How to remove and replace differential bushings

#1

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268

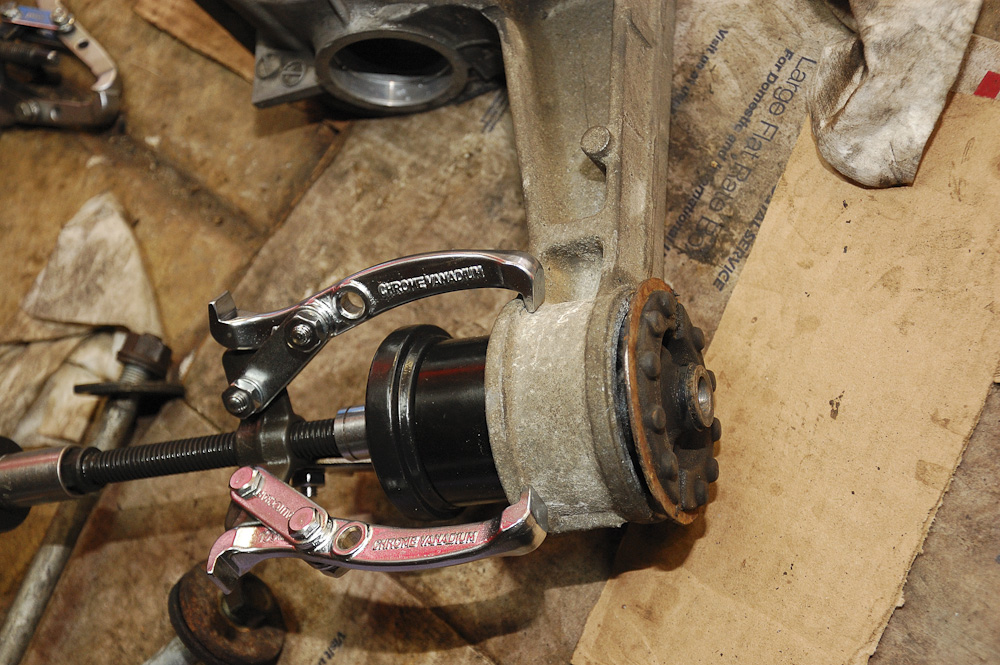

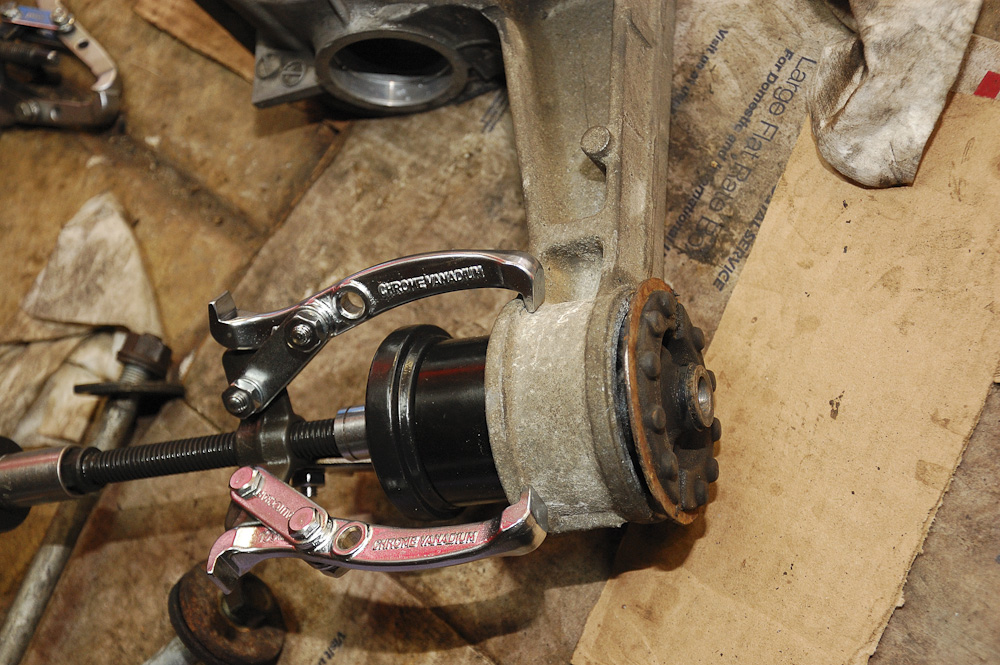

Just did this now and it works great. You need a jaw puller (I used a 4" 3-jaw puller from Advance Auto) and harbor freight ball joint press (you need this for suspension bushings anyways).

Anyways, pictures of how it all works.

You take the puller. Put a 1/2 to 3/4 adapter on it. From the ball joint tool, use the disk and 2.5" OD receiver tube.

Heat up the area with a torch for best effect. Go slowly. Check to make sure your puller doesn't come off.

Bushing comes out fairly easy and without any mess.

Use a 2.5" wire brush attachment to quickly clean up the bushing bores.

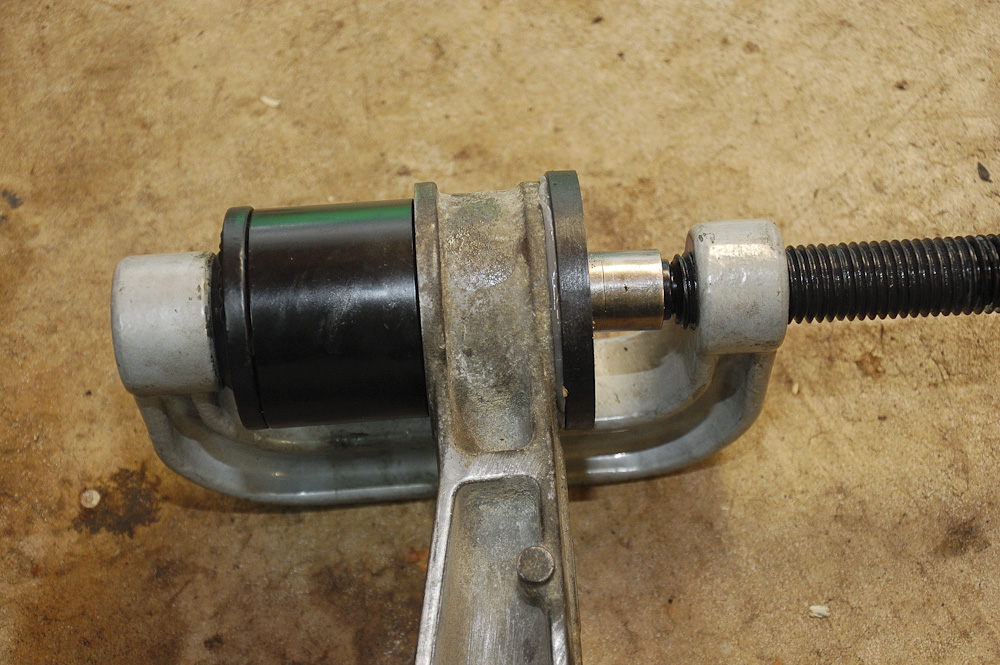

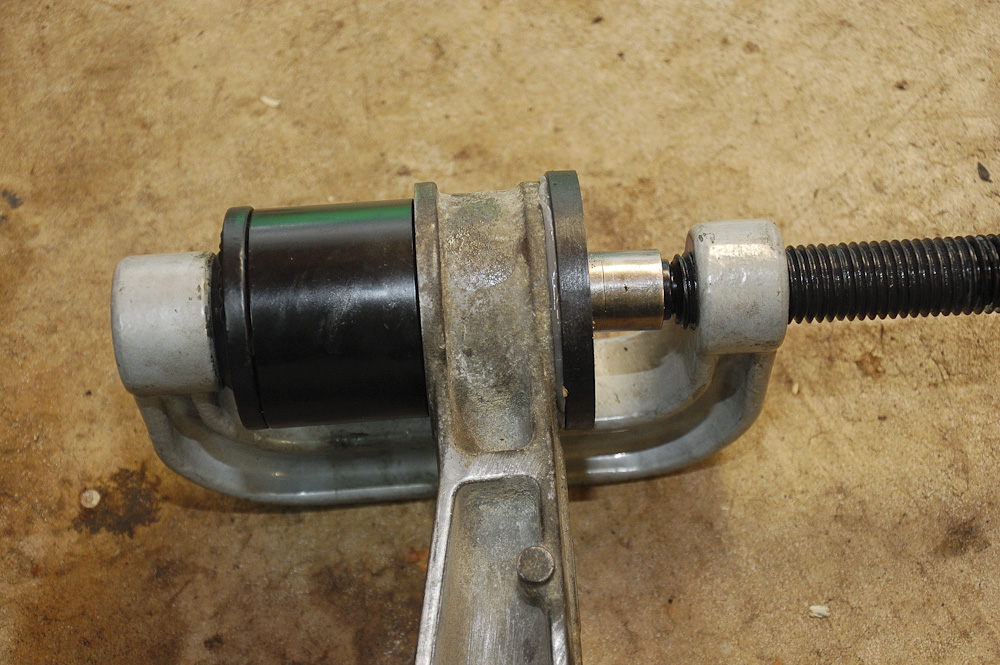

You can press the new bushings in by hand or just use the tool. easy.

Anyways, pictures of how it all works.

You take the puller. Put a 1/2 to 3/4 adapter on it. From the ball joint tool, use the disk and 2.5" OD receiver tube.

Heat up the area with a torch for best effect. Go slowly. Check to make sure your puller doesn't come off.

Bushing comes out fairly easy and without any mess.

Use a 2.5" wire brush attachment to quickly clean up the bushing bores.

You can press the new bushings in by hand or just use the tool. easy.

#4

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

All I used was a chisel and hammer and mine out in 5min.

The key was breaking the metal ring around the bushing, you hit it right at the seem and pry it inward. That relieves all the pressure and it slides out with a few hammer taps. Drilled a few holes in the bushing too, but I found the metal ring was the key.

see the one on the ground? notice how the edge is bent in? that's all there is to it.

But I dont reccommend those solid mounts...at least not with a cltuch LSD.

The key was breaking the metal ring around the bushing, you hit it right at the seem and pry it inward. That relieves all the pressure and it slides out with a few hammer taps. Drilled a few holes in the bushing too, but I found the metal ring was the key.

see the one on the ground? notice how the edge is bent in? that's all there is to it.

But I dont reccommend those solid mounts...at least not with a cltuch LSD.

#12

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

That's not what I'd be worried about. I just think the idea of a torch is silly. You can drill on the center section of the bushing easy...and a lot faster than waiting for the rubber to burn off.

Take a chisel, hit it in the sweet spot to remove the pressure, and it will hammer right out.

Take a chisel, hit it in the sweet spot to remove the pressure, and it will hammer right out.

#13

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268

The torch is not to "burn the rubber" - it's to make the rubber softer so it slides out easier.

#14

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

There's still the metal ring around the edge...that's what hold the bushings in so hard...it's compressed in, decompress it by forcing the metal edges away from each other, inteasd of butt-edged tightly and you're in business.

#19

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I honestly think I sprayed mine with PB Blaster and then hammered them out with a chunk of 2x4 and a framing hammer. In the great British tradition, reinstallation was reverse of removal.

Is this a corrosion thing for you guys?

Is this a corrosion thing for you guys?