Wilwood Rear Calipers

#21

Lolwut? He's comparing OTS button head screws, which means 18-8 or 316 and about 70ksi minimum yield stress. OTS "racing" button heads are 6Al-4V, which is at least 125ksi minimum.

Didn't realize precipitation-hardened, martensitic stainless button head screws were so common...

Didn't realize precipitation-hardened, martensitic stainless button head screws were so common...

P.S. A2 stainless is 145ksi

#23

About as common as Ti screws, I'd imagine. No argument that button heads are awful in general, but (good) Ti ones are not stronger then (good) steel ones, pot metal kit screws notwithstanding. There really isn't a reason to use button heads at all, I use metric blue socket head capscrews (12.9) on my mounts.

P.S. A2 stainless is 145ksi

P.S. A2 stainless is 145ksi

- Button heads and SHCS are both worse choices than hex head or flanged hex head, since the upright has no counterbore. FM uses button heads.

- A2 stainless is an ISO spec most closely aligned with plain-as-**** 304 / 18-8 stainless steel

- No ISO property class of A2 has 145ksi yield stress or even tensile stress. The strongest ISO A2 spec is weaker than property class 8.8

- ASTM graded 6Al-4V Ti is rated to a higher yield stress than every ISO property class of A2

- Nobody mentioned "good steel." But the ASTM 6Al-4V Ti spec is pretty closely overlapped with 10.9, which is the OE bolt spec.

- A 12.9 SHCS preloaded to a torque spec for a 10.9 property class fastener (as the spec for the caliper would be) is worse than 10.9 in every way.

#26

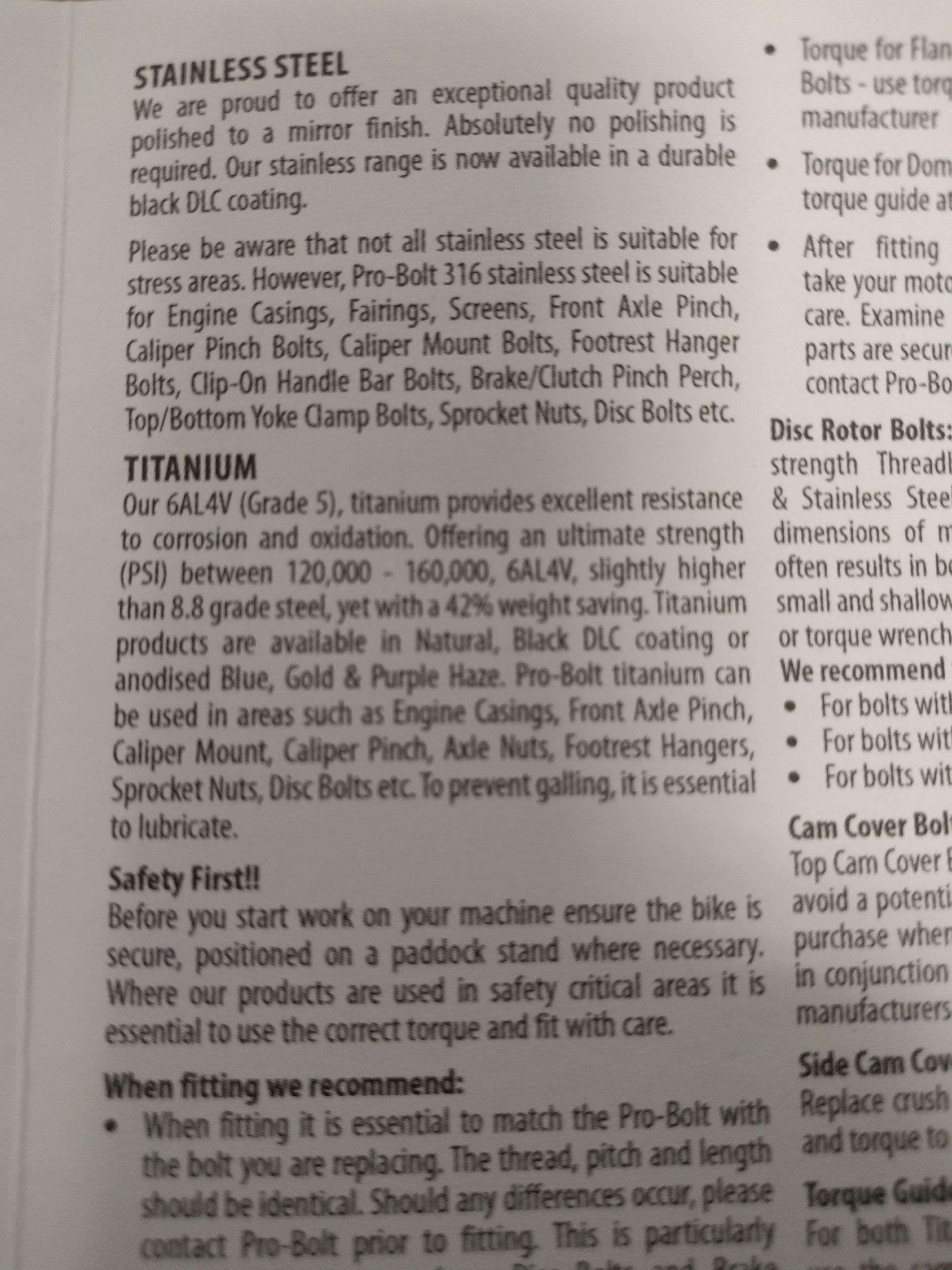

The Ti bolt is in fact 6AL4V and the seller has them rated as grade 5 or slightly higher than 8.8.

And my apologies to Madjak for the massive thread derailment. I only mentioned the fastener choice since sometimes when you are looking to get rid of pounds (kilo's in your case) that last ounce (or grams) is all so satisfying. Also, big thanks to AFM for his knowledge of fasteners and letting me know the Ti bolt we chose is not up to spec.

And lastly, when you are trying to get rid of weight on a parking lot racer you do stupid **** to your brake rotors. That's a rear obviously. The front is worse but hey Coleman wants $800 for a pair of custom fronts and they are only willing to estimate the weight down to 9 lbs. We got the fronts down to 9 lbs doing this to a rotor that was already holy and weighed 10.1 lbs.

#28

Did someone say stupid **** for a parking lot racer? yea I went there. front rotor and hat 10.5" = ~5.6 lbs, rear rotor and hat 10.25" = ~5.0 lbs. oh and I also thought the stainless button heads FM sends were stupid. Really hard to get good torque on them. I replaced them with regular 10.9 socket head cap screws.

#29

Did someone say stupid **** for a parking lot racer? yea I went there. front rotor and hat 10.5" = ~5.6 lbs, rear rotor and hat 10.25" = ~5.0 lbs. oh and I also thought the stainless button heads FM sends were stupid. Really hard to get good torque on them. I replaced them with regular 10.9 socket head cap screws.

So much win

So much win

#35

So I found this while searching for swiss cheese rotors .. https://www.tbmbrakes.com/product/ma...ack-track-kit/

Also learned that its not really worth the time to swiss cheese the centric blanks with a home drill press unless you're trying to shave 10ths or even 100ths for a trophy. The losses were minimal for time spent.

With 13/64 holes ..

Enlarged to 3/8 .. countersinking the holes might lose another 1 oz.

Also learned that its not really worth the time to swiss cheese the centric blanks with a home drill press unless you're trying to shave 10ths or even 100ths for a trophy. The losses were minimal for time spent.

With 13/64 holes ..

Enlarged to 3/8 .. countersinking the holes might lose another 1 oz.

#39

They are heavy though! I could fit 11.75" vented rotors to the hats I have but they weigh lots more. I run them up front but this powerlite is both cheap and way lighter than any other caliper. As long as its better than oem I'm happy.

btw I spent 4 hours grinding the rear hubs to save a few ounces... time is free!

btw I spent 4 hours grinding the rear hubs to save a few ounces... time is free!

#40

Time is free... if it isn't, then you are working all the time and who wants that? I'll take 4 hours on a grinder / mill / lathe over 4 hours of work anyday! And I love my work so that is saying something.

So are you saying I shouldn't have spent 60 hours taking grams off my crank?

So are you saying I shouldn't have spent 60 hours taking grams off my crank?

Last edited by Madjak; 07-31-2018 at 09:57 PM.