Active rear wing test

#61

Supporting Vendor

iTrader: (33)

Join Date: Jul 2006

Location: atlanta-ish

Posts: 12,659

Total Cats: 134

Wiper motors like to just spin and spin in one direction and they only have logic to return to a single position, not two (or variable). Without complicated controls, the headlight motor is much better.

My only concern with this being hooked to the brake light is triple digit trail braking at the limit where you are counting on a certain level of grip that might not be there with the wing in air brake mode.

Edit: I typed this about 2 hours before my phone sent it. Psi switch on brakes would be better to trigger.

My only concern with this being hooked to the brake light is triple digit trail braking at the limit where you are counting on a certain level of grip that might not be there with the wing in air brake mode.

Edit: I typed this about 2 hours before my phone sent it. Psi switch on brakes would be better to trigger.

I *am* talking about building a complicated control, so it looks like the wiper motor could be a better choice than headlight motors, for a low budget solution. A position sensor will be incorporated for closed loop control and fault detection.

#62

Ben, you're on the right track, but you can do the same thing with the wiper motor, and you have the benefit of the motor's absolute position stops. You can use the built in switches to prevent wing over-travel and make sure your extreme positions are perfectly repeatable. You could simply add an encoder to the rotation shaft (on the back) and you'll know the absolute position at all times (as long as you keep to one side of the motor's rotation). The linkage kinematics will be a little different if you let the motor rotate on its other side.

#63

Ben, you're on the right track, but you can do the same thing with the wiper motor, and you have the benefit of the motor's absolute position stops. You can use the built in switches to prevent wing over-travel and make sure your extreme positions are perfectly repeatable. You could simply add an encoder to the rotation shaft (on the back) and you'll know the absolute position at all times (as long as you keep to one side of the motor's rotation). The linkage kinematics will be a little different if you let the motor rotate on its other side.

Both the wiper motor and the headlight motors spin all the way around, in both cases its the linkage causing the motion between the two positions. The headlight motor has stops for both positions and the wiper only has one. If you're not using the stop built into the motor, any sort of power window or power seat motor will provide a high torque output and be non-backdrivable.

#64

As someone who's actually tried triple digit braking with this, however, I'm not concerned. The car didn't seem loose on turn-in at all, although I'll admit that trailbraking is not one of my usual techniques. Even if you did lose a bit on trailbraking, if your overall braking is improved then it may be worth the tradeoff - just like we trade off drag on the straights for downforce in the corners.

#65

Well, it's going to be part of the car's driving characteristics - the car will act the same way every time. I'm assuming you'd learn them before going out to set the fastest lap on qualifying, so you'd be familiar with how the car behaves in high speed braking.

As someone who's actually tried triple digit braking with this, however, I'm not concerned. The car didn't seem loose on turn-in at all, although I'll admit that trailbraking is not one of my usual techniques. Even if you did lose a bit on trailbraking, if your overall braking is improved then it may be worth the tradeoff - just like we trade off drag on the straights for downforce in the corners.

As someone who's actually tried triple digit braking with this, however, I'm not concerned. The car didn't seem loose on turn-in at all, although I'll admit that trailbraking is not one of my usual techniques. Even if you did lose a bit on trailbraking, if your overall braking is improved then it may be worth the tradeoff - just like we trade off drag on the straights for downforce in the corners.

#66

The wing is quite visible in the rear view mirror, so you'd know as soon as it happened. But yes, failure of the actuator would be best avoided. As with all other systems on a race car. It's also surprising when the internal seals in your master cylinder fail, and you don't find out about that until it's too late...

#68

Why not look at stepper motor control of the headlight actuator mechanism for variable position control. Maybe even use a stepper directly actuating the wing similar to the headlight actuator. I don't know how much torque you can get at 12 volts without insane currents. Just an idea.

I have been looking at several steppers for CNC control that could do it, but at higher voltages.

I have been looking at several steppers for CNC control that could do it, but at higher voltages.

#69

. But of course, you'll want to engineer things to be strong enough for the intended use. Heck, solid linkages for brakes are probably more reliable than hydraulics, but we don't use those anymore

. But of course, you'll want to engineer things to be strong enough for the intended use. Heck, solid linkages for brakes are probably more reliable than hydraulics, but we don't use those anymore  Just because it's a potential failure point doesn't mean it shouldn't be investigated. We rely on electric motors for our fans and our fuel pumps without any real concerns, it shouldn't be too hard to make them work for aero as well.

Just because it's a potential failure point doesn't mean it shouldn't be investigated. We rely on electric motors for our fans and our fuel pumps without any real concerns, it shouldn't be too hard to make them work for aero as well.

#71

Sorry if this was mentioned already, but when you brake is the wing's angle of attack so steep that its "stalled"?

Its my understanding that as you angle a wing steeper it will tend to produce more downforce and more drag, then at a certain point lose downforce and create a heap of drag. To word my question another way, is this tilting forward to increase drag and down force, or sacrificing downforce to be used as an air brake?

Its my understanding that as you angle a wing steeper it will tend to produce more downforce and more drag, then at a certain point lose downforce and create a heap of drag. To word my question another way, is this tilting forward to increase drag and down force, or sacrificing downforce to be used as an air brake?

#72

For real nerdy control, make the damn thing tunable by track location and speed, fed by GPS.

Then there is no problem setting it up at any possible angle of attack for brake-zone, mid-corner (high, mid and low speed), straight speed whatever.

You would of course make it dance whatever routine you want while in the pits.

But the current Airbrake function is cool enough, just because someone actually have tested it and not just typed about it.

LINEAR ACTUATOR WITH POSITION FEEDBACK ?

Then there is no problem setting it up at any possible angle of attack for brake-zone, mid-corner (high, mid and low speed), straight speed whatever.

You would of course make it dance whatever routine you want while in the pits.

But the current Airbrake function is cool enough, just because someone actually have tested it and not just typed about it.

LINEAR ACTUATOR WITH POSITION FEEDBACK ?

#73

Vilko, yes. I'm trading off downforce for massive amounts of drag. However, the same concept could be used to just increase downforce although it wouldn't be as effective at slowing the car.

Niklas, we've already discussed the linear actuators with position feedback. I started this whole experiment with one in hand, but it wasn't suitable. Scenturion is loaning me a couple of high speed ones to play with, so we'll see what the next iteration looks like. It's highly unlikely I'll investigate GPS control, although I have had a few offers of interesting toys from various sources. Most likely, I'll go with my original intent of a DRS setting triggered by the driver, an airbrake triggered by the brake lights and a default cornering position.

Niklas, we've already discussed the linear actuators with position feedback. I started this whole experiment with one in hand, but it wasn't suitable. Scenturion is loaning me a couple of high speed ones to play with, so we'll see what the next iteration looks like. It's highly unlikely I'll investigate GPS control, although I have had a few offers of interesting toys from various sources. Most likely, I'll go with my original intent of a DRS setting triggered by the driver, an airbrake triggered by the brake lights and a default cornering position.

#74

Being pragmatic and realistic using the simplest possible way to move between two positions have already been proven (the Airbrake already works).

Now you only need to add a similar system in series (e.g. move the other mounting point with another mechanics and simple motors).

Since the Normal->DRS movement is much smaller, doing that with the same motor would mean higher precision than needed and the important angle would be between the end points.

How much movement would be needed on the front mount point to go from Normal to DRS? Small movement means small motors with gearing/brackets/rods.

But this have probably been covered in one of the first posts

Now you only need to add a similar system in series (e.g. move the other mounting point with another mechanics and simple motors).

Since the Normal->DRS movement is much smaller, doing that with the same motor would mean higher precision than needed and the important angle would be between the end points.

How much movement would be needed on the front mount point to go from Normal to DRS? Small movement means small motors with gearing/brackets/rods.

But this have probably been covered in one of the first posts

#75

I've been thinking about this in the simplest, most effective way to do this. And keep in mind I've never been to the track. Nor have I had to wire anything to do with actuators before. But what if you just had 3 settings. Minimum drag-low downforce, High downforce-moderate drag and Airbrake.

When the accelerator is pressed if switches to low drag. When the brake is pressed it goes into air brake mode and disconnects the low drag function. And when neither is pressed it goes to high downforce.

Ideally you would probably want a 2-3 second delay on moving to the low drag so little blips don't have the wing going wild and on corner exist it won't reduce downforce until you are actually on the straight. Though I'm not sure if you can wire in the delay without introducing complex computers and programming.

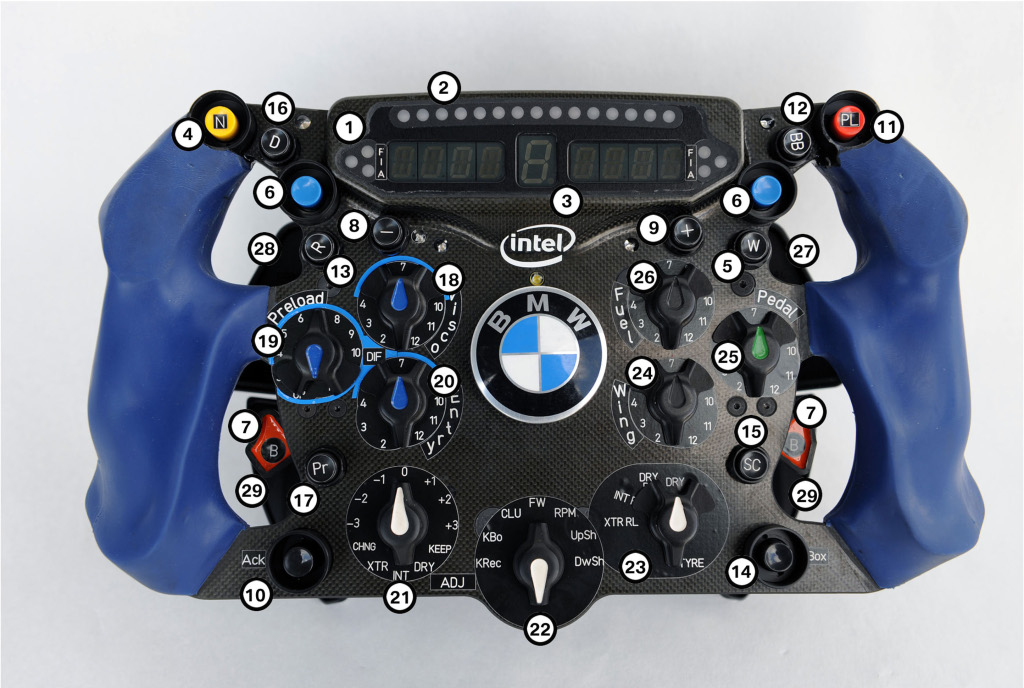

And maybe a momentary bypass switch on the steering wheel to disable the airbrake for trail braking.

If you took the time to design it right you could get it as simple as each setting and condition allowing only 1 of 3 wires to be recieving power. All using only simple mechanical switches. Except for the delay, I have no idea how to wire that haha. Is it possible for those 3 inputs to translate into 3 position actuator or are complex computers and chips required?

When the accelerator is pressed if switches to low drag. When the brake is pressed it goes into air brake mode and disconnects the low drag function. And when neither is pressed it goes to high downforce.

Ideally you would probably want a 2-3 second delay on moving to the low drag so little blips don't have the wing going wild and on corner exist it won't reduce downforce until you are actually on the straight. Though I'm not sure if you can wire in the delay without introducing complex computers and programming.

And maybe a momentary bypass switch on the steering wheel to disable the airbrake for trail braking.

If you took the time to design it right you could get it as simple as each setting and condition allowing only 1 of 3 wires to be recieving power. All using only simple mechanical switches. Except for the delay, I have no idea how to wire that haha. Is it possible for those 3 inputs to translate into 3 position actuator or are complex computers and chips required?

#76

From my very first post:

I like to corner on the throttle, so I wouldn't want the accelerator to determine low drag positioning. Having it on a button is easier, triggered by the left thumb.

I will be trying to implement this using the new actuators that are on the way. The controllers are off-the-shelf units with just a bit of relay logic to get them what they need when they need it.

The initial plan was to use a SPAL linear actuator with a cool three-position controller. I'd have a low drag setting (triggered by a momentary button on the steering wheel), normal (the default) and high drag (triggered by the brake lights). Unfortunately, the speed of the SPAL part was just too slow, 1/2" per second. I could speed that up with linkages, but it was less than ideal.

I will be trying to implement this using the new actuators that are on the way. The controllers are off-the-shelf units with just a bit of relay logic to get them what they need when they need it.

#77

Supporting Vendor

iTrader: (33)

Join Date: Jul 2006

Location: atlanta-ish

Posts: 12,659

Total Cats: 134

I think we can solve the problem of accidentally triggering DRS on throttle in a corner by adding an accelerometer. Or if we want to go bigger, steering angle detection is possible -- it just costs money. A 3-axis accel can be added to the design inexpensively, and it requires no special install.

#78

I like to corner on the throttle, so I wouldn't want the accelerator to determine low drag positioning. Having it on a button is easier, triggered by the left thumb.

I will be trying to implement this using the new actuators that are on the way. The controllers are off-the-shelf units with just a bit of relay logic to get them what they need when they need it.

I will be trying to implement this using the new actuators that are on the way. The controllers are off-the-shelf units with just a bit of relay logic to get them what they need when they need it.