Req_fuel & low z injector help

#1

Junior Member

Thread Starter

Join Date: May 2007

Location: Mountain View, CA

Posts: 220

Total Cats: 0

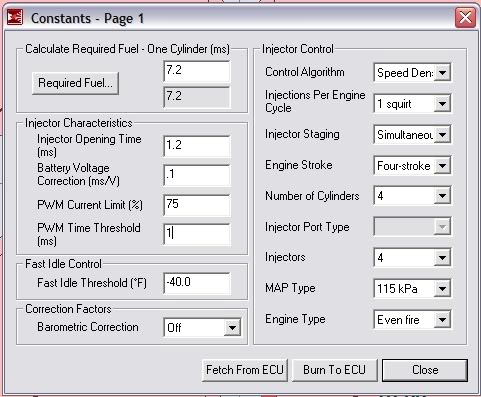

I am trying to do the req_fuel calc right now and am inputting 450cc displacement, 440cc/min injector, and 14.0 afr. Is this correct?? It gives me 7.1 as my req_fuel but then a bunch of errors for the ms, ms/v, ......should I just enter in manually what it says to put if you are not an expert?

Also how do I set it for low z injectors??

Also how do I set it for low z injectors??

#2

Have you read the MS-Extra Manual???

The answers to most of your questions are in there.

The answers to most of your questions are in there.

Setting the PWM Criteria

To tune the PWM [pulse width modulation] values for your engine, you need to know what kind of injectors you have: low impedance or high impedance.

* If you are running high-impedance injectors (greater than 10 Ohms), then set the:

o PWM Time Threshold to 25.4 msec, and the

o PWM Current Limit (%) to 100%.

In essence you are disabling the PWM mode. This allows full voltage to the injectors throughout the pulse widths.

* For low-impedance injectors (less than 3 Ohms), you need to limit the current to avoid over heating the injectors. To do this, there is a period of time that you apply full battery voltage [peak] current, then switch over to a lower current-averaged [hold] current, i.e. peak and hold. Alternatively, you can add resistors in series with the injectors. See the Injectors and Fuel Supply section of this manual for more details.

To run low-impedance injectors with the PWM current limit mode, you need to set two parameters - the "PWM Current Limit (%)" and the "PWM Time Threshold (ms)" - both are on the “Constants” page. The current limit % is the percent duty cycle when the current limit is invoked. The time threshold is the amount of time from when the injector is first opened until the current limit is activated.

To tune the PWM [pulse width modulation] values for your engine, you need to know what kind of injectors you have: low impedance or high impedance.

* If you are running high-impedance injectors (greater than 10 Ohms), then set the:

o PWM Time Threshold to 25.4 msec, and the

o PWM Current Limit (%) to 100%.

In essence you are disabling the PWM mode. This allows full voltage to the injectors throughout the pulse widths.

* For low-impedance injectors (less than 3 Ohms), you need to limit the current to avoid over heating the injectors. To do this, there is a period of time that you apply full battery voltage [peak] current, then switch over to a lower current-averaged [hold] current, i.e. peak and hold. Alternatively, you can add resistors in series with the injectors. See the Injectors and Fuel Supply section of this manual for more details.

To run low-impedance injectors with the PWM current limit mode, you need to set two parameters - the "PWM Current Limit (%)" and the "PWM Time Threshold (ms)" - both are on the “Constants” page. The current limit % is the percent duty cycle when the current limit is invoked. The time threshold is the amount of time from when the injector is first opened until the current limit is activated.

On the Settings/Constants page:

If you are running high-impedance injectors (greater than 10 Ohms), then set the:

* PWM Time Threshold to 25.5 msec, and the

* PWM Current Limit (%) to 100%.

If you have low impedance injectors (less than 4 Ohms), set the:

* PWM Time Threshold is the time required to open the injector, this is when full power is used to open the injector. Start at 1.0 msec, and

* PWM Current Limit is the Pulse Width thats used after the Time Threshold, this actually pulses the injectors on and off, keeping the injector from over heating at high duty cycles. Try starting at around 75% (30% if you have installed the 'Flyback Board' daughter card or if using a V3.0 pcb with the Flyback components installed).

You will tune these after getting the engine running. See “Setting the PWM Criteria” in this section. Failure to perform these steps can result in damage to your injectors. If you have high-impedance injectors, set these values to 25.5 ms and 100%, and you do not need to tune them further.

If you are running high-impedance injectors (greater than 10 Ohms), then set the:

* PWM Time Threshold to 25.5 msec, and the

* PWM Current Limit (%) to 100%.

If you have low impedance injectors (less than 4 Ohms), set the:

* PWM Time Threshold is the time required to open the injector, this is when full power is used to open the injector. Start at 1.0 msec, and

* PWM Current Limit is the Pulse Width thats used after the Time Threshold, this actually pulses the injectors on and off, keeping the injector from over heating at high duty cycles. Try starting at around 75% (30% if you have installed the 'Flyback Board' daughter card or if using a V3.0 pcb with the Flyback components installed).

You will tune these after getting the engine running. See “Setting the PWM Criteria” in this section. Failure to perform these steps can result in damage to your injectors. If you have high-impedance injectors, set these values to 25.5 ms and 100%, and you do not need to tune them further.

Required Fuel – (Req_Fuel) this is top field of the Constants window. It has a calculation dialog to help you find an appropriate value. It should contain the injector pulse width, in milliseconds, required to supply the fuel for a single injection event at stoichiometric combustion and 100% volumetric efficiency.

Ensure that the NUMBER of CYLINDERS has been set before using the wizard!

In order to come up with this value, MegaTune provides a calculator that will suffice for 99% of applications (those for which it will not work generally require changes to the MegaSquirt controller code itself, and that is beyond the scope of this manual). To use the wizard, click on the Required Fuel button, and fill in the fields (Engine Displacement, Number of cylinders, Injector flow, and Air:Fuel ratio(14.7), then click 'Okay').

For a 4-stroke, a complete stroke cycle is 720 degrees of crankshaft rotation (i.e. two revolutions); for a 2-stroke, it is 360 degrees (this is also factored in the REQ_FUEL value down loaded to MegaSquirt).

In the tuning software, the upper REQ_FUEL box is the amount per cylinder, as noted above. The lower REQ_FUEL box is the value down loaded to MegaSquirt. It is the REQ_FUEL number on top, but scaled by your selected injection mode (number of squirts and alternate/simultaneous), this can be ignored as it is the upper number thats the important value.

For example, if you inject simultaneous and one injection, and have the same number of injectors as cylinders [i.e. port injection], then REQ_FUEL on the bottom is the same as REQ_FUEL on top. Same with alternate and two squirts. If you put in simultaneous and two squirts, then REQ_FUEL is divided in half - because you squirt twice, you need to inject 1/2 the fuel on each shot.

Note: if you choose alternating for port injection, make sure your number of squirts is an even number (2,4,...) and evenly divisible into the number of cylinders. For example, with an eight cylinder engine, you could use alternating and 2, 4, or 8 squirts/cycle. With a six cylinder, if you choose alternating, you MUST use 2 or 6 squirts/cycle. Also, the only possible combinations for an odd-cylinder count engine are either 1 squirt/simultaneous or N squirt/simultaneous combination, where N is the number of cylinders."

Ensure that the NUMBER of CYLINDERS has been set before using the wizard!

In order to come up with this value, MegaTune provides a calculator that will suffice for 99% of applications (those for which it will not work generally require changes to the MegaSquirt controller code itself, and that is beyond the scope of this manual). To use the wizard, click on the Required Fuel button, and fill in the fields (Engine Displacement, Number of cylinders, Injector flow, and Air:Fuel ratio(14.7), then click 'Okay').

For a 4-stroke, a complete stroke cycle is 720 degrees of crankshaft rotation (i.e. two revolutions); for a 2-stroke, it is 360 degrees (this is also factored in the REQ_FUEL value down loaded to MegaSquirt).

In the tuning software, the upper REQ_FUEL box is the amount per cylinder, as noted above. The lower REQ_FUEL box is the value down loaded to MegaSquirt. It is the REQ_FUEL number on top, but scaled by your selected injection mode (number of squirts and alternate/simultaneous), this can be ignored as it is the upper number thats the important value.

For example, if you inject simultaneous and one injection, and have the same number of injectors as cylinders [i.e. port injection], then REQ_FUEL on the bottom is the same as REQ_FUEL on top. Same with alternate and two squirts. If you put in simultaneous and two squirts, then REQ_FUEL is divided in half - because you squirt twice, you need to inject 1/2 the fuel on each shot.

Note: if you choose alternating for port injection, make sure your number of squirts is an even number (2,4,...) and evenly divisible into the number of cylinders. For example, with an eight cylinder engine, you could use alternating and 2, 4, or 8 squirts/cycle. With a six cylinder, if you choose alternating, you MUST use 2 or 6 squirts/cycle. Also, the only possible combinations for an odd-cylinder count engine are either 1 squirt/simultaneous or N squirt/simultaneous combination, where N is the number of cylinders."

#7

The manual says 14.7 for gasoline, he even posted the quoted manual for you.

"To use the wizard, click on the Required Fuel button, and fill in the fields (Engine Displacement, Number of cylinders, Injector flow, and Air:Fuel ratio(14.7), then click 'Okay')."

You need to ender your full engine displacement which is liek 1850cc not the per cylinder displacement.

"To use the wizard, click on the Required Fuel button, and fill in the fields (Engine Displacement, Number of cylinders, Injector flow, and Air:Fuel ratio(14.7), then click 'Okay')."

You need to ender your full engine displacement which is liek 1850cc not the per cylinder displacement.

#9

I just calculated it and got 6.9, 7.0 should be fine. Different engine cc values will make it vary that much I suppose.

If you have a wideband, you have no excuse if you blow your own motor. Long as you use the timing tables DIY provided and tune fuel from rich to lean you should be golden though.

If you have a wideband, you have no excuse if you blow your own motor. Long as you use the timing tables DIY provided and tune fuel from rich to lean you should be golden though.

Last edited by cjernigan; 09-26-2007 at 12:40 AM.

#12

Junior Member

Thread Starter

Join Date: May 2007

Location: Mountain View, CA

Posts: 220

Total Cats: 0

And bye the way, that constants page is incorrect. I had not opened a .msg file so the fields were not automatically filler in.

How do I get the idle to come down? And where should the spark angle and a/f ratio be (14.7 I think)

How do I get the idle to come down? And where should the spark angle and a/f ratio be (14.7 I think)

#18

Supporting Vendor

iTrader: (5)

Join Date: Jun 2006

Location: Duluth, GA 30097

Posts: 803

Total Cats: 0

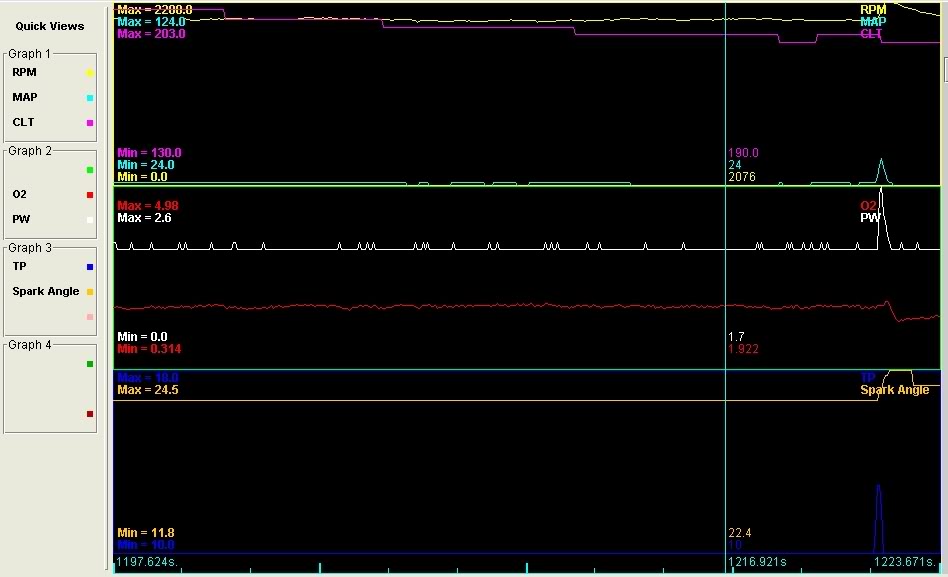

Kyle's been in touch with us-- anytime you've made changes to your engine, particularly injectors, and then you start idling this high, first thing you want to check is for a vacuum leak. I checked his datalog and the idle valve is doing everything it can to bring the idle down, it's at the minimum 9dc, but it's still idling around 2000rpm even when fully warmed up. Air is getting in somewhere else. He's noted that there's at least one small leak, I've seen a couple cases though where the injector seals themselves are leaking and that's a common culprit after changing injectors.

Do the injectors all rotate freely or are any of them bound up? They should all rotate fairly easily after the rail is bolted down.

I wouldn't recommend adjusting the idle screw since in his case it was fine before, and should be fine still-- changing it will just be one more variable to get right later, and it's right now-- he's got a massive vacuum leak somewhere...

Do the injectors all rotate freely or are any of them bound up? They should all rotate fairly easily after the rail is bolted down.

I wouldn't recommend adjusting the idle screw since in his case it was fine before, and should be fine still-- changing it will just be one more variable to get right later, and it's right now-- he's got a massive vacuum leak somewhere...

__________________

Jerry a.k.a. 'FoundSoul'

DIYAutoTune.com

'91 Miata BEGi S3 GT2560 w/ MSPNP - 14.1psi - 253whp, 232wtq

'95 Miata n/a

A few other cars....

Jerry a.k.a. 'FoundSoul'

DIYAutoTune.com

'91 Miata BEGi S3 GT2560 w/ MSPNP - 14.1psi - 253whp, 232wtq

'95 Miata n/a

A few other cars....

#19

Junior Member

Thread Starter

Join Date: May 2007

Location: Mountain View, CA

Posts: 220

Total Cats: 0

Yeah, when I went to start the car for the first time I primed the pump 3 times because I could hear air bleeding off. The problem was that on the 3rd prime I heard a big bang and a clunk. I had blown a cap off of the #4 intake runner nipple. It was causing my high idle. Plugged it back up and now it is fine. The injectors do rotate freely as well.

My problem now is that I am getting a stumble or very fast cut-out while cruising, where the car jerks and the tach drops. After that it is fine. I have not had time to dig into the cause yet but does anyone have ideas of common causes??

My problem now is that I am getting a stumble or very fast cut-out while cruising, where the car jerks and the tach drops. After that it is fine. I have not had time to dig into the cause yet but does anyone have ideas of common causes??

#20

Elite Member

iTrader: (1)

Join Date: Jun 2006

Location: Warrington/Birmingham

Posts: 2,642

Total Cats: 42

Yeah, when I went to start the car for the first time I primed the pump 3 times because I could hear air bleeding off. The problem was that on the 3rd prime I heard a big bang and a clunk. I had blown a cap off of the #4 intake runner nipple. It was causing my high idle. Plugged it back up and now it is fine. The injectors do rotate freely as well.

My problem now is that I am getting a stumble or very fast cut-out while cruising, where the car jerks and the tach drops. After that it is fine. I have not had time to dig into the cause yet but does anyone have ideas of common causes??

My problem now is that I am getting a stumble or very fast cut-out while cruising, where the car jerks and the tach drops. After that it is fine. I have not had time to dig into the cause yet but does anyone have ideas of common causes??