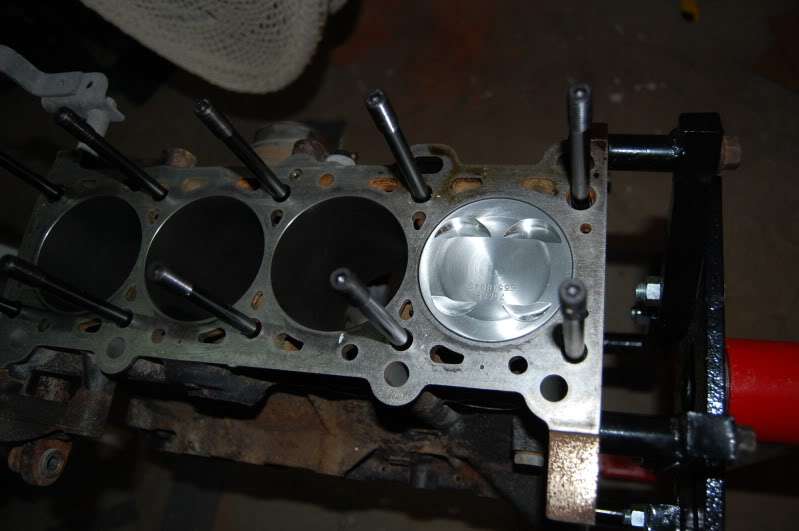

Pistons...

#23

I know at least one person who despises the rings that came with the wiseco's--me. I have more blowby than I really should have. In reality, it's probably less the fault of the rings and more the fault of the machinist. Northwest Connecting Rod in Seattle FTL.

I wouldn't use the top rings. Just use the seconds, and find a machinist who's worked with them before. Cylinder wall finish is important with any rings, but some say it is particularly important with the TS rings.

I wouldn't use the top rings. Just use the seconds, and find a machinist who's worked with them before. Cylinder wall finish is important with any rings, but some say it is particularly important with the TS rings.

#25

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

OK, I'm bored, **** it I'll check it out...

According to Belfab they use 4032. According to Wiseco they use 2618.

Looking up the CTEs for both materials, using the T6 condition:

Aluminum 4032-T6 has a CTE of 10.8 µin/in-°F

Aluminum 2618-T6 has a CTE of 12.4 µin/in-°F

(properties taken from Matweb)

Therefore, the Wiseco piston will expand about 23% more than the Belfab piston for a given temperature rise. CTE is a function of temperature, so I used the same temp range for both alloys.

#29

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

I don't have much of any...but my oil turns black fast. I need to do an UOA to see if its fuel contamination.

#33

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

Never heard that one. Let me know if you run across any hard evidence of that. I am not sure that is possible since CTE has to to with molecular interaction (chemistry) so the core chemistry of the material would have to change somehow.

#35

Sorry to butt into the piston thread, but I also just bought MTuned rods and am looking at pistons. My machinist said he could get me JE Pistons 9.0:1 83.5mm for $510 including the pistons,wrist pins,and rings. This sounded like a pretty good price to me, but wondering what the consensus is on the JE vs. others being discussed in this thread? Thanks

#37

Just compare the thermal expansion coefficients (CTE) of the two alloys.

OK, I'm bored, **** it I'll check it out...

According to Belfab they use 4032. According to Wiseco they use 2618.

Looking up the CTEs for both materials, using the T6 condition:

Aluminum 4032-T6 has a CTE of 10.8 µin/in-°F

Aluminum 2618-T6 has a CTE of 12.4 µin/in-°F

(properties taken from Matweb)

Therefore, the Wiseco piston will expand about 23% more than the Belfab piston for a given temperature rise. CTE is a function of temperature, so I used the same temp range for both alloys.

OK, I'm bored, **** it I'll check it out...

According to Belfab they use 4032. According to Wiseco they use 2618.

Looking up the CTEs for both materials, using the T6 condition:

Aluminum 4032-T6 has a CTE of 10.8 µin/in-°F

Aluminum 2618-T6 has a CTE of 12.4 µin/in-°F

(properties taken from Matweb)

Therefore, the Wiseco piston will expand about 23% more than the Belfab piston for a given temperature rise. CTE is a function of temperature, so I used the same temp range for both alloys.

#38

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

1. I worry about thin cylinder walls at 400whp+

2. The only HG available that will do a 2.5mm overbore is the Maruha copper gasket, at $160. Seeing as how I went through two OEMs before one sealed up, that would have cost me a fortune.

#39

Boost Pope

Thread Starter

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,593

Lots of ink has been used on discussions of aluminum piston material. Forged 2618 was used for piston material in Second World War aircraft engines. In certain piston engine applications, forged 4032 was preferred because of its lower coefficient of expansion. Alloy 2618 is often described as having higher strength than 4032, but at elevated temperatures (where pistons tend to operate), the strength distinction becomes quite small (Table 3). In fact, at 400°F, the 32 ksi YS of 4032 alloy is 18% higher than that of 2618 (27 ksi) at the same temperature. However, 2618 has an impressive resistance to weakening with prolonged exposure to elevated temperatures. 2618 is a copper-magnesium alloy with low silicon, but it expands with temperature about 15% faster than the high-silicon 4032 alloy. Currently, piston manufacturers seem to prefer the 2618 alloy, and many have done slight modifications either to the chemistry or to the tolerances to produce "proprietary" alloys. (source: EPI Inc. Advanced Engine Materials)

Decisions, decisions... One would expect either piston to massively out-perform a stock unit under extreme abnormal aspiration. I tend to gravitate in the direction of the Supertechs on the basis of their lower thermal expansion and consequently tighter bore tolerance.

#40

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

Decisions, decisions...

One would expect either piston to massively out-perform a stock unit under extreme abnormal aspiration. I tend to gravitate in the direction of the Supertechs on the basis of their lower thermal expansion and consequently tighter bore tolerance.

One would expect either piston to massively out-perform a stock unit under extreme abnormal aspiration. I tend to gravitate in the direction of the Supertechs on the basis of their lower thermal expansion and consequently tighter bore tolerance.

I had the benefit of using a builder who's done so many FI miatas that tolerance and bore decisions, which varied by piston material, were chosen from experience and not some general text-book rule.