MaxG Engine Compartment Brace (For NA/NB [MSM and non-MSM])

#1

Howdy Folks!

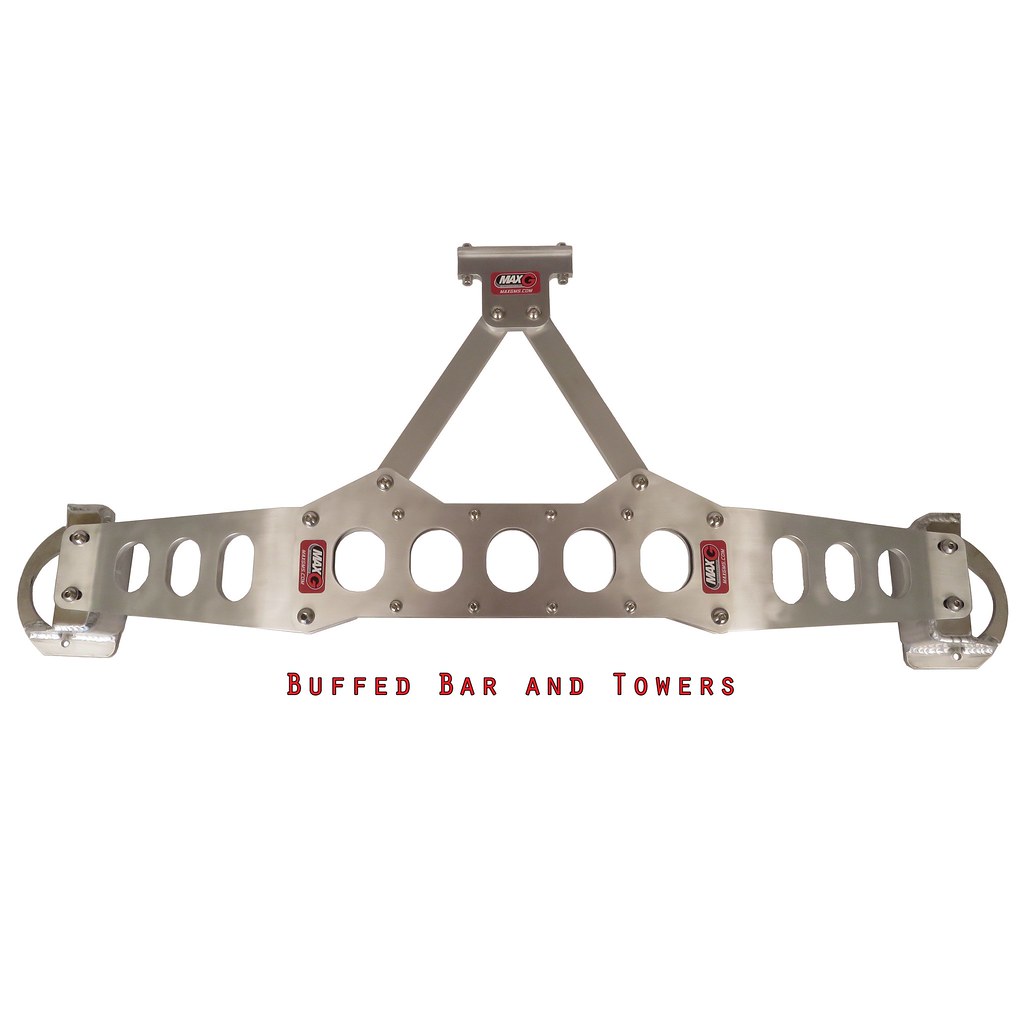

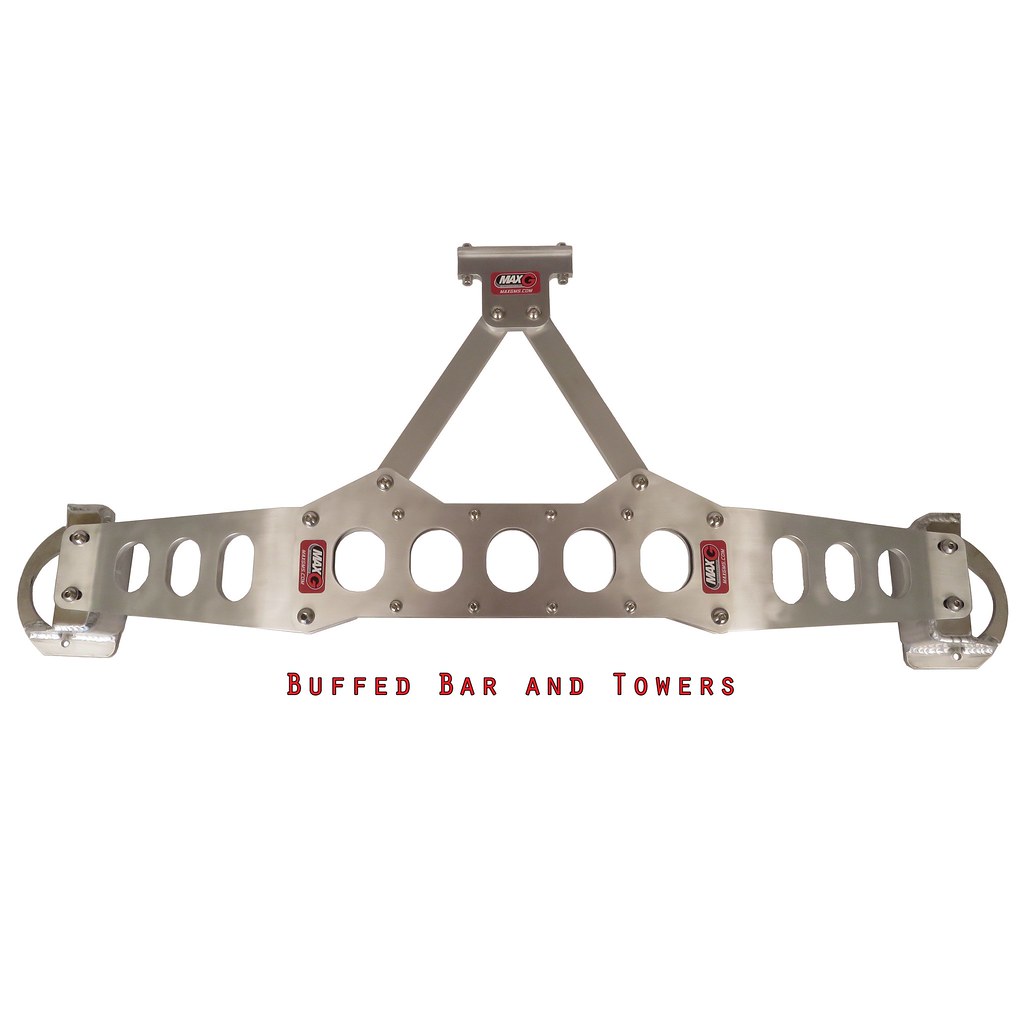

We are excited to offer our Engine Compartment Brace (Non-MSM Models)! We also have our Engine Compartment Brace (MSM Models) that allows the use and retention of the stock MSM bar towers to deliver the same triangulation of the front of the chassis as with the Non-MSM version with our towers.

The MaxG Engine Compartment Brace goes beyond just a normal strut bar/brace by triangulating the shock towers and firewall to stiffen the chassis.

Features and Benefits

An additional key note includes compatibility with our Dual Flow Coolant Reroute Kit!

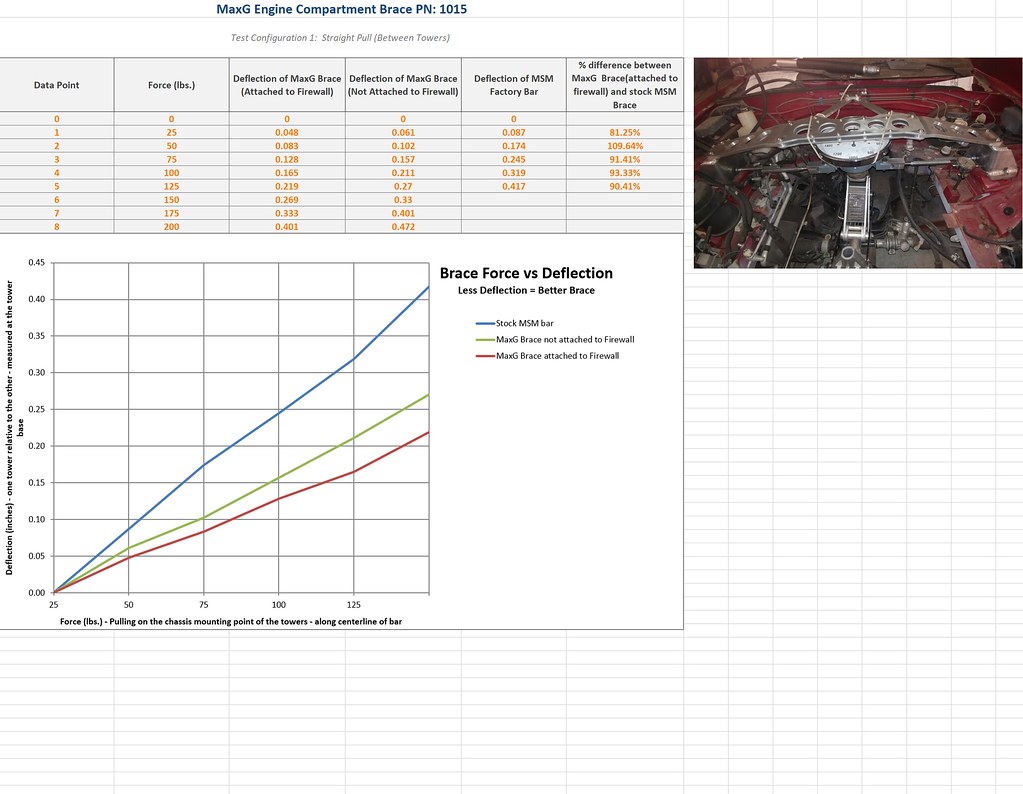

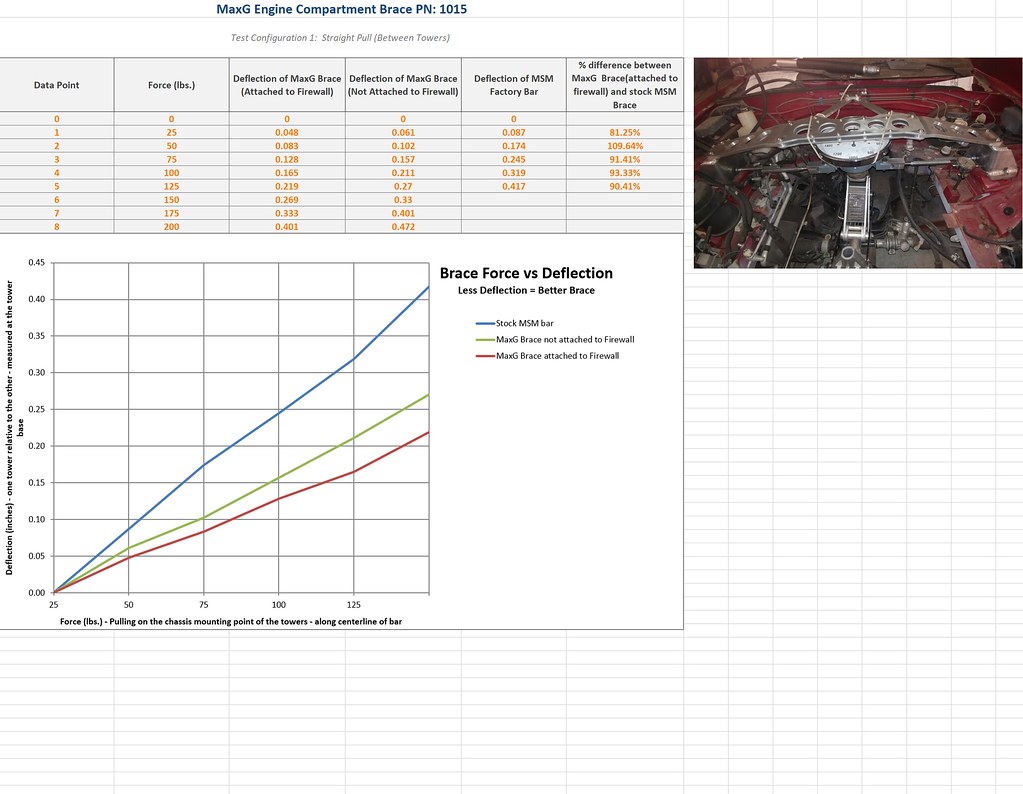

Here is a chart demonstrating the results of our testing of our brace versus the factory MSM bar:

It should be noted we tested the brace with and without the firewall reinforcement to compare the results of triangulating the brace between the towers and the firewall, versus just having the brace bridge the two shock towers.

We welcome any questions or comments and look forward to hearing from the community!

Regards,

Josh

We are excited to offer our Engine Compartment Brace (Non-MSM Models)! We also have our Engine Compartment Brace (MSM Models) that allows the use and retention of the stock MSM bar towers to deliver the same triangulation of the front of the chassis as with the Non-MSM version with our towers.

The MaxG Engine Compartment Brace goes beyond just a normal strut bar/brace by triangulating the shock towers and firewall to stiffen the chassis.

Features and Benefits

- Improved steering response, feedback, and feel

- Integrates engine compartment structure by connecting shock towers and the firewall

- Twice as stiff as the factory MSM bar

- Buffed/Polished Brace without MaxG towers weighs 6.1lbs; Powder Coated Brace without MaxG towers weighs 6.6lbs

- Buffed/Polished brace with MaxG towers weighs just 8.9lbs; Powder Coated Brace with MaxG towers weighs 9.5lbs

- Buffed

- Black Powder Coat

- Polished

An additional key note includes compatibility with our Dual Flow Coolant Reroute Kit!

Here is a chart demonstrating the results of our testing of our brace versus the factory MSM bar:

It should be noted we tested the brace with and without the firewall reinforcement to compare the results of triangulating the brace between the towers and the firewall, versus just having the brace bridge the two shock towers.

We welcome any questions or comments and look forward to hearing from the community!

Regards,

Josh

#6

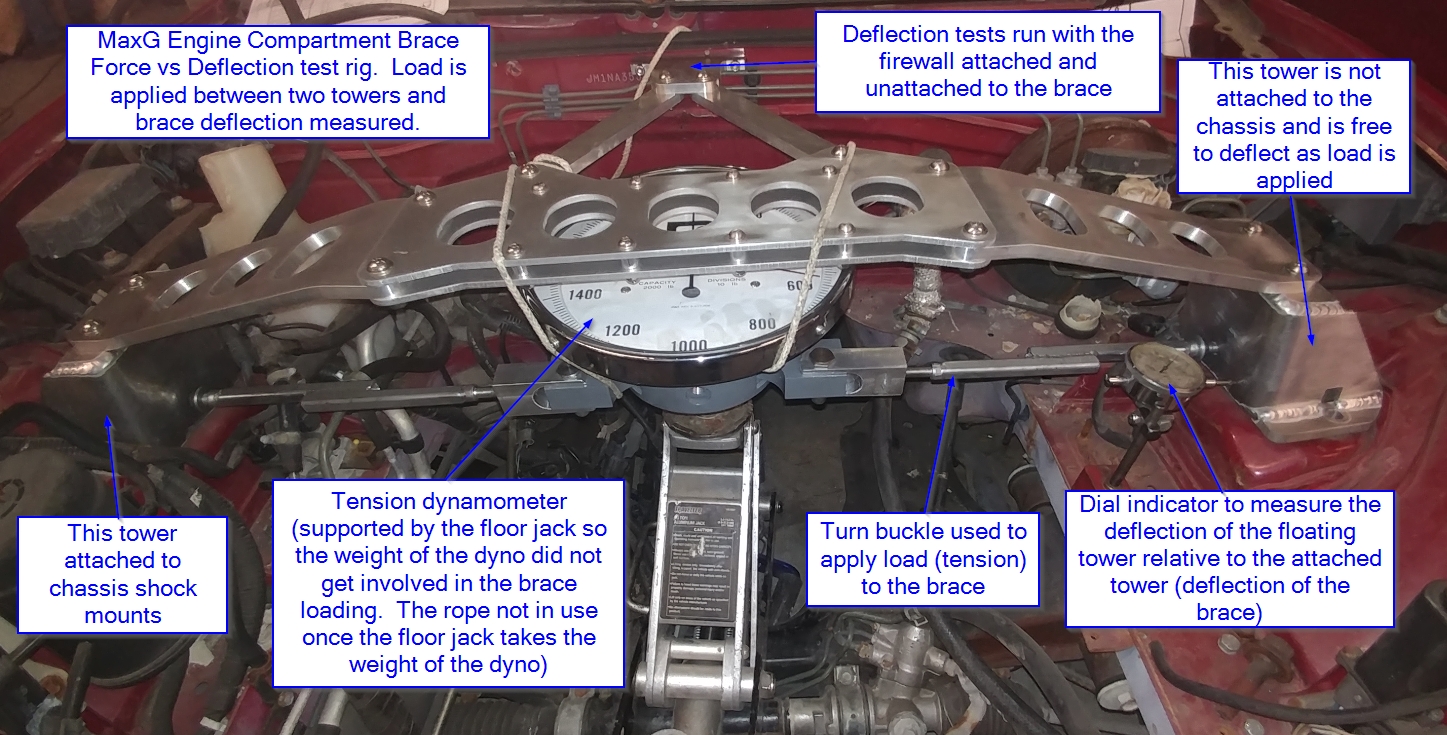

Below is a larger photo of the testing setup that describes what was done to actually measure the deflection, where the load is applied between the two tower through the use of turn buckles; no vertical force is applied on the center of the bar.

Hope that answers your question!

#8

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,203

Total Cats: 1,138

I'm guessing to allow it to move, however with the Miata's front suspension design, the shock would just pivot with the tower. It's a well thought out test, but I think bolting the shock up was an unnecessary step.

cat props to the PO for actually delivering a sturdy brace with a well thought out test and data!

cat props to the PO for actually delivering a sturdy brace with a well thought out test and data!

#9

For the former, we wanted to test the stiffness with and without being connected to the firewall to see if there was a measurable difference in deflection; there was! For the later, leaving one free to move allowed use to see just how the deflection actually affected the firewall itself; had we had both towers bolted down, the deflection forces would have been larger and would have made it more of a challenge to observe deflection differences between the bars we tested.

The firewall attachment plays a significant role in attempting to reduce front subframe twisting when the chassis is loading while turning or making sudden road inputs (avoiding a pothole, lane change, etc.)

Hopefully that all makes sense!

#10

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

There was no actual vertical force applied to the brace during the testing; it's hard to see from the photo, but the jack is only there to support the weight of the tension dynamometer instead of hanging it off the brace.

Below is a larger photo of the testing setup that describes what was done to actually measure the deflection, where the load is applied between the two tower through the use of turn buckles; no vertical force is applied on the center of the bar.

[img ]https://farm1.staticflickr.com/904/28039466078_c10e6a5cd8_o.jpg

Hope that answers your question!

Below is a larger photo of the testing setup that describes what was done to actually measure the deflection, where the load is applied between the two tower through the use of turn buckles; no vertical force is applied on the center of the bar.

[img ]https://farm1.staticflickr.com/904/28039466078_c10e6a5cd8_o.jpg

Hope that answers your question!

Thread

Thread Starter

Forum

Replies

Last Post

chriscar

Insert BS here

16

05-28-2011 05:32 PM

bobsaget

Suspension, Brakes, Drivetrain

41

11-21-2010 05:58 PM