MS3 PRO Knock Detection Thread

#21

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

Ok so I got my ECU back from DIY Autotune. They said the knock chip was bad, and they replaced it.

Anyways, I got the ecu back , hooked it up, and I'm still not getting any knock input! I went through all the troubelshooting again, ending with me playing a Sine Wave Sweep into the MS3 PRO and still got nothing.

I emailed them but it's the weekend so nothing back yet.

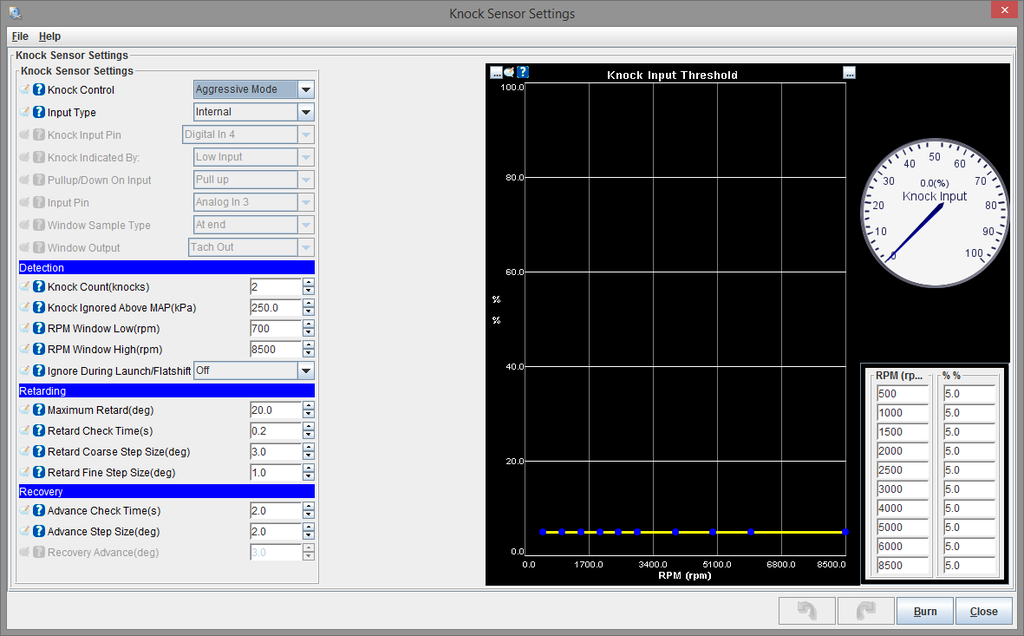

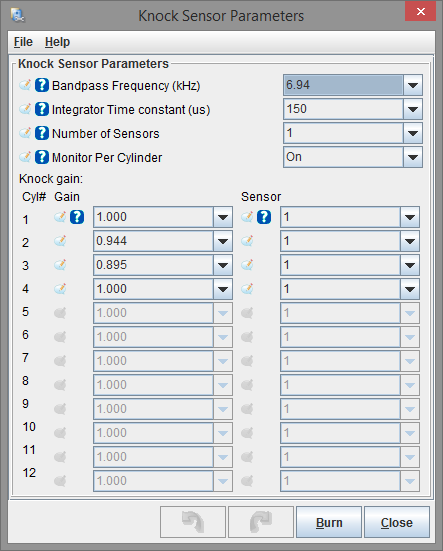

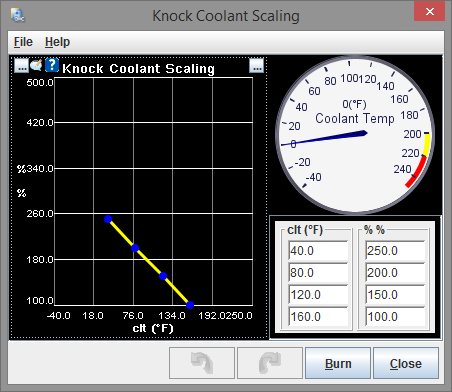

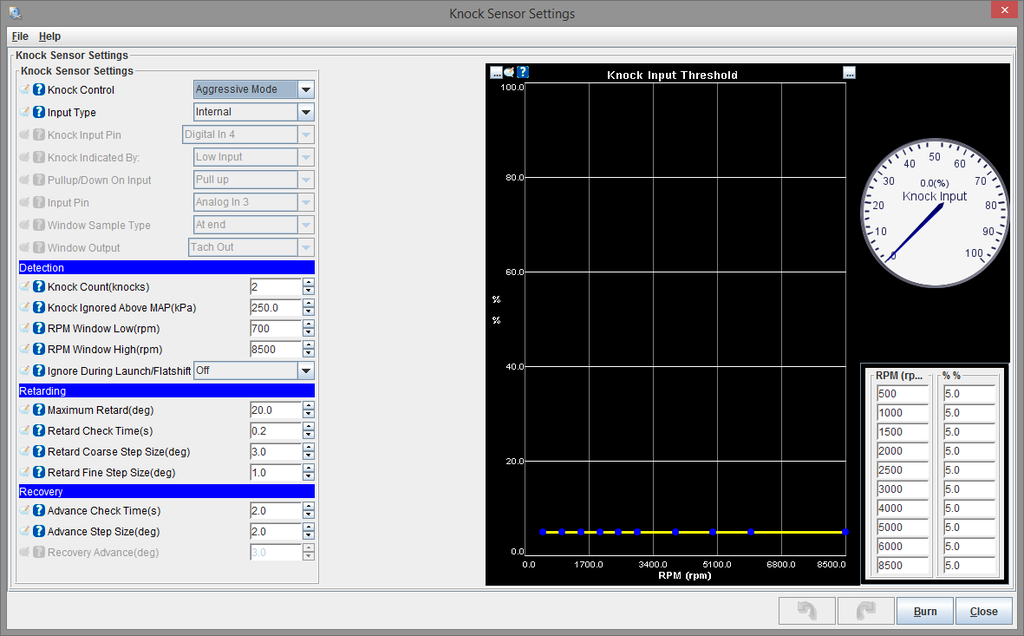

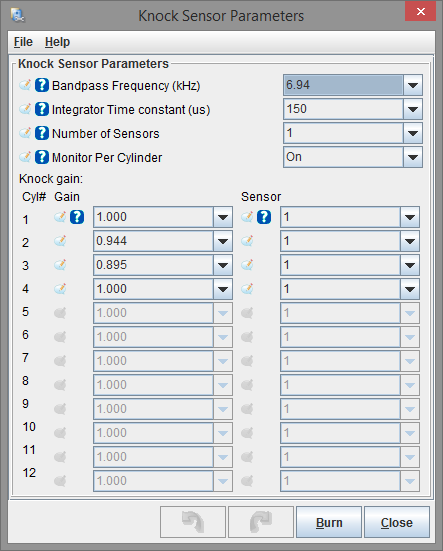

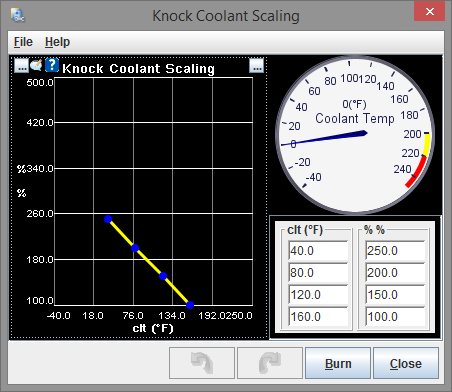

Can anyone take a look at my settings and make sure there's nothing obviously wrong?

Pics:

Anyways, I got the ecu back , hooked it up, and I'm still not getting any knock input! I went through all the troubelshooting again, ending with me playing a Sine Wave Sweep into the MS3 PRO and still got nothing.

I emailed them but it's the weekend so nothing back yet.

Can anyone take a look at my settings and make sure there's nothing obviously wrong?

Pics:

#23

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

I tried that a while back, it made no difference. I turned the gain as high as it would allow and still got nothing.

I ended up sending the ECU in to be repaired again, they fixed it today! Even sent me a log showing it working. So now just waiting to get it back and into the car.

So, my questions for anyone that will take the time to answer:

1. Are the settings I posted good? The only thing I plan to change vs what I posted screenshots of is to change the duration from 50* to 20*. I used 50 for testing. That and I'll have to tune the knock threshold of course.

2. Does the MS3 detect knock all the way to redline? Or does it get overwhelmed with noise at some RPM?

I ended up sending the ECU in to be repaired again, they fixed it today! Even sent me a log showing it working. So now just waiting to get it back and into the car.

So, my questions for anyone that will take the time to answer:

1. Are the settings I posted good? The only thing I plan to change vs what I posted screenshots of is to change the duration from 50* to 20*. I used 50 for testing. That and I'll have to tune the knock threshold of course.

2. Does the MS3 detect knock all the way to redline? Or does it get overwhelmed with noise at some RPM?

#24

I've done knock sensor development in a lab and I can tell you that noise increases exponentially with rpm and it's entirely possible that the sensor is blind to 1 or more cylinders at certain speeds and loads. As in, the engine can be knocking but the sensor won't pick it up. You don't hear about that when people tune spark on stock ecu knock systems for other cars (subaru etc) because somebody at the OEM set the gains and frequency and window and thresholds in order to mask/work around the blindness.

That's all by measuring knock with cylinder pressure sensors and comparing to lab grade knock sensors/accelerometers.

Knock control and knock limit is very much judgment calls and opinions.

That's all by measuring knock with cylinder pressure sensors and comparing to lab grade knock sensors/accelerometers.

Knock control and knock limit is very much judgment calls and opinions.

#25

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

I've done knock sensor development in a lab and I can tell you that noise increases exponentially with rpm and it's entirely possible that the sensor is blind to 1 or more cylinders at certain speeds and loads. As in, the engine can be knocking but the sensor won't pick it up. You don't hear about that when people tune spark on stock ecu knock systems for other cars (subaru etc) because somebody at the OEM set the gains and frequency and window and thresholds in order to mask/work around the blindness.

That's all by measuring knock with cylinder pressure sensors and comparing to lab grade knock sensors/accelerometers.

Knock control and knock limit is very much judgment calls and opinions.

That's all by measuring knock with cylinder pressure sensors and comparing to lab grade knock sensors/accelerometers.

Knock control and knock limit is very much judgment calls and opinions.

But hear me out. I don't have a lab, dyno, or a million dollars to do this to the OEM level. So what can I actually do to make the most of this? That's the question I need answered.

For example:

1. To set knock threshold, I've read people do this by reving in Neutral. This seems odd. I think pull say 5* and do a pull to redline, and use that as a baseline of no-knock. Agreed?

2. Once I know what the baseline threshold is, how much "higher" should I set the real knock threshold? I would think some % higher than the baseline. Say, 10%? Or should this vary with RPM? Perhaps more sensitive at low RPMs (because less noise) but a higher threshold at higher RPMs (since more noise)?

3. How much authority should I assign to the knock sensor? I've read some setups only pull up to 4*, but I believe Subaru does a lot more than this. I think the norm is something higher than 4*, likely more like 8*?

Answers to these questions would help me a lot.

#27

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>Are these settings different car to car? How does an OEM get away with a single setup for all motors. Could we potentially crowd fund some sort of lab grade testing and apply it to all setups?</p>

#28

Stock sensors work a lot different though right, as in actively filtering and listening to multiple frequencies from the same sensor/speaker.

All of the megasquirt stuff I've seen just seems to generate a duty cycle off of signal to noise ratio or something. It's largely unfixable, at least like OEM.

So we'd need a signal amplifier on the knock sensor, crossovers and filters stolen from a stock ecu somehow, maybe by sweeping a signal against stock ecu jimstim to watch and plot what input frequencies and levels pulls timing. Then make a knockbox or somehing to send PWM or TTL signal to the megasquirt.

That's all way over my head. I like my detcans and moderation tuning.

All of the megasquirt stuff I've seen just seems to generate a duty cycle off of signal to noise ratio or something. It's largely unfixable, at least like OEM.

So we'd need a signal amplifier on the knock sensor, crossovers and filters stolen from a stock ecu somehow, maybe by sweeping a signal against stock ecu jimstim to watch and plot what input frequencies and levels pulls timing. Then make a knockbox or somehing to send PWM or TTL signal to the megasquirt.

That's all way over my head. I like my detcans and moderation tuning.

#31

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

Yes I'll do it, but not at full boost. But at light-moderate loads I'd do it. I'd prefer to wear some type of det cans while I can hear it in my ear, and see the response from the knock sensor.

#32

Your options are limited without a loading dyno, or any dyno really. When you start banging through gears on the street the drive train movement can affect the noise curve, especially if you don't have a nice even road surface.

You can hold it in some higher gear, give it part throttle, and take some logs as it runs up in engine speed. Then try to repeat it but it with more spark and see if you notice something.

What I would personally do is try to induce knock at low speed lugging where the noise is naturally lower, the engine likes to knock, and cylinder pressure is lower so the risk of damage isn't so high. Floor it at 1000 rpm in 5th, or maybe 1200 or 1500 at most.

You should hear more of a faint chirping sound when it knocks, especially at 1000. The background noise from combustion is very low at such low speeds, but there's still potential for other noise.

You can hold it in some higher gear, give it part throttle, and take some logs as it runs up in engine speed. Then try to repeat it but it with more spark and see if you notice something.

What I would personally do is try to induce knock at low speed lugging where the noise is naturally lower, the engine likes to knock, and cylinder pressure is lower so the risk of damage isn't so high. Floor it at 1000 rpm in 5th, or maybe 1200 or 1500 at most.

You should hear more of a faint chirping sound when it knocks, especially at 1000. The background noise from combustion is very low at such low speeds, but there's still potential for other noise.

#33

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

Your options are limited without a loading dyno, or any dyno really. When you start banging through gears on the street the drive train movement can affect the noise curve, especially if you don't have a nice even road surface.

You can hold it in some higher gear, give it part throttle, and take some logs as it runs up in engine speed. Then try to repeat it but it with more spark and see if you notice something.

What I would personally do is try to induce knock at low speed lugging where the noise is naturally lower, the engine likes to knock, and cylinder pressure is lower so the risk of damage isn't so high. Floor it at 1000 rpm in 5th, or maybe 1200 or 1500 at most.

You should hear more of a faint chirping sound when it knocks, especially at 1000. The background noise from combustion is very low at such low speeds, but there's still potential for other noise.

You can hold it in some higher gear, give it part throttle, and take some logs as it runs up in engine speed. Then try to repeat it but it with more spark and see if you notice something.

What I would personally do is try to induce knock at low speed lugging where the noise is naturally lower, the engine likes to knock, and cylinder pressure is lower so the risk of damage isn't so high. Floor it at 1000 rpm in 5th, or maybe 1200 or 1500 at most.

You should hear more of a faint chirping sound when it knocks, especially at 1000. The background noise from combustion is very low at such low speeds, but there's still potential for other noise.

Also what specifically would I be looking for? I'm guessing to determine what real knock looks like so I can set my thresholds accordingly?

#34

Ok thanks for the info.

But hear me out. I don't have a lab, dyno, or a million dollars to do this to the OEM level. So what can I actually do to make the most of this? That's the question I need answered.

For example:

1. To set knock threshold, I've read people do this by reving in Neutral. This seems odd. I think pull say 5* and do a pull to redline, and use that as a baseline of no-knock. Agreed?

2. Once I know what the baseline threshold is, how much "higher" should I set the real knock threshold? I would think some % higher than the baseline. Say, 10%? Or should this vary with RPM? Perhaps more sensitive at low RPMs (because less noise) but a higher threshold at higher RPMs (since more noise)?

3. How much authority should I assign to the knock sensor? I've read some setups only pull up to 4*, but I believe Subaru does a lot more than this. I think the norm is something higher than 4*, likely more like 8*?

Answers to these questions would help me a lot.

But hear me out. I don't have a lab, dyno, or a million dollars to do this to the OEM level. So what can I actually do to make the most of this? That's the question I need answered.

For example:

1. To set knock threshold, I've read people do this by reving in Neutral. This seems odd. I think pull say 5* and do a pull to redline, and use that as a baseline of no-knock. Agreed?

2. Once I know what the baseline threshold is, how much "higher" should I set the real knock threshold? I would think some % higher than the baseline. Say, 10%? Or should this vary with RPM? Perhaps more sensitive at low RPMs (because less noise) but a higher threshold at higher RPMs (since more noise)?

3. How much authority should I assign to the knock sensor? I've read some setups only pull up to 4*, but I believe Subaru does a lot more than this. I think the norm is something higher than 4*, likely more like 8*?

Answers to these questions would help me a lot.

1. There's no easy answer to this without a lot of risky testing. Pull 5 degrees method is closer to what I'd do, but you've got transient and drive train effects from doing pulls on the street.

Running in neutral unfortunately doesn't load the engine down so much, but we don't know the sensitivity of background noise to load. That's the kind of thing you study when you configure a knock sensor in a lab.

You could do both and see if any of the numbers make any sense.

2. If you're not willing to beat the **** out of the engine to find out (who could blame you), 10% is as good as any. It's kind of arbitrary as nobody can seem to agree on where the line is first crossed and how much knock is too much.

3. Ok so if you had a modern model based ecu you would have a minimum spark curve map that's tuned in the combustion portion of the engine torque model. This tells the ecu how much spark it can pull without misfiring. It's used for cat lightoff, knock retard, and torque reduction requests on gear shift. That's done by sweeping spark and looking at combustion and torque fluctuation.

I don't have any kind of cylinder pressure data or misfire data. So we go off rules of thumb, past experience, educated guesses. I'd go with 4 because I'm concerned that more than that could overheat exhaust and melt something or cause a misfire. But you can always increase it later.

#36

Stick it in 5th at 1000rpm. Floor it up to 2000rpm. Save log. Advance 1 or 2 degrees, do it again. Compare knock sensor activity. Keep advancing until you hear audible knock. Shouldn't be too loud. See if you have some kind of trend of spark vs knock sensor activity. Be mindful of air intake temps changing knock limit.

There's a small risk of preignition but I think it probably won't be an issue. That will make a louder sound and be more unpredictable than spark knock.

If you can't get any knock sensor activity but you can hear it audibly, or its just way too low, I would wonder about the gain and the frequency settings.

There's a small risk of preignition but I think it probably won't be an issue. That will make a louder sound and be more unpredictable than spark knock.

If you can't get any knock sensor activity but you can hear it audibly, or its just way too low, I would wonder about the gain and the frequency settings.

#37

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,298

Total Cats: 477

Ok im coming back to this now.

1. There's no easy answer to this without a lot of risky testing. Pull 5 degrees method is closer to what I'd do, but you've got transient and drive train effects from doing pulls on the street.

Running in neutral unfortunately doesn't load the engine down so much, but we don't know the sensitivity of background noise to load. That's the kind of thing you study when you configure a knock sensor in a lab.

You could do both and see if any of the numbers make any sense.

2. If you're not willing to beat the **** out of the engine to find out (who could blame you), 10% is as good as any. It's kind of arbitrary as nobody can seem to agree on where the line is first crossed and how much knock is too much.

3. Ok so if you had a modern model based ecu you would have a minimum spark curve map that's tuned in the combustion portion of the engine torque model. This tells the ecu how much spark it can pull without misfiring. It's used for cat lightoff, knock retard, and torque reduction requests on gear shift. That's done by sweeping spark and looking at combustion and torque fluctuation.

I don't have any kind of cylinder pressure data or misfire data. So we go off rules of thumb, past experience, educated guesses. I'd go with 4 because I'm concerned that more than that could overheat exhaust and melt something or cause a misfire. But you can always increase it later.

1. There's no easy answer to this without a lot of risky testing. Pull 5 degrees method is closer to what I'd do, but you've got transient and drive train effects from doing pulls on the street.

Running in neutral unfortunately doesn't load the engine down so much, but we don't know the sensitivity of background noise to load. That's the kind of thing you study when you configure a knock sensor in a lab.

You could do both and see if any of the numbers make any sense.

2. If you're not willing to beat the **** out of the engine to find out (who could blame you), 10% is as good as any. It's kind of arbitrary as nobody can seem to agree on where the line is first crossed and how much knock is too much.

3. Ok so if you had a modern model based ecu you would have a minimum spark curve map that's tuned in the combustion portion of the engine torque model. This tells the ecu how much spark it can pull without misfiring. It's used for cat lightoff, knock retard, and torque reduction requests on gear shift. That's done by sweeping spark and looking at combustion and torque fluctuation.

I don't have any kind of cylinder pressure data or misfire data. So we go off rules of thumb, past experience, educated guesses. I'd go with 4 because I'm concerned that more than that could overheat exhaust and melt something or cause a misfire. But you can always increase it later.

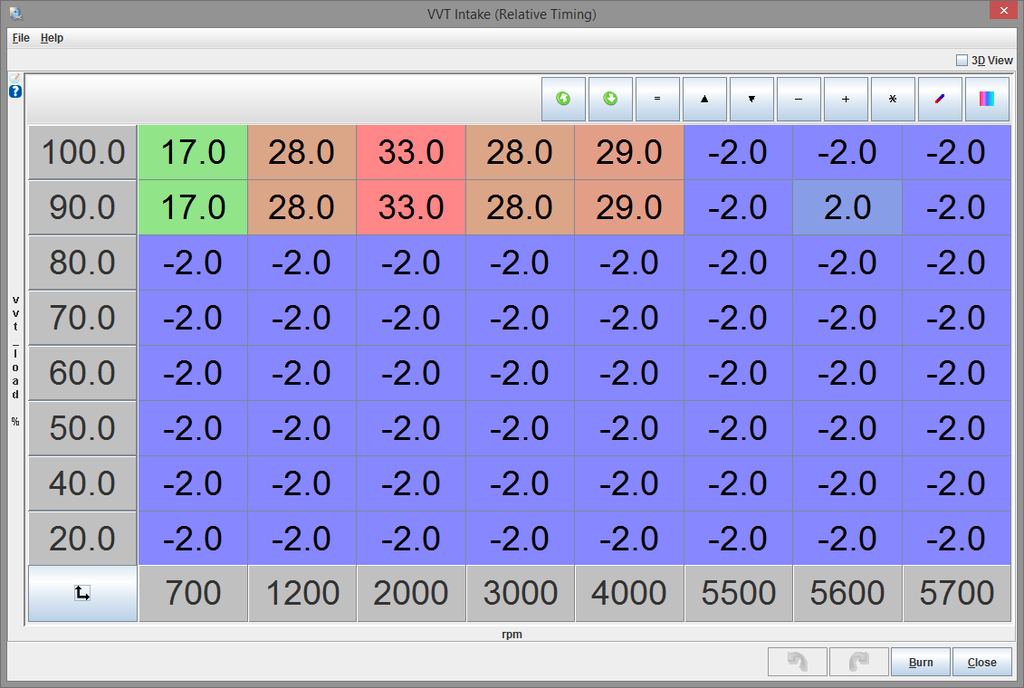

Here is my current VVT map:

1.- Alright I think I'll do the pull 5 degrees approach. I am 99.9% sure my current map does not knock, as I already pulled 3* from it when I know it knocked on that map at some point. I believe it was knocking in the 2000-2500 RPM, 150+kpa range with very high AITs, but at the time I just pulled from all the boosted cells to be safe.

So I think I'll do a baseline the way it is now (minus 3) and another baseline at minus 5, and another at minus 7, etc. Just to "see" what changes. For my knowledge, more data will be useful and help me see what's normal.

2. If I break this engine, I'm tempted to build a cheaper one and use it for testing. There's a lot of things I want to test, and knock control is for sure one of them. But for the question 2, I'm thinking once I have the data from the test in point 1, it should be easier to establish a knock threshold.

Stick it in 5th at 1000rpm. Floor it up to 2000rpm. Save log. Advance 1 or 2 degrees, do it again. Compare knock sensor activity. Keep advancing until you hear audible knock. Shouldn't be too loud. See if you have some kind of trend of spark vs knock sensor activity. Be mindful of air intake temps changing knock limit.

There's a small risk of preignition but I think it probably won't be an issue. That will make a louder sound and be more unpredictable than spark knock.

If you can't get any knock sensor activity but you can hear it audibly, or its just way too low, I would wonder about the gain and the frequency settings.

There's a small risk of preignition but I think it probably won't be an issue. That will make a louder sound and be more unpredictable than spark knock.

If you can't get any knock sensor activity but you can hear it audibly, or its just way too low, I would wonder about the gain and the frequency settings.

I'm doing a pulley upgrade too so new boost level will be around 30 PSI at 7,700, it was 23 PSI at 8,500 before. 30% more pulley now.

#39

Tweaking Enginerd

iTrader: (2)

Join Date: Mar 2013

Location: Boulder, CO

Posts: 1,778

Total Cats: 358

The MS3PRO module uses the TPIC8101. The datasheet and application notes do a pretty good job of speaking to the integrator time constant. I ~think~ I remember the integration time being determined by the knock window, but it has been a long time since I looked at this stuff.

#40

The MS3PRO module uses the TPIC8101. The datasheet and application notes do a pretty good job of speaking to the integrator time constant. I ~think~ I remember the integration time being determined by the knock window, but it has been a long time since I looked at this stuff.

you manually set the integrator time constant under the bandpass filter. Initial setting 150 ms