Engine falls flat after ~6,800, can't figure this out!

#81

Plenty of people made big power on vvt engines, some 500-600 on stock cams too (i'll find the thread later, it was posted on here for sure, guy is in europe).

I mean, even FaeFae made 400whp. That's right, faefae

But I will admit that, all of them were turbo. No idea how that translates to supercharging.

I mean, even FaeFae made 400whp. That's right, faefae

But I will admit that, all of them were turbo. No idea how that translates to supercharging.

#82

Also I don't know why everyone uses VVT at anything but heavy load. That's only for fuel economy and emissions, which can't normally tuned without an engine dyno. It just makes VE map tuning more complicated. It's just a case where everybody starts copying and pasting somebody else's maps and eventually nobody knows why the numbers are there.

When you tune a VVT engine from scratch at an OEM level you set the cams at locked baseline position, populate VE tables, then fill out internal EGR models and gas flow models as the cams are phased.

It's much easier if you build a VE table with vvt zero'd first.

When you tune a VVT engine from scratch at an OEM level you set the cams at locked baseline position, populate VE tables, then fill out internal EGR models and gas flow models as the cams are phased.

It's much easier if you build a VE table with vvt zero'd first.

#83

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

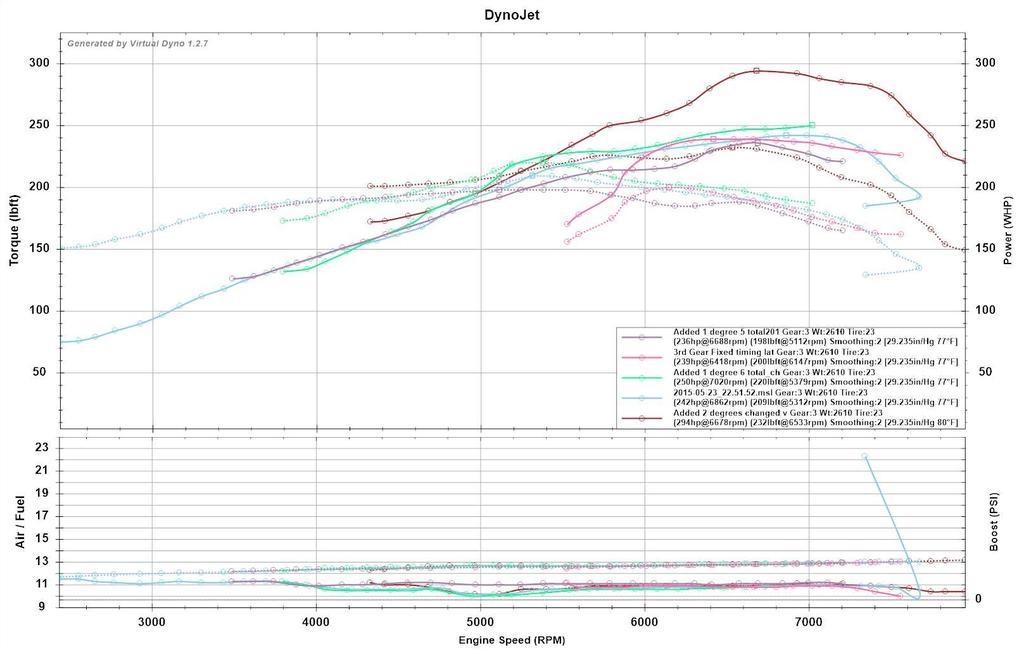

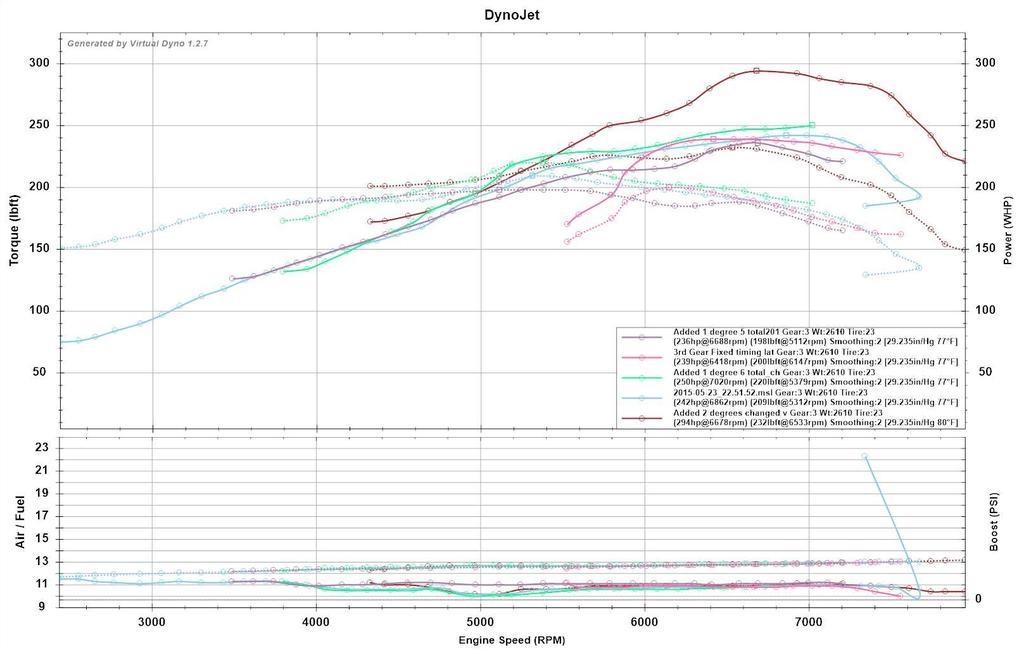

Update, making progress! Apparently SC motor are more sensitive to timing than I thought.

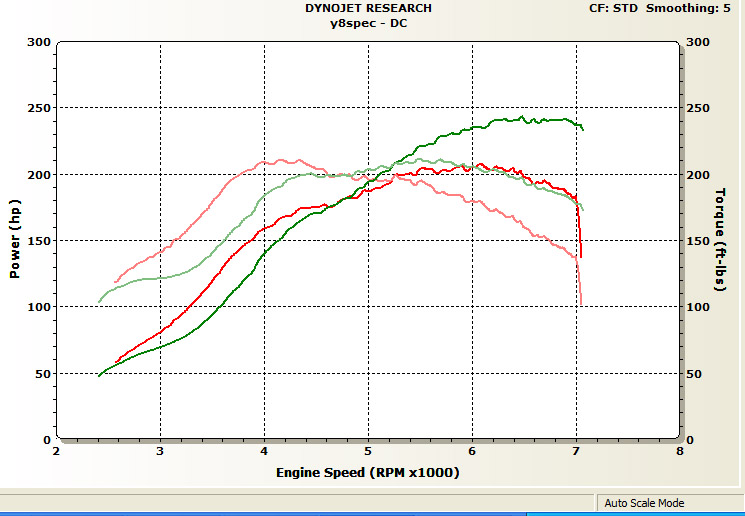

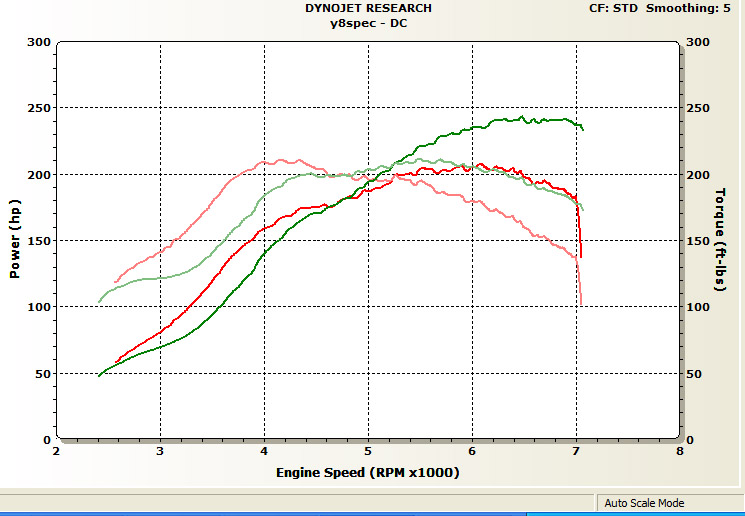

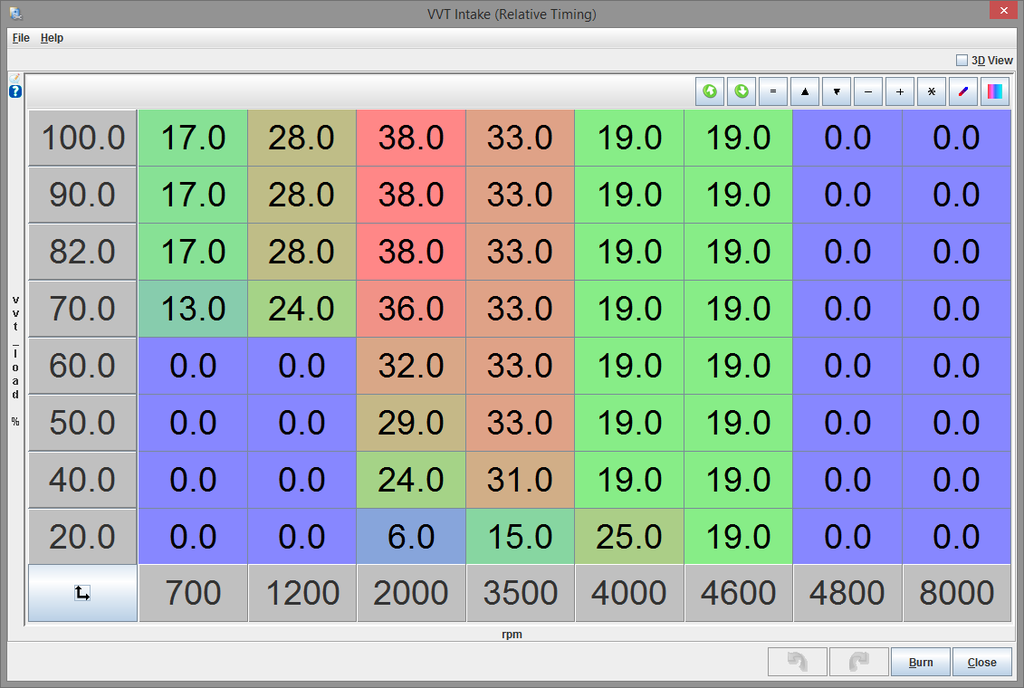

Added 2 degrees and changed the VVT table a bit and just got this. Also videos too for comparison to the ones in beginning of thread.

VD:

Video 1st-3rd. Yes I missed 2nd, I was trying to hold my phone with one hand and steer with it, and shift with the other. Also this is the first time I've been WOT in 1st or 2nd at this power level, so it kinda surprised me.

Video revving the engine. Damn does it rev fast! Also, it has a stock 18lb flywheel.

I'm about to pull the plugs again. I'm seeing two different spots on the strap with a color band, so not sure which one is right.... Gotta do more reading on that.

Added 2 degrees and changed the VVT table a bit and just got this. Also videos too for comparison to the ones in beginning of thread.

VD:

Video 1st-3rd. Yes I missed 2nd, I was trying to hold my phone with one hand and steer with it, and shift with the other. Also this is the first time I've been WOT in 1st or 2nd at this power level, so it kinda surprised me.

Video revving the engine. Damn does it rev fast! Also, it has a stock 18lb flywheel.

I'm about to pull the plugs again. I'm seeing two different spots on the strap with a color band, so not sure which one is right.... Gotta do more reading on that.

#84

Let me say it a different way. My preferred method is to 0 vvt tables. Build a VE map with the cams (just intake cam in this case, no exhaust vvt) locked. Then tune full load vvt at high speed first. See if you pick up any power by advancing the cam over about 4000rpm because of the intake airflow inertia effects and closing timing. There's a good chance you wont.

Then tune vvt in the middle range and low speed range. On NA and SC engines you have runner length tuning effects to account for. On turbos you get more scavenging with more spool, and your closing timing affects knocking tendency and the amount of boost required to make torque. Later closing means less overlap, lower effective compression, less trapped mass, but better inertia effect at higher speeds.

then iteratively tune VE table as you adjust vvt. You've got to get the PID for the vvt straightened out as well. In most cases part load vvt is a waste of time. It just causes driveability problems.

Then tune vvt in the middle range and low speed range. On NA and SC engines you have runner length tuning effects to account for. On turbos you get more scavenging with more spool, and your closing timing affects knocking tendency and the amount of boost required to make torque. Later closing means less overlap, lower effective compression, less trapped mass, but better inertia effect at higher speeds.

then iteratively tune VE table as you adjust vvt. You've got to get the PID for the vvt straightened out as well. In most cases part load vvt is a waste of time. It just causes driveability problems.

#85

Also I don't know why everyone uses VVT at anything but heavy load. That's only for fuel economy and emissions, which can't normally tuned without an engine dyno. It just makes VE map tuning more complicated. It's just a case where everybody starts copying and pasting somebody else's maps and eventually nobody knows why the numbers are there.

When you tune a VVT engine from scratch at an OEM level you set the cams at locked baseline position, populate VE tables, then fill out internal EGR models and gas flow models as the cams are phased.

It's much easier if you build a VE table with vvt zero'd first.

When you tune a VVT engine from scratch at an OEM level you set the cams at locked baseline position, populate VE tables, then fill out internal EGR models and gas flow models as the cams are phased.

It's much easier if you build a VE table with vvt zero'd first.

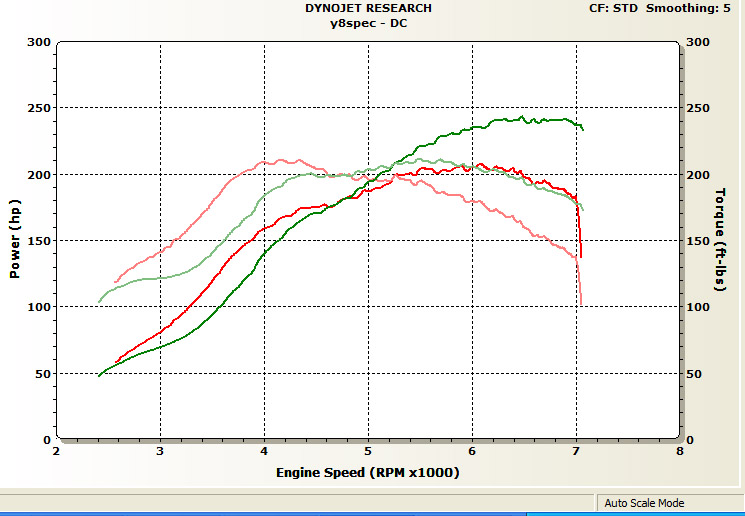

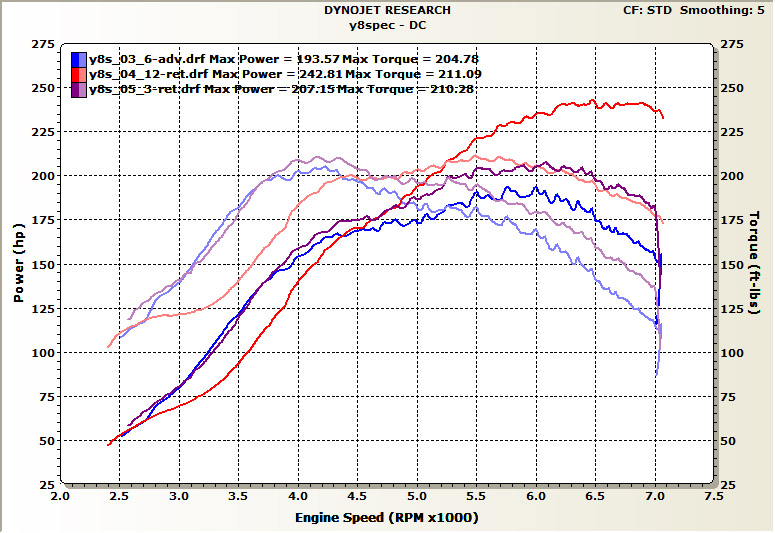

I personally gained lowend/midrange torque tuning vvt

Also many did testing and found really impressive results with vvt

So no it's not just emissions and economy.

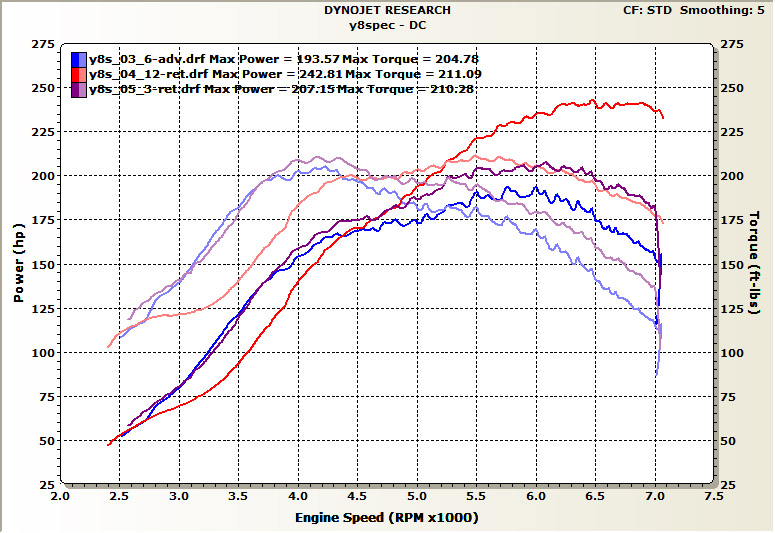

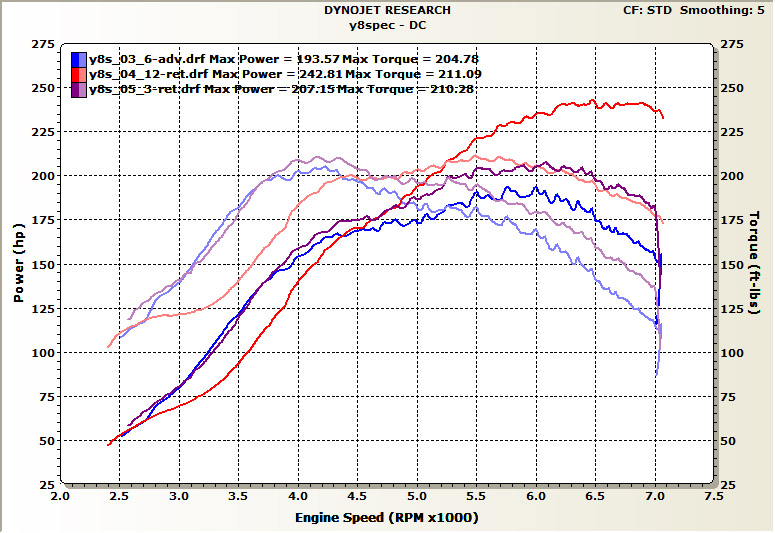

Take a look at this:

Same car same setup nothing changed besides vvt tuning

even if people don't know it front to back, that's some serious shifts in torque

Let me say it a different way. My preferred method is to 0 vvt tables. Build a VE map with the cams (just intake cam in this case, no exhaust vvt) locked. Then tune full load vvt at high speed first. See if you pick up any power by advancing the cam over about 4000rpm because of the intake airflow inertia effects and closing timing. There's a good chance you wont.

Then tune vvt in the middle range and low speed range. On NA and SC engines you have runner length tuning effects to account for. On turbos you get more scavenging with more spool, and your closing timing affects knocking tendency and the amount of boost required to make torque. Later closing means less overlap, lower effective compression, less trapped mass, but better inertia effect at higher speeds.

then iteratively tune VE table as you adjust vvt. You've got to get the PID for the vvt straightened out as well. In most cases part load vvt is a waste of time. It just causes driveability problems.

Then tune vvt in the middle range and low speed range. On NA and SC engines you have runner length tuning effects to account for. On turbos you get more scavenging with more spool, and your closing timing affects knocking tendency and the amount of boost required to make torque. Later closing means less overlap, lower effective compression, less trapped mass, but better inertia effect at higher speeds.

then iteratively tune VE table as you adjust vvt. You've got to get the PID for the vvt straightened out as well. In most cases part load vvt is a waste of time. It just causes driveability problems.

agreed on approach too

Update, making progress! Apparently SC motor are more sensitive to timing than I thought.

Added 2 degrees and changed the VVT table a bit and just got this. Also videos too for comparison to the ones in beginning of thread.

I'm about to pull the plugs again. I'm seeing two different spots on the strap with a color band, so not sure which one is right.... Gotta do more reading on that.

Added 2 degrees and changed the VVT table a bit and just got this. Also videos too for comparison to the ones in beginning of thread.

I'm about to pull the plugs again. I'm seeing two different spots on the strap with a color band, so not sure which one is right.... Gotta do more reading on that.

Last edited by 18psi; 05-24-2015 at 04:49 PM.

#86

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

Thanks! Yes it's running way better now vs when I started this thread. I'm very grateful for the help and ideas from everyone, it's making a difference. I appreciate it gentlemen.

Alright, so I gotta go pull the plugs again, but does anybody here know how to read plugs? I'm running NGKs and the strap has a coating. So there's one mark where the coating is burning off, and then there's a second color mark on the coating itself further towards the threaded portion.

The first mark is only about 3/16" from the tip of the Strap, but the second mark is right on the bend. What I've read says you want that color mark right on the bend more or less, so now I'm hesitant to change much since I don't know which mark to go by.

I've read some people actually use a dremel and wire wheel to knock the NGK coating off and then tune that way. Maybe that's what I should do?

Still overall happy, it's getting better! Also at 23 PSI now!

Alright, so I gotta go pull the plugs again, but does anybody here know how to read plugs? I'm running NGKs and the strap has a coating. So there's one mark where the coating is burning off, and then there's a second color mark on the coating itself further towards the threaded portion.

The first mark is only about 3/16" from the tip of the Strap, but the second mark is right on the bend. What I've read says you want that color mark right on the bend more or less, so now I'm hesitant to change much since I don't know which mark to go by.

I've read some people actually use a dremel and wire wheel to knock the NGK coating off and then tune that way. Maybe that's what I should do?

Still overall happy, it's getting better! Also at 23 PSI now!

#87

Senior Member

iTrader: (1)

Join Date: Jan 2011

Location: Chattanooga, Tn

Posts: 1,234

Total Cats: 283

^^^ what that guy said^^^ building a car like this and not tuning it on a dyno is like buying a $5,000 torque wrench that you know isn't calabrated and then using your 50 yr old bathroom scales and a ruler to try and calabrated it

#88

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

I actually thought something was wrong with it before, since it was so down on power given the boost I was running. By now I can see the tune was just way off before, timing, latency, etc.

So what should I do when I get it on a dyno? I've never tuned on a dyno before. I agree it would be much better to use a dyno. Should I still be reading the plugs while on the dyno? Does it matter what kind of dyno I use?

#89

You need det cans or another effective means of knock detection. Then tune for MBT on a proper load bearing dyno

I'm really not sure why you're reading your plugs 10000000000000 times, that's more something people did before widebands and proper knock detection

But these guys have way more dyno tuning exp so I'll just leave it at that

I'm really not sure why you're reading your plugs 10000000000000 times, that's more something people did before widebands and proper knock detection

But these guys have way more dyno tuning exp so I'll just leave it at that

#90

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

The reason I was reading the plugs is so that if it's detonating, I'd see it on the plugs. I broke a motor about 3 weeks ago so trying to be careful....

Ok so I have some old mechanical det cans, I'll get them hooked back up. I bought the stuff to build electronic det cans but the amp/mic I bought has a poor signal/noise ratio so I may skip that for now and use the simple ones.

Also I want to run more boost, so I should probably order the new pulley and get it installed before I spend the time/$$$ on a dyno.

Ok so I have some old mechanical det cans, I'll get them hooked back up. I bought the stuff to build electronic det cans but the amp/mic I bought has a poor signal/noise ratio so I may skip that for now and use the simple ones.

Also I want to run more boost, so I should probably order the new pulley and get it installed before I spend the time/$$$ on a dyno.

#91

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,219

Total Cats: 1,145

Plus they can only be read by killing the engine at a specific rpm, otherwise you're just reading your idle cells as you pull into the garage. And yes, you're only really reading fuel, which we have a wideband for.

If you wanna learn, idle at 11:1, then read the plugs. Do the same for 12, 13, 14, 15, 16, and 17, and you'll see how they change.

If you wanna learn, idle at 11:1, then read the plugs. Do the same for 12, 13, 14, 15, 16, and 17, and you'll see how they change.

#92

Senior Member

iTrader: (1)

Join Date: Jan 2011

Location: Chattanooga, Tn

Posts: 1,234

Total Cats: 283

I'm saying take it to a dyno and pay someone to tune it. That's what I did...I save money doing the things I know how to do....and I save money by paying someone to do the things I don't know how to do.

I tried doing my own tunes and thought I had it close. Then I took the car to a well known very reputable tuner and found out I wasn't even close.

You don't want to take a chance on poping another motor or beating your head against the wall unnecessaryly.

Proper tuning will cost you $100-$150 an hour and will take 3 or 4 hours

I tried doing my own tunes and thought I had it close. Then I took the car to a well known very reputable tuner and found out I wasn't even close.

You don't want to take a chance on poping another motor or beating your head against the wall unnecessaryly.

Proper tuning will cost you $100-$150 an hour and will take 3 or 4 hours

#93

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

Plus they can only be read by killing the engine at a specific rpm, otherwise you're just reading your idle cells as you pull into the garage. And yes, you're only really reading fuel, which we have a wideband for.

If you wanna learn, idle at 11:1, then read the plugs. Do the same for 12, 13, 14, 15, 16, and 17, and you'll see how they change.

If you wanna learn, idle at 11:1, then read the plugs. Do the same for 12, 13, 14, 15, 16, and 17, and you'll see how they change.

I was making a pull, then drive the car about 1 minute and shut it down, pull the plugs. I know you can't tune fuel with plugs doing this of course (have to shut it down and check as you say), but I believe you can use it to check for signs of detonation. Also you can see the electrode to tell if timing is right, and supposedly that too you don't have to shut it down right during the pass to tell.

Drag racers running nitrous make a pass and check the two things I just mentioned to tune ignition. They say when the heat mark is at the 90* bend of the electrode and you don't show black specs or aluminum on the insulator, that's when the timing is correct/fastest MPH.

All of the above is according to what I read on the internet, no idea if it's correct. Anyone have an opinion or experience on this?

I'm saying take it to a dyno and pay someone to tune it. That's what I did...I save money doing the things I know how to do....and I save money by paying someone to do the things I don't know how to do.

I tried doing my own tunes and thought I had it close. Then I took the car to a well known very reputable tuner and found out I wasn't even close.

You don't want to take a chance on poping another motor or beating your head against the wall unnecessaryly.

Proper tuning will cost you $100-$150 an hour and will take 3 or 4 hours

I tried doing my own tunes and thought I had it close. Then I took the car to a well known very reputable tuner and found out I wasn't even close.

You don't want to take a chance on poping another motor or beating your head against the wall unnecessaryly.

Proper tuning will cost you $100-$150 an hour and will take 3 or 4 hours

But I really want to learn to do it myself the right way. I'm willing to put in the time to learn. I bet you are right though, a pro could squeeze a lot more out of it than I can right now. Still I want to learn! I would prefer to not break another engine though.

#94

I know you're all fancy with your OEM stuff, but we're talking about simple ms and a miata bp here, so we just do what works.

I personally gained lowend/midrange torque tuning vvt

Also many did testing and found really impressive results with vvt

So no it's not just emissions and economy.

Take a look at this:

Same car same setup nothing changed besides vvt tuning

even if people don't know it front to back, that's some serious shifts in torque

I personally gained lowend/midrange torque tuning vvt

Also many did testing and found really impressive results with vvt

So no it's not just emissions and economy.

Take a look at this:

Same car same setup nothing changed besides vvt tuning

even if people don't know it front to back, that's some serious shifts in torque

2000rpm and 40kPa has no need for vvt cam advance. That's emission and fuel economy only. It doesn't give you low end torque, it just dilutes intake charge. Then I read in other threads about people complaining over driveability problems, especially when cold, due to control of the VVT phaser, oil viscosity, oil temperature.

You're making the tuning more difficult by just copying and pasting a VVT map in there with all this part throttle cam advance. Now you need to make your PID gains and feedback control work in all these areas where they're not necessary, while still have stable control at full load. You also get really ugly VE tables--not that "pretty" is good and "ugly" is bad, but rather, having a lot of uneven areas in the VE table just makes overall fuel control harder.

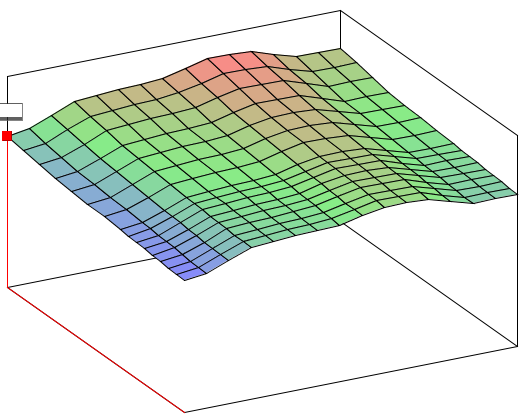

Here's a VE table 3D map from Ryephile's build (1.6 turbo, fixed cam engine).

You start doing VVT cam advance at low speed and load and now you've gotta put divits and valleys in the map. You've got to worry about interpolation more and you're making o2 feedback more difficult.

So I've been writing Rx-7 tuning guides for years. The point here is that you make your life a lot easier if you tune the VE and VVT, closed loop fuel, idle control, etc in a sequence, leaving room to make changes to the sequence as you learn, rather than scattershot chasing your tail. That's what OP is running into now. I'm not saying that to criticize or to attack anyone. It's just an explanation that there are specific methods and order-of-operations you can use that will reduce confusion and frustration. It's not about what exact numbers to put in the maps, because every engine will vary because no setup is the same.

https://www.miataturbo.net/build-thr...d-80222/page6/

Here's my general method. Because dyno time costs a lot, you should start with some street tuning like you are doing now

1) start with some kind of base spark map

2) get the car to be consistently starting and idling without dying

3) Zero out VVT maps. Tune cruising VE area and cruising fuel feedback PID control for stability.

4) extrapolate VE maps into higher loads. For example, take all the VE in the 80kPa row and copy it to 90kPa, then multiply by some factor such as 1.02 . Use that process to extrapolate a VE table.

5) do street pulls, starting at half throttle or so, to make sure the VE is in the ballpark and safe.

6) if you have boost control (not a concern on n/a or supercharger), begin to tune open loop portion so you have a rough idea of what's going on

7) adjust IAT air density compensation table as the weather changes so that in idle and cruising areas, close loop fuel is adding or subtracting no more than 5%. This gets your density table close.

7) do mechanical checks on the engine and then go to the dyno. Pick one with loading capability.

At Dyno

1) begin with fast ramping shakedown pulls, such as in 2nd gear, or by doing a fast ramp rate with the brake. so maybe 2000-7000 rpm in 10 seconds if you have the dyno set the ramp.

2) perform load sweeps at the VE table breakpoints. That means have the dyno hold a fixed rpm while someone drives the car and slowly pushes the throttle down in steps while you save data in the Megasquirt. This gets steadier data in specific speed and load columns rather than running through cells super fast on the street, having transient effects and normal driving issues (incline in the road, safety concerns). Adjust the rpm columns up or down by some factor in order to smooth the VE table so you don't get fuel jumping around so much. This assumes you did an ok job of extrapolating the load (kPa) portion as I mentioned before.

3) after load sweeps, analyze data and make VE table changes. Perform longer rpm sweeps with the dyno brake - maybe 2000-7000rpm in 15 seconds. It's a lot easier to get consistent data by ramping the rpm with the dyno brake than relying on your foot.

4) when you are satisfied with the VE table, move on to spark. Take all the heavy load columns and globally advance in 1 degree steps. Look for improvement in torque. So do +1, +2, then -1 from your base values. Analyze the data and add timing in areas where the torque is dipping and see if that helps at all, assuming boost control and fuel control aren't the actual problems. Figure out how sensitive the engine is to timing. If adding 2 degrees is getting you 2 horsepower than maybe it's not worth adding more. If 2 degrees is getting you 10 horsepower than your initial timing curves were not close to optimal. The closer you are to optimal, the less benefit you get from making changes - same applies to adjusting AFR.

5) NOW tune the VVT table, starting at roughly 80kPa MAP and up. Do 4000rpm - just below redline sweeps, ramping with the brake. Start by globally moving 10 degrees for that rpm range and see if it does anything. Add in say 5 degree increments after that up to maybe 20 degrees advance. Look through the datalogs and see which rpms liked more advance and which didn't. You are figuring out where the VVT advance curve tapers off. You may have to make some VE adjustments so it doesn't get too lean. Hopefully you can work through any VVT PID control issues on the street beforehand.

6) Do ramps from about 1500-4000rpm. Move in about 10 degree steps initially. You will most likely want to be at max advance if you are turbo, in order to get scavenging and build more boost. With n/a and superchargers, it depends more on the exhaust system design and runner length tuning.

7) smooth out the VE table and if you want to do some final pulls to check. Work on incidental things like injection timing and cruise tuning. If you really want to mess with part throttle VVT, do it last as it's just not very important.

8) Take the car off the dyno and verify that what you did didn't cause some driveability issue that you couldn't spot, or some other unpredictable effect.

Last edited by arghx7; 05-24-2015 at 11:22 PM.

#95

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

afghx7- Thank you a lot! I appreciate the feedback on everything and the info you just posted. That's awesome!

On the VVT, I did start with a generic VVT table. I ended up zeroing out the VVT at idle as it seemed I didn't need that. I thought about zeroing it out at light load too, but nobody did that so I wasn't' sure. But what you say makes perfect sense.

I'll try tuning it as you say. It makes sense and I'm all for doing this better.

On the VVT, I did start with a generic VVT table. I ended up zeroing out the VVT at idle as it seemed I didn't need that. I thought about zeroing it out at light load too, but nobody did that so I wasn't' sure. But what you say makes perfect sense.

I'll try tuning it as you say. It makes sense and I'm all for doing this better.

#96

Props for a really good post. I agree - the method/approach is good

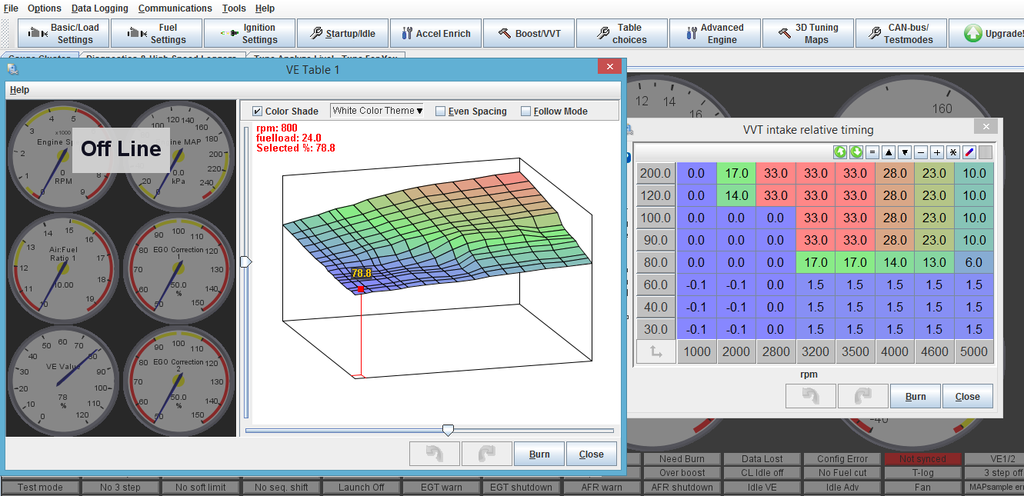

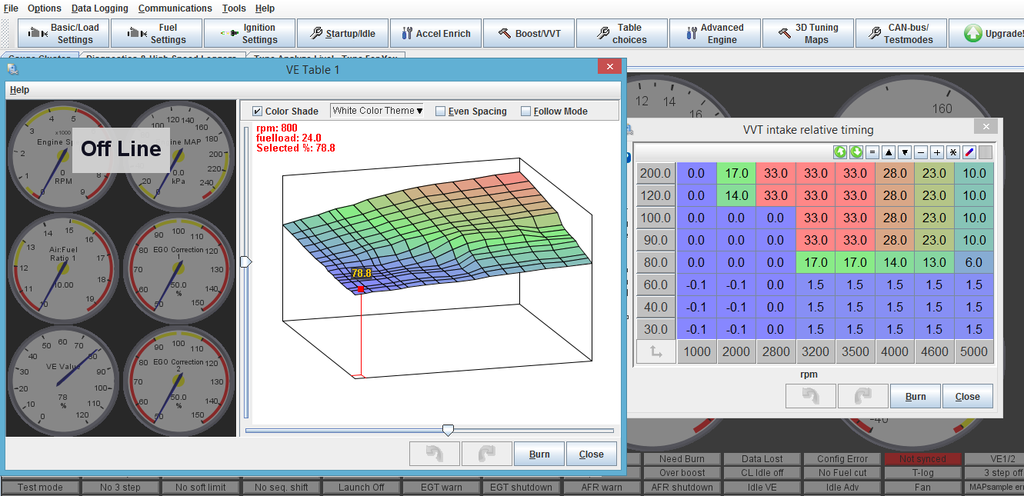

Just for kicks, this was my ve and vvt maps when I did my 01, and it ran great. No weirdness in the VE map, at least that I can see

I guess that slight advance at 80kpa might be what you're talking about, but the car felt way better like that to me vs none - better response, more crisp and quicker torque onset.

I agree with you though that the "common" copy/pasted vvt tables with insane advance all the way down to 20kpa are kinda silly.

I think everyone just copies DIYautotune's table, which is like that:

Just for kicks, this was my ve and vvt maps when I did my 01, and it ran great. No weirdness in the VE map, at least that I can see

I guess that slight advance at 80kpa might be what you're talking about, but the car felt way better like that to me vs none - better response, more crisp and quicker torque onset.

I agree with you though that the "common" copy/pasted vvt tables with insane advance all the way down to 20kpa are kinda silly.

I think everyone just copies DIYautotune's table, which is like that:

#97

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

Well I zero'd out the VVT up to 80 KPA and drove it. Damn, much better driveability. It used to "jump" at 2K when taking off since it threw a ton of advance at it. Kinda fun, but hard to drive as you have to guess what it's about to do. Now it drives.... more predictably. I like it.

#98

When you tune vvt, watch target vs actual because until you've tuned PID completely it's gonna be all over the place. Also there was a bug in the software/firmware that would cause full advance/retard in certain situations. But that's a whole 'nother topic and I won't pollute your thread with it. You can search for the threads later.

#99

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,302

Total Cats: 480

Target vs actual are almost perfect! I have a pair of gauges (target and actual) side by side and they move together very well. Datalogs show it works great. And all I did was find somebody's VVT PID values that seemed to understand how to tune PID and used them.... They work.  I do run regular 30 weight motor oil though, I think that affects it.

I do run regular 30 weight motor oil though, I think that affects it.

Thanks for the info though. It's funny that this one thing just worked as I took apart the VVT actuator twice and put random internet PID values and wired it up myself, and it worked right out of the box!

I do run regular 30 weight motor oil though, I think that affects it.

I do run regular 30 weight motor oil though, I think that affects it. Thanks for the info though. It's funny that this one thing just worked as I took apart the VVT actuator twice and put random internet PID values and wired it up myself, and it worked right out of the box!