rear knuckle upper spherical discussion

#224

The bushings are teflon/oil impregnated bronze. shouldnt need much of any lubracation. it still has some surfaces sliding against urethane I've had the bes luck with copper antisize mixed with grease for that.

#225

About 1/365th at least the rate needed with straight urethane to keep it pivoting smoothly Iím hoping. Static friction difference is about 45lbs less force measured at the wheel to initiate sliding friction compared to freshly greased straight urethane as well but it should retain the lack of bushing alignment bind associated with going to Delrin over urethane.

The bushings are teflon/oil impregnated bronze. shouldnt need much of any lubracation. it still has some surfaces sliding against urethane I've had the bes luck with copper antisize mixed with grease for that.

The bushings are teflon/oil impregnated bronze. shouldnt need much of any lubracation. it still has some surfaces sliding against urethane I've had the bes luck with copper antisize mixed with grease for that.

#229

I am interested in seeing how these metal to metal bushings hold out. When I worked on aircraft in the military we had a hard time fighting corrosion when using dissimilar metals such as these, but that was mostly when you used aluminum sheeting and metal steel screws. I also experienced some on the magnesium reduction gear housing and some of the associated hardware. Of course these were carrier based aircraft, so the conditions they were subject to are probably way worse than anything these bushings would be subject to.

With that said, I think they are pretty awesome!

Edit: I can't word

With that said, I think they are pretty awesome!

Edit: I can't word

Last edited by 90civichhb; 01-20-2015 at 11:01 PM.

#230

I am interested in seeing how these metal to metal bushings hold out. When I worked on aircraft in the military we had a hard time fighting corrosion when using dissimilar metals such as these, but that was mostly when you used aluminum sheeting and metal screws. I also experienced some on the magnesium reduction gear housing and some of the associated hardware. Of course these were carrier based aircraft, so the conditions they were subject to are probably way worse than anything these bushings would be subject to.

With that said, I think they are pretty awesome!

With that said, I think they are pretty awesome!

#231

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

at work we use bronze sleeves ubiquitously, some are older than me, some i replace every few weeks on the automation equipment. id like to hear back how these wear for you.

#232

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

much excite!

bacon bits not included

turbo kitten is watching you install spherical bearings into your rear knuckle

for some reason the machinist made 5 extra. i think he was super happy that i pre-payed him. he was complaining a lot about other customer just disappearing after parts were made. wtf is wrong with people? anyway, i now have 4 sets available still for sale. ill make a posting in the classifieds if they dont go soon once i get all the spacers made up.

i have a busy weekend, so ill start making spacers on Monday and hope to start shipping these out to you guys next week.

bacon bits not included

turbo kitten is watching you install spherical bearings into your rear knuckle

for some reason the machinist made 5 extra. i think he was super happy that i pre-payed him. he was complaining a lot about other customer just disappearing after parts were made. wtf is wrong with people? anyway, i now have 4 sets available still for sale. ill make a posting in the classifieds if they dont go soon once i get all the spacers made up.

i have a busy weekend, so ill start making spacers on Monday and hope to start shipping these out to you guys next week.

#233

Thats cool. Those came out really well.

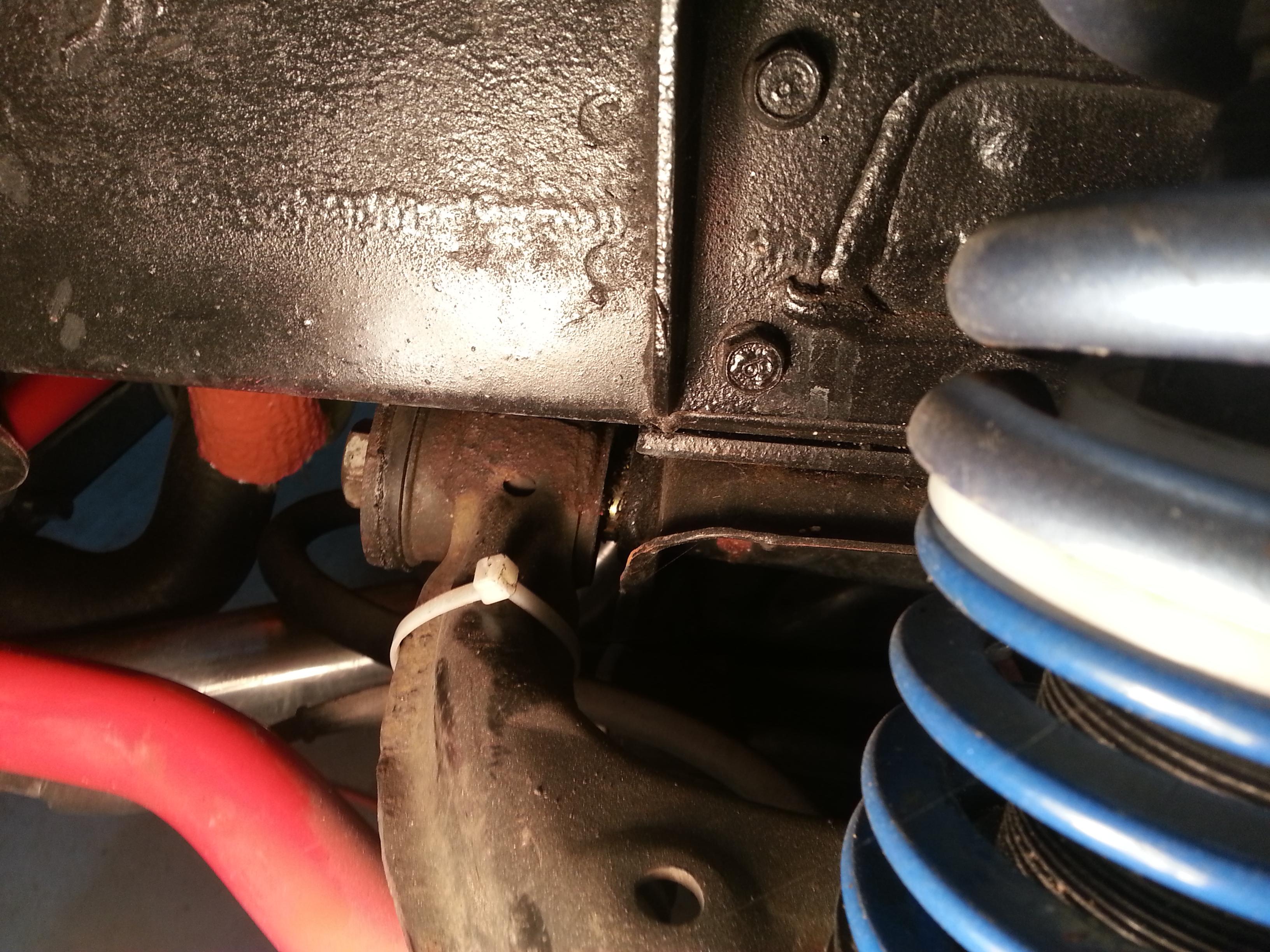

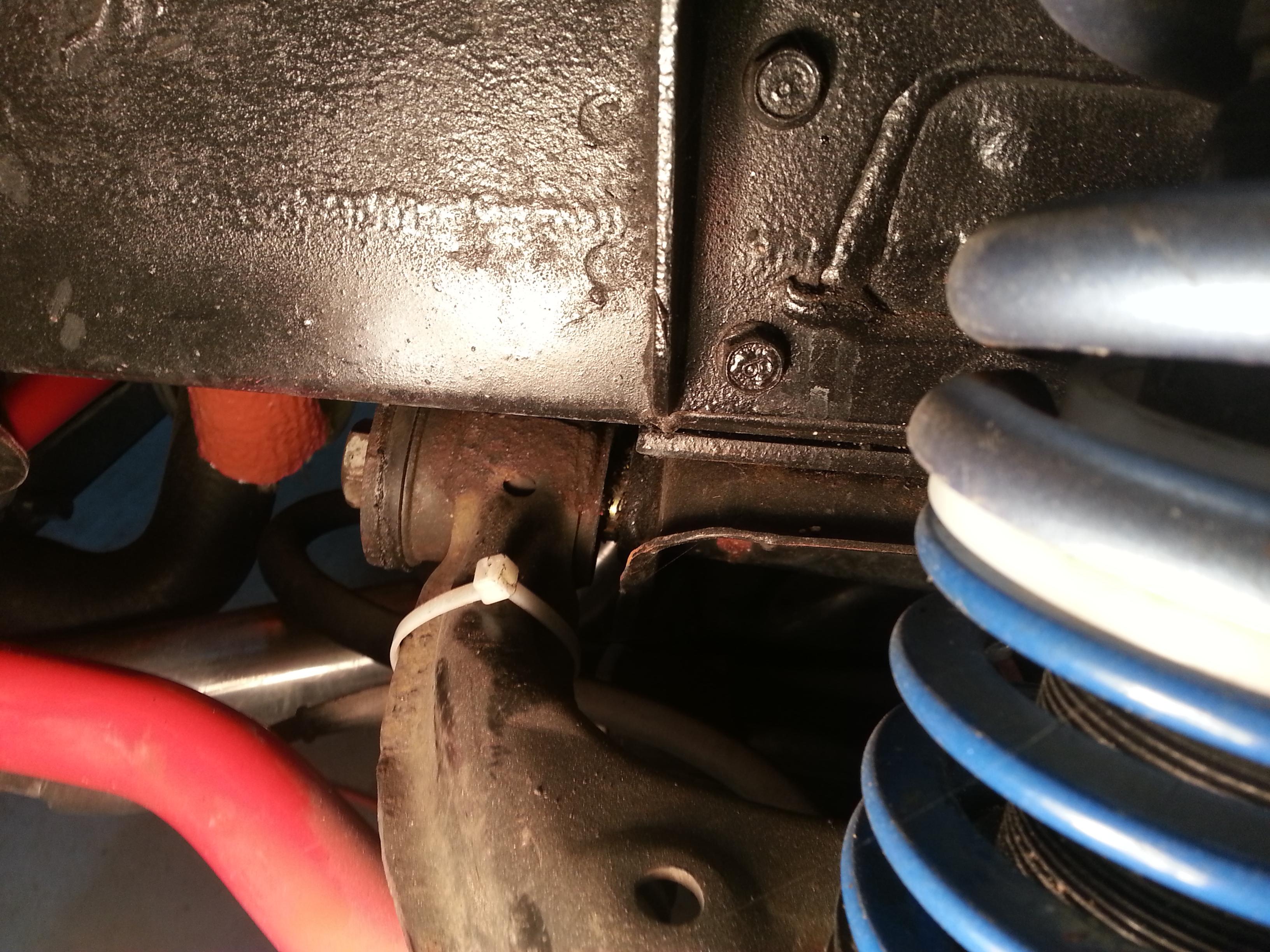

On to other bushings. The front uppers. Does anyone else arms slide forward? Like so.

Trying to figure out something to combat this. Its like the metal sleeves are too long. It is interesting that by playing with the sleeve lengths you can skew some more caster into the car.

On to other bushings. The front uppers. Does anyone else arms slide forward? Like so.

Trying to figure out something to combat this. Its like the metal sleeves are too long. It is interesting that by playing with the sleeve lengths you can skew some more caster into the car.

#234

I am about to order some parts from McMaster-Carr and I was wondering if these bearings would work for the sleeves. I think the outer diameter may be a bit too small though.

Edit: Well it won't let me direct link to the bearing, but it is the 1 3/16 OD with a 5/8 ID.

Edit: Well it won't let me direct link to the bearing, but it is the 1 3/16 OD with a 5/8 ID.

#235

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

I am about to order some parts from McMaster-Carr and I was wondering if these bearings would work for the sleeves. I think the outer diameter may be a bit too small though.

Edit: Well it won't let me direct link to the bearing, but it is the 1 3/16 OD with a 5/8 ID.

Edit: Well it won't let me direct link to the bearing, but it is the 1 3/16 OD with a 5/8 ID.

#237

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

i found a possible easy seal solution for you guys, although a little pricey.

the timken 480889

the same place i ordered my sphericals from has them, so if youre going to get your bearings there...

https://www.motionindustries.com/pro...p?sku=01316673

if you go the qa1 route at summit, well they have them too

http://www.summitracing.com/parts/tmk-480889

ebay

480889 National New Seal | eBay

its for a 1.3125" bore and has an ID of 0.812". the spacers are 0.825", it should be perfect and allow just a few degrees of misalignment. i would press it all the way up against the bearing/shoulder to reduce the amount of spacer movement it will see. i havnt tried this myself yet though, so no guarantees.

your local oreilly can order them too, but @ $10 each

i have yet to find an oring of suitable dimensions

in other news my set went through their first track day today, running with 2 drivers in 2 different groups, so consider it 2 track days. they performed flawlessly.

#238

Thats cool. Those came out really well.

On to other bushings. The front uppers. Does anyone else arms slide forward? Like so.

Trying to figure out something to combat this. Its like the metal sleeves are too long. It is interesting that by playing with the sleeve lengths you can skew some more caster into the car.

On to other bushings. The front uppers. Does anyone else arms slide forward? Like so.

Trying to figure out something to combat this. Its like the metal sleeves are too long. It is interesting that by playing with the sleeve lengths you can skew some more caster into the car.