Making Composite Parts

#21

Another tip- don't buy from fiberglast. Most of what they sell is hugely overpriced and all of their private label stuff is just other products relabeled. For example, their system 3000 epoxy resin is just aeropoxy. $200 a gallon from fiberglast, $140 a gallon everywhere else. I buy fabrics for wet layup from soller composites.

#22

Senior Member

Thread Starter

Join Date: Oct 2011

Location: The Race Track & St Pete FL

Posts: 638

Total Cats: 57

I'm working on the bottom part of the trunk

And if anyone was wondering what I do for a living, well I worked for one of the biggest composite tooling company in the US (Marine Concepts/JRL Ventures). Now I make Carbon Fiber and Kevlar/fiberglass boats for Barker Boatworks

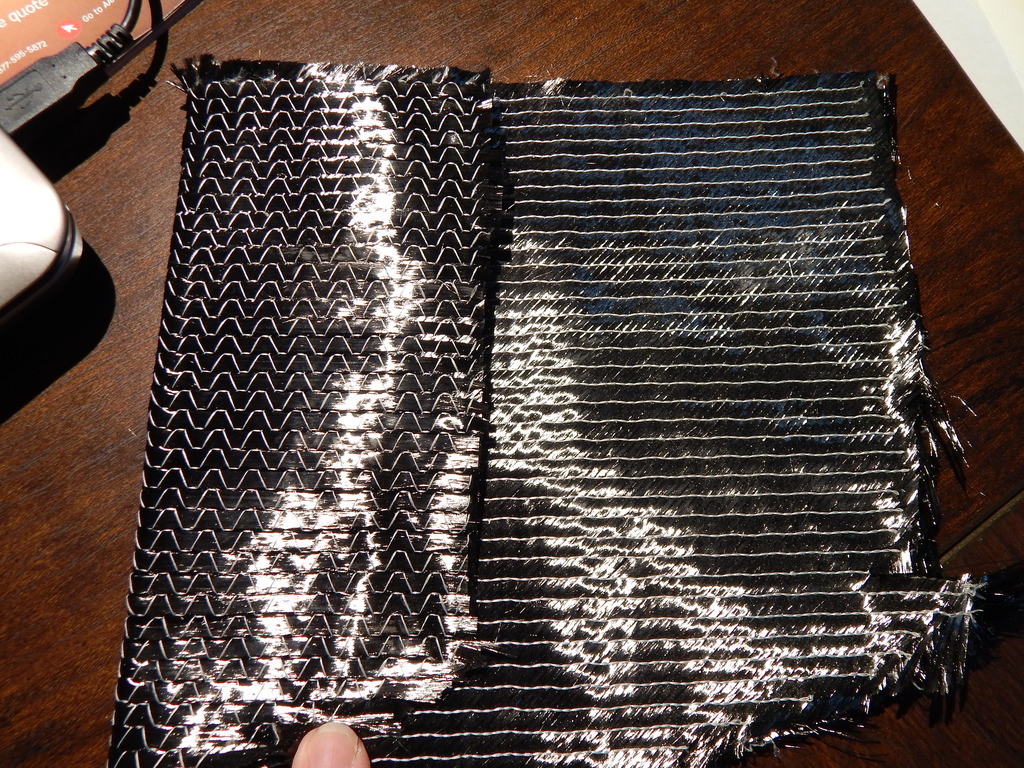

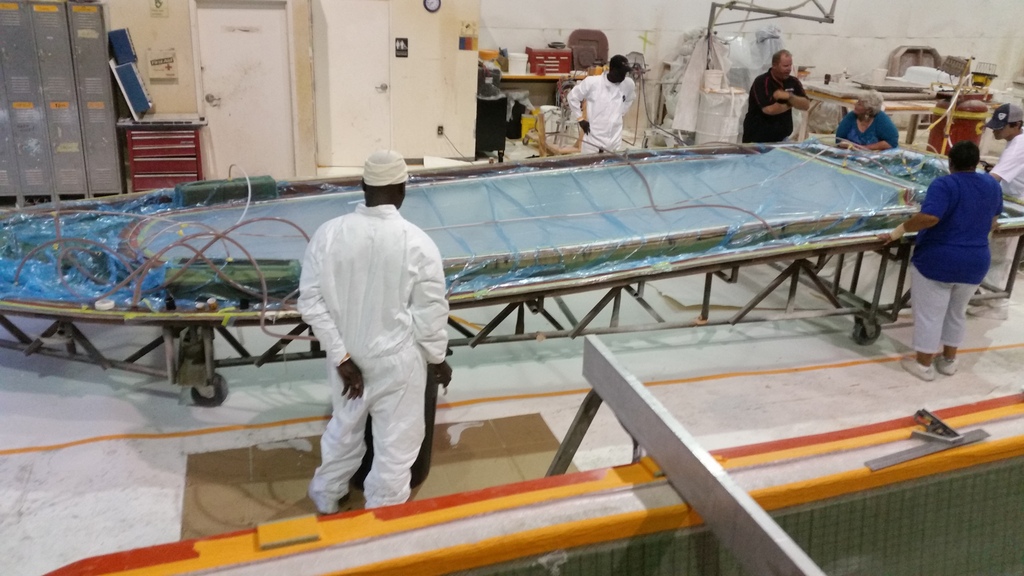

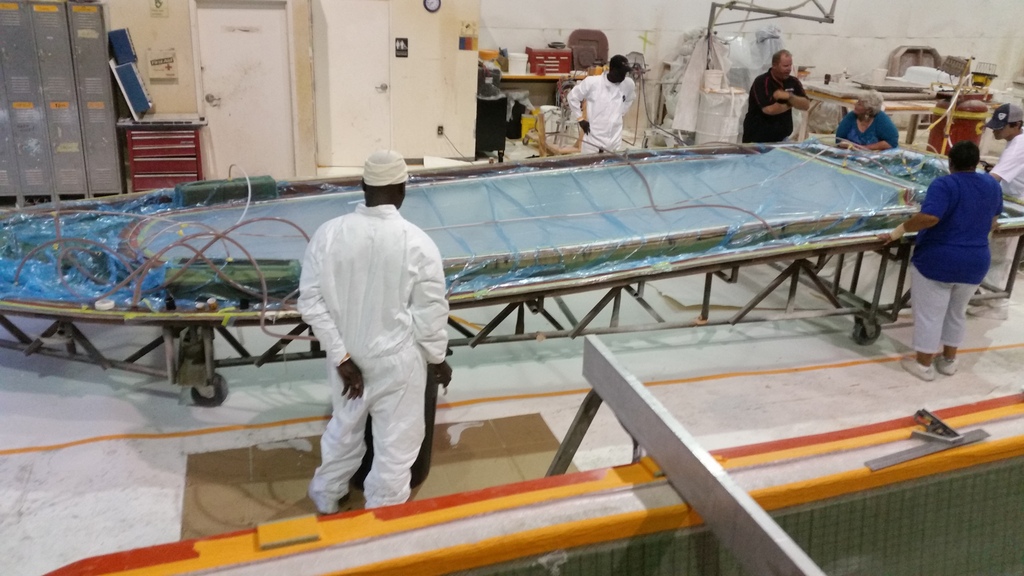

Vacuum Infusing A Fiberglass/Kevlar deck (from today)

Foam core about to go down over the Kevlar

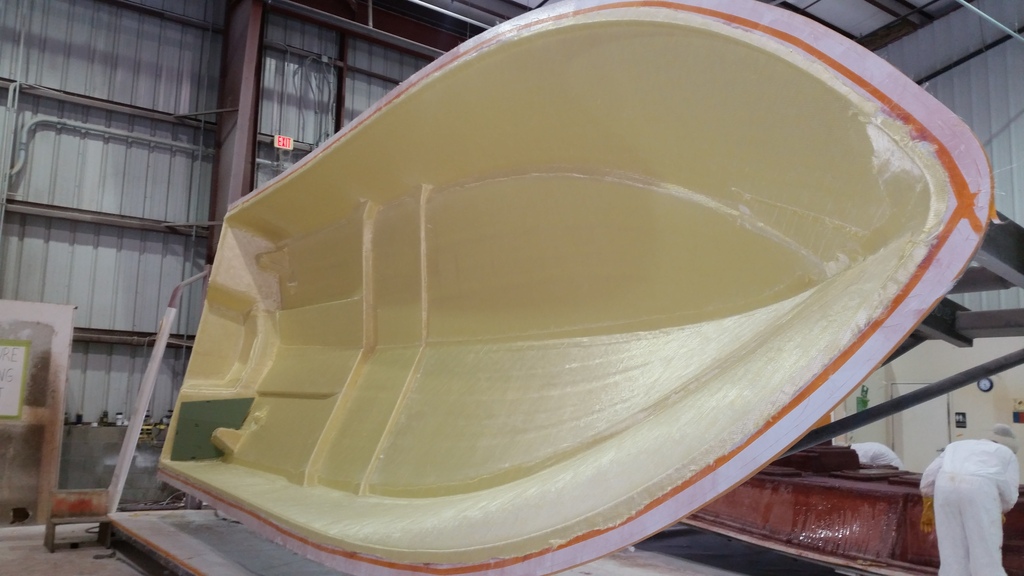

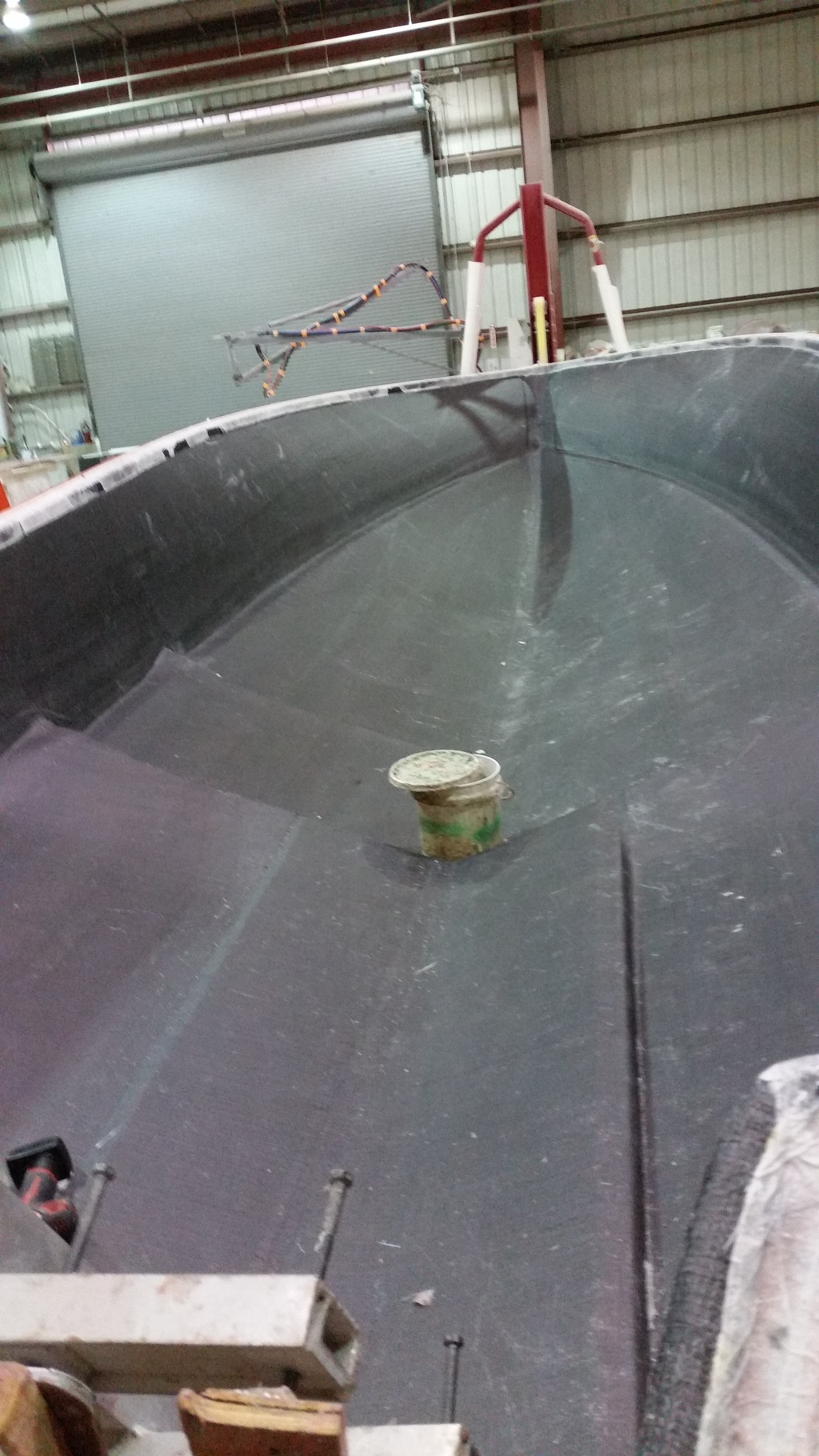

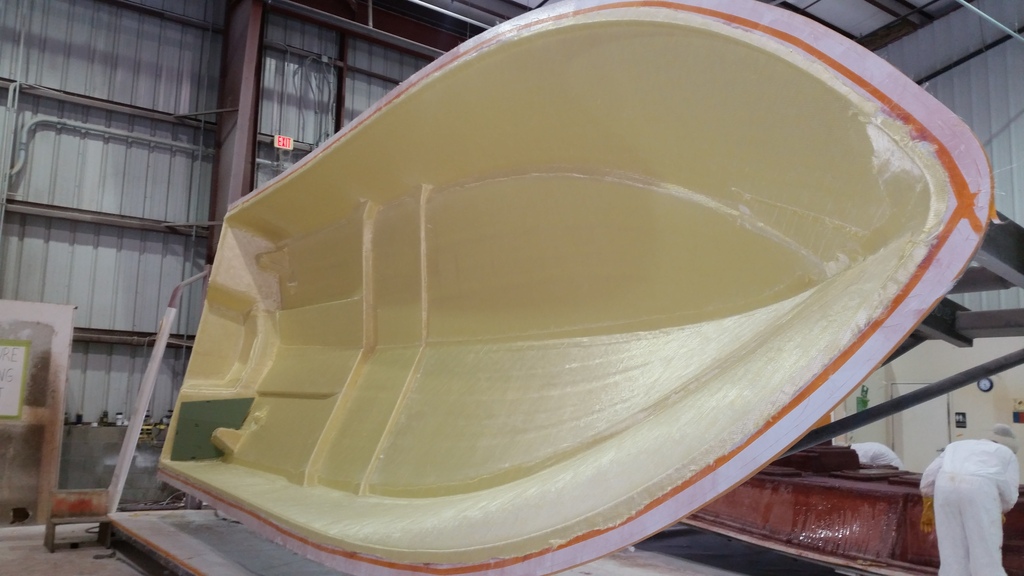

Just done Carbon Hull

And if anyone was wondering what I do for a living, well I worked for one of the biggest composite tooling company in the US (Marine Concepts/JRL Ventures). Now I make Carbon Fiber and Kevlar/fiberglass boats for Barker Boatworks

Vacuum Infusing A Fiberglass/Kevlar deck (from today)

Foam core about to go down over the Kevlar

Just done Carbon Hull

#23

I made a hood with the headlight covers built into it (since the head lights no ,on get exist).

I used normal twill weave set (2x2?) top and bottom, 411 x 2 layers and then a 3mm core.

it came up very stiff, and I have track tested it several times.

I also only only did the top of the hood, so there is no bracing and no hinge mounting points.

I used normal twill weave set (2x2?) top and bottom, 411 x 2 layers and then a 3mm core.

it came up very stiff, and I have track tested it several times.

I also only only did the top of the hood, so there is no bracing and no hinge mounting points.

Last edited by Tim_Aus; 05-06-2016 at 08:07 AM.

#26

Subscribed. I've got a fiberglass 1/2 bumper front air dam I need to make a mold of so I can make me some more in carbon fiber. Been struggling with how exactly to make the mold and flanges. I'm thinking I need to separate the air dam from the rest of the front bumper but I worry that it will not be rigid enough if I do that. I think originally they may have taken a splash while the entire front bumper was mounted to the car. I also need to get all the vacuum bag stuff like bags, connectors, etc. for my vacuum pump. I'd also like to try my hand at vacuum infusion process at some point.

#27

2 Props,3 Dildos,& 1 Cat

iTrader: (8)

Join Date: Jun 2005

Location: Fake Virginia

Posts: 19,338

Total Cats: 573

Subscribed. I've got a fiberglass 1/2 bumper front air dam I need to make a mold of so I can make me some more in carbon fiber. Been struggling with how exactly to make the mold and flanges. I'm thinking I need to separate the air dam from the rest of the front bumper but I worry that it will not be rigid enough if I do that. I think originally they may have taken a splash while the entire front bumper was mounted to the car. I also need to get all the vacuum bag stuff like bags, connectors, etc. for my vacuum pump. I'd also like to try my hand at vacuum infusion process at some point.

#29

Senior Member

Thread Starter

Join Date: Oct 2011

Location: The Race Track & St Pete FL

Posts: 638

Total Cats: 57

Subscribed. I've got a fiberglass 1/2 bumper front air dam I need to make a mold of so I can make me some more in carbon fiber. Been struggling with how exactly to make the mold and flanges. I'm thinking I need to separate the air dam from the rest of the front bumper but I worry that it will not be rigid enough if I do that. I think originally they may have taken a splash while the entire front bumper was mounted to the car. I also need to get all the vacuum bag stuff like bags, connectors, etc. for my vacuum pump. I'd also like to try my hand at vacuum infusion process at some point.

Post your DIY Aero - Time Attack Forums

#30

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

I made a hood with the headlight covers built into it (since the head lights no ,on get exist).

I used normal twill weave set (2x2?) top and bottom, 411 x 2 layers and then a 3mm core.

it came up very stiff, and I have track tested it several times.

I also only only did the top of the hood, so there is no bracing and no hinge mounting points.

I used normal twill weave set (2x2?) top and bottom, 411 x 2 layers and then a 3mm core.

it came up very stiff, and I have track tested it several times.

I also only only did the top of the hood, so there is no bracing and no hinge mounting points.

#31

Senior Member

Thread Starter

Join Date: Oct 2011

Location: The Race Track & St Pete FL

Posts: 638

Total Cats: 57

I wanted to see if anyone has worked with Spread Tow Carbon fiber. I was woundering if I could use 2 layers of 160gr/m with a 1/4 honeycomb use for a trunk could be doable

http://www.easycomposites.co.uk/#!/f...ain-weave.html

http://www.easycomposites.co.uk/#!/f...ain-weave.html

#33

Is it partly stock bumper with added air dam? maybe post #3 might inspire you

Post your DIY Aero - Time Attack Forums

Post your DIY Aero - Time Attack Forums

#36

Wow that looks like great material.

I have a hobby ski press and would love to find some of that triax. Any idea what it runs per yard? And can you get 10 yard quantities?

PM me if you'd like to share your source; no one I deal with carries stitched 18oz carbon...

Man and that foam core for the boat... do you cnc mill the entire core?

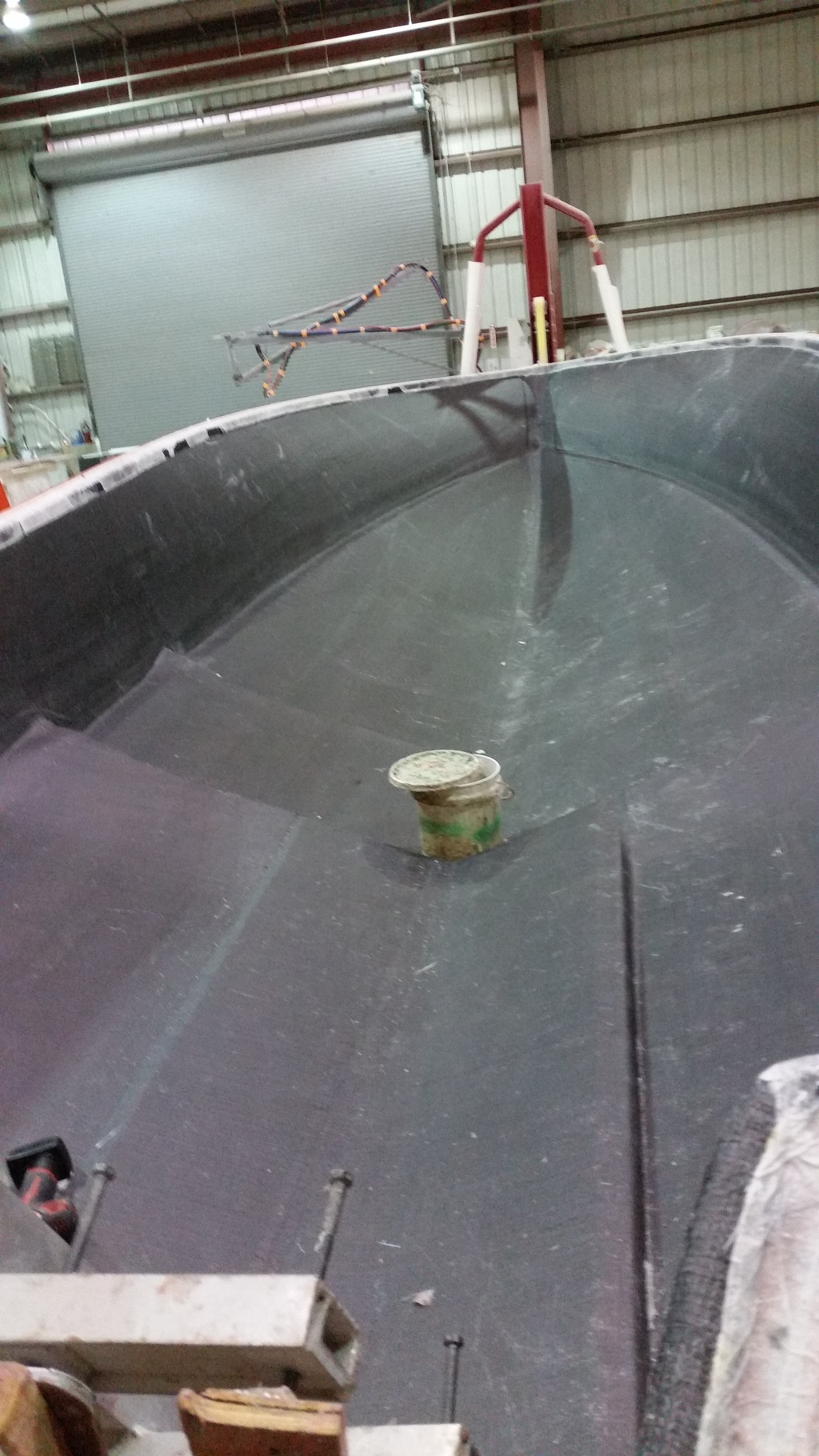

Some random pics:

Urethane moat pour in the core

I have a hobby ski press and would love to find some of that triax. Any idea what it runs per yard? And can you get 10 yard quantities?

PM me if you'd like to share your source; no one I deal with carries stitched 18oz carbon...

Man and that foam core for the boat... do you cnc mill the entire core?

Some random pics:

Urethane moat pour in the core

#37

Senior Member

Thread Starter

Join Date: Oct 2011

Location: The Race Track & St Pete FL

Posts: 638

Total Cats: 57

Wow that looks like great material.

I have a hobby ski press and would love to find some of that triax. Any idea what it runs per yard? And can you get 10 yard quantities?

PM me if you'd like to share your source; no one I deal with carries stitched 18oz carbon...

Man and that foam core for the boat... do you cnc mill the entire core?

We have a outside company cut our foam kits, but I can't remember from a book but i think a piece of 1/4 core makes the laminate 70X stiffer

What kind of materials are you using now?

I have a hobby ski press and would love to find some of that triax. Any idea what it runs per yard? And can you get 10 yard quantities?

PM me if you'd like to share your source; no one I deal with carries stitched 18oz carbon...

Man and that foam core for the boat... do you cnc mill the entire core?

We have a outside company cut our foam kits, but I can't remember from a book but i think a piece of 1/4 core makes the laminate 70X stiffer

What kind of materials are you using now?

Multiaxials | PRF Composites

and some other places for other types of carbon

Composite Reinforcement Fabrics : Carbon Fiber Panels/Sheets, Fabric/Cloth, COLORED Carbon/Kevlar, Composite Envisions

http://www.easycomposites.co.uk/#!/f...-reinforcement

http://www.sollercomposites.com,carbon fiber,carbon fiber sleeve,Kevlar sleeve, fiberglass sleeves,carbon fiber fabric,epoxy,west system epoxy,nitrile,gloves,nitrile gloves,aramid,fiberglass,kevlar,tape,biaxial tape, biaxial sleeve

#39

I have been trying to come up with a plan to make a high quality hood without going the prepreg route- The materials cost on a prepreg hood is huge and you would need a 60" wide roll which is generally more expensive/harder to find than a 50" roll. I want to do wet layup and I don't want to do infusion. I also want to make the part as light as possible and extract the maximum of resin that I can out of the part.

My current plan looks like this:

Two layers of 5.9oz 2k twill vac bagged and cured. After curing, lay nomex honeycomb into the mold and one additional layer of carbon. Vac bag again. I think this will work well since I can get maximum resin extraction on each half of the part while still getting a glossy tool surface.

Suggestions for a resin? Carbon in the sun + engine bay heat means it needs to be higher temp than most RT cure epoxy. I have been using aeropoxy and am looking at pro-set. The hood is too big for my oven so I would need something I can RT cure and then do some crude post cure on using either a polycarbonate/wood box and the sun, or some light bulbs/heat gun setup. The pro-set Lam135/224 combination lists a TG of 223f with post cure but the work time on that is marginal for a part so big. I don't want to deal with handling vinylester or polyester resins in my attached garage.

My current plan looks like this:

Two layers of 5.9oz 2k twill vac bagged and cured. After curing, lay nomex honeycomb into the mold and one additional layer of carbon. Vac bag again. I think this will work well since I can get maximum resin extraction on each half of the part while still getting a glossy tool surface.

Suggestions for a resin? Carbon in the sun + engine bay heat means it needs to be higher temp than most RT cure epoxy. I have been using aeropoxy and am looking at pro-set. The hood is too big for my oven so I would need something I can RT cure and then do some crude post cure on using either a polycarbonate/wood box and the sun, or some light bulbs/heat gun setup. The pro-set Lam135/224 combination lists a TG of 223f with post cure but the work time on that is marginal for a part so big. I don't want to deal with handling vinylester or polyester resins in my attached garage.

#40

I have been trying to come up with a plan to make a high quality hood without going the prepreg route- The materials cost on a prepreg hood is huge and you would need a 60" wide roll which is generally more expensive/harder to find than a 50" roll. I want to do wet layup and I don't want to do infusion. I also want to make the part as light as possible and extract the maximum of resin that I can out of the part.

My current plan looks like this:

Two layers of 5.9oz 2k twill vac bagged and cured. After curing, lay nomex honeycomb into the mold and one additional layer of carbon. Vac bag again. I think this will work well since I can get maximum resin extraction on each half of the part while still getting a glossy tool surface.

Suggestions for a resin? Carbon in the sun + engine bay heat means it needs to be higher temp than most RT cure epoxy. I have been using aeropoxy and am looking at pro-set. The hood is too big for my oven so I would need something I can RT cure and then do some crude post cure on using either a polycarbonate/wood box and the sun, or some light bulbs/heat gun setup. The pro-set Lam135/224 combination lists a TG of 223f with post cure but the work time on that is marginal for a part so big. I don't want to deal with handling vinylester or polyester resins in my attached garage.

My current plan looks like this:

Two layers of 5.9oz 2k twill vac bagged and cured. After curing, lay nomex honeycomb into the mold and one additional layer of carbon. Vac bag again. I think this will work well since I can get maximum resin extraction on each half of the part while still getting a glossy tool surface.

Suggestions for a resin? Carbon in the sun + engine bay heat means it needs to be higher temp than most RT cure epoxy. I have been using aeropoxy and am looking at pro-set. The hood is too big for my oven so I would need something I can RT cure and then do some crude post cure on using either a polycarbonate/wood box and the sun, or some light bulbs/heat gun setup. The pro-set Lam135/224 combination lists a TG of 223f with post cure but the work time on that is marginal for a part so big. I don't want to deal with handling vinylester or polyester resins in my attached garage.