Help me hook up my air compressor

#41

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

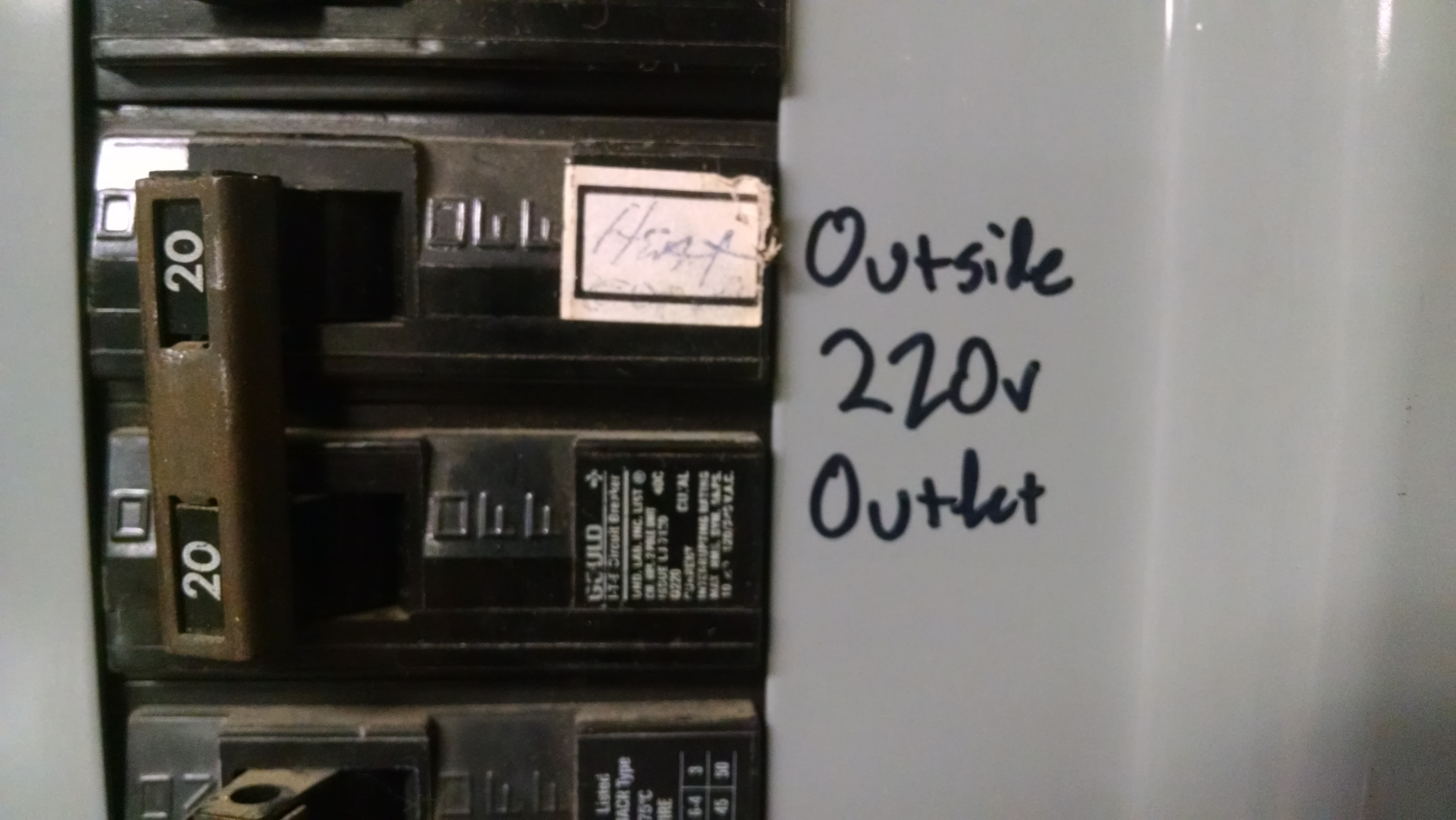

I just learned something new, some manufacturers have different rated beakers for different inrush current loads, basically different trip characteristics.

That's probably a AC plug, why else would it be outside? It's probably got a inductive load curve breaker, for motors.

There's another curve that apparently tolerates inrush currents for longer, but apparently it can damage inductive loads like motors allowing them to operate outside spec for longer than necessary.

Since it has a AC compressor breaker, or probably the standard residential "c" curve breaker, you might be able to switch to the "d" curve breaker. It would still pop at 12gauge safe levels, but it might be the extra bit it needs to get running if it won't now.

That's probably a AC plug, why else would it be outside? It's probably got a inductive load curve breaker, for motors.

There's another curve that apparently tolerates inrush currents for longer, but apparently it can damage inductive loads like motors allowing them to operate outside spec for longer than necessary.

Since it has a AC compressor breaker, or probably the standard residential "c" curve breaker, you might be able to switch to the "d" curve breaker. It would still pop at 12gauge safe levels, but it might be the extra bit it needs to get running if it won't now.

#43

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,052

Total Cats: 6,615

Originally Posted by everyone

(lots of discussion about motor direction.)

#47

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,052

Total Cats: 6,615

I edited nothing.

I was also a little slow to hit the "submit" button on that last post, as the whole single-phase vs. three-phase debate has long since been addressed. A helpful note for those not so educated: in everyday practice, single-phase and split-phase are the same thing. The standard for residential power distribution in the US is 240v single-phase with a center tap, and to get 120v, we "split" it by only using one of the windings relative to the center tap, which is connected to ground (literally, to a metal rod pounded into the soil) and, in modern installations, also distributed as an isolated "neutral" conductor. And regardless of which half you take, the other half is always equally opposite. When placing breakers in a splt-phase panel, there are no absolute rules for phase positioning. You just try to keep the 120v stuff roughly balanced (half of it on one leg, and half on the other), and it does not matter in the least whether the 240v breakers wind up on black-red or red-black. You could have two 240v outlets right next to one another on a wall which are wired "opposite" one another with regard to the incoming main, and it doesn't matter one bit.

(Well, unless you're an idiot and you try to parallel them externally without phase-checking first. That will blow **** up in a big damn hurry. I've only had to do this once in my entire life, and it was when we were installing temporary radio transmitters in any space we could find during the week immediately following Sep 11, 2001. Those were crazy times.)

But for a 240v appliance, it's physically impossible to "reverse" the two phases, as they are always 180° opposed to one another. In terms of external wiring, you can *only* screw up motor rotation in a 3-phase system, which we don't have in residential applications. The notes regarding rotation on the motor label refer to wiring which is internal to the motor itself. That was set at the factory, and nothing you do externally can mess with it. If there wasn't a starting circuit, you could start the shaft spinning by hand, then apply power to the motor, and it would continue to rotate in whatever direction you started it in.

To address deezums's comments concerning run current. That motor is rated to draw 22A continuously when operating against a load which requires it to produce the full 5HP for which it is rated. In a compressor, as in an automobile, this is a function of gearing and compression ratio. If you were to run the motor with no load attached, it'd spin up to its rated 1,740 RPM and then draw only enough current to overcome bearing friction and air resistance. Probably less than an amp, which you could supply over a piece of CAT5 cable.

While it's possible that the compressor attached to that motor was designed and geared to place exactly a 5HP load on the motor, this is unlikely in practice. I can't guarantee this, obviously, without actually instrumenting the motor under operation. But there's nothing to be lost from trying it. Like I said, the worst-case scenario (aside from the fire resulting in cat death and **** loss) is that the breaker will trip.

A "250 HP" engine does not produce 250 HP when cruising down the highway at 70 MPH. And the faceplate rating of the motor is not the actual running current of the compressor system as a whole.

Will it work? **** if I know. But there's nothing to be lost from trying it.

As an aside, WTF is the third-from-last picture in post #28 from? While it's not the shittiest wiring I've ever seen, it's close. And the picture above it isn't much better. No offense meant to those in the trade (I manage an IBEW 1212 shop), but at least 1/3 of electricians I've known should be put to the stocks. Wanna see quality electrical work? Spend a month working at the Meyer Werft shipyards in Papenburg, Germany. Those guys (and gals- dear God, she was hot) treat every light fixture like it's safety-critical wiring on a spacecraft. I was in awe.

I was also a little slow to hit the "submit" button on that last post, as the whole single-phase vs. three-phase debate has long since been addressed. A helpful note for those not so educated: in everyday practice, single-phase and split-phase are the same thing. The standard for residential power distribution in the US is 240v single-phase with a center tap, and to get 120v, we "split" it by only using one of the windings relative to the center tap, which is connected to ground (literally, to a metal rod pounded into the soil) and, in modern installations, also distributed as an isolated "neutral" conductor. And regardless of which half you take, the other half is always equally opposite. When placing breakers in a splt-phase panel, there are no absolute rules for phase positioning. You just try to keep the 120v stuff roughly balanced (half of it on one leg, and half on the other), and it does not matter in the least whether the 240v breakers wind up on black-red or red-black. You could have two 240v outlets right next to one another on a wall which are wired "opposite" one another with regard to the incoming main, and it doesn't matter one bit.

(Well, unless you're an idiot and you try to parallel them externally without phase-checking first. That will blow **** up in a big damn hurry. I've only had to do this once in my entire life, and it was when we were installing temporary radio transmitters in any space we could find during the week immediately following Sep 11, 2001. Those were crazy times.)

But for a 240v appliance, it's physically impossible to "reverse" the two phases, as they are always 180° opposed to one another. In terms of external wiring, you can *only* screw up motor rotation in a 3-phase system, which we don't have in residential applications. The notes regarding rotation on the motor label refer to wiring which is internal to the motor itself. That was set at the factory, and nothing you do externally can mess with it. If there wasn't a starting circuit, you could start the shaft spinning by hand, then apply power to the motor, and it would continue to rotate in whatever direction you started it in.

To address deezums's comments concerning run current. That motor is rated to draw 22A continuously when operating against a load which requires it to produce the full 5HP for which it is rated. In a compressor, as in an automobile, this is a function of gearing and compression ratio. If you were to run the motor with no load attached, it'd spin up to its rated 1,740 RPM and then draw only enough current to overcome bearing friction and air resistance. Probably less than an amp, which you could supply over a piece of CAT5 cable.

While it's possible that the compressor attached to that motor was designed and geared to place exactly a 5HP load on the motor, this is unlikely in practice. I can't guarantee this, obviously, without actually instrumenting the motor under operation. But there's nothing to be lost from trying it. Like I said, the worst-case scenario (aside from the fire resulting in cat death and **** loss) is that the breaker will trip.

A "250 HP" engine does not produce 250 HP when cruising down the highway at 70 MPH. And the faceplate rating of the motor is not the actual running current of the compressor system as a whole.

Will it work? **** if I know. But there's nothing to be lost from trying it.

As an aside, WTF is the third-from-last picture in post #28 from? While it's not the shittiest wiring I've ever seen, it's close. And the picture above it isn't much better. No offense meant to those in the trade (I manage an IBEW 1212 shop), but at least 1/3 of electricians I've known should be put to the stocks. Wanna see quality electrical work? Spend a month working at the Meyer Werft shipyards in Papenburg, Germany. Those guys (and gals- dear God, she was hot) treat every light fixture like it's safety-critical wiring on a spacecraft. I was in awe.

#48

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

3rd to last picture is the end of the plug that was wired in at one point. Its from home depot. You screw the spades on, and stick them through the plastic body.

#49

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,052

Total Cats: 6,615

(Oxford comma, bitches.)

I was doing better-quality work than that when I was ten years old. I'm not kidding. Ask my mother; she'll tell you stories about all the times I electrocuted myself, but I never burned the house down.

#50

My thoughts were that the motor would demand more current the longer it's run, I'd imagine it needs to work harder with more pressure in the tank. When it's fully juiced up the name of the game is getting it back to full ASAP for maximum CFM, so running it as close to the motor's max would be beneficial.

It seems like a pretty heavy duty unit, meant for high duty cycles. Guess I was wrong though.

It hadn't occurred to me to suggest gearing it down though, that'd be pretty easy and cheap.

It seems like a pretty heavy duty unit, meant for high duty cycles. Guess I was wrong though.

It hadn't occurred to me to suggest gearing it down though, that'd be pretty easy and cheap.

#51

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Whoever wired that should be punished in a way which is more complex than I care to imagine right now. It involves several spools of sewing thread, the prime minister of Lithuania, two five-gallon containers of lard, and an ostrich.

(Oxford comma, bitches.)

I was doing better-quality work than that when I was ten years old. I'm not kidding. Ask my mother; she'll tell you stories about all the times I electrocuted myself, but I never burned the house down.

(Oxford comma, bitches.)

I was doing better-quality work than that when I was ten years old. I'm not kidding. Ask my mother; she'll tell you stories about all the times I electrocuted myself, but I never burned the house down.

#52

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,052

Total Cats: 6,615

If you have the supply capacity, run the thing as hard as you can. If you don't, decrease the cutoff pressure and (if practical) increase the drive ratio.

And, again, for a given load, all electric motors draw maximum current when starting up from zero RPM. To decrease this current inrush, you can decrease the load by lowering the pressure setpoint at which the motor kicks in.

#53

Aiden's compressor confuses me in that regard, I think it has a set mechanical switch.

Most compressors I'm famialir with, outside the huge computer controlled screw machines, use a diaphram or something similar as a mechanical contactor.

He's got what looks like a electromagnetic contactor in there for a measly 20A 220 load, and it appears the coil must be 220 as well, or it shunts 110 through ground 24/7?

Whats under the cover on the pressure switch?

Most compressors I'm famialir with, outside the huge computer controlled screw machines, use a diaphram or something similar as a mechanical contactor.

He's got what looks like a electromagnetic contactor in there for a measly 20A 220 load, and it appears the coil must be 220 as well, or it shunts 110 through ground 24/7?

Whats under the cover on the pressure switch?

#54

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I wrote yes and no originally.

It is totally possible to reverse rotation on a single phase AC motor. Not on the main lines but at the motor.

Now that I see this thing has some crazy mechanical switchery and contact blocks there should be no chance of rewiring to the motor.

Picture 3 above is reason enough to either get the right plug or the right cord.

It is totally possible to reverse rotation on a single phase AC motor. Not on the main lines but at the motor.

Now that I see this thing has some crazy mechanical switchery and contact blocks there should be no chance of rewiring to the motor.

Picture 3 above is reason enough to either get the right plug or the right cord.

Thread

Thread Starter

Forum

Replies

Last Post