AHaidet's '93 1.8 swap with FM kit and MS3x

#42

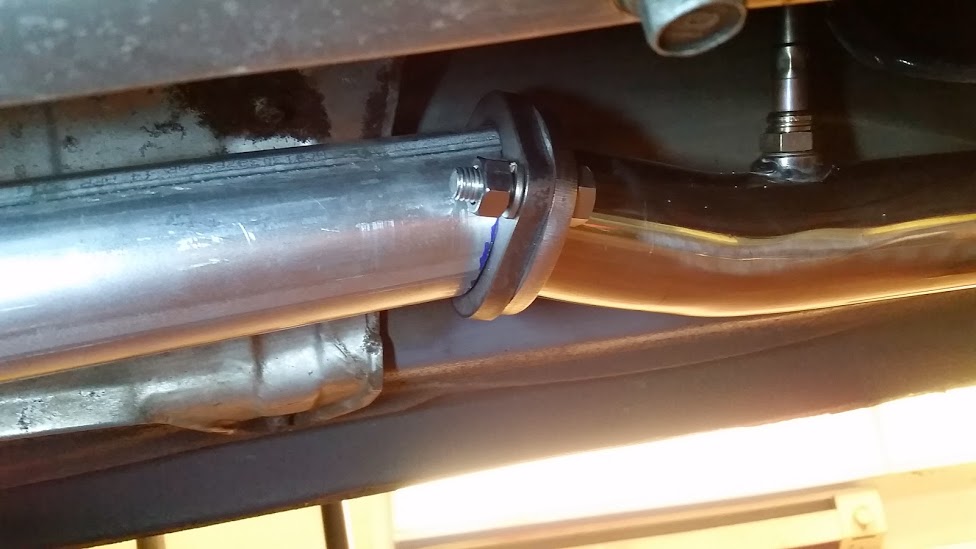

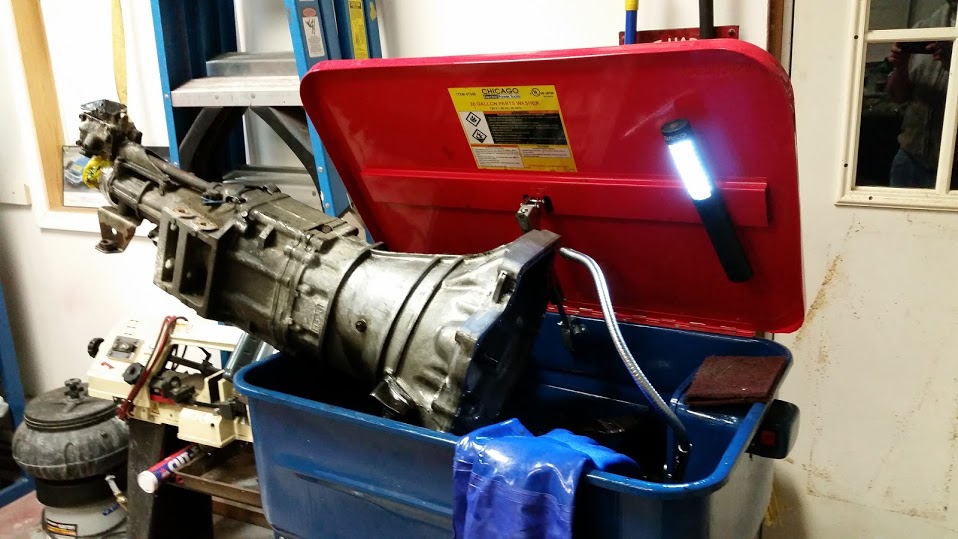

I am pretty sure the transmissions seals were leaking causing the mess in the bellhousing.

So I replaced both seals on the front of the transmission, the gasket and oil seal.

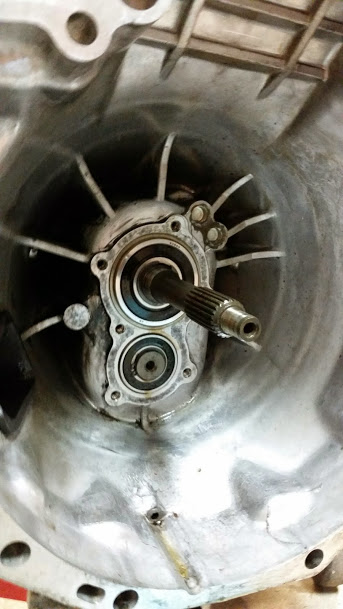

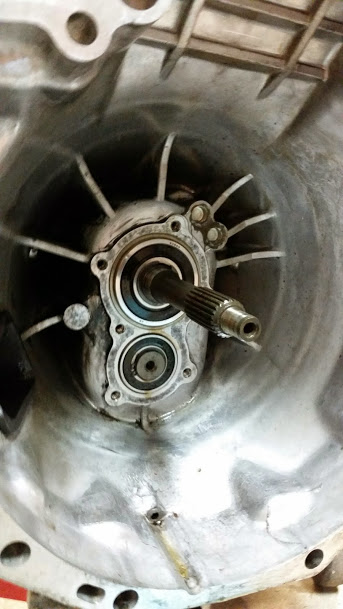

Cleaned up and seals replaced:

Ready to mate to the 1.8L motor now.

So I replaced both seals on the front of the transmission, the gasket and oil seal.

Cleaned up and seals replaced:

Ready to mate to the 1.8L motor now.

Last edited by ahaidet; 11-16-2014 at 11:55 PM.

#44

So... time for an update finally.

I powder coated the brackets I made for the ignition coils, the water pump pulley, and the alternator bracket. First I sand blasted all the parts:

Alternator bracket partly done.

Then I sprayed the powder and baked them.

The booth I made a few years ago out of plywood and a Harbor Freight cart.

The oven I bought at an industrial surplus locally called HGR.

I powder coated the brackets I made for the ignition coils, the water pump pulley, and the alternator bracket. First I sand blasted all the parts:

Alternator bracket partly done.

Then I sprayed the powder and baked them.

The booth I made a few years ago out of plywood and a Harbor Freight cart.

The oven I bought at an industrial surplus locally called HGR.

#47

One problem I found out shortly after the parts cooled...

The alternator bracket doesn't transfer to the 1.8L motor... The 1.6L alternator transfers to the 1.8L bracket to mount to the 1.8L motor. So I wasted my time on the bracket :(

But the other parts still look great.

If anyone is interested in a nicely powder coated 1.6L alternator bracket shoot me a message and we can work out a deal.

The alternator bracket doesn't transfer to the 1.8L motor... The 1.6L alternator transfers to the 1.8L bracket to mount to the 1.8L motor. So I wasted my time on the bracket :(

But the other parts still look great.

If anyone is interested in a nicely powder coated 1.6L alternator bracket shoot me a message and we can work out a deal.

#48

It's Super 88 electrical tape you can get it at Lowes, HD, etc.. Its more flexible and stronger than your average electrical tape. Its also better at lower and higher temps.

I thought about using heat shrink but I have not found an affordable source of heat shrink elbows, Tees and Ys.

#50

Product Catalog Scotch® Professional Grade Vinyl Electrical Tape Super 88 : Electrical Commercial and Industrial: 3M US

I dont think its adhesive free.

Super 88 should be ok for the injector harness as its good too 220F.

Maybe I should look into using the 130c for the rest of the connections. Where do you buy it?

I dont think its adhesive free.

Super 88 should be ok for the injector harness as its good too 220F.

Maybe I should look into using the 130c for the rest of the connections. Where do you buy it?

#53

Well I didn't beat the snow.

I did get the engine installed:

I also installed the FM intercooler as well:

The engine went in fairly smoothly with the help of a few friends.

Then life got super busy around the holidays and the weather turned to complete **** for a month or more (Northeast Ohio had the coldest February ever, literally). I worked on what I could and got a little done. Now that the weather is starting to break I am getting more focused and the warmer weather makes garage time more comfortable.

I did get the engine installed:

I also installed the FM intercooler as well:

The engine went in fairly smoothly with the help of a few friends.

Then life got super busy around the holidays and the weather turned to complete **** for a month or more (Northeast Ohio had the coldest February ever, literally). I worked on what I could and got a little done. Now that the weather is starting to break I am getting more focused and the warmer weather makes garage time more comfortable.

#54

I was able to make progress on mounting the NGK AGX Wideband Display in the spot under the radio:

Here is a mockup:

I 3d printed a bracket to hold the AGX display and then I 3d printed a panel to hold the AGX bracket as well as some buttons for data logging, traction control and launch control (master switch). I also wanted to install a USB charger and the microphone for the Bluetooth phone connection on the radio.

The only issue is the 37 pin harness that Rev supplied with my MS3 doesn't seem to have the wires for data logging, launch control attached like his instructions suggested. I have no problem adding them myself but Rev hasn't replied yet to my email for a diagram for the PIN outs on the MS3 37 pin connection.

Here is a mockup:

I 3d printed a bracket to hold the AGX display and then I 3d printed a panel to hold the AGX bracket as well as some buttons for data logging, traction control and launch control (master switch). I also wanted to install a USB charger and the microphone for the Bluetooth phone connection on the radio.

The only issue is the 37 pin harness that Rev supplied with my MS3 doesn't seem to have the wires for data logging, launch control attached like his instructions suggested. I have no problem adding them myself but Rev hasn't replied yet to my email for a diagram for the PIN outs on the MS3 37 pin connection.

#55

So it has been a few months since I updated and a lot has happened! I did some traveling for work and for pleasure and when I returned home it was time to make a serious push to get the car done for the coming spring/summer weather.

The Rev built MS3 needed installed into the passenger foot well to replace the stock unit. This was fairly straight forward and went smoothly. The only wiring that needed done was for the wide band O2 sensor. I forgot to snap pictures of the unit fully installed but I will get some soon when I go back in to make some changes.

Next I needed to seal up the cooling system with the re-route. This turned out to be a bit of a choir and still has some lingering issues. I should have read more info on carefully disconnecting the heater hoses from the heater core connections in the engine bay... both heater core pipes got a little mangled by me working the cooling hose pick tool around trying to free up the hose. This is a common mistake/problem. The trick is to be more gentle. At any rate there are a variety of options to fix this problem once you've created it. I tried a variety of options. First the drivers side hose was easy enough to massage back round and then I used two hose clamps to be sure it sealed (and it has so far stayed sealed) The passenger side required more attention. I tried sliding sockets down the ID to try and open it back up and remove the dents. This helped some. Finally I bought the following tool:

both heater core pipes got a little mangled by me working the cooling hose pick tool around trying to free up the hose. This is a common mistake/problem. The trick is to be more gentle. At any rate there are a variety of options to fix this problem once you've created it. I tried a variety of options. First the drivers side hose was easy enough to massage back round and then I used two hose clamps to be sure it sealed (and it has so far stayed sealed) The passenger side required more attention. I tried sliding sockets down the ID to try and open it back up and remove the dents. This helped some. Finally I bought the following tool:

HDX Swaging Tool-HDX053 - The Home Depot

Which helped. I was concerned that it still wasnt perfectly round and that tightening a hose clamp would make it worse. So the last trick (short of replacing the heater core) is to insert 1/2"; copper pipe into the inside to reinforce the heater core outlet. I drove it into the heater core outlet with light taps from a hammer and it fits remarkably well. I then tightened two hose clamps around it again. So far so good and no leaks from this portion of the cooling system.

I put silver heat resistant foil around both heater hoses because of their proximity to the turbo and exhaust manifold.

I also replaced the grommets that the heater core outlets pass through when they meet the firewall. This is a common failure point on older Miatas and is way easier to fix now with everything apart.

Next it was onto finishing the coolant re-route.

The Rev built MS3 needed installed into the passenger foot well to replace the stock unit. This was fairly straight forward and went smoothly. The only wiring that needed done was for the wide band O2 sensor. I forgot to snap pictures of the unit fully installed but I will get some soon when I go back in to make some changes.

Next I needed to seal up the cooling system with the re-route. This turned out to be a bit of a choir and still has some lingering issues. I should have read more info on carefully disconnecting the heater hoses from the heater core connections in the engine bay...

both heater core pipes got a little mangled by me working the cooling hose pick tool around trying to free up the hose. This is a common mistake/problem. The trick is to be more gentle. At any rate there are a variety of options to fix this problem once you've created it. I tried a variety of options. First the drivers side hose was easy enough to massage back round and then I used two hose clamps to be sure it sealed (and it has so far stayed sealed) The passenger side required more attention. I tried sliding sockets down the ID to try and open it back up and remove the dents. This helped some. Finally I bought the following tool:

both heater core pipes got a little mangled by me working the cooling hose pick tool around trying to free up the hose. This is a common mistake/problem. The trick is to be more gentle. At any rate there are a variety of options to fix this problem once you've created it. I tried a variety of options. First the drivers side hose was easy enough to massage back round and then I used two hose clamps to be sure it sealed (and it has so far stayed sealed) The passenger side required more attention. I tried sliding sockets down the ID to try and open it back up and remove the dents. This helped some. Finally I bought the following tool:

HDX Swaging Tool-HDX053 - The Home Depot

Which helped. I was concerned that it still wasnt perfectly round and that tightening a hose clamp would make it worse. So the last trick (short of replacing the heater core) is to insert 1/2"; copper pipe into the inside to reinforce the heater core outlet. I drove it into the heater core outlet with light taps from a hammer and it fits remarkably well. I then tightened two hose clamps around it again. So far so good and no leaks from this portion of the cooling system.

I put silver heat resistant foil around both heater hoses because of their proximity to the turbo and exhaust manifold.

I also replaced the grommets that the heater core outlets pass through when they meet the firewall. This is a common failure point on older Miatas and is way easier to fix now with everything apart.

Next it was onto finishing the coolant re-route.

#56

My re-route is based on the "Easy Coolant Reroute." I used a BEGI thermostat spacer as I showed installing in a previous post and a GM radiator hose from AutoZone. Others that have used the same GM SUV hose can just run this hose all the way to the front and connect to the radiator. With the Flying Miata intercooler pipe this creates a territory dispute between these two hoses. So another Autozone hose to the rescue. (I can dig up the part numbers if anyone is interested but simply searching "Easy Coolant Reroute Miata" should find the info) With both hoses connected together, with a 1.25"; union from Pegasus Autoracing, ran a little to close to the intake manifold and specifically the throttle body for my tastes. The hose clamps were scary close to the throttle cable and I really wasn't looking forward to a possible stuck throttle situation.

So I ordered a 17'; straight aluminum pipe with beads rolled on each end from BEGI.

The aluminum pipe was both thinner and straighter than the GM rubber hose. I simply trimmed the excess hose off. This however created a new issue as where the hoses were now trimmed they were not perfectly round. At the time it seemed like a good idea to use T-bolt clamps from McMaster to really cinch down the hoses to help force them round.

Fast forward a month or so to me getting ready to start the car...

So I ordered a 17'; straight aluminum pipe with beads rolled on each end from BEGI.

The aluminum pipe was both thinner and straighter than the GM rubber hose. I simply trimmed the excess hose off. This however created a new issue as where the hoses were now trimmed they were not perfectly round. At the time it seemed like a good idea to use T-bolt clamps from McMaster to really cinch down the hoses to help force them round.

Fast forward a month or so to me getting ready to start the car...

#57

I always use a no-spill funnel to allow the system to bleed any air out.

I finished filling it and without even pressurizing the system found a leak shortly after...

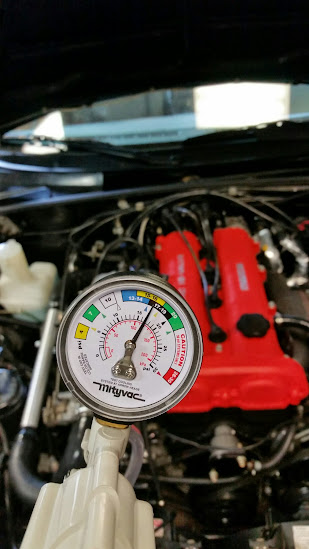

This photo was taken up through the transmission tunnel at the back of the head where the BEGI spacer is located. It was leaking from the NPT fitting that the heater hose connects to. After some investigating I found that the brass hose barb was bottoming out the NPT threads in the spacer. It was not sealing like a pipe thread is designed. I tried using extra teflon tape and had no luck. Finally I used some silicone sealant on the threads. I also contacted BEGI who is sending me a replacement spacer. I am not looking forward to replacing the spacer with the engine in the car but I do not trust the threads and silicone to stay sealed long term. The silicone has held well to allow further testing. Next I pressure tested the system. Using the following MityVac tool:

Autozone rents something similar for free but I like having this around to quickly use when needed.

I found another leak at the T-bolt clamps for the re-route.

I then went in search of a better hose clamp. The T-bolt clamps work well when the hose is round but were leaking under the section where the bolt is located. I found what I think is the ideal hose clamp for this situation. Gates Power Grip:

It basically is heat shrink tubing. They advertise it for use in situations where the hose or fitting may be out of round.

Slip the fittings half way over the rubber hose and half way over the aluminum pipe and use a heat gun to shrink the fitting.

Ultimately I think it makes for a much cleaner look.

It also seems to seal very well.

Only downside I have seen so far is the cost; about $5 for one in this size. They also are not re-usable and must be carefully cut off.

#58

I have some more updates of the install and even some more 3d printing and fabrication content to add but..

I have started the car and drove it and its running hot (215-230F) without getting into boost much. I think the radiator is the main culprit here and it looks like I will be ordering a radiator very soon. It is on it's last legs anyhow based on the color of the plastic end tanks.

I like the engineering and testing that went into the FM crossflow unit but the price is a little tough to swallow. Koyo has a new Hyper V unit as well that looks promising at a lower price. The SuperMiata crossflow looks like a good choice as well but is not in stock. The TSE unit is even more than the FM unit...

I suspect the Koyo isn't as capable as the FM unit however it is $200 cheaper.

The end goal is to be able to take the car to do track days a few times a year, Auto X maybe once a month, and still drive it to work on sunny summer days in Ohio. All while spending as little time laying under it fixing broken things.

I've read a bunch of threads on cooling and understand ultimately I need ducting, a radiator, and hood vents to solve the cooling issues.

I am open to suggestions/tips on which radiator to buy.

I have started the car and drove it and its running hot (215-230F) without getting into boost much. I think the radiator is the main culprit here and it looks like I will be ordering a radiator very soon. It is on it's last legs anyhow based on the color of the plastic end tanks.

I like the engineering and testing that went into the FM crossflow unit but the price is a little tough to swallow. Koyo has a new Hyper V unit as well that looks promising at a lower price. The SuperMiata crossflow looks like a good choice as well but is not in stock. The TSE unit is even more than the FM unit...

I suspect the Koyo isn't as capable as the FM unit however it is $200 cheaper.

The end goal is to be able to take the car to do track days a few times a year, Auto X maybe once a month, and still drive it to work on sunny summer days in Ohio. All while spending as little time laying under it fixing broken things.

I've read a bunch of threads on cooling and understand ultimately I need ducting, a radiator, and hood vents to solve the cooling issues.

I am open to suggestions/tips on which radiator to buy.

#59

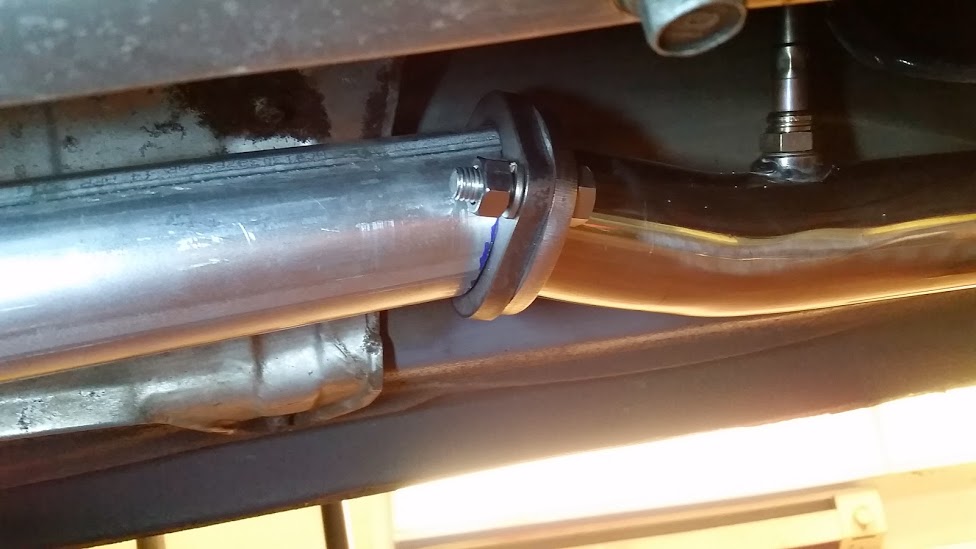

After the cooling system was finished (sorta). I needed to connect the FM downpipe to the old exhaust system a Goodwin Racing RoadsterSport. I had considered installing a catalytic converter but the car doesn't need to be emissions checked in my area. I still may install a CAT to cut back on the smell and to help the environment out but for the sake of getting the car running more quickly I decided to build a test pipe. The test pipe could also serve as the template needed to fab the pipes for a high flow cat down the road. The issue with the Miata CAT is that the flanges are at very akward angles in relation to the direction of the exhaust pipe. I know ideally I would bend the pipes to meet the flanges so that a straight cut could be made but this will do for now. I found steel flanges that would work at Summit Racing and picked up a piece of aluminized 2.5" pipe.

I wanted to figure out what angle to cut the pipe to meet the downpipe. Every method I thought of with involved a lot of trial and error with a grinder, a file and band saw. Then I had an idea...

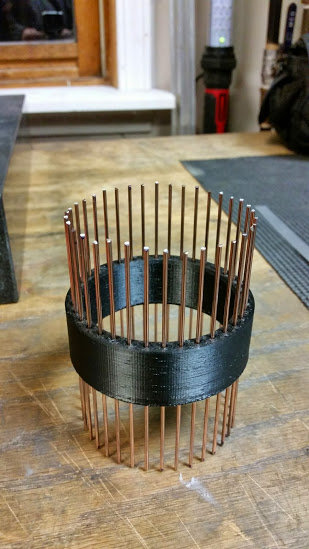

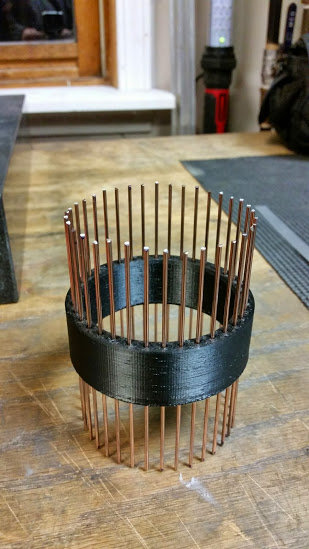

I whipped up a model in CAD to make a tool for measuring the angle. I then 3d printed it in black ABS plastic and cut TIG welding wire to fit in the smaller holes.

The ID of the bigger circle is just a hair over 2.5"

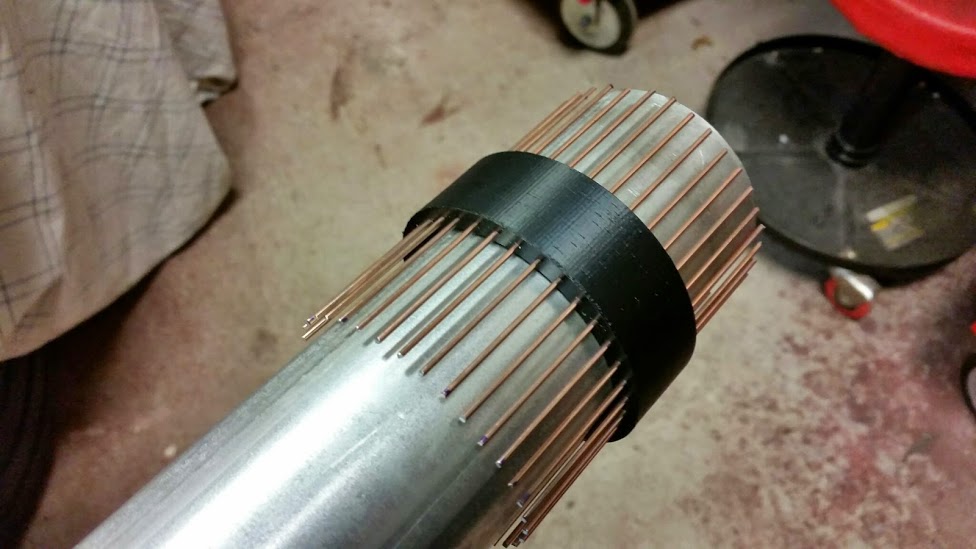

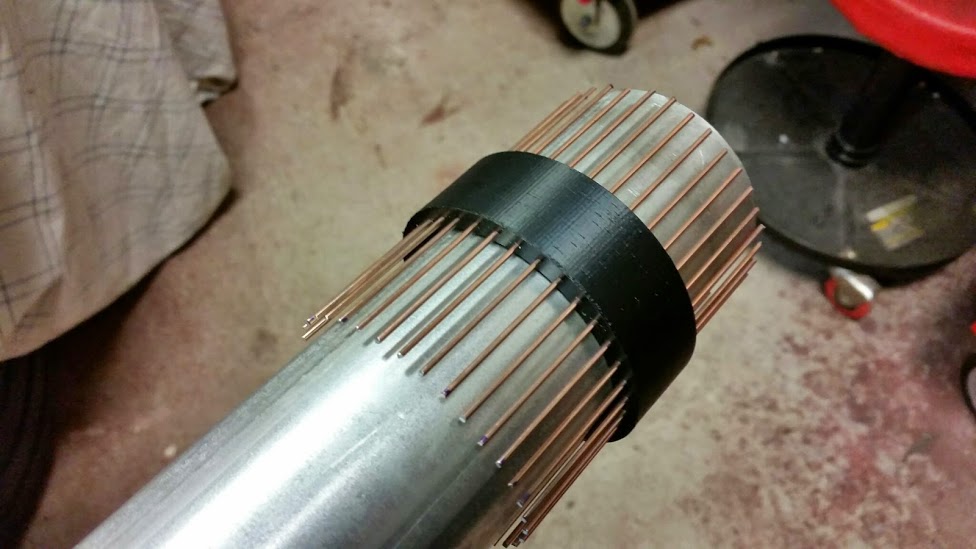

This allowed it to slide over the exhaust pipe. I came up with a few ideas to avoid having to cut a slightly short piece to figure out the first angle but instead just decided it was easier to sacrifice a short piece of cheap exhaust tubing.

This tool allowed me to transfer both cuts and cut them on my bandsaw and do a little finish work with the grinder.

To say I am pleased with the fit would be an understatement!

I wanted to figure out what angle to cut the pipe to meet the downpipe. Every method I thought of with involved a lot of trial and error with a grinder, a file and band saw. Then I had an idea...

I whipped up a model in CAD to make a tool for measuring the angle. I then 3d printed it in black ABS plastic and cut TIG welding wire to fit in the smaller holes.

The ID of the bigger circle is just a hair over 2.5"

This allowed it to slide over the exhaust pipe. I came up with a few ideas to avoid having to cut a slightly short piece to figure out the first angle but instead just decided it was easier to sacrifice a short piece of cheap exhaust tubing.

This tool allowed me to transfer both cuts and cut them on my bandsaw and do a little finish work with the grinder.

To say I am pleased with the fit would be an understatement!