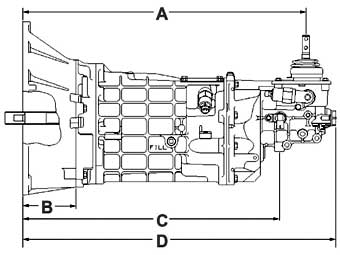

BP Bellhousing CAD drawing

#43

Guess I'll have to hit my buddy up for the details. We put a VW TDI (1.9l) on a supra 5 speed for a vovlo project and it worked flawlessly, what I don't remember is what we did for the shaft length. I'll see if I can get some info.

Interestingly, he just put a T5 in another volvo, rebuilt it and said it was a snap.

Huh, only useful pic I found:

and it wasn't that useful.

A large enough flatbed scanner is a quick way to make a template of something. :-)

Interestingly, he just put a T5 in another volvo, rebuilt it and said it was a snap.

Anyone have a t56 template...I can make one with that and tim's awesome .dxf.

Turning tim's into a cleaned up .dwg right now so I can feed it into MasterCAD for the waterjet later.

I'm seriously considering skipping the Torsen route and using the Lincoln LS rear end to be ready for LSx power later. Using a t56 tranny as well would be a no brainer if I could get away with not making a custom interim driveshaft and use the whole kit. Would depend on where the spacer-tranny mating plane ends up in relation to the V8 installs.

I will do one custom driveshaft during the life of this car, but two would be stupid.

EDIT: Quick search netted some files in post #4 here:

T56 bolt pattern drawing? - Turbobricks Forums

Will have to check to make sure it's what we're really looking for...I've never even seen a t56 in person.

NEVERMIND....THAT'S A FORD T5

Turning tim's into a cleaned up .dwg right now so I can feed it into MasterCAD for the waterjet later.

I'm seriously considering skipping the Torsen route and using the Lincoln LS rear end to be ready for LSx power later. Using a t56 tranny as well would be a no brainer if I could get away with not making a custom interim driveshaft and use the whole kit. Would depend on where the spacer-tranny mating plane ends up in relation to the V8 installs.

I will do one custom driveshaft during the life of this car, but two would be stupid.

EDIT: Quick search netted some files in post #4 here:

T56 bolt pattern drawing? - Turbobricks Forums

Will have to check to make sure it's what we're really looking for...I've never even seen a t56 in person.

NEVERMIND....THAT'S A FORD T5

Huh, only useful pic I found:

and it wasn't that useful.

A large enough flatbed scanner is a quick way to make a template of something. :-)

#44

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I got a Faro arm at work, that's what I used on the miata trans. I could do another trans...or I have plenty of LS blocks and small block ford blocks at work, I could faro the bell housing flange of each...would that help? We probably have any american V8 block...except a small block chevy (a big joke at work).

#46

ACME ADAPTERS Suzuki Samurai Turbo Diesel

I guess this is where the output shaft adapter came from, though the plate we made ourselves with a cheapy harbor freight plasma cutter and some wooden guides we made on a bandsaw.

I guess this is where the output shaft adapter came from, though the plate we made ourselves with a cheapy harbor freight plasma cutter and some wooden guides we made on a bandsaw.

#47

Elite Member

iTrader: (11)

Join Date: Jun 2007

Location: Overland Park, Kansas

Posts: 5,360

Total Cats: 43

T5s sell for 200$. T56's sell for 800 - 2000$ used I've seen. You can get an aftermarket Tremec branded TKO-600 which will hold 600+ # of torque. You can order a TKO straight out of jegs for less than 2000$ shipped IIRC, or buy a Tremec 3550 from a mustang owner for < 500$ used. I've seen straight cut gear sets, syncrodelete conversions, all sorts of goofy crazy ****.

Two HUGE HUGE advantages of the T series tremec style transmissions is unlike OUR unit the bellhousing is a separable piece. To compensate for extra added thickness of an adapter plate, just take the bell housing and cut off the engine side of the plate. Machine up a new engine mount for it, tig it on. The T5's input shaft is a 10 spline and is larger than ours, so a new one would have to be fabricated or a 10 spline clutch disk would need to be made, then have the shaft turned down slightly. Most T5s used cable clutch release, but specifically the bellhousing for the Ford Thunderbird TurboCoupe used a hydraulic slave cylinder and fork similar to our factory unit.

Also available in later model mustangs and not as durable is the T45. I'd stay away from these simply because they're just not as strong. Seriously doubt we'd break ANY of them though.

Borg Warner T5:

Tremec 3550:

Borg Warner T56:

The T56 might be a little harder to stuff in a miata 4 cylinder due to space requirements, but I've honestly never really measured them up side by side. There is really little difference between a Ford, Chevy, or Chrysler T56. IRRC there were two manufactures, Tremec made a few but more commonly was the Borg Warner. They're pretty stout transmissions, but you have to take care of them. Missing 1-2 shifts too many times will pretty well trash it. I've seen more than one F-Body person miss shifts too many times, overshift with improperly adjusted shift stops on aftermarket shifters, etc. Bends the shift forks pretty easily and requires a rebuild eventually. If you take your time and shift properly but swiftly you'll have very little problem with them.

One last thing that just came into mind. All of the above will require driveshaft modifications, and since our u-joints aren't user serviceable much like upper ball joints, you'll need output yolk from the ford unit, have it welded onto the end of your shaft, maybe cut down, whatever differential provisions on the other end. I know a good local driveline shop here in Kansas City Missouri who does EXCELLENT work if anyone needs a place to send theirs to. Took them a shaft, measurements, and what yolks were needed. They cut it down to length, welded on new ends, new u-joints, balanced it.. 135$. Took 3 days.

Just my random input to the transmission thread, sorry it has nothing to do with FWD application OP...

#48

Senior Member

Thread Starter

iTrader: (2)

Join Date: Oct 2007

Location: Northeastern CT

Posts: 547

Total Cats: 2

no problem, the fwd topic is a little OT for this forum anyway

the last time i heard from "the guy making the plate", he said he should be finished sometime this weekend.... i've got my fingers crossed that i'll hear from him soon, and that he will be shipping this week!

the last time i heard from "the guy making the plate", he said he should be finished sometime this weekend.... i've got my fingers crossed that i'll hear from him soon, and that he will be shipping this week!

#50

Senior Member

Thread Starter

iTrader: (2)

Join Date: Oct 2007

Location: Northeastern CT

Posts: 547

Total Cats: 2

more delays...

Apparently the drawing that TurboTim made with his faro arm a few months ago is somehow too far off to use. The machinist making my adapter cut a test piece on his CNC based on that pattern, and the crank centerline was off by 0.073". The bolt pattern on the oil pan section of the bellhousing is also slightly different between FWD/AWD and RWD, which i didnt realize.

Anyway, he had his BP pattern scanned on a CMM table and using that new pattern made up a sample adapter... close but no cigar, the crank centerline was still off by 0.010". He is making some final adjustments and should be finished soon.

Apparently the drawing that TurboTim made with his faro arm a few months ago is somehow too far off to use. The machinist making my adapter cut a test piece on his CNC based on that pattern, and the crank centerline was off by 0.073". The bolt pattern on the oil pan section of the bellhousing is also slightly different between FWD/AWD and RWD, which i didnt realize.

Anyway, he had his BP pattern scanned on a CMM table and using that new pattern made up a sample adapter... close but no cigar, the crank centerline was still off by 0.010". He is making some final adjustments and should be finished soon.

#51

Here is a .dxf of the bellhousing of my '92 5 speed. It is the raw data from the Faro arm. Sorry, I do not have time to go thru and make it all pretty-like.

Let me know if you need any other info on this, I may have measured it.

Thanks to Paul for hosting this.

Tim

http://www.inoneear.com/outtheother/MazdaBPTrans.DXF

Let me know if you need any other info on this, I may have measured it.

Thanks to Paul for hosting this.

Tim

http://www.inoneear.com/outtheother/MazdaBPTrans.DXF

Regards,

Miguel

#52

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

more delays...

Apparently the drawing that TurboTim made with his faro arm a few months ago is somehow too far off to use. The machinist making my adapter cut a test piece on his CNC based on that pattern, and the crank centerline was off by 0.073". The bolt pattern on the oil pan section of the bellhousing is also slightly different between FWD/AWD and RWD, which i didnt realize.

Anyway, he had his BP pattern scanned on a CMM table and using that new pattern made up a sample adapter... close but no cigar, the crank centerline was still off by 0.010". He is making some final adjustments and should be finished soon.

Apparently the drawing that TurboTim made with his faro arm a few months ago is somehow too far off to use. The machinist making my adapter cut a test piece on his CNC based on that pattern, and the crank centerline was off by 0.073". The bolt pattern on the oil pan section of the bellhousing is also slightly different between FWD/AWD and RWD, which i didnt realize.

Anyway, he had his BP pattern scanned on a CMM table and using that new pattern made up a sample adapter... close but no cigar, the crank centerline was still off by 0.010". He is making some final adjustments and should be finished soon.

Clairetoo used my .dxf when she did her KL to miata trans adapter. That works great.

Sorry it didn't work out for you!

Sorry it didn't work out for you!If you want to risk using my perhaps incorrect .dxf, PM me your email address, or email me. You can find my email address if you try.

#53

another dead thread revival is the BP bellhousing dxf still around? I'd love to get a copy

dead thread revival...

after TurboTim was kind enough to make this DXF for me, i was having a hell of a time getting someone to do the toyota bellhousing for a reasonable price. in the meantime i kept talking to people about this, and eventually found somone who's working on the same thing for his BPT powered 323 GTX rally car.

the best part... he works at a cnc machine shop in CA. he was able to use a CMM on the toyota bellhousing, and right now is working on combining the two patterns into a usable adapter plate! i'm just going to purchase the finished piece from him, rather than making my own. custom mounts should be no big deal, and i already have all the other parts purchased aside from a clutch disc.

almost there (i hope)!

after TurboTim was kind enough to make this DXF for me, i was having a hell of a time getting someone to do the toyota bellhousing for a reasonable price. in the meantime i kept talking to people about this, and eventually found somone who's working on the same thing for his BPT powered 323 GTX rally car.

the best part... he works at a cnc machine shop in CA. he was able to use a CMM on the toyota bellhousing, and right now is working on combining the two patterns into a usable adapter plate! i'm just going to purchase the finished piece from him, rather than making my own. custom mounts should be no big deal, and i already have all the other parts purchased aside from a clutch disc.

almost there (i hope)!

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-26-2018 11:00 PM