DIY manifold

#162

Senior Member

Thread Starter

iTrader: (5)

Join Date: Sep 2009

Location: Lompoc, CA

Posts: 577

Total Cats: 13

Dunno... I like your fancy drawing though. The problem was that Weir tech's turbo inlet flange was bigger than stock. So instead of choking it down somehow, I figured porting the housing would give me better results. Plus, more spools.

#163

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,898

Total Cats: 399

I use a harborfreight bearing press to ovalize the pipes. Super simple. I also do it once the manifold is finished.

1.5 sch. 40 matches the 1.6 & 1.8 ports pretty damn close once oval, they are a little bigger. 1.25" is on the small side but should be perfectly fine if you can handle a die grinder to smooth out the flange to the pipe inside at the flange. Kinda like that the 3D cnc flanges look like but doing it manually and after it's all welded, smooth it all out. It doesn't take long with a good agressive bit. I have only made one 1.25" manifold for a local customer, log style, super low budget. I have always wanted to make a 1.25" manifold for myself and run them back to back because i feel the 1.5" is a little large, but never got around to it.

1.5 sch. 40 matches the 1.6 & 1.8 ports pretty damn close once oval, they are a little bigger. 1.25" is on the small side but should be perfectly fine if you can handle a die grinder to smooth out the flange to the pipe inside at the flange. Kinda like that the 3D cnc flanges look like but doing it manually and after it's all welded, smooth it all out. It doesn't take long with a good agressive bit. I have only made one 1.25" manifold for a local customer, log style, super low budget. I have always wanted to make a 1.25" manifold for myself and run them back to back because i feel the 1.5" is a little large, but never got around to it.

#165

Senior Member

Thread Starter

iTrader: (5)

Join Date: Sep 2009

Location: Lompoc, CA

Posts: 577

Total Cats: 13

Well the manifold is finished. It's all welded up, ported out the sharp edges and cleaned up the openings, all that's left is a light resurfacing of the flanges. The turbo doesn't hit the block, and fabbing the downpipe should be stupid easy. The wastegate actuator is a bit close to the subframe, but with some stiffer mounts, it shouldn't be a problem.

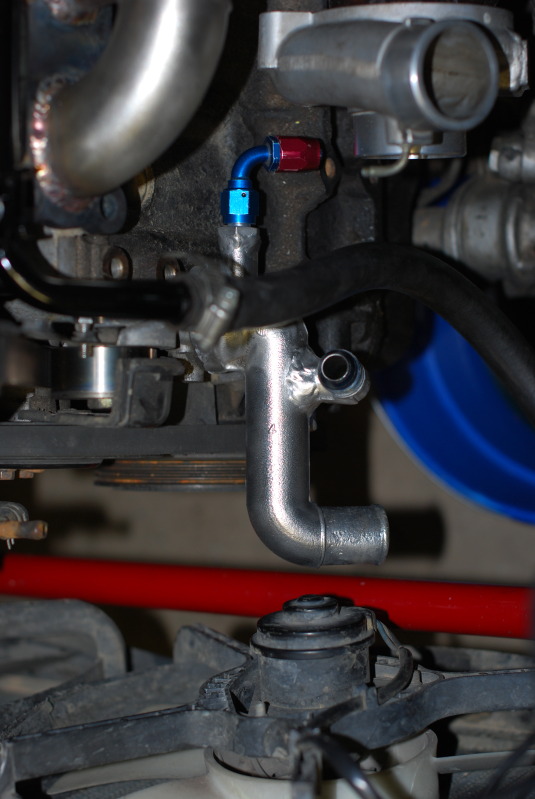

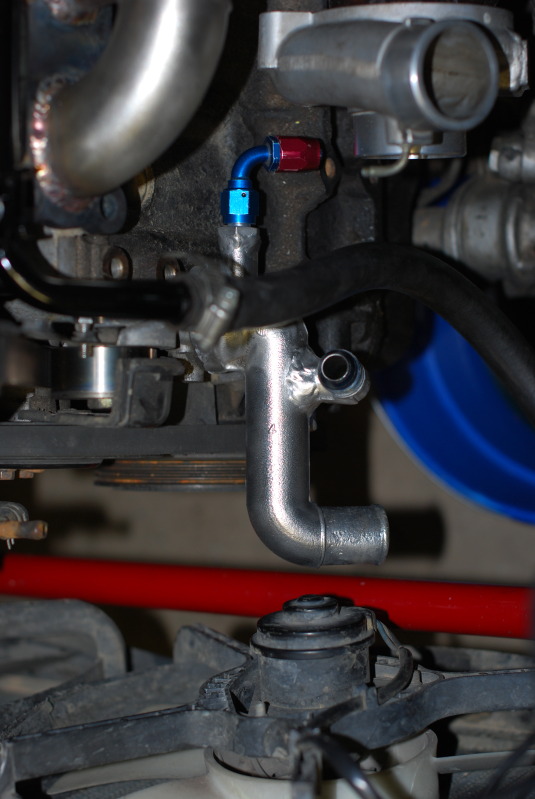

I also started on all the rest of the stuff that has to be relocated, rebuilt or otherwise changed. You can see my solution for the heater core return in these pics. It's just two stock heater core hard lines welded together in strategic ways. I'm rather pleased with it, it fits well and is hard mounted. My heater core is already converted to an NB aluminum unit with -10 push lock hose. The curly-q line will get changed soon too. It was like that to fit over/around the supercharger.

And here's what I did with the stock mixing manifold. Flipped it around, welded a -10 90* fitting to it for the heater core, a -6 for the turbo return, and capped off the stock heater core port. I'm still waiting on the -10 push lock fitting to show up to finish it. I've got a slick plan in mind for the turbo coolant feed, but I'll share that later after the parts arrive and I know it will work.

I also started on all the rest of the stuff that has to be relocated, rebuilt or otherwise changed. You can see my solution for the heater core return in these pics. It's just two stock heater core hard lines welded together in strategic ways. I'm rather pleased with it, it fits well and is hard mounted. My heater core is already converted to an NB aluminum unit with -10 push lock hose. The curly-q line will get changed soon too. It was like that to fit over/around the supercharger.

And here's what I did with the stock mixing manifold. Flipped it around, welded a -10 90* fitting to it for the heater core, a -6 for the turbo return, and capped off the stock heater core port. I'm still waiting on the -10 push lock fitting to show up to finish it. I've got a slick plan in mind for the turbo coolant feed, but I'll share that later after the parts arrive and I know it will work.

#166

WAITWUT?

All of them resulted in a quick car and win all around

That looks great man, very nice. Same as my 1st manifold, but pointing down instead of up. Same design though. Your downpipe path will be MUCH better than mine though, of course.

Good job. You're going to love the torque onset of that turbo. It hits very hard on the subarus.

All of them resulted in a quick car and win all around

Good job. You're going to love the torque onset of that turbo. It hits very hard on the subarus.

#167

^ Nice mani! Just a comment, but I'm looking forward to building the next one now that I have a plasma cutter. Curious to see how much easier/faster it will be to cope the stainless weld els. It was slow going cutting and grinding. Going to be a while, though. Have a lot to do first.

On another note, once CAD data would be worked out on a simple mani a shop with a 4 axis tube laser could crank out a bulk batch of cut weld els that could sell as a kit. I'd think it could be as low as $100 for the weld el pieces, $50 for flanges. $200 weld-it-yourself kit would likely generate some interest if it was truly "jig and weld" ready.

On another note, once CAD data would be worked out on a simple mani a shop with a 4 axis tube laser could crank out a bulk batch of cut weld els that could sell as a kit. I'd think it could be as low as $100 for the weld el pieces, $50 for flanges. $200 weld-it-yourself kit would likely generate some interest if it was truly "jig and weld" ready.

#171

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

No no, I should start another thread. But this time full of win, rather than MY current full of fail thread in the supercharger section

Didn't Renown try to sell us this a while back?

I know this would sell, I'd have bought one. Id recommend doing it in mild though, rather than stainless, opens the market for us guys who can't/don't TIG

And I agree, NICE WORK! I just hope mine comes out even half that nice. I'm interested to see what you have in mind for the coolant lines.

So my turbo noobness is going to show through pretty hard here, but reading through the Garrett site they say that the "feed" side for coolant should be lower than the "return" side to aid in natural coolant convection after the engine is turned off. Is that really an issue, or is it more of a "best practices" thing?

On another note, once CAD data would be worked out on a simple mani a shop with a 4 axis tube laser could crank out a bulk batch of cut weld els that could sell as a kit. I'd think it could be as low as $100 for the weld el pieces, $50 for flanges. $200 weld-it-yourself kit would likely generate some interest if it was truly "jig and weld" ready.

I know this would sell, I'd have bought one. Id recommend doing it in mild though, rather than stainless, opens the market for us guys who can't/don't TIG

And I agree, NICE WORK! I just hope mine comes out even half that nice. I'm interested to see what you have in mind for the coolant lines.

So my turbo noobness is going to show through pretty hard here, but reading through the Garrett site they say that the "feed" side for coolant should be lower than the "return" side to aid in natural coolant convection after the engine is turned off. Is that really an issue, or is it more of a "best practices" thing?

Last edited by EO2K; 10-24-2012 at 01:09 PM.

#172

I am going to build a manifold for my car, it will be a 99 or VTT motor on a 99 car w AC and PS.

I am wondering if anyone has built a forward top mounted EFR turbo maninifold? I'd like to tilt the turbo a little to point the exhaust down about 10-15 degrees to make it easier to route the 3"down pipe since the EFR turbo is pretty long.

Another question is if this heavy turbo should have a secondary mounting point to help it from stressing and cracking the manifold?

Here are some pics of the manifold I built for a 1.6 this summer

Thanks for he advise. Harold

I am wondering if anyone has built a forward top mounted EFR turbo maninifold? I'd like to tilt the turbo a little to point the exhaust down about 10-15 degrees to make it easier to route the 3"down pipe since the EFR turbo is pretty long.

Another question is if this heavy turbo should have a secondary mounting point to help it from stressing and cracking the manifold?

Here are some pics of the manifold I built for a 1.6 this summer

Thanks for he advise. Harold

#173

I dont think anyone did a top mount efr yet, you should, you certainly seem to have the fab skills for it.

I'm not sure i'd be comfortable tilting a super expensive ball bearing turbo like that, thought you probably would be "OK" doing it as long as it was a minor angle like you mentioned.

Why not do it ABSURD style like the one you just posted? Seems like that is the best design yet

I'm not sure i'd be comfortable tilting a super expensive ball bearing turbo like that, thought you probably would be "OK" doing it as long as it was a minor angle like you mentioned.

Why not do it ABSURD style like the one you just posted? Seems like that is the best design yet

#174

I was hoping to make a manifold like the one I copied from Tim for the 1.6 since it is so much easier to make and has great low end performance, but when I got the turbo and put it in the car it is all very tight w the AC and PS.

Tim said that he made a fwd mount manifold and it had very good top end but lost some initial spooling, I'm hoping that by using the EFR and VVT motor and the shortest possible intake with WA IC like I made for my SC NA

I will gain some of the midrange lost to the fwd mount turbo and have a clean installation.

I will probably cut the engine bay drivers side corner like the V-8 conversions do and mock things up again once I have the motor back in the car in a month or two.

Tim said that he made a fwd mount manifold and it had very good top end but lost some initial spooling, I'm hoping that by using the EFR and VVT motor and the shortest possible intake with WA IC like I made for my SC NA

I will gain some of the midrange lost to the fwd mount turbo and have a clean installation.

I will probably cut the engine bay drivers side corner like the V-8 conversions do and mock things up again once I have the motor back in the car in a month or two.

#176

I tried my hand at welding again today. May not be making my own manifold LOL. I finally feel like I can modulate heat reasonably well, not like earlier attempts where it felt like an on/off switch, but still blew plenty of holes in what I was playing with. I figured that being a jeweler and brazing/welding precious metals for 23 years would at least get me a decent head start. Nope. I'd almost rather pay a pro at this point. My hat is off to anyone in here who has fabbed their own manifold. Not giving up the dream yet, but damn, I'm close.

#177

Using a w/a ic on such a nice setup is blasphemy.

Also the length of the intake/piping will have very minimal effect on your spool.

Also with a vvt motor and EFR turbo you should be getting RIDICULOUS fast spool and response. Also tim made a ac/ps compatible version of the ABSURDflow that cleared both. Why not go that route?

I think you're overthining this, and under-estimating efr/vvt. Even if you use a long tube mani, a super long intake, and super long piping, I bet you'll still spool faster than most folks here.

Also the length of the intake/piping will have very minimal effect on your spool.

Also with a vvt motor and EFR turbo you should be getting RIDICULOUS fast spool and response. Also tim made a ac/ps compatible version of the ABSURDflow that cleared both. Why not go that route?

I think you're overthining this, and under-estimating efr/vvt. Even if you use a long tube mani, a super long intake, and super long piping, I bet you'll still spool faster than most folks here.

#178

I guess that I'm getting old and have not enjoyed driving de-powered PS cars, I either hit my elbows on the door and seat when autocrossing or hate turning the wheel at low speed with fat stikey tires, I figured out a while back that my driving is a bigger handicap than 10lbs on the car so I rather keep the PS :(

Matthew,

If you are tug welding try to start by learning how to controll a puddle on a flat thick piece of stainless once you have that mastered you can start adding rood and then jointing parts together, I think that most people in this thread will agree that unless you earn minimum wage paying for a manifold is the cheaper way to go, I enjoy fabricating things so that is why I do it.

Good luck !

Matthew,

If you are tug welding try to start by learning how to controll a puddle on a flat thick piece of stainless once you have that mastered you can start adding rood and then jointing parts together, I think that most people in this thread will agree that unless you earn minimum wage paying for a manifold is the cheaper way to go, I enjoy fabricating things so that is why I do it.

Good luck !

#180

Matthew,

If you are tug welding try to start by learning how to controll a puddle on a flat thick piece of stainless once you have that mastered you can start adding rood and then jointing parts together, I think that most people in this thread will agree that unless you earn minimum wage paying for a manifold is the cheaper way to go, I enjoy fabricating things so that is why I do it.

Good luck !

If you are tug welding try to start by learning how to controll a puddle on a flat thick piece of stainless once you have that mastered you can start adding rood and then jointing parts together, I think that most people in this thread will agree that unless you earn minimum wage paying for a manifold is the cheaper way to go, I enjoy fabricating things so that is why I do it.

Good luck !