DIY manifold

#81

Shops like ours are ridiculously busy right now. We are quoting 10 weeks on CNC machining which was unheard of a few years ago. Six was as far out as you could push someone the entire last decade.

#83

Senior Member

Thread Starter

iTrader: (5)

Join Date: Sep 2009

Location: Lompoc, CA

Posts: 577

Total Cats: 13

That's pretty awesome. I'm not convinced I want to use Weir-tech's turbo inlet flange. The hole in the center is the same size as the gasket, the problem is, the turbo inlet is considerably smaller than the gasket so there is a big step down. I can't decide if I want to match the size to the turbo or port the exhaust housing.

#85

Senior Member

Thread Starter

iTrader: (5)

Join Date: Sep 2009

Location: Lompoc, CA

Posts: 577

Total Cats: 13

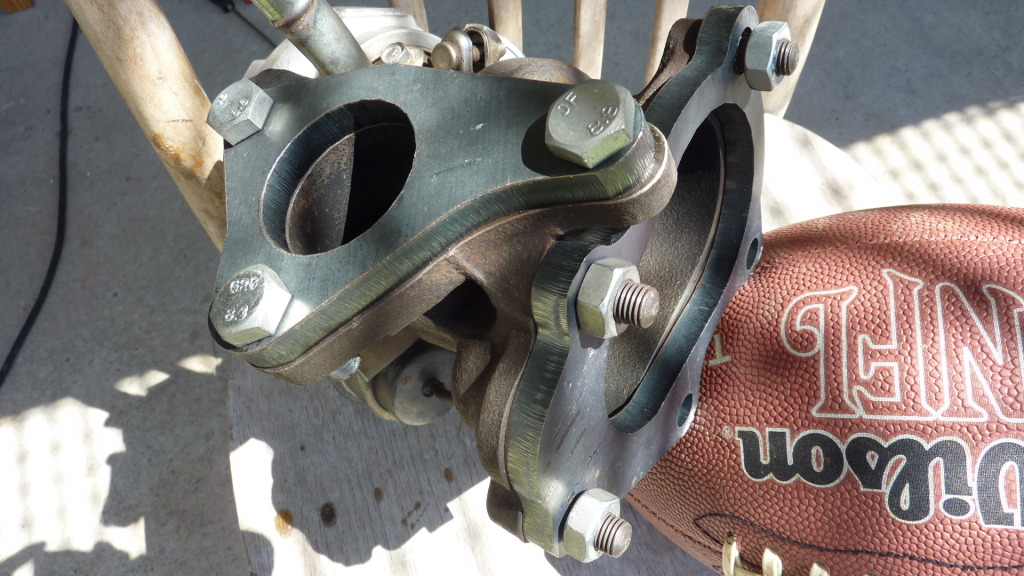

More progress... well actually progress has been pretty steady, I've just been too lazy to upload pics. But here they are.

First I fit this piece in there.

Then I made another one that is a pretty close copy but fits a little better.

Then I cut two giant holes in the first two pretty pipes I made, which I forgot to take a picture of. But it was incredibly frustrating and the last thing I wanted to do was stop and take pictures. So then I got all the pipes put back together and started the real welding today.

Autogenous root pass that I'm pretty proud of.

And another, along with a started cap pass that I'm also pretty happy with.

And I ended the day with a fair bit welded together.

First I fit this piece in there.

Then I made another one that is a pretty close copy but fits a little better.

Then I cut two giant holes in the first two pretty pipes I made, which I forgot to take a picture of. But it was incredibly frustrating and the last thing I wanted to do was stop and take pictures. So then I got all the pipes put back together and started the real welding today.

Autogenous root pass that I'm pretty proud of.

And another, along with a started cap pass that I'm also pretty happy with.

And I ended the day with a fair bit welded together.

#99

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I missed this thread until now :( Very very nice job!

In the beginning I would have said that I have had bad luck with Weirtech's mild flanges, but from the pics it looks like he is back to whatever material he used to have. The last few I bought were a hot rolled? material with a bunch of slag coating each side, and on the inside of each hole from his plasma cutter, that would have to be ground off and even then still got into the welds. Major PITA. Like...4 hours to weld the pipes to the head flange instead of 40 minutes PITA. Once you get the bubblies in your weld you would have to bust out the die grinder and remove all of it, try again, etc. And that's not fun if it's on the inside of a bend between the pipe and the flange

But your pics show a nice shiny almost tumbled surface finish, shouldn't be a problem.

But your pics show a nice shiny almost tumbled surface finish, shouldn't be a problem. I shipped elesjuan my last $20 crap mild head flange yesterday USPS flat rate box $11. I've shipped an entire manifold, a 90deg section of 3" pipe, and a downpipe flange in the same box for the same price, but it's the smallest box a head flange will fit in :(

My limited experience with job shops for your flange quotes...you definitely get what you pay for. I've dealt with only a half dozen or so, and quality is directly related to price. Personally, I'd rather pay the $80+ for a CNC'd flange or a quality waterjetted flange than $20 for a plasma or rusty poor surface finish WJ flange or whatever that needs XXX hours to prep.

EDIT: It looks like your weirtech head flange may need some cleaning up, I can't tell. But in this pic (I know it's not yours but shows what I"m talkign about), all the bluegreen-ish colored coating, all that ---- needs to come off where you will be welding else your welds will make your life miserable. At least that's my experience, maybe I'm doing something wrong

How did your tacks go? Any splitter splatter?

How did your tacks go? Any splitter splatter?

Must be the kid wearing his sisters jeans..

Must be the kid wearing his sisters jeans..