ABSURDflow Turbo KLDE Mazda V6 Thread

#563

Elite Member

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Thank you!

I'm lazy. I'd promise more videos but that'd be a lie. I need someone who:

1. takes video in landscape

2. doesn't cover the microphone

3. doesn't comment while taking the video

I have nice videos of boost, but none meet the above 3.

I wasn't sure what the PMO intake was so i google imaged...yeah this is sort of like that but not as compact. Injectors are in the stock spot, runner length & plenum volume more 'correct'. How much is/was that PMO intake?

I wasn't sure what the PMO intake was so i google imaged...yeah this is sort of like that but not as compact. Injectors are in the stock spot, runner length & plenum volume more 'correct'. How much is/was that PMO intake? But then no TURBOOOOOOOO

If NA, Cowel CAI would be simple though.

#566

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

If you use a clear plenum top, plan to use a metal reinforcing ring on top of the flange. most clear peices that you would be able to use wont seal very well and easily fracture, as im sure you are aware.

I would personally do a nicely shaped top to use the space you have vs being able to see into it. make it like a nissan VQ intake manifold so you can unbolt the top if you need to inspect inside of it and change trumpets.

I would personally do a nicely shaped top to use the space you have vs being able to see into it. make it like a nissan VQ intake manifold so you can unbolt the top if you need to inspect inside of it and change trumpets.

#569

Elite Member

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

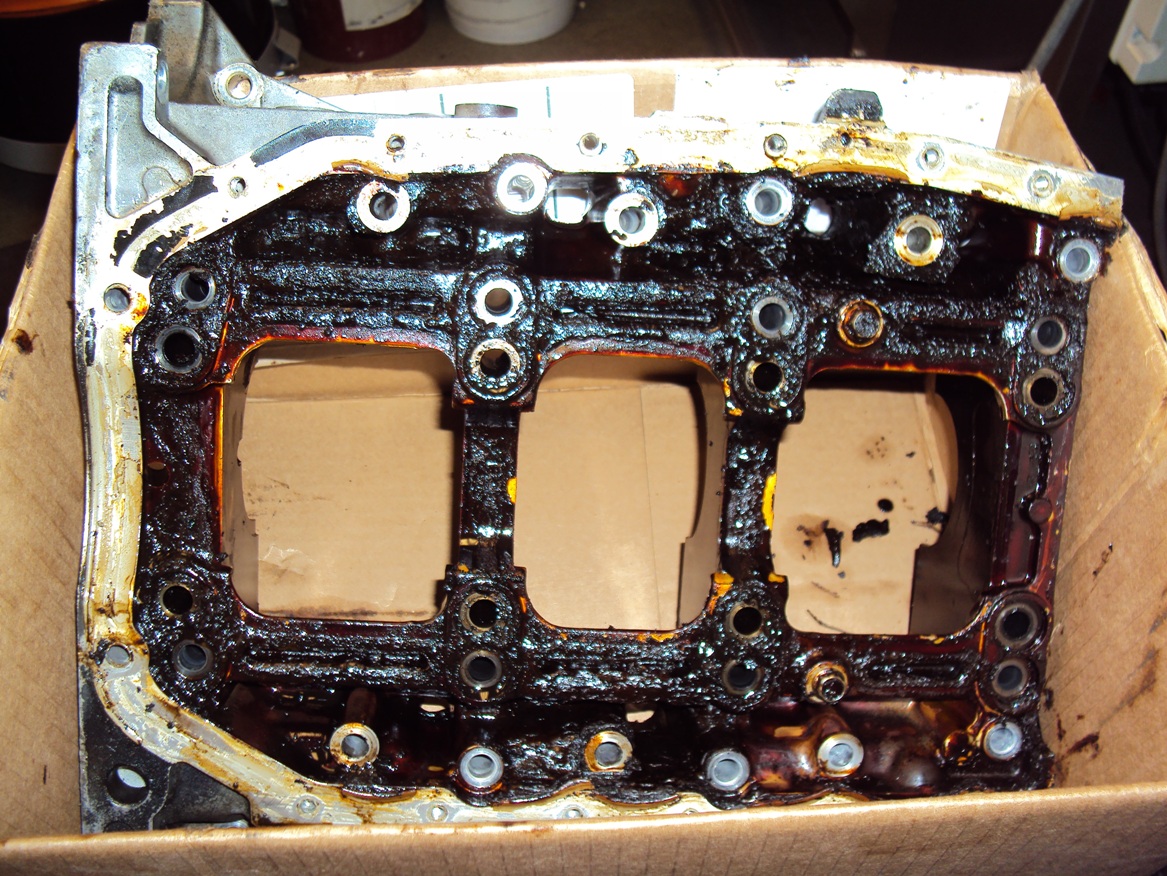

So after teaching myself a CAM package and learning how to run a Haas, I made the lower intake plenum last week. I didn't even scrap any material or tools. And...it fits!

Next up is ordering the material for the runners and upper plenum. Fun stuff.

Next up is ordering the material for the runners and upper plenum. Fun stuff.

#571

Elite Member

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Yeah, I figured with only one piece of 'free' material and only needing one part, I could/should take my time with my first part. And I thought my fixturing was sketchy. But damn did I learn how not to do finish passes. That part took over 4 hours to make. 80% of the time I was cutting air basically. I ended up +300% on my finish pass feedrates.

And I used 'conventional milling'?? feed/speed tables but adaptive roughing/high speed tool paths with shallow depth of cuts. All of our Mills, the Haas' included, are high speed capable. The guys are telling me to stop being a bitch and crank up the rpm/feed, do full depth of cut, bla bla bla. But they aren't paying for the material But I'll have to as the upper plenum's depth of cut is over 3.5". That'd take all weekend if I do it the same way as this piece.

But I'll have to as the upper plenum's depth of cut is over 3.5". That'd take all weekend if I do it the same way as this piece.

And I used 'conventional milling'?? feed/speed tables but adaptive roughing/high speed tool paths with shallow depth of cuts. All of our Mills, the Haas' included, are high speed capable. The guys are telling me to stop being a bitch and crank up the rpm/feed, do full depth of cut, bla bla bla. But they aren't paying for the material

But I'll have to as the upper plenum's depth of cut is over 3.5". That'd take all weekend if I do it the same way as this piece.

But I'll have to as the upper plenum's depth of cut is over 3.5". That'd take all weekend if I do it the same way as this piece.

#572

I dont know what cam software you were using. Normally with aluminum I run my spindle speed at the max rpm of the machine (12k rpm is bitchen), and either use the feedrate in the tool's catalog which is defined as like inch per tooth with 50% engagement or if I really want to push the speed I'll run the speed based off chip load and use a trochoidal tool path with a high depth of cut but only like a small step over. It almost sounds like you're using espirt based on the conventional milling and cutting air on the finish pass. You can totally do the finish pass without cutting air and it took me a while to figure it out and I'd need the software in front of me to remember how.

#573

Elite Member

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I'm using HSMWorks directly within solidworks. We have a seat of almost all software packages for whatever reason, but hey I'm not complaining. HSMworks seemed the slickest and easiest for me to pick up on quickly.

Everyone else here loves/uses Gibbs which is a standalone program. They import my solidworks part files, extract geometry...etc. I got a quickie crash course on it a few years ago so I could do my 2D bridgeport EZTrack stuff (what I made all my V6 stuff on so far), but it (gibbs) seems a step backwards for what I'm doing. HSMworks integrated directly within solidworks was more obvious for someone with my background. If I can't get it to do what I want, I draw the toolpath as a 3D sketch in solidworks. I'm going to have to do that with the undercuts/lollypop cutter on my runners.

The HSM works I'm using doesn't have tricordial cuts, but Gibbs does and that's what they use in the production shop. Max rpm/feed accordingly, light cuts, full depth of cut, little spirals along the toolpath. We also have all sorts of crazy tooling and inserts that they say I can/should use (well over a week's pay for each tool), but for this initial path I wanted to use worn traditional tooling from the recycle bin that costs me nothing if I break. All I can do with HSMworks is the 'adaptive' clearing, where you set an engagement amount and it attempts to maintain that.

Each programmer has their own recommendations too. Someone will walk by and suggest something different than the last guy. I get my specs out of the Garr book because it's easy to read, but holy damn some of their specs sound nuts. I'm just clamping the plate with a vice to save on operations and fixturing$$, and not that tight either (so it doesn't bow too badly).

I'm not sure what you call it, but we also have the tooling for real shallow depth of cut but insane feed rate. The tooling has a very shallow angle on it so the load is mostly axially along the tool instead of radially like traditional tools. So you cut only say .030 deep but at 500ipm. Perhaps beyond my scope, I have no *****.

Everyone else here loves/uses Gibbs which is a standalone program. They import my solidworks part files, extract geometry...etc. I got a quickie crash course on it a few years ago so I could do my 2D bridgeport EZTrack stuff (what I made all my V6 stuff on so far), but it (gibbs) seems a step backwards for what I'm doing. HSMworks integrated directly within solidworks was more obvious for someone with my background. If I can't get it to do what I want, I draw the toolpath as a 3D sketch in solidworks. I'm going to have to do that with the undercuts/lollypop cutter on my runners.

The HSM works I'm using doesn't have tricordial cuts, but Gibbs does and that's what they use in the production shop. Max rpm/feed accordingly, light cuts, full depth of cut, little spirals along the toolpath. We also have all sorts of crazy tooling and inserts that they say I can/should use (well over a week's pay for each tool), but for this initial path I wanted to use worn traditional tooling from the recycle bin that costs me nothing if I break. All I can do with HSMworks is the 'adaptive' clearing, where you set an engagement amount and it attempts to maintain that.

Each programmer has their own recommendations too. Someone will walk by and suggest something different than the last guy. I get my specs out of the Garr book because it's easy to read, but holy damn some of their specs sound nuts. I'm just clamping the plate with a vice to save on operations and fixturing$$, and not that tight either (so it doesn't bow too badly).

I'm not sure what you call it, but we also have the tooling for real shallow depth of cut but insane feed rate. The tooling has a very shallow angle on it so the load is mostly axially along the tool instead of radially like traditional tools. So you cut only say .030 deep but at 500ipm. Perhaps beyond my scope, I have no *****.

#574

500ipm stupid fast. Best I had going was a 1" depth of cut with 10% engagement at 12k rpm and 300ipm, trochoidal pocket. That was removing some serious stock. That was just a dumb "cheap" uncoated carbide 5/8" endmil. I also exploded one of those at 12k when I had my rapid height set wrong and rapided fully engaged into the part, thats one way to wake up at 4am.

#575

Harvey Tool has a line of good profiling stuff especially if your doing small profiling/chambering work. Find Specialty Carbide End Mills and Cutting Tools at Harvey Tool.

Your guys in the shop can ask vendors for samples to help you out.

Your guys in the shop can ask vendors for samples to help you out.

#577

Elite Member

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I'm real happy about these here. I made the die a few years ago when I first did this swap but never thought it'd actually work. So I said F it, ordered 3 feet of annealed 304ss from mcmcaster, and cut some blanks. I'm sooooo surprised how easy it flowed. I was able to do one rough cut test piece and the 6 lathe cut finish pieces during lunch. This gives me too many ideas.

The die, made from some scrap tool steel camshaft material.

Pipe cleaned up with scotchbrite, cut to length and deburred on a lathe:

PUSH!

Done. ID's are sooo smoooth.

I also made these a few years ago on the 2-D cnc bridgeport: flanges for these runners.