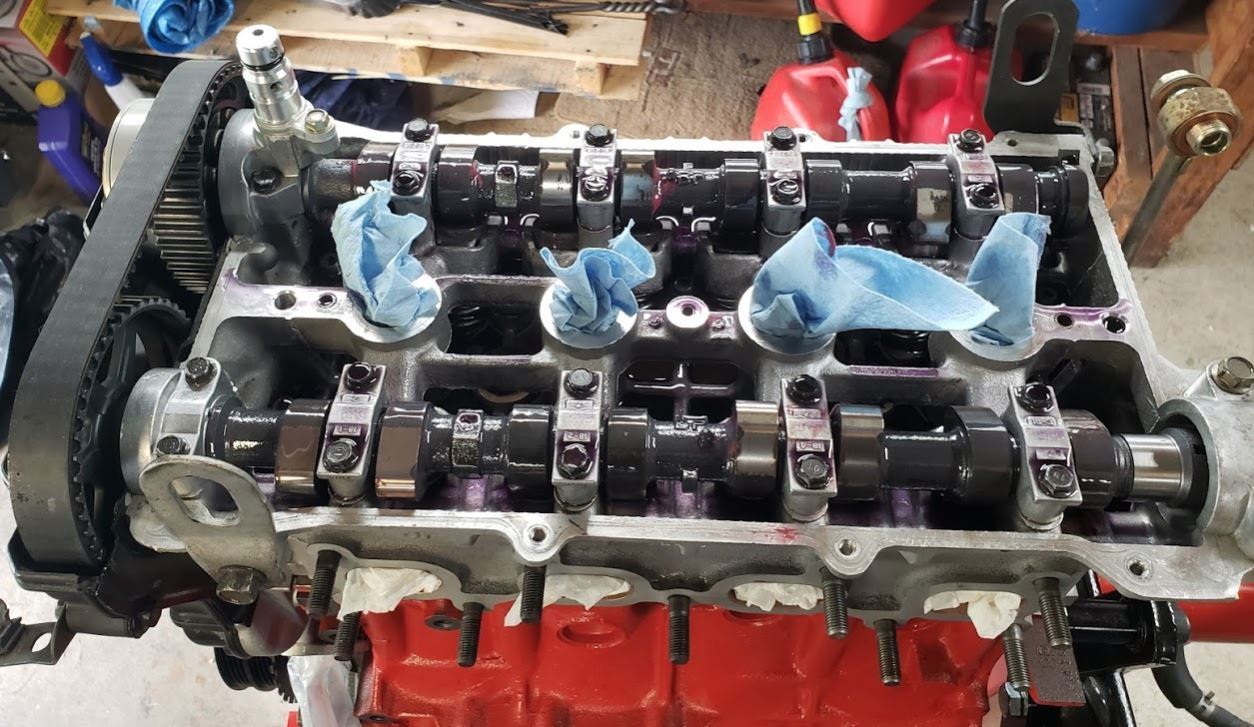

Just finished building, installing, and rewiring my first engine. The car is a 1991, engine is a 2003 with VVT heads:

-Carillo Super-A Beam rods

-Supertech 84mm 9:1 pistons – measured CR is 8.65:1, tops coated with heat rejection ceramic coating

-Full SuperMiata CNC head, +1mm intake, +2mm exhaust, custom cams from Mike Keegan, coated combustion chamber

-Skunk2 throttle body, ported to IM

-Flat top intake manifold, ports matched to head

-Stock 1994-1997 exhaust manifold into stock 1.6 full exhaust

-Hydra 2.7 with base map from Flyin Miata

The engine is now running and broken in using the floor-it-and-coast method, about 60 miles on it. Nothing has come flying through the hood yet, so a success thus far.

A few observations:

-This thing runs HOT. The hood is too hot to touch even just after idling for 15 minutes. The timing light clamp was almost too hot to touch after just a minute or so. The shifter is hot, the cabin is hot…I don’t recall anything like this from the 1.6.

-The base map was waaay too rich for start up and idling. I cut the fuel more than in half for cranking and it finally fires without needing throttle. Seems like I need to keep pulling more fuel. Zeroing out the post-start fuel trim helped a lot too.

Questions:

-Idle MAP is 60 kpa – is this a problem? ISC duty cycle is around 33% with the idle screw roughly in the middle of its adjustment range. Idle target is 864, it bounces between 860-925, sometimes going into a surge after idling for a minute or two.

-The alternator belt squeals like a banshee getting turned inside out. I have the 100 amp FD alternator installed. I’ve tightened the belt more than any belt I’ve ever tightened, and it helps, but it will actually smoke for a minute or two if the battery is low after starting before the squeal stops. Anyone else have this problem?

-Oil pressure when hot seems to max out around 50 psi on the gauge in the dash. When cold it is at the 90 psi mark. Oil is Royal Purple 10w30 Break In oil that I will be changing to conventional 10w40 immediately. What would cause this?

-One of the intake manifold vacuum ports can be turned by hand, not easily, but it will turn. Is this a probable vacuum leak?

-Carillo Super-A Beam rods

-Supertech 84mm 9:1 pistons – measured CR is 8.65:1, tops coated with heat rejection ceramic coating

-Full SuperMiata CNC head, +1mm intake, +2mm exhaust, custom cams from Mike Keegan, coated combustion chamber

-Skunk2 throttle body, ported to IM

-Flat top intake manifold, ports matched to head

-Stock 1994-1997 exhaust manifold into stock 1.6 full exhaust

-Hydra 2.7 with base map from Flyin Miata

The engine is now running and broken in using the floor-it-and-coast method, about 60 miles on it. Nothing has come flying through the hood yet, so a success thus far.

A few observations:

-This thing runs HOT. The hood is too hot to touch even just after idling for 15 minutes. The timing light clamp was almost too hot to touch after just a minute or so. The shifter is hot, the cabin is hot…I don’t recall anything like this from the 1.6.

-The base map was waaay too rich for start up and idling. I cut the fuel more than in half for cranking and it finally fires without needing throttle. Seems like I need to keep pulling more fuel. Zeroing out the post-start fuel trim helped a lot too.

Questions:

-Idle MAP is 60 kpa – is this a problem? ISC duty cycle is around 33% with the idle screw roughly in the middle of its adjustment range. Idle target is 864, it bounces between 860-925, sometimes going into a surge after idling for a minute or two.

-The alternator belt squeals like a banshee getting turned inside out. I have the 100 amp FD alternator installed. I’ve tightened the belt more than any belt I’ve ever tightened, and it helps, but it will actually smoke for a minute or two if the battery is low after starting before the squeal stops. Anyone else have this problem?

-Oil pressure when hot seems to max out around 50 psi on the gauge in the dash. When cold it is at the 90 psi mark. Oil is Royal Purple 10w30 Break In oil that I will be changing to conventional 10w40 immediately. What would cause this?

-One of the intake manifold vacuum ports can be turned by hand, not easily, but it will turn. Is this a probable vacuum leak?

#2

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,780

Total Cats: 360

Idle map at 60 is no good. It should be ~35 or less with all accessories on at stock idle on a stock profile. Aggressive cams will effect this, check with your cam specialist. Start with mechanical and spark timing. Make sure you don't have a major exhaust restriction.

#4

Yes, the plan is a 6258. It's actually swaintech coated with a speed sensor installed, ready to go in, but I am one of the people caught in the TSE business where I bought a kit last fall right as everything fell apart, and I'm waiting on the downpipe and lines to arrive someday. Because of that, the intake is the flat top manifold and skunk2 throttle body, but just the OEM plastic crossover tube from 2003 mated to the 1991 airbox with the AFM removed. I'm sure the 1.6 exhaust is a restriction but I don't want to spend any money on something that is going to be replaced as soon as possible anyway.

Pardon my ignorance, but I am struggling a little with the concept of idle MAP going up and down. The MAP is directly related to the restriction on the incoming air, right? For MAP to go down, from 60 kPa to 30 kPa, either the throttle would need to close better, the idle air screw would need to be adjusted in, or the ICV would need to close more. Assuming I didn't screw up the throttle stop screw, that component can be ignored. So the process is to increase timing or change fueling to get idle RPM to go up, then close the air screw and reduce ICV duty cycle until the rpm drops back down to ~850 but now with higher vacuum? Essentially, make more power at idle with less air?

Pardon my ignorance, but I am struggling a little with the concept of idle MAP going up and down. The MAP is directly related to the restriction on the incoming air, right? For MAP to go down, from 60 kPa to 30 kPa, either the throttle would need to close better, the idle air screw would need to be adjusted in, or the ICV would need to close more. Assuming I didn't screw up the throttle stop screw, that component can be ignored. So the process is to increase timing or change fueling to get idle RPM to go up, then close the air screw and reduce ICV duty cycle until the rpm drops back down to ~850 but now with higher vacuum? Essentially, make more power at idle with less air?

#5

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,780

Total Cats: 360

Idle map isn't something you ~set~. The map at idle (if the idle is constant) is a measurement of the air mass ~required~ to maintain that idle. If the engine requires 60 kpa to develop the power to maintain idle, then it is extremely inefficient. You could potentially have a serious issue with the car, and if it were me, I would not drive it until I figured it out.

MAP sensor fault or issues in the vac line to the MAP sensor need to be investigated as well.

MAP sensor fault or issues in the vac line to the MAP sensor need to be investigated as well.

#6

More data:

Idle with VVT unplugged: 60 KPa

Idle with VVT plugged in: 65 KPa

MAP at ~2000 RPM no load: 35 KPa, no change over 20 seconds or so

MAP under decel 4000 RPM - 2500 RPM: 35 down to 28 KPa

Not sure how to interpret this. A vacuum leak that has less effect at higher RPM as air volume past the throttle increases relative to air through the leak? Higher lift and long overlap cams giving a poor idle but functioning better at 2000 RPM?

Idle with VVT unplugged: 60 KPa

Idle with VVT plugged in: 65 KPa

MAP at ~2000 RPM no load: 35 KPa, no change over 20 seconds or so

MAP under decel 4000 RPM - 2500 RPM: 35 down to 28 KPa

Not sure how to interpret this. A vacuum leak that has less effect at higher RPM as air volume past the throttle increases relative to air through the leak? Higher lift and long overlap cams giving a poor idle but functioning better at 2000 RPM?

#7

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,780

Total Cats: 360

No-load map actually decreases with rpm increase. HP increases with RPM, it takes a certain amount of HP to maintain the rpm. Engine efficiency improves with engine speed, so the map required decreases. As I mentioned, cams can do this, but they would need to be really race-oriented in order to make this much impact. 35kpa at no load 2000 is still too high at or near MBT, I would expect mid to high 20's.

#9

Ted75zcar,

That map is an excellent reference, thank you. I don't know the specs of the cams, I only have a dyno curve that should be pretty close to what my cams produce but I was asked not to share it. There is little to no torque below 4500 rpm, then torque is flat to 6500 rpm, power is flat from 6500-8000 rpm. It is more of a race cam than a street cam, I believe.

My MAP sensor reads 95 KPa with the engine off. Barometric pressure in my location is 100.8. It is possible the vacuum line to the ECU is slightly constricted where it goes through the firewall hole grommet next to a bunch of wires, but it seems to respond quickly to changes in RPM. Not sure if that can be ruled out or not. The stable KPa at 2000 rpm over time is supposed to rule out an exhaust restriction, according to the internet. Ive checked base timing with a timing light, it is difficult to say for sure because the idle is not rock steady, but I come up with 8 degrees, which matches the number in the software. Idle spark timing is 12 degrees, I changed it to 15 degrees and nothing happened. I tried waving an unlit propane torch around the intake manifold, concentrating near vacuum lines, but there was no change in engine RPM detectable by ear. Idle AFR is around 13:1, leaning out over time as it autotunes, although that is somewhat erratic as well.

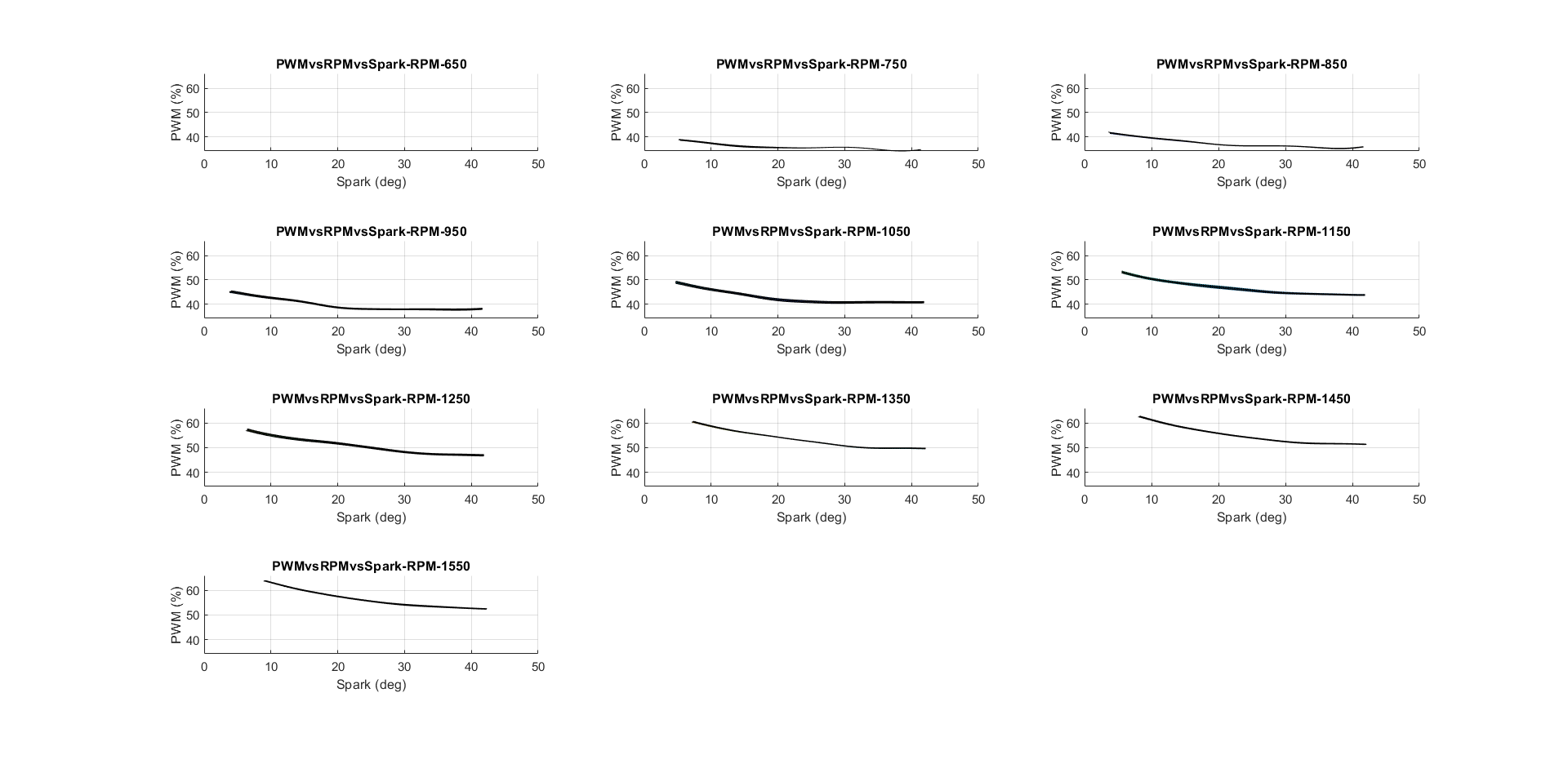

Based on the map, it looks like I could go a lot further with spark advance. I'm not sure what else to do other than ignore the high KPa, or possibly get a smoke machine to check for vacuum leaks and exhaust restrictions. I'm open to suggestions, and appreciate the help.

That map is an excellent reference, thank you. I don't know the specs of the cams, I only have a dyno curve that should be pretty close to what my cams produce but I was asked not to share it. There is little to no torque below 4500 rpm, then torque is flat to 6500 rpm, power is flat from 6500-8000 rpm. It is more of a race cam than a street cam, I believe.

My MAP sensor reads 95 KPa with the engine off. Barometric pressure in my location is 100.8. It is possible the vacuum line to the ECU is slightly constricted where it goes through the firewall hole grommet next to a bunch of wires, but it seems to respond quickly to changes in RPM. Not sure if that can be ruled out or not. The stable KPa at 2000 rpm over time is supposed to rule out an exhaust restriction, according to the internet. Ive checked base timing with a timing light, it is difficult to say for sure because the idle is not rock steady, but I come up with 8 degrees, which matches the number in the software. Idle spark timing is 12 degrees, I changed it to 15 degrees and nothing happened. I tried waving an unlit propane torch around the intake manifold, concentrating near vacuum lines, but there was no change in engine RPM detectable by ear. Idle AFR is around 13:1, leaning out over time as it autotunes, although that is somewhat erratic as well.

Based on the map, it looks like I could go a lot further with spark advance. I'm not sure what else to do other than ignore the high KPa, or possibly get a smoke machine to check for vacuum leaks and exhaust restrictions. I'm open to suggestions, and appreciate the help.

#10

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,780

Total Cats: 360

A vac leak large enough to allow 65kpa would cause the engine to rev to redline.

If I had to guess, assuming it isn't the cam profile, you lined your ex cam up with E where the I should be, or the intake cam was off, or not at TDC.

If I had to guess, assuming it isn't the cam profile, you lined your ex cam up with E where the I should be, or the intake cam was off, or not at TDC.

#11

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,780

Total Cats: 360

You want your idle advance to actually be in the middle of the sloped section, not at MBT. That way idle correction advance has a lot of torque range to work with, both for increasing and decreasing the idle rpm. If you look carefully, you will realize that just about everybody configures their idle advance incorrectly, increacing timing with load, as opposed to decreasing timing with load. There is a perception that increased load correlates with increased rpm.

The timing table OTOH should be setup for MBT, which will also look very different than what you see in most tunes.

The timing table OTOH should be setup for MBT, which will also look very different than what you see in most tunes.

#19

I replaced the cheap Autozone belt with an OEM ones, which is made by Gates, then tightened the crap out of it. It did not squeal for roughly 2 start ups, and now it squeals on start again. I'm going to try tightening it again, but beyond that I'm lost. One thing that is kind of cool, I can actually see it slipping in the Hydra software as the battery voltage slowly climbs from ~12 to ~13.2 after starting. Without slip I think it should immediately be 13.2V.

Thread

Thread Starter

Forum

Replies

Last Post