The custom fabrication thread! (Post pics of stuff you have made)

#962

That didnt really do dick. I bolted mine to a stock header with every bolt as tight as I ******* could and I was worried that wouldnt be good enough. I also machined a 3/4" think steel plate with both the BP flange and the T25 flange if anyone is interested in buying a pimpy fixture plate for cranking out a lot of these.

#963

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

That didnt really do dick. I bolted mine to a stock header with every bolt as tight as I ******* could and I was worried that wouldnt be good enough. I also machined a 3/4" think steel plate with both the BP flange and the T25 flange if anyone is interested in buying a pimpy fixture plate for cranking out a lot of these.

It was my first manifold and I learned a lot. I won't build another one without a band saw, fixture to hold the flange, backpurging, and post flow. Also I would go with 1/2" flanges instead of 3/8"

#964

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

FWIW, I use a 2" piece of cold rolled and it gets to be burn your hand hot after welding all of the runners to the head flange, even with the purge gas going through it. The turbo flange gets equally as hot, because its small... but your spending a lot less time on it because its pretty open and easy to weld before you get the rest of the manifold in the way.

With this method, I have had really good luck with welding the flanges and have generally no need to surface the flanges. I do surface them on my belt sander to make totally sure that each product is top of the line, ready to go. Its more of a quality assurance than quality control.

#966

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,652

Total Cats: 3,011

A buddy of mine with a really nice CNC machine makes 1/2 flanges.

Mazworx - BP #965515

Mark is a really interesting guy. He carves new RB26 and SR20 blocks out of huge chunks of aluminum with one of his CNC machines (amongst other things).

Specifications:

- Made from 1/2" thick 1018 cold rolled steel

- CNC machine cut

- Stepped to accept 1 1/2" sch. 10 pipe

Made in the USA.

- Made from 1/2" thick 1018 cold rolled steel

- CNC machine cut

- Stepped to accept 1 1/2" sch. 10 pipe

Made in the USA.

Mark is a really interesting guy. He carves new RB26 and SR20 blocks out of huge chunks of aluminum with one of his CNC machines (amongst other things).

#968

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

A buddy of mine with a really nice CNC machine makes 1/2 flanges.

Mazworx - BP #965515

Mark is a really interesting guy. He carves new RB26 and SR20 blocks out of huge chunks of aluminum with one of his CNC machines (amongst other things).

Mazworx - BP #965515

Mark is a really interesting guy. He carves new RB26 and SR20 blocks out of huge chunks of aluminum with one of his CNC machines (amongst other things).

#973

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

If a flanges is milled for sch. 10, then it'll fit sch. 40 as they are the same OD. Don't worry about the slight ID difference for flow but if you must, a few min with a die grinder will fix that.

That's not as silly, and we only do silly here.

Mention something silly and hope the guy figures out the obvious smarter solution, which ultimately helps his self esteem.

That's not as silly, and we only do silly here.

Mention something silly and hope the guy figures out the obvious smarter solution, which ultimately helps his self esteem.

#975

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

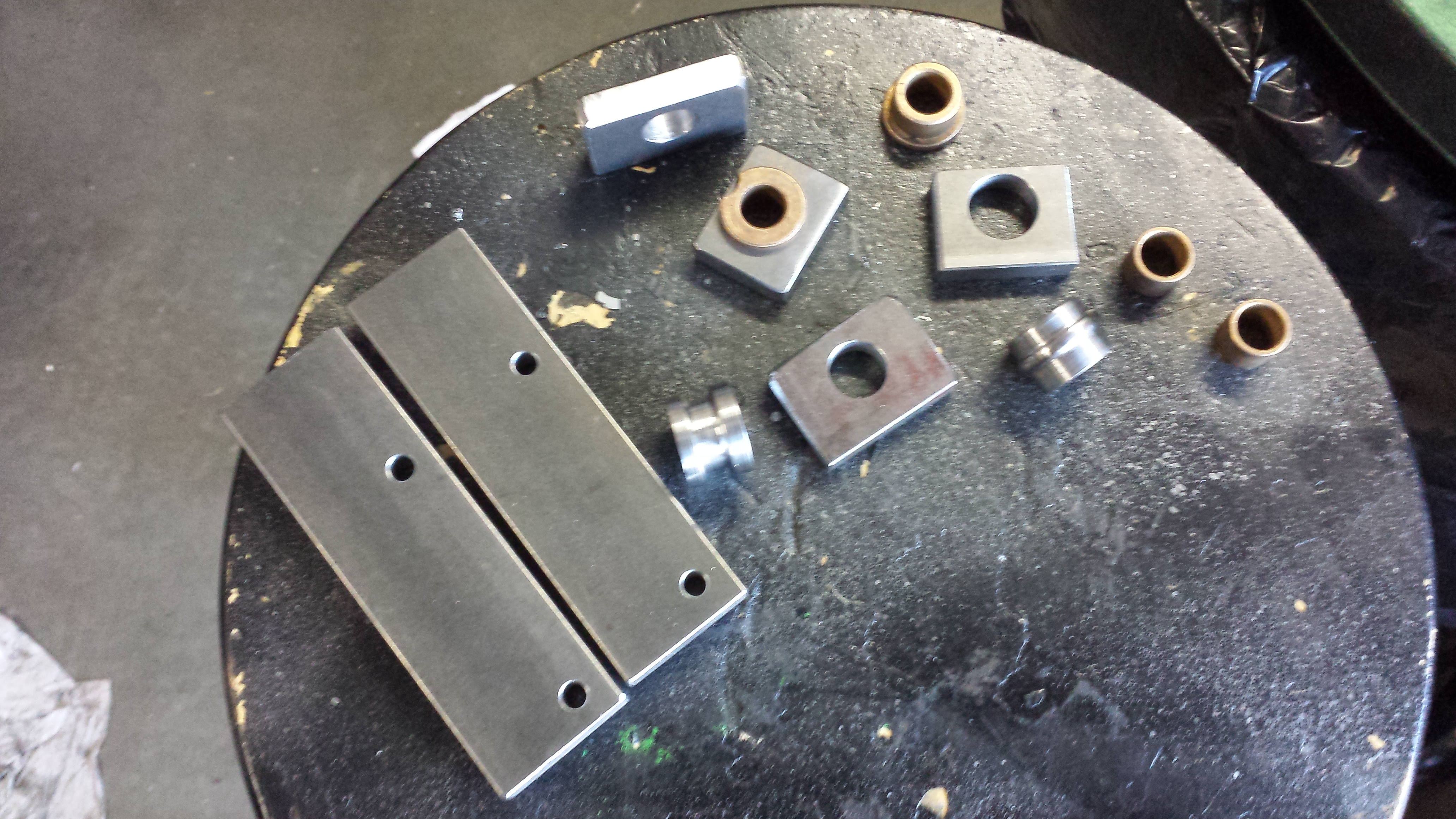

just finished it

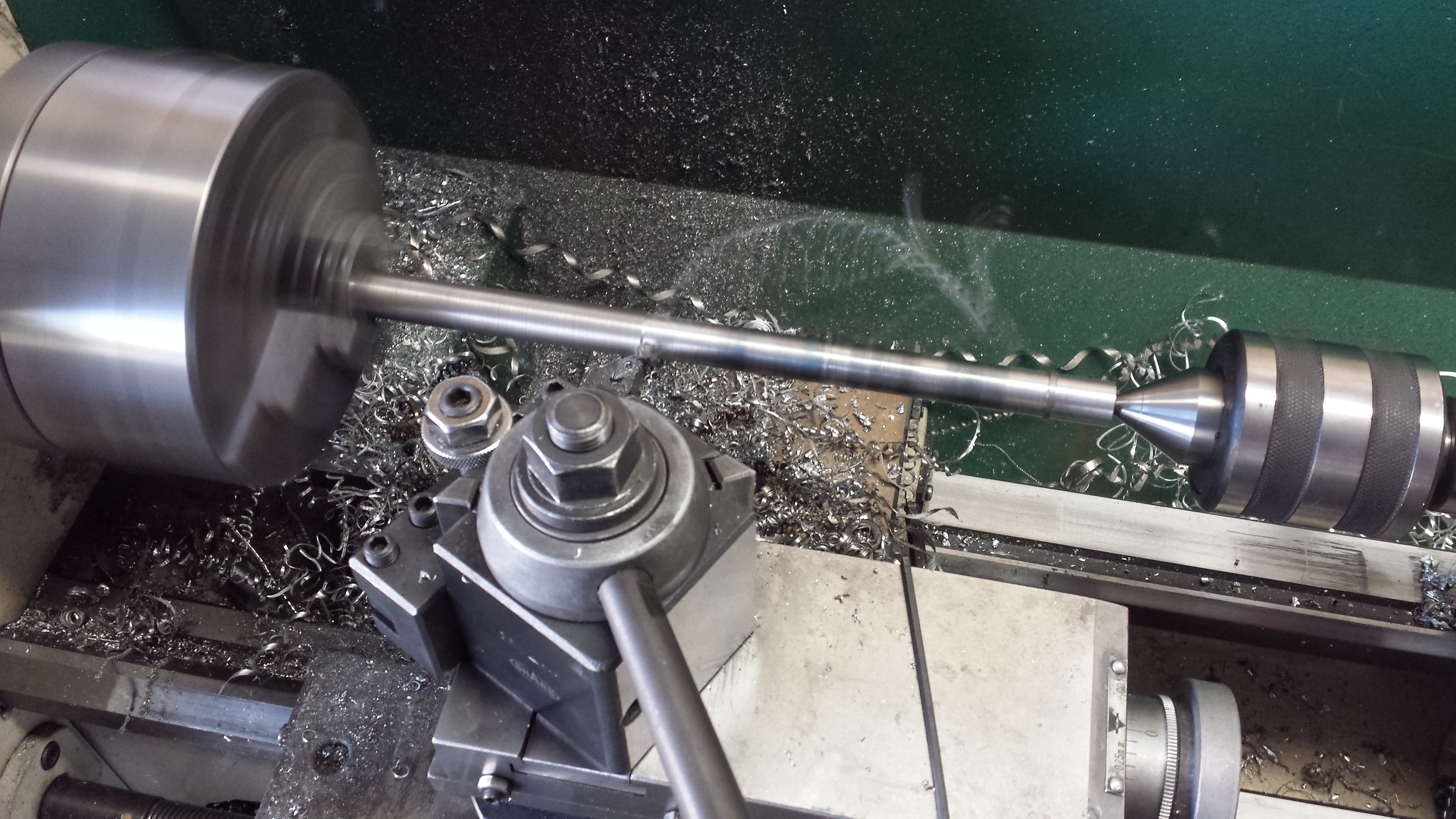

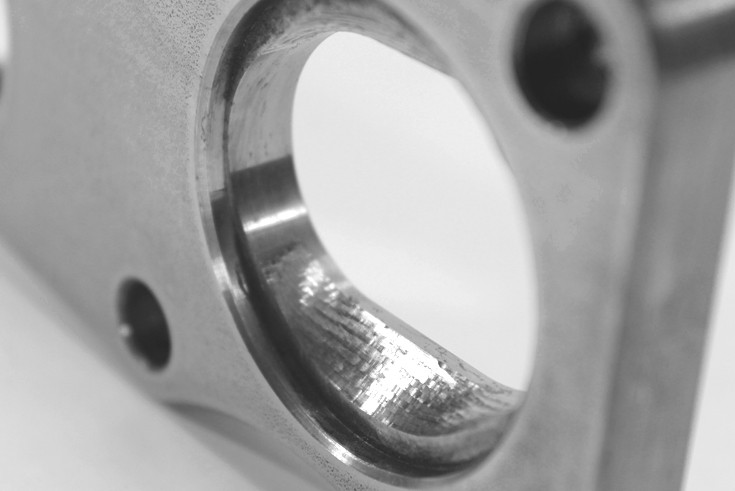

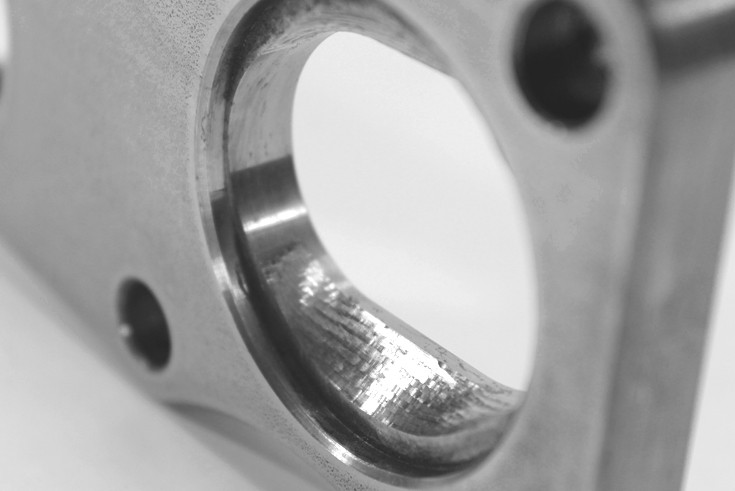

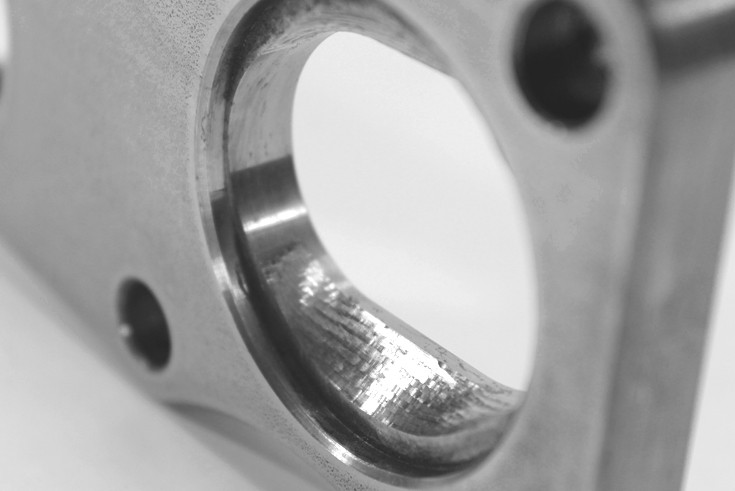

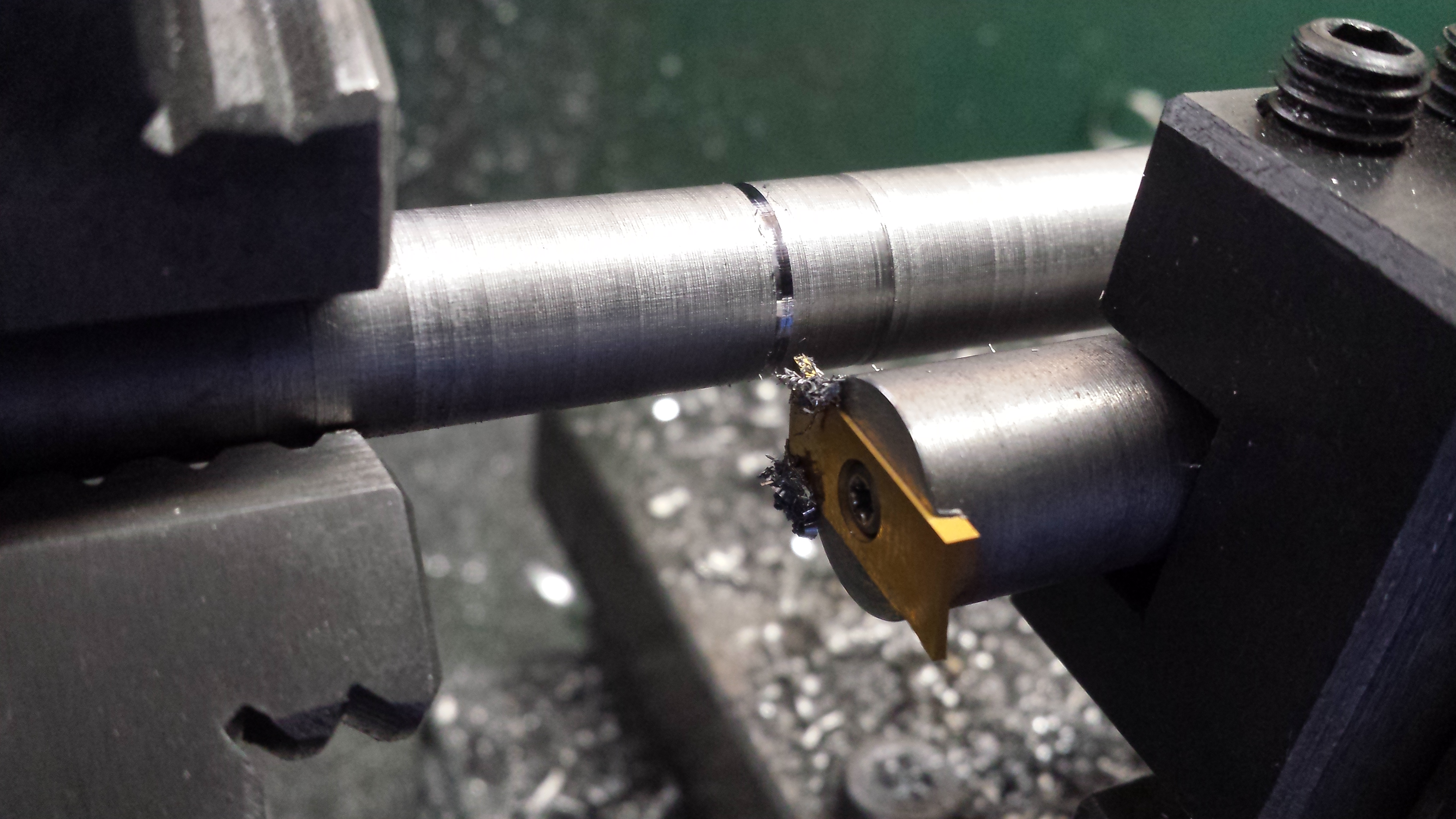

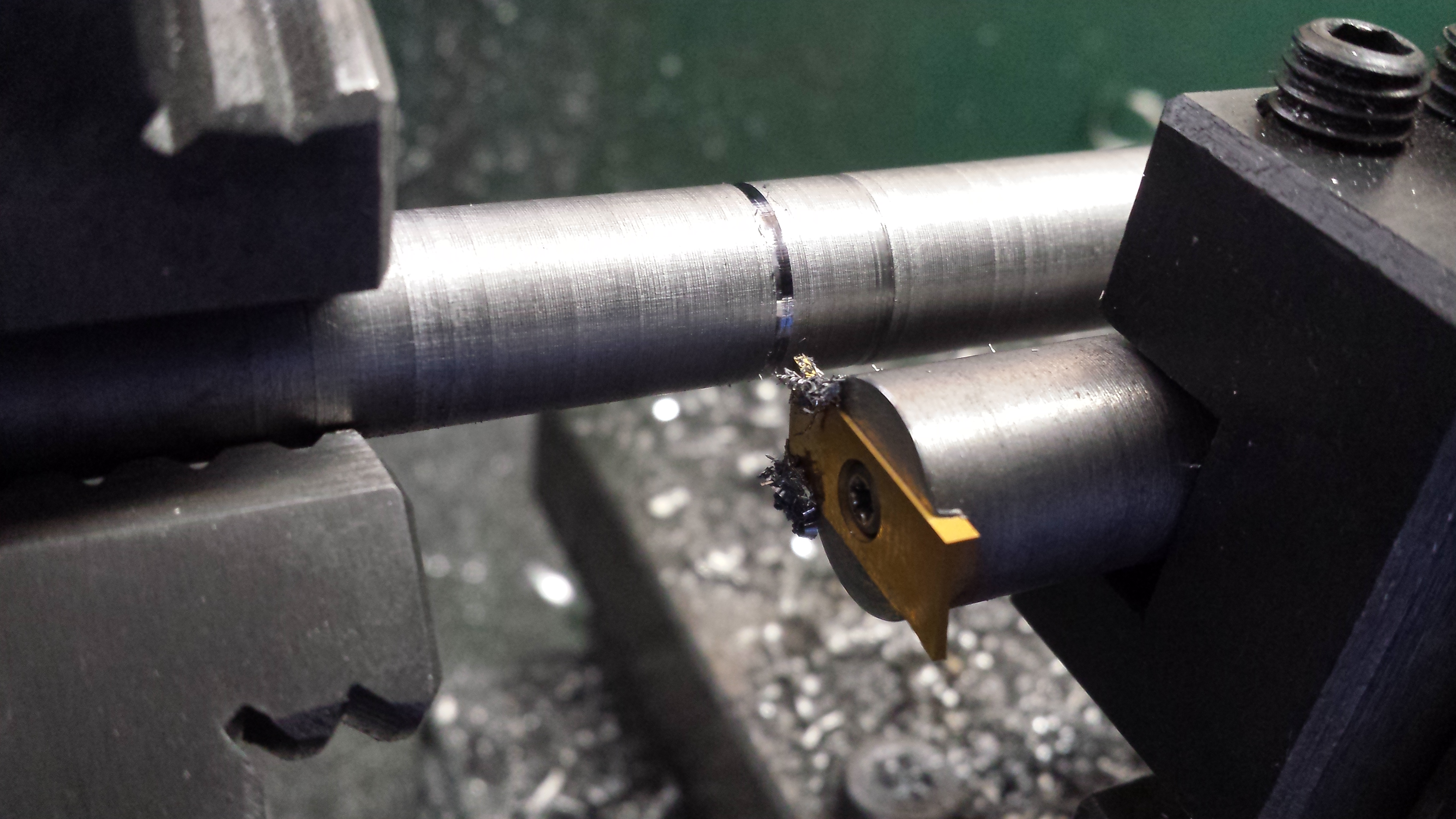

snap ring groove

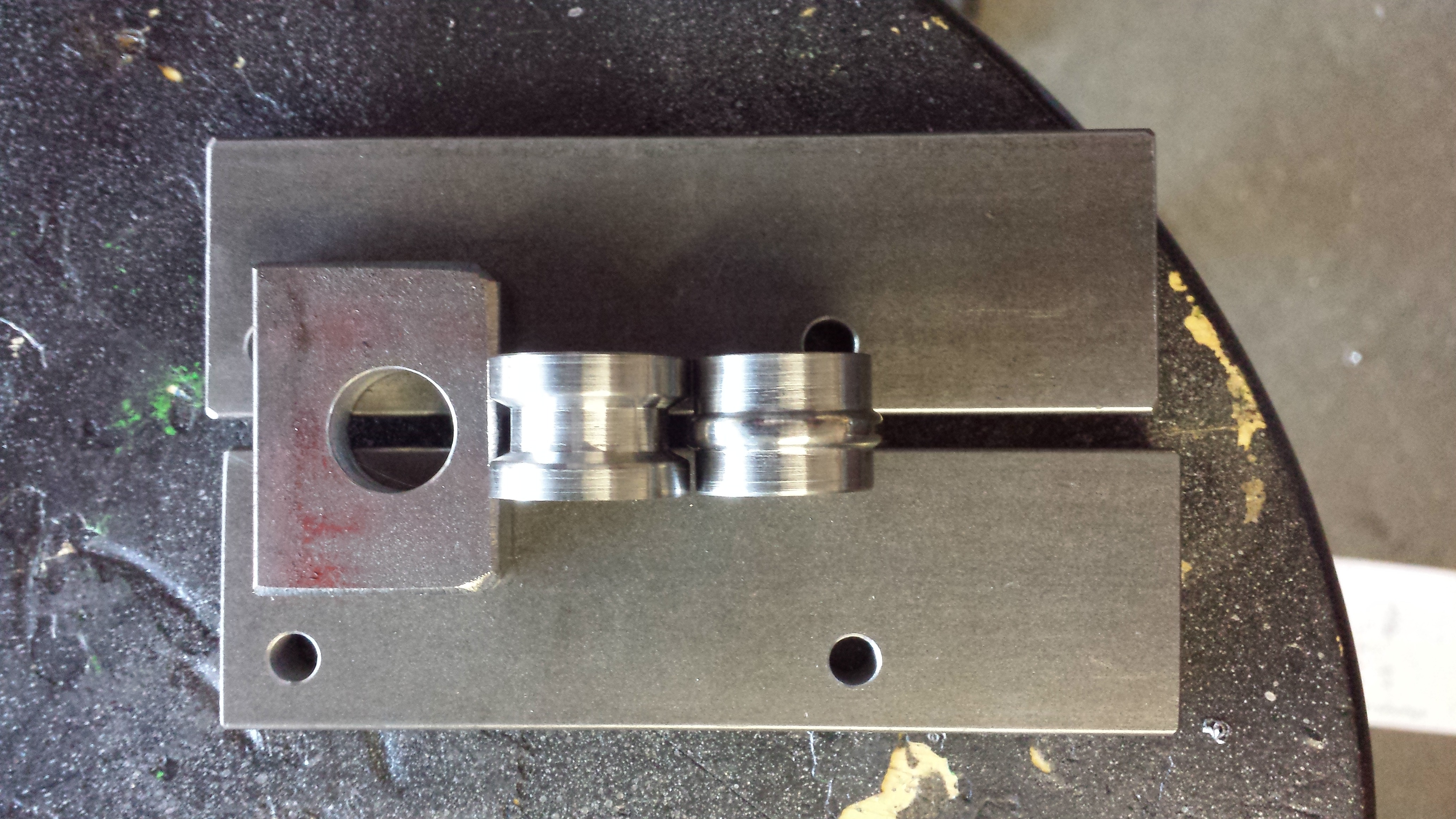

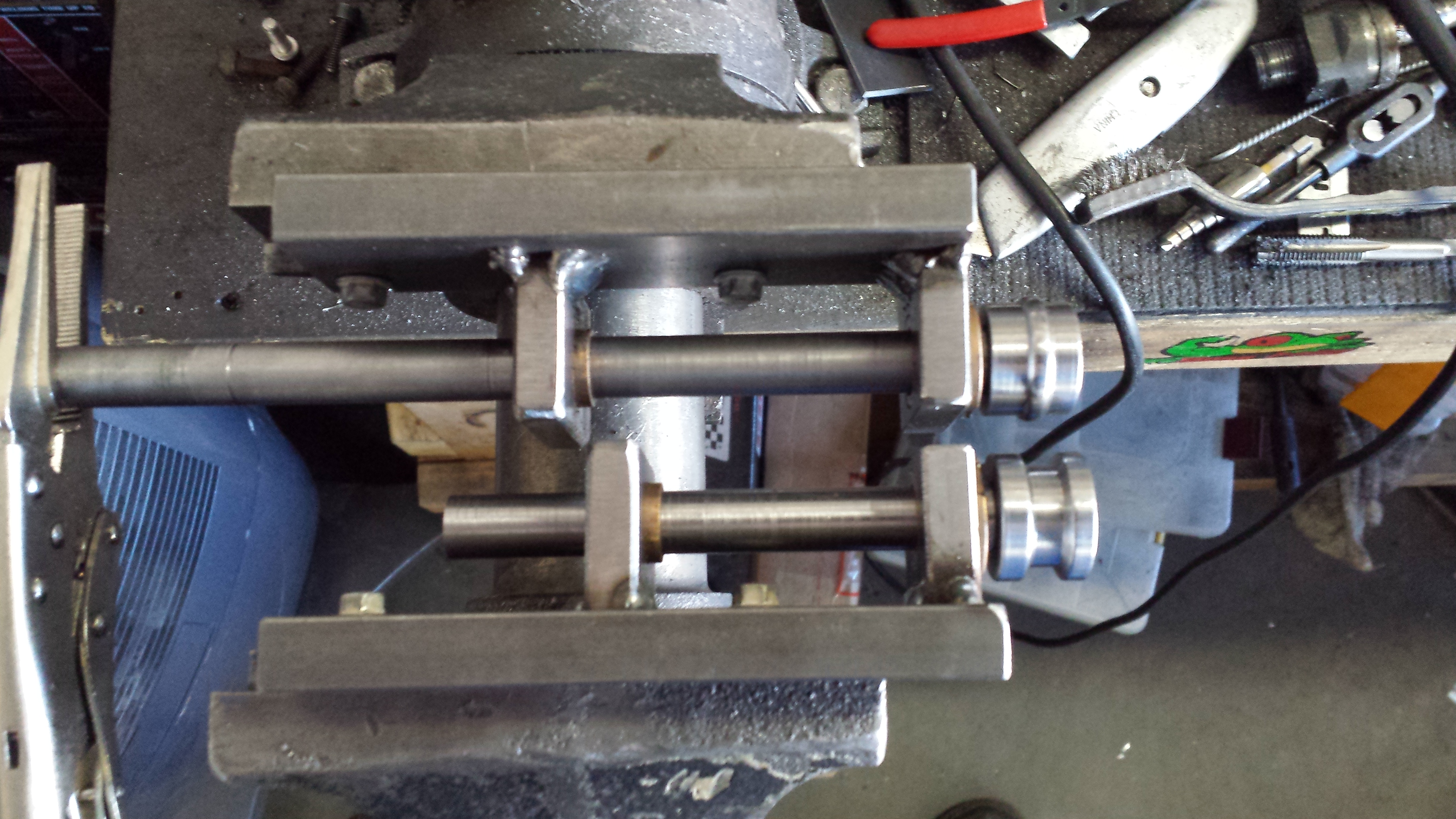

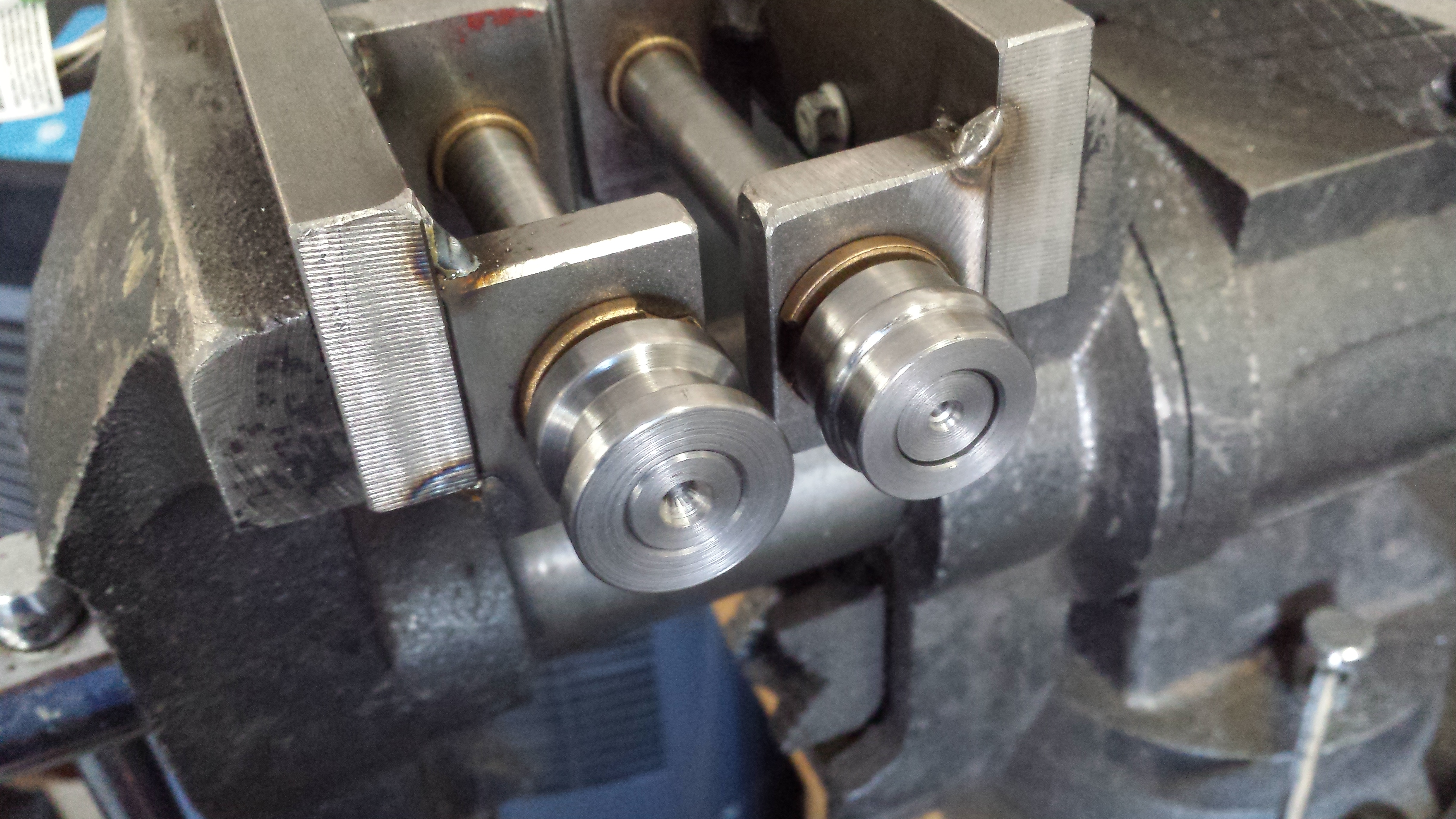

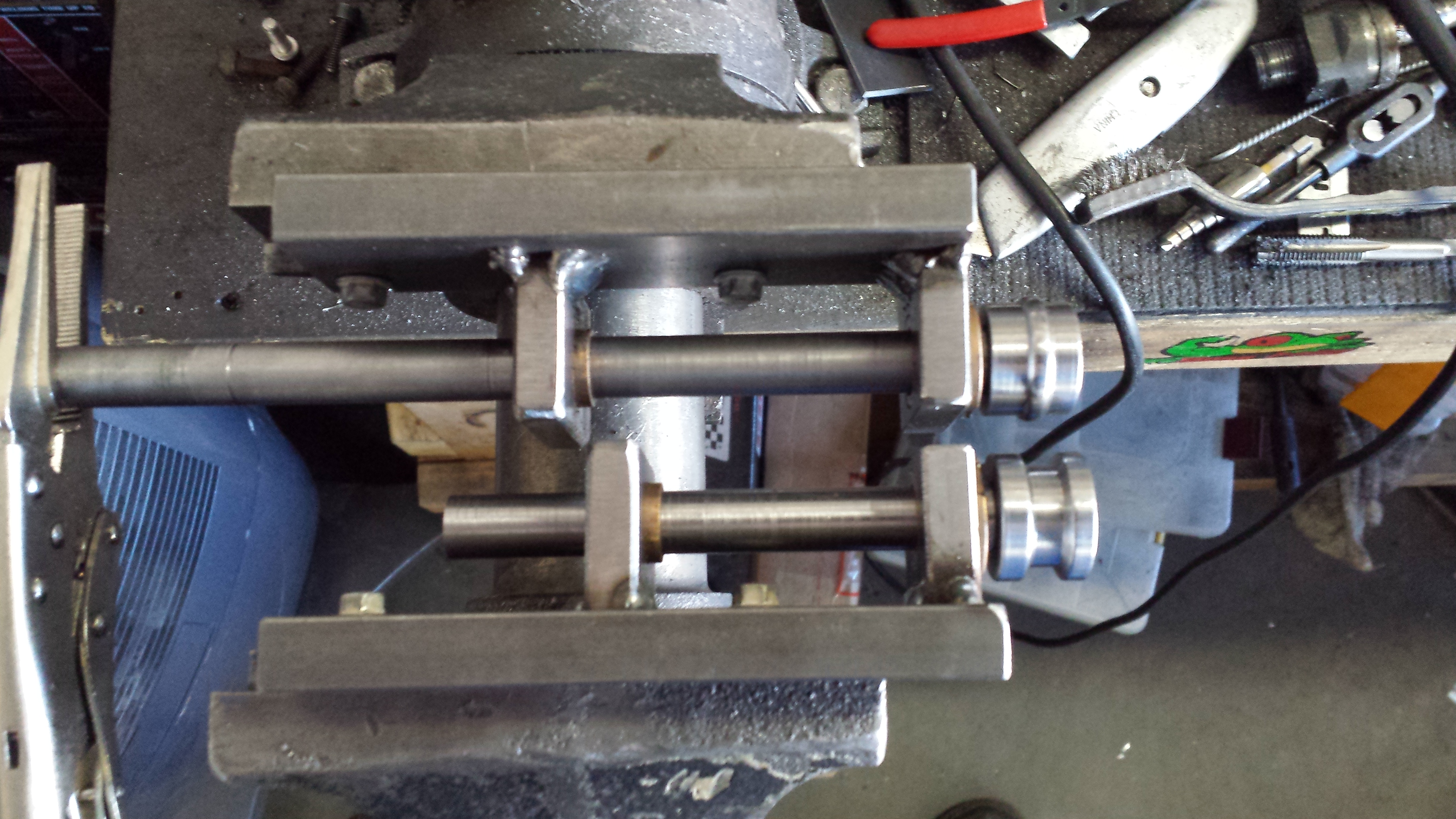

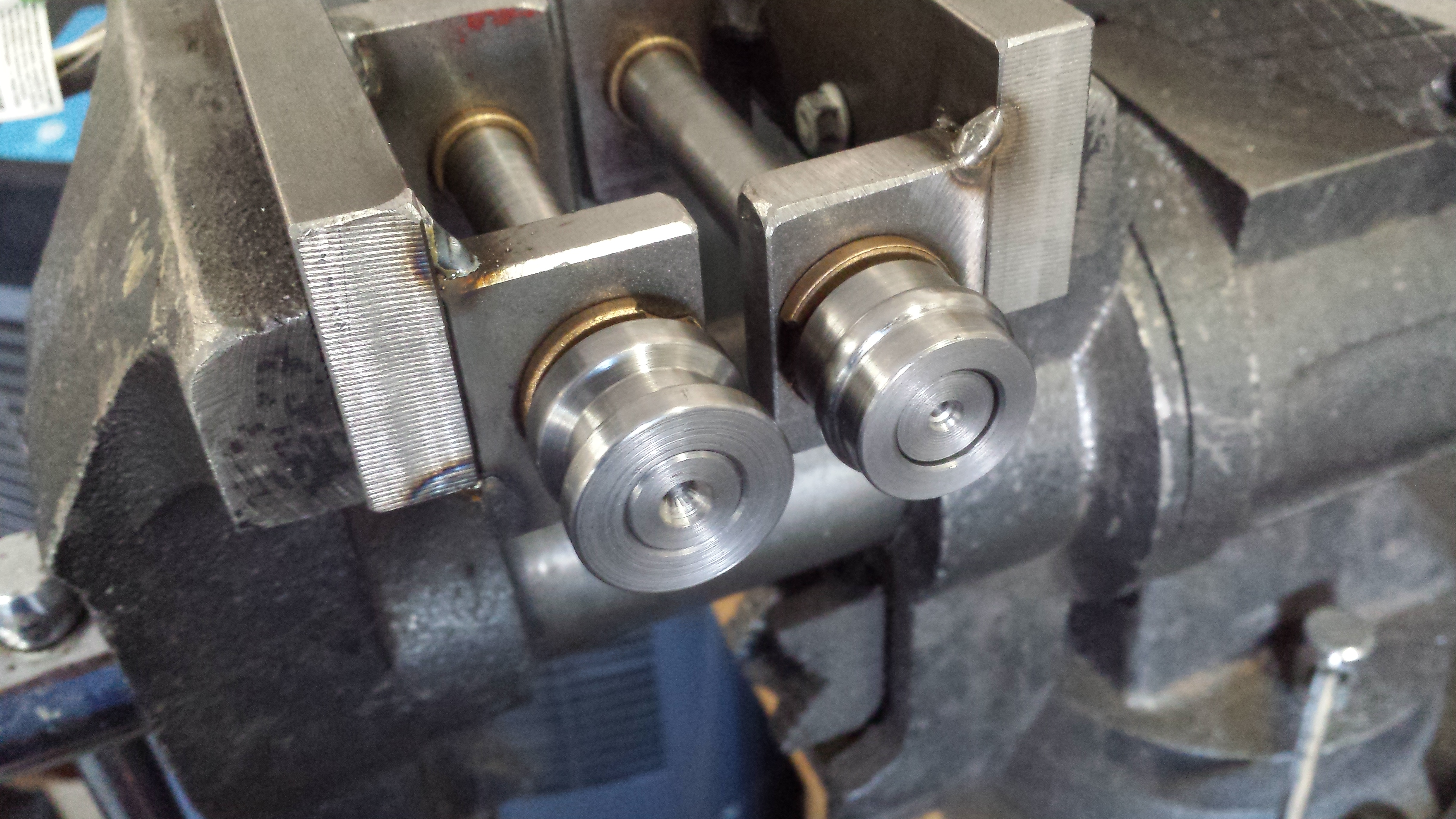

assembled

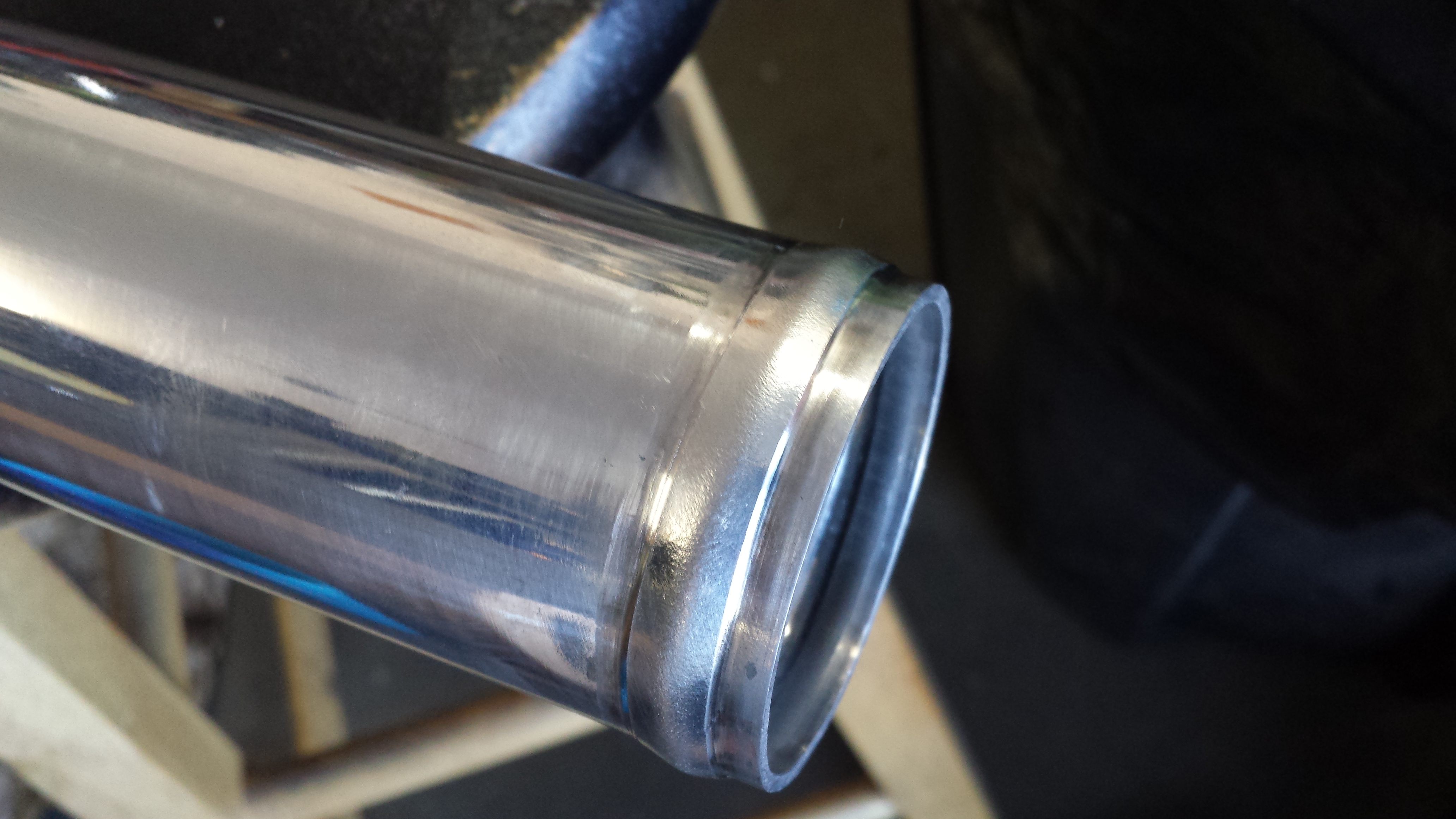

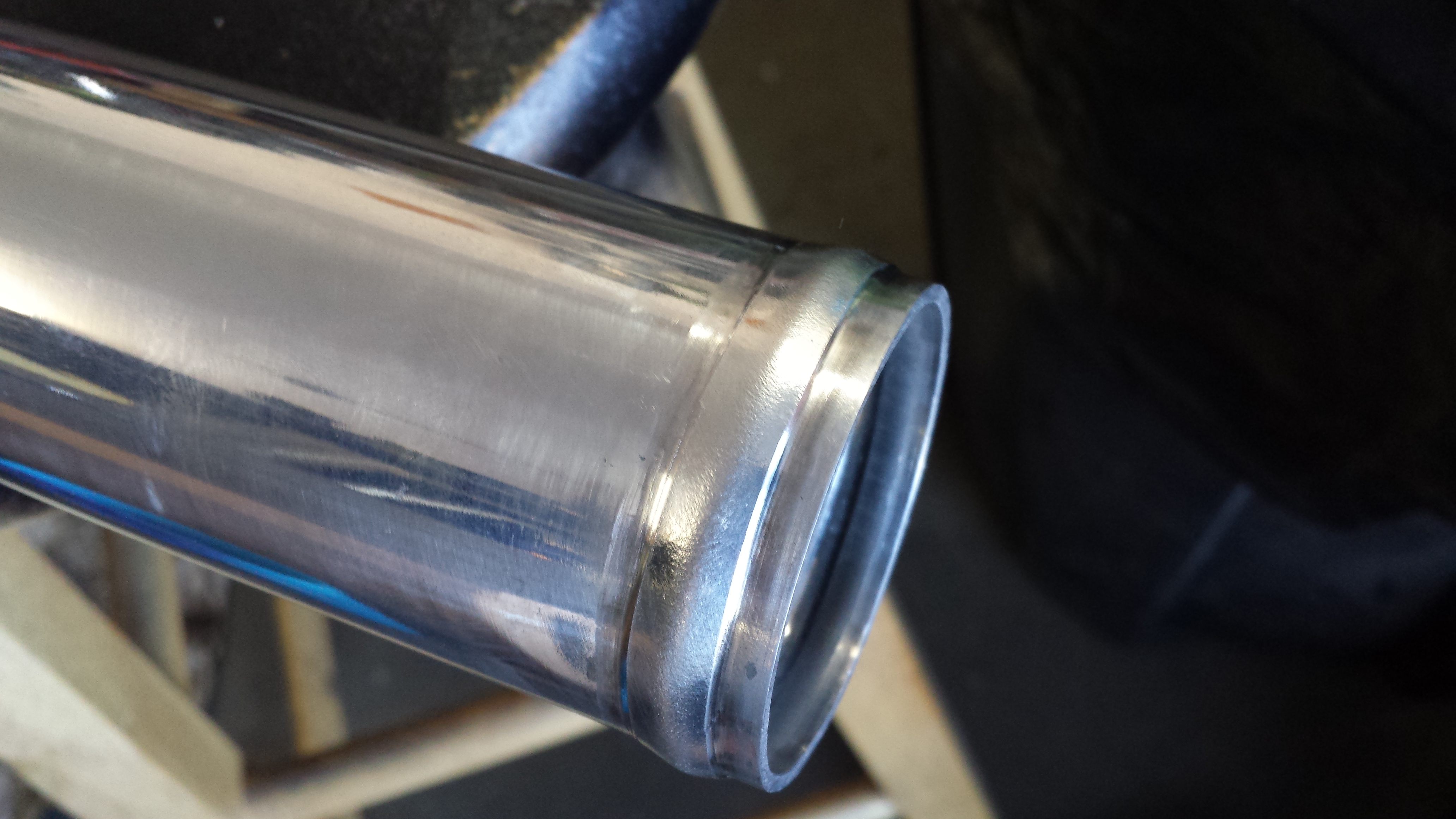

my vise is a total piece of ****; one of the jaws tries to climb the other when i roll it in one direction, so i can only roll in the other, the jaws are a little wiggly and i have to "steer" the pipe. in a nice vise, i bet it would be solid.

this was my first attmept. you can see how i left a sharp edge on the female die so it left a ridge. it has since been rounded off and the 2nd one came out much better. pics of 2nd attempt were potato.

snap ring groove

assembled

my vise is a total piece of ****; one of the jaws tries to climb the other when i roll it in one direction, so i can only roll in the other, the jaws are a little wiggly and i have to "steer" the pipe. in a nice vise, i bet it would be solid.

this was my first attmept. you can see how i left a sharp edge on the female die so it left a ridge. it has since been rounded off and the 2nd one came out much better. pics of 2nd attempt were potato.

#978

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

the gears provide more positive drive. i have to apply torque to the pipe and the "hand crank" without them. works fine for pipe this size. thicker walls and/or steel would require a set of gears or chain.