Ian's 99 build thread

#1082

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Well, no Miatas@MRLS photos for me because my car wasn't at Miatas@MRLS. I towed it down Friday for the pre-Miatas@MRLS Trackmasters day, after putting all the go-fast bits back in and adding a 12mm rear sway bar. Went out for a shakedown run in the first session and was getting weird power loss. Came in and looked at the logs, saw it was showing lean, but no indication why -- fuel pressure was good injector on-time was good. Then I thought about the RL TC, it cuts power when it senses wheelspin by cutting fuel to alternating cylinders, which means it's blowing unburned oxygen into the exhaust, which shows up as lean. Second session I went back to out to explore it, got 2 instances in 2 laps, turned off the TC, and it never happened again. So yeah, sounds like the TC was doing it. So why was the TC activating? Savington says it's probably the rear swaybar, but I'm sure my 90K mile Torsen with 75 track days and 100+ autocrosses on it isn't helping.

I have an LED hooked up to the TC so that it flashes whenever it's cutting fuel, but it's too far out of my line of sight to see it from the driver's seat. I really need to remount it somewhere else. The TC has 6 different modes -- wet, dry, 10%, 20%, 25%, and off (or something like that). I normally use it in "dry", but for the 3rd session I went out with Geoff as a passenger so that he could watch for the light flickering while I tried different modes. While I did get some expected TC activation (mainly in turn 11), I didn't get any of the weird random power loss that I'd been experiencing in the first session, so that was somewhat inconclusive.

During the 2nd session I'd been having some trouble shifting the tranny, and in the 3rd session it started popping out of 3rd in turn 11. That's the only corner on the track where I use that gear, so it took me a few laps to figure out that's why it was doing it, rather than just me screwing up the shift. Geoff said it was popping out right as the TC light activated. I did the rest of that session holding the transmission in 3rd with my right hand while steering with my left -- not the fast way through that corner.

After the 3rd session was lunch, then I got in the car to go fill it up with fuel since it was at 1/4 tank. On the way to the pumps I noticed it was rattling, a lot in 1st and 2nd gear. Uh oh. Further investigation showed that it would rattle whenever the input shaft was spinning -- push the clutch in while stopped and it would stop, but roll the car in gear with the clutch in and it would still make noise. Looks like my 6-speed bit the dust.

Fortunately I had picked up the salvage MSM transmission that Ed was selling that morning, so I had a spare. I wasn't going to try to change it in the paddock, though, so I towed the car home to spend Saturday trying to get it installed. I'd hoped to get it done in time to run on Sunday, but by 9PM Saturday night I was only as far as having the old transmission out and on the floor. It's really crunchy. I drained the fluid from it and there was half an inch of metal shavings stuck to the magnetic drain plug, and that's in the 4K miles since I put the current motor in.

So I didn't make it there for the track sessions on Sunday either, alas. That puts me back at 50% success ratio for Miatas@MRLS -- 2009 I lost my coolant, ultimately triggering my first motor build, 2012 I killed the 5 speed, 2015 the throttle body killed my first build motor triggering the second build (and this thread), and now 2017 I killed the 6-speed. 2010, 2013, 2014, and 2016 were free of major damage (there was no 2011 event).

I drove the FD down Saturday morning to hang out with folks for a little bit and collect my t-shirt, was good to see other folks there.

To make matters more interesting, when I went out to put the trailer away this afternoon the truck wouldn't start. Somehow it lost the fuel prime and needed a bunch of pumping on the manual prime pump. I'm kinda glad I wasn't trying to diagnose that in the paddock at Laguna, or in the dark at 6AM Sunday morning while trying to tow the car down there.

Put some more work into installing the transmission from Ed today. It's bolted to the motor and PPF, still need to put the driveshaft, wiring harnesses, and exhaust back in.

--Ian

I have an LED hooked up to the TC so that it flashes whenever it's cutting fuel, but it's too far out of my line of sight to see it from the driver's seat. I really need to remount it somewhere else. The TC has 6 different modes -- wet, dry, 10%, 20%, 25%, and off (or something like that). I normally use it in "dry", but for the 3rd session I went out with Geoff as a passenger so that he could watch for the light flickering while I tried different modes. While I did get some expected TC activation (mainly in turn 11), I didn't get any of the weird random power loss that I'd been experiencing in the first session, so that was somewhat inconclusive.

During the 2nd session I'd been having some trouble shifting the tranny, and in the 3rd session it started popping out of 3rd in turn 11. That's the only corner on the track where I use that gear, so it took me a few laps to figure out that's why it was doing it, rather than just me screwing up the shift. Geoff said it was popping out right as the TC light activated. I did the rest of that session holding the transmission in 3rd with my right hand while steering with my left -- not the fast way through that corner.

After the 3rd session was lunch, then I got in the car to go fill it up with fuel since it was at 1/4 tank. On the way to the pumps I noticed it was rattling, a lot in 1st and 2nd gear. Uh oh. Further investigation showed that it would rattle whenever the input shaft was spinning -- push the clutch in while stopped and it would stop, but roll the car in gear with the clutch in and it would still make noise. Looks like my 6-speed bit the dust.

Fortunately I had picked up the salvage MSM transmission that Ed was selling that morning, so I had a spare. I wasn't going to try to change it in the paddock, though, so I towed the car home to spend Saturday trying to get it installed. I'd hoped to get it done in time to run on Sunday, but by 9PM Saturday night I was only as far as having the old transmission out and on the floor. It's really crunchy. I drained the fluid from it and there was half an inch of metal shavings stuck to the magnetic drain plug, and that's in the 4K miles since I put the current motor in.

So I didn't make it there for the track sessions on Sunday either, alas. That puts me back at 50% success ratio for Miatas@MRLS -- 2009 I lost my coolant, ultimately triggering my first motor build, 2012 I killed the 5 speed, 2015 the throttle body killed my first build motor triggering the second build (and this thread), and now 2017 I killed the 6-speed. 2010, 2013, 2014, and 2016 were free of major damage (there was no 2011 event).

I drove the FD down Saturday morning to hang out with folks for a little bit and collect my t-shirt, was good to see other folks there.

To make matters more interesting, when I went out to put the trailer away this afternoon the truck wouldn't start. Somehow it lost the fuel prime and needed a bunch of pumping on the manual prime pump. I'm kinda glad I wasn't trying to diagnose that in the paddock at Laguna, or in the dark at 6AM Sunday morning while trying to tow the car down there.

Put some more work into installing the transmission from Ed today. It's bolted to the motor and PPF, still need to put the driveshaft, wiring harnesses, and exhaust back in.

--Ian

#1084

Supporting Vendor

iTrader: (1)

Join Date: Sep 2010

Location: Lake Forest, CA

Posts: 7,951

Total Cats: 1,004

One minor correction: that's not the salvage transmission. That's the one out of the 76k mile one that needed the engine. Thankfully transmissions don't need the fluid serviced super regularly like engines do... The fluid that came out of that trans looked great. We installed the higher mileage trans out of the wrecked car because that way we could guarantee the trans we were selling.

#1086

Supporting Vendor

iTrader: (1)

Join Date: Sep 2010

Location: Lake Forest, CA

Posts: 7,951

Total Cats: 1,004

Thanks, G. People get weird when a part, though unaffected, came out of a wrecked car. Figured it'd be much easier to sell a transmission out of what we know was a running, driving, low-mile car.

Rough weekend for the MT.net crew though, haha.

Rough weekend for the MT.net crew though, haha.

#1089

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

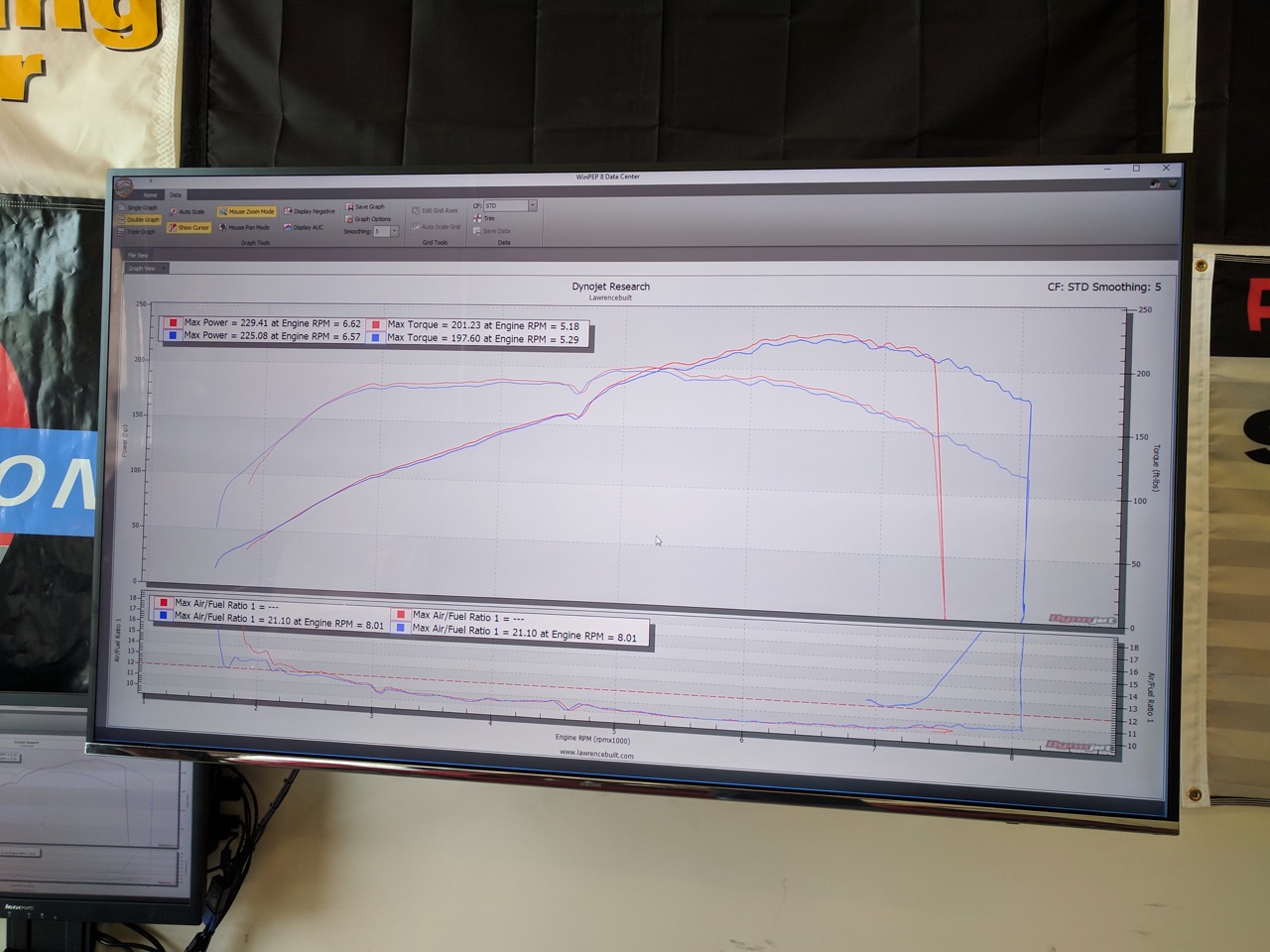

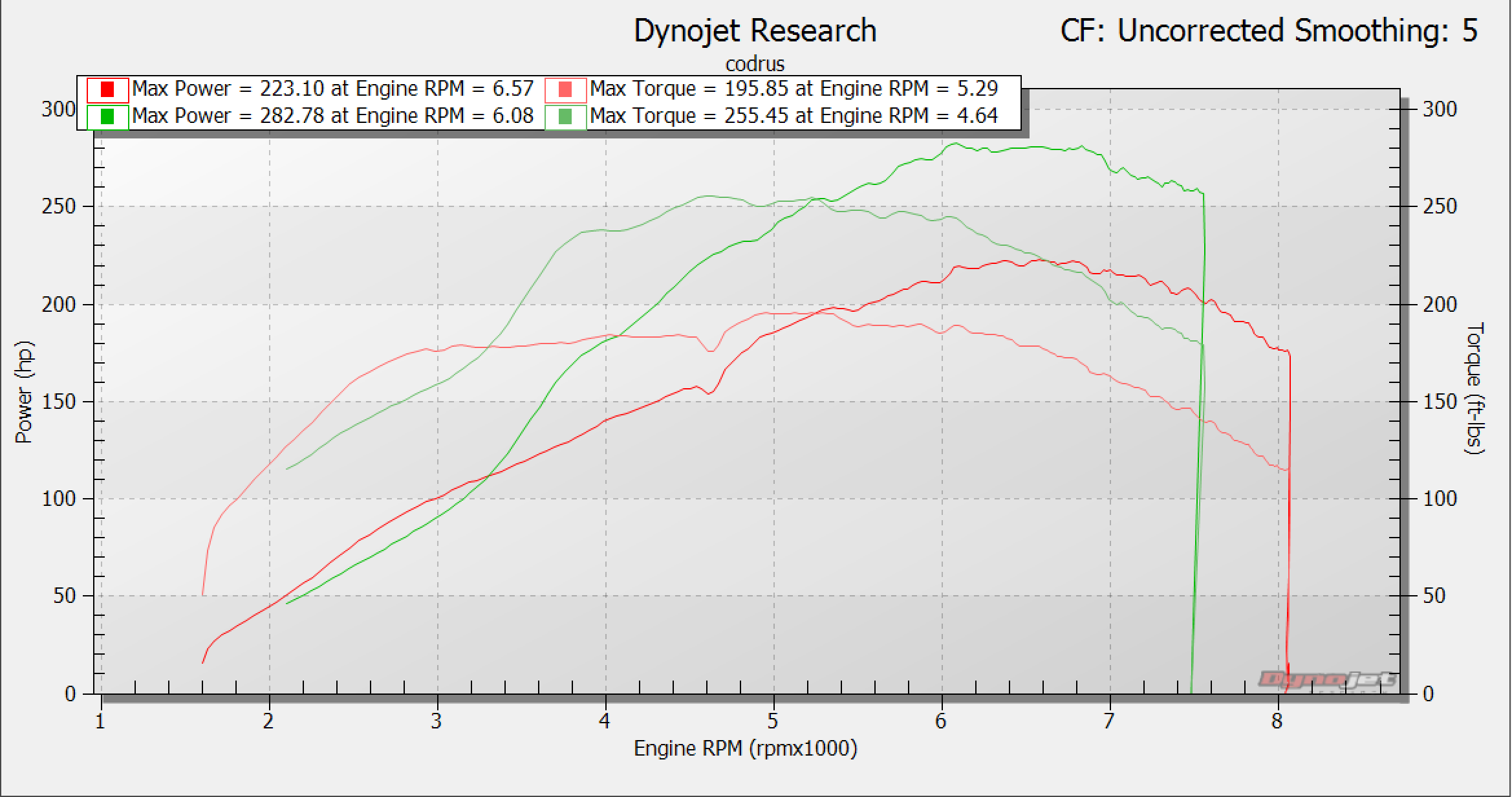

Took the Miata to the dyno today, my goal was to see what valve springs had done, and whether or not it had picked up any power at the top end from preventing valve float. Below about 210 kpa there wasn't much difference, but at 240 and 270 it was quite noticable. At a nominal 270 it made 20 more hp despite having 10 kpa less manifold pressure (I hadn't tuned the EBC bias table very well up there, so it was only making 260 kpa vs the dyno from 2 years ago when it did 270).

Unfortunately it's misfiring at 260+ kpa, looks like I either need to revisit my dwell numbers or close down the gaps on the plugs if I want to run that much. I don't know that I'm going to run that high very often -- it's well beyond the point at which I can run MBT timing, so it's not something I'd want on the track.

I haven't gotten the new dynojet viewer software installed yet, so all I have are cell phone shots of the display at the dyno. Once I get that done I'll post comparisons, but for now:

--Ian

Unfortunately it's misfiring at 260+ kpa, looks like I either need to revisit my dwell numbers or close down the gaps on the plugs if I want to run that much. I don't know that I'm going to run that high very often -- it's well beyond the point at which I can run MBT timing, so it's not something I'd want on the track.

I haven't gotten the new dynojet viewer software installed yet, so all I have are cell phone shots of the display at the dyno. Once I get that done I'll post comparisons, but for now:

--Ian

#1092

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

--Ian

#1093

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

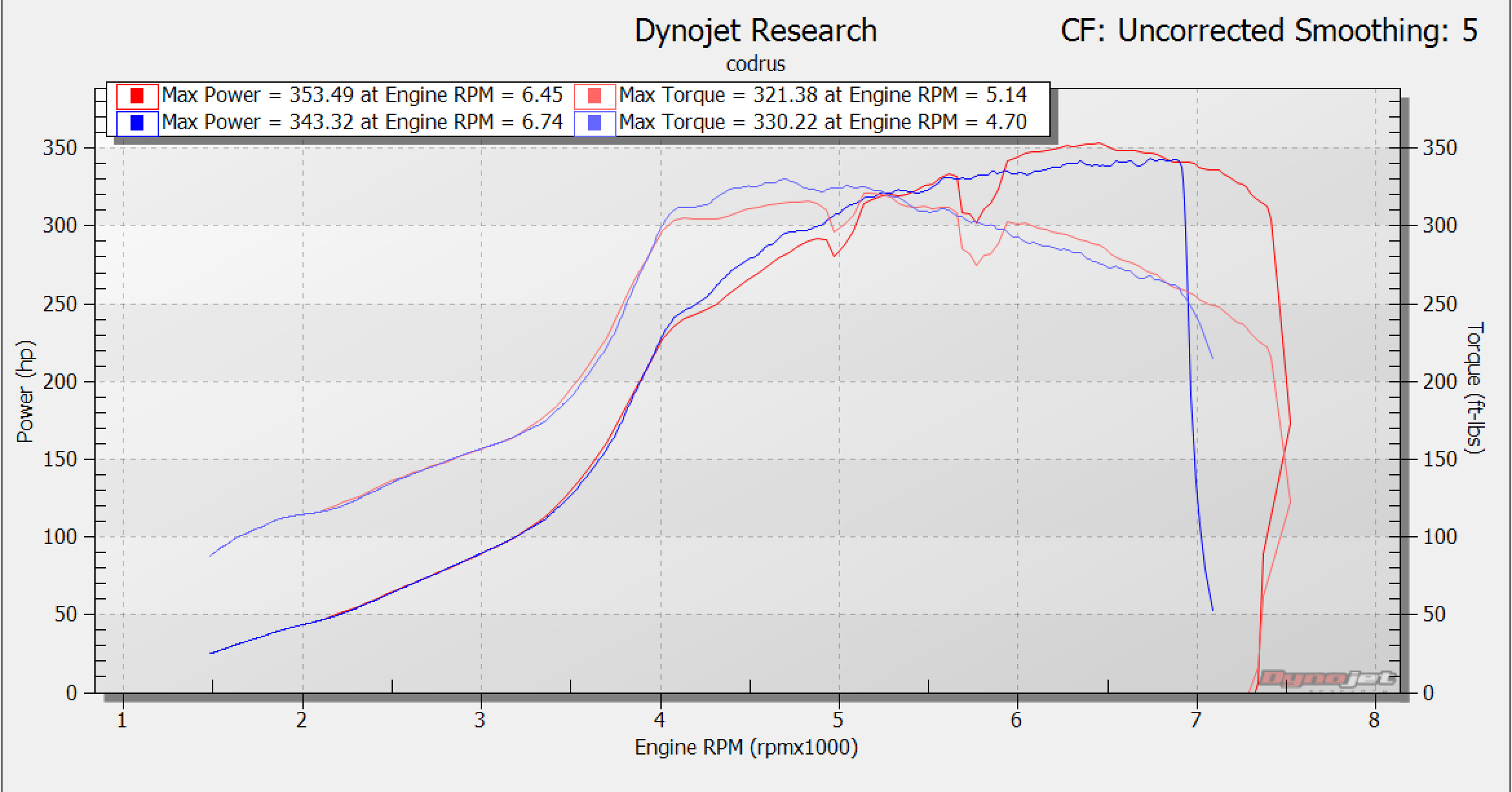

I got the WinPEP 8 viewer to run and made some graphs. The primary goal of this dyno trip was to see if the valve spring replacement did anything. The answer is definitively yes:

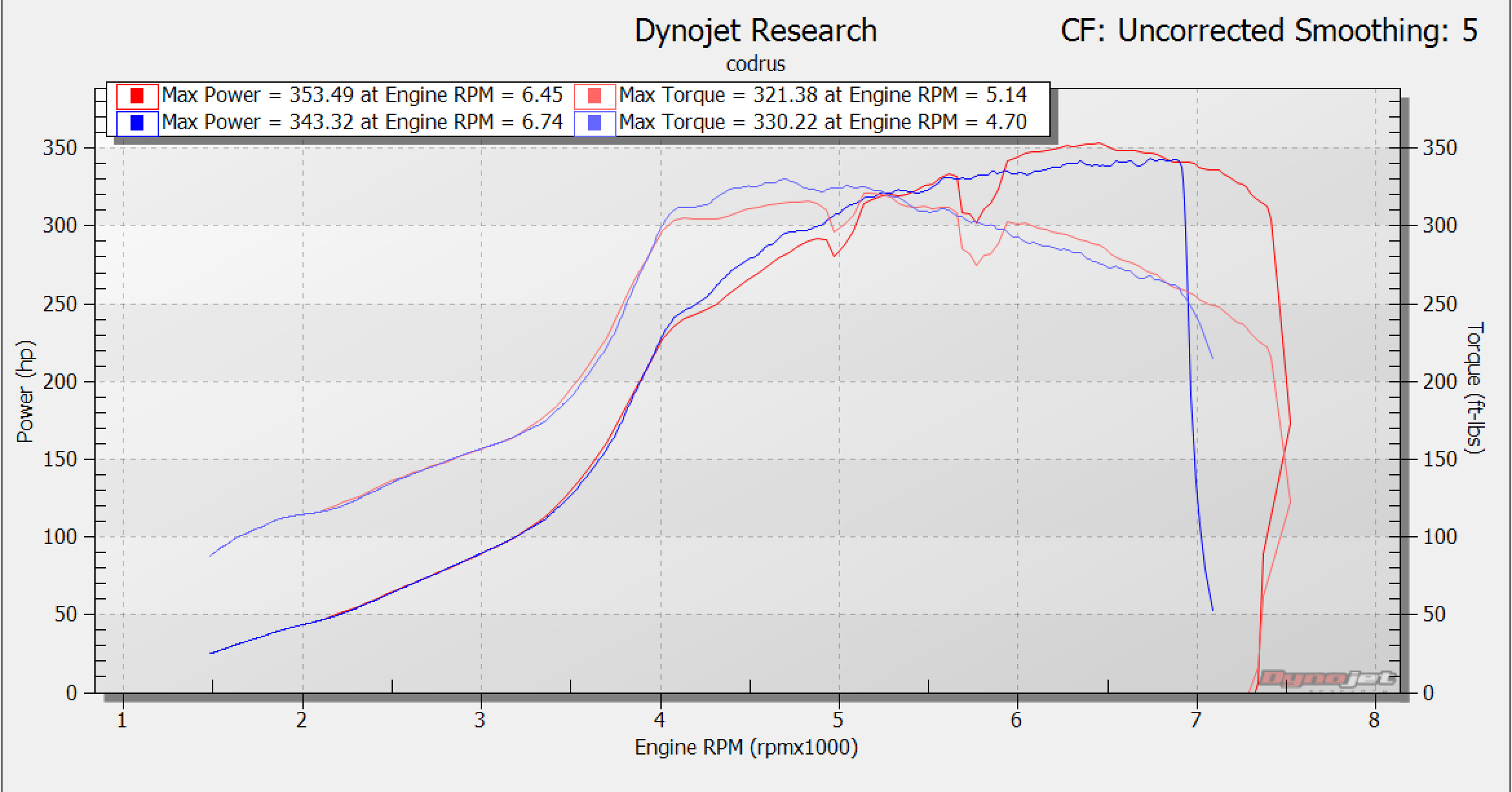

Blue is old, red is new. There are a few problems with the run, specifically it's misfiring, the EBC bias table isn't set up properly for this boost level (260 kpa), and my wideband is dying (I've abused it on the track too many times), so the fueling is about half a point too rich on the new one, and that's costing some power. It's about 30 kpa below target from 3K-4K (which is why the new graph is lower), but it's only 10 kpa below target above 6K and it's picked up a whole bunch of power up there. Plus I can run it to 7500 without floating the valves.

I need to tune the EBC and fuel and fix the misfire (dwell? plug gap? Not sure yet) and get another run. I was out of time to do that on the dyno, had an iffy wideband, and the dyno rate had gone up to $200/hour, so I wasn't going to do all of that there.

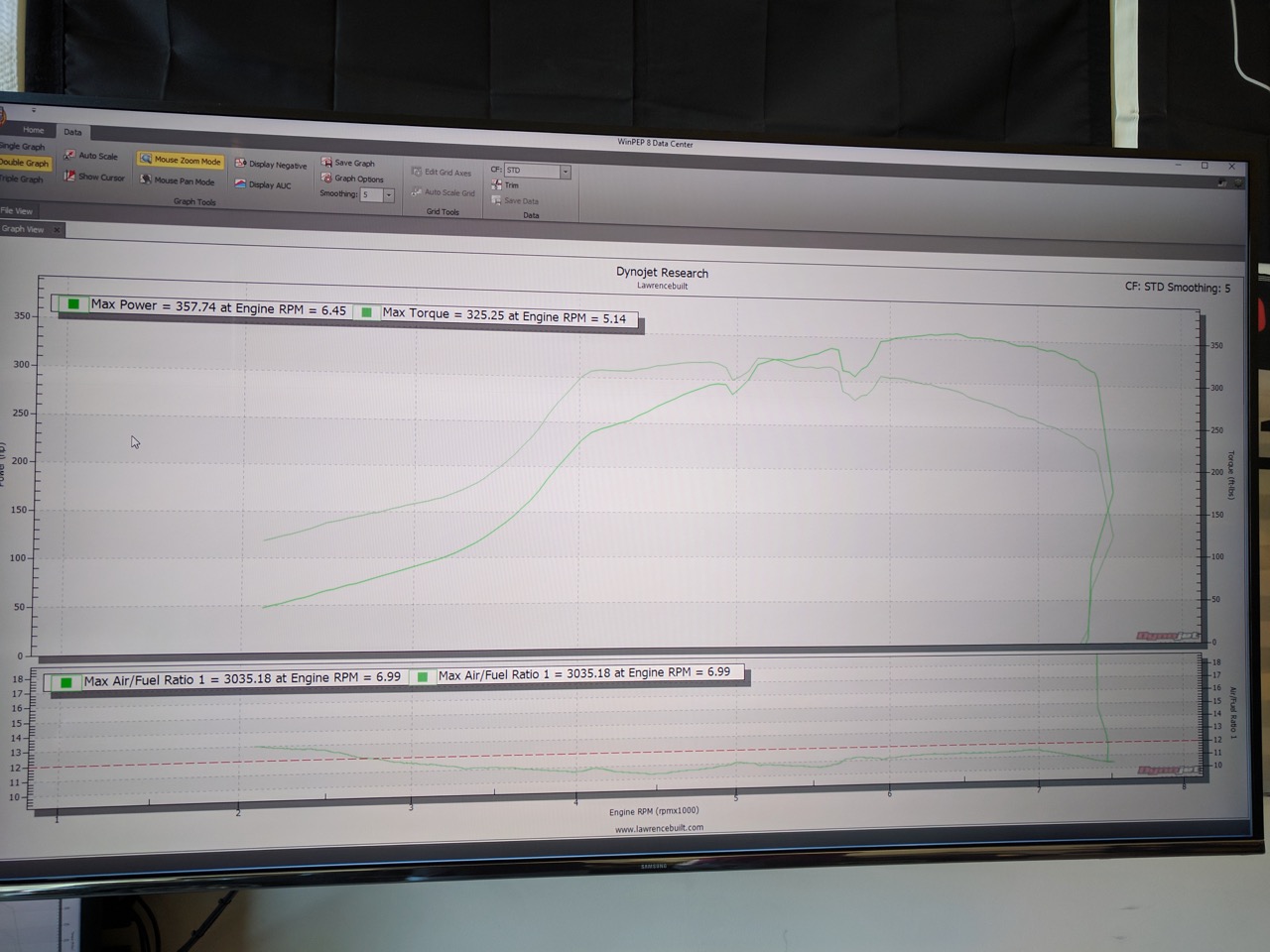

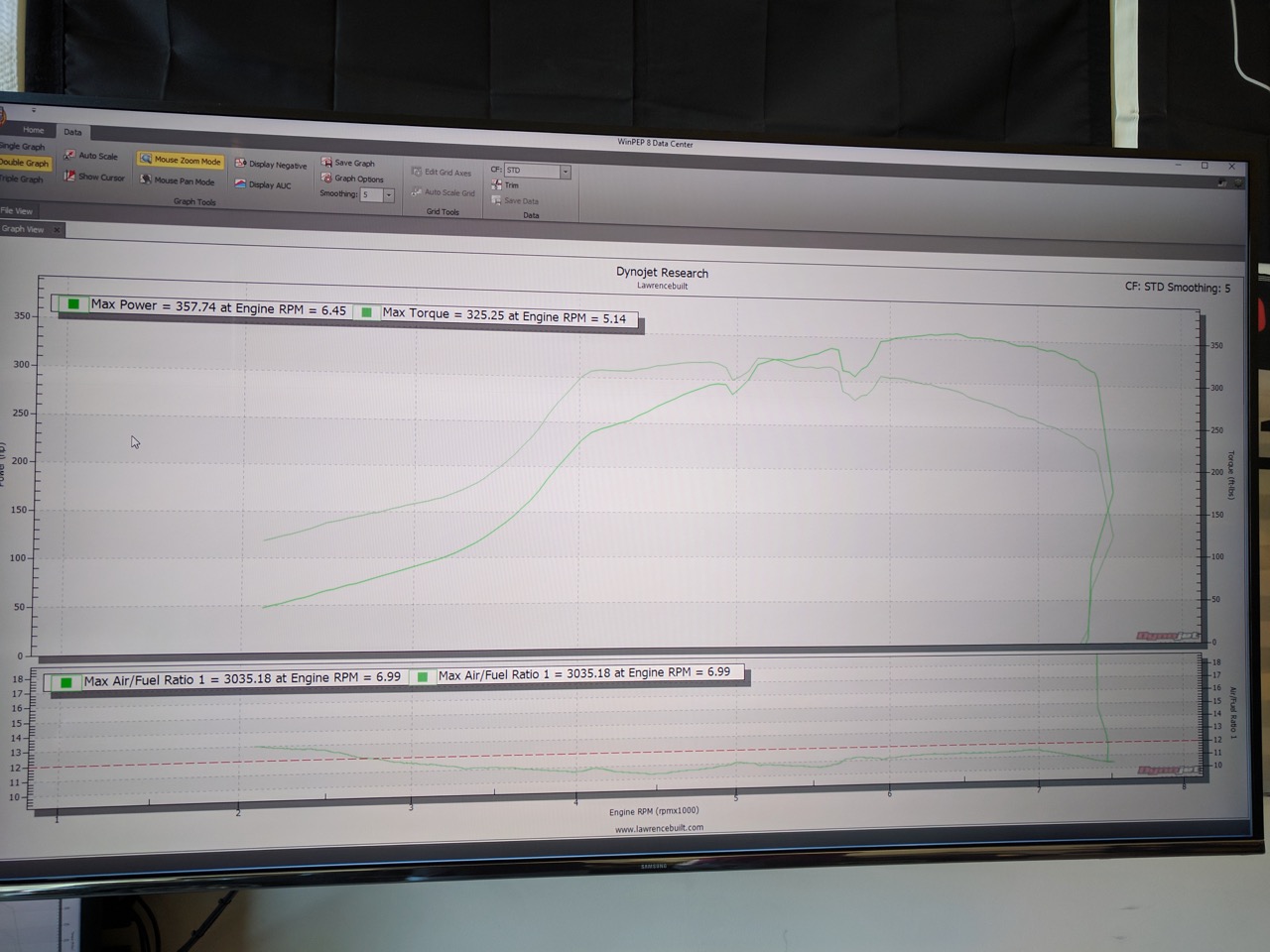

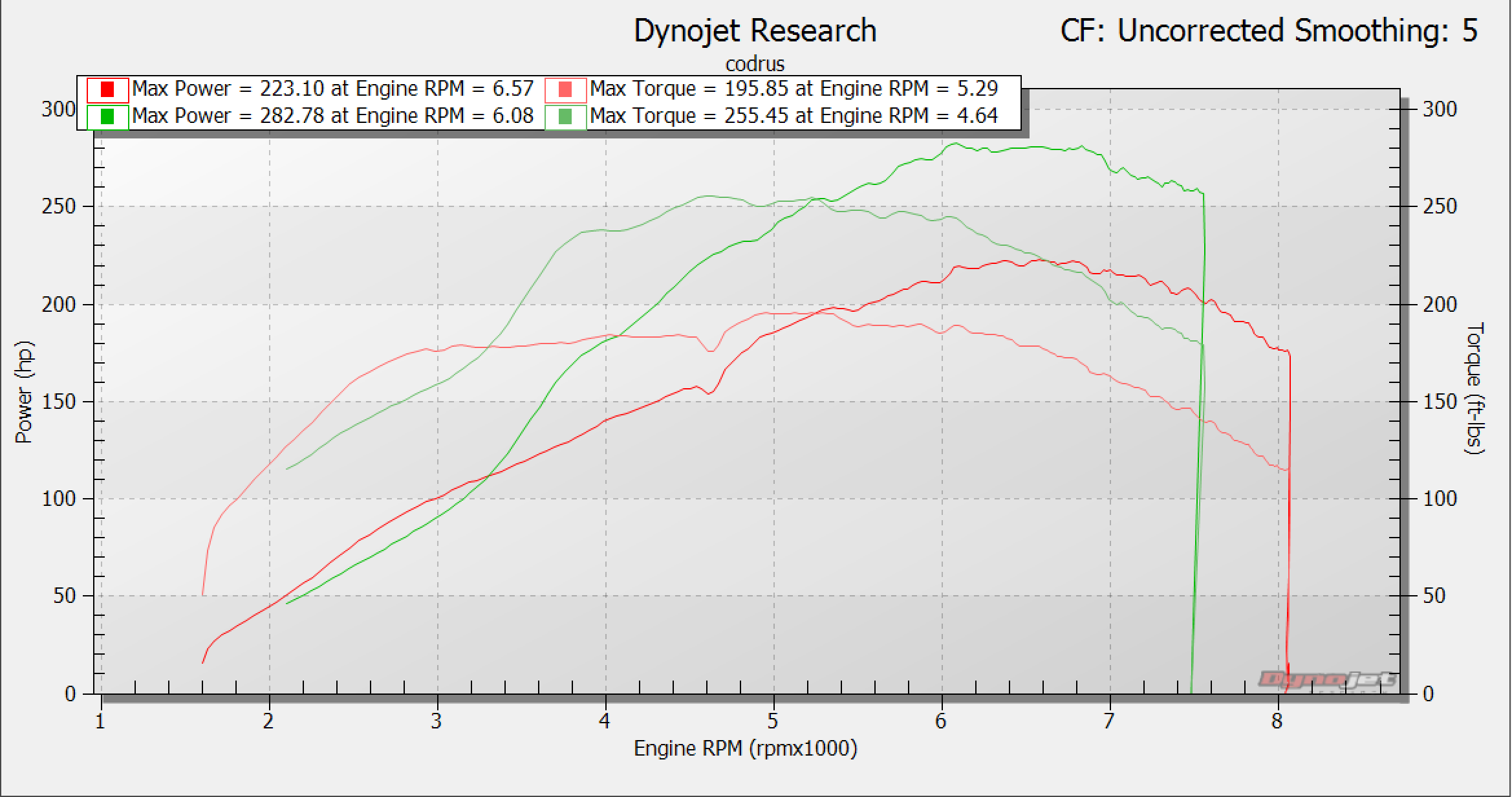

For amusement, I also put together a comparison of the FD vs the lowest boost level that I ran on the Miata. That's 170-180 kpa on the FD, vs 190 on the Miata.

The Miata has 100 octane gas in it (vs 91 in FD), a full aftermarket ECU vs stock, and the advantage of 25 year newer turbo technology.

--Ian

Blue is old, red is new. There are a few problems with the run, specifically it's misfiring, the EBC bias table isn't set up properly for this boost level (260 kpa), and my wideband is dying (I've abused it on the track too many times), so the fueling is about half a point too rich on the new one, and that's costing some power. It's about 30 kpa below target from 3K-4K (which is why the new graph is lower), but it's only 10 kpa below target above 6K and it's picked up a whole bunch of power up there. Plus I can run it to 7500 without floating the valves.

I need to tune the EBC and fuel and fix the misfire (dwell? plug gap? Not sure yet) and get another run. I was out of time to do that on the dyno, had an iffy wideband, and the dyno rate had gone up to $200/hour, so I wasn't going to do all of that there.

For amusement, I also put together a comparison of the FD vs the lowest boost level that I ran on the Miata. That's 170-180 kpa on the FD, vs 190 on the Miata.

The Miata has 100 octane gas in it (vs 91 in FD), a full aftermarket ECU vs stock, and the advantage of 25 year newer turbo technology.

--Ian

#1095

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

I have LS3 coils in it -- I had them at 4.5, turned it up to 5.5 while on the dyno and it didn't seem to help. I need to check the plug gaps. Running extra rich wasn't helping it either.

--Ian

--Ian

#1096

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Anyone ever used one of the Innovate wideband heat sink thingeys? I picked one up to protect the new wideband that I'm installing (killed the other one at the track), it's basically a plug that goes into the O2 sensor bung, with two small holes in the gas flow. The wideband mounts into the end of the heat sink, and there's a small space inside it that exhaust gas is supposed to flow through via those two holes. To do this, one of the holes needs to be aligned pointing forwards, into the main gas flow, and there's an index mark on the hex head to indicate which way is correct.

The issue is that when I install it, it touches down finger-tight just barely past the correct alignment, and I really don't think there's 3/4 to 7/8 of a turn in it, even with the crush washer. Any thoughts on how to fix that? I thought about doubling up on crush washers, but didn't have a spare one the right size.

--Ian

The issue is that when I install it, it touches down finger-tight just barely past the correct alignment, and I really don't think there's 3/4 to 7/8 of a turn in it, even with the crush washer. Any thoughts on how to fix that? I thought about doubling up on crush washers, but didn't have a spare one the right size.

--Ian

#1097

Senior Member

iTrader: (2)

Join Date: Oct 2013

Location: Goleta, Southern California

Posts: 520

Total Cats: 27

I'm concerned for the readings that wideband will give with that thing. Looks like an O2 space used to cover up catalyst codes to get by an emissions test. MIL is on, but the car blows clean. Put one of those in the down stream O2 and suddenly the ecu doesn't think the cat is bad anymore. Emissions passed.

I predict slow or in accurate wideband readings.

I predict slow or in accurate wideband readings.

#1098

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Drill moar holes at the correct index, but I think williams805 hit the nail on the head about slow reading and etc. I'd swiss cheese that thing if it was me.

I've been using a 4" diameter 0.0625" thick piece of brass with a hole drilled in the center as my O2 sensor gasket, It's been working great for years. The only O2 sensor I've have problems with is the one that I smashed the tip into the concrete last month.

I've been using a 4" diameter 0.0625" thick piece of brass with a hole drilled in the center as my O2 sensor gasket, It's been working great for years. The only O2 sensor I've have problems with is the one that I smashed the tip into the concrete last month.

#1099

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I have one of those sitting on the shelf, pretty sure the only way to get proper alignment is to be one of the lucky ~5%, or weld a bung in that's been pre-clocked to it. The design is such that if they are installed properly, the readings should not be laggy or slow, except maybe at idle.

I left at lunch time to go try to get the tranny installed for Sunday.

I left at lunch time to go try to get the tranny installed for Sunday.