Pat's Ebay Turbo Compound Boost Build

#1121

Well i understand what its actually testing. Im saying if an engine with normal cams and properly sealed valves, it must be the pistons? If thats the case, what happens when you throw tons of boost and cylinder pressure at pistons/rings that are slightly worn/not sealing the best they could be? Compared to a very healthy cyclinder? Will it be down on power? Have more blow by? What are the consequences?

#1122

All of the above, in completely varying amounts depending on how bad ring seal really is.

with a turbo though, I think this would be less noticed as long as the turbo has more headroom for flow.

dieselS running 200 psi boost only have a CR of ike 3.5-4:1 not even enough to start without ether, but they make like 2500 hp and 4000 tq.

with a turbo though, I think this would be less noticed as long as the turbo has more headroom for flow.

dieselS running 200 psi boost only have a CR of ike 3.5-4:1 not even enough to start without ether, but they make like 2500 hp and 4000 tq.

#1124

Elite Member

iTrader: (1)

Join Date: Apr 2014

Location: SF Bay Area, CA

Posts: 3,078

Total Cats: 553

My car makes healthy power for a stock block with 245,000 miles. Don't plan to check compression, I don't want to know. Might explain why I am running out of breath up top and need so much boost.

There is definitely an old school mentality of running higher compression than allowed in a specific class with huge cams "cheating." Because they don't make good compression at low rpm, they make it at high rpm.

There is definitely an old school mentality of running higher compression than allowed in a specific class with huge cams "cheating." Because they don't make good compression at low rpm, they make it at high rpm.

#1125

Dynamic compression vs static compression is a big deal, yes.

I think the reason for the gauge-to-gauge variability is that you are effectively adding the volume of the adapter, hose & gauge to the combustion chamber. Different gauges have different internal volumes and thus change the ratio by a different amount.

--Ian

I think the reason for the gauge-to-gauge variability is that you are effectively adding the volume of the adapter, hose & gauge to the combustion chamber. Different gauges have different internal volumes and thus change the ratio by a different amount.

--Ian

#1126

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Dynamic compression vs static compression is a big deal, yes.

I think the reason for the gauge-to-gauge variability is that you are effectively adding the volume of the adapter, hose & gauge to the combustion chamber. Different gauges have different internal volumes and thus change the ratio by a different amount.

--Ian

I think the reason for the gauge-to-gauge variability is that you are effectively adding the volume of the adapter, hose & gauge to the combustion chamber. Different gauges have different internal volumes and thus change the ratio by a different amount.

--Ian

#1128

Compression ratio is equal to combustion chamber volume plus swept volume divided by combustion chamber volume:

CR = ( Vc + Vs ) / Vc

Every cc of volume in the hose is added to Vc. A 1/4" diameter hose that's 12 inches long has 0.6 cubic inches of volume inside it, or 10ccs. Add 10ccs to the 50cc combustion chamber volume and you change the compression ratio by quite a bit.

Assuming a stock 99 motor, Vs is 460 cc and CR is 9.5 (spec), so Vc is 54 cc. Bump that up to 64 cc by adding that hose and now your compression ratio is only 8.2:1. Double the length of hose to 2 feet and it's only 7.2:1.

--Ian

#1130

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Yes it does. Cranking it longer will ensure you measure the peak pressure, but the volume in the hose before the one-way valve makes a big difference in what that peak pressure is.

Compression ratio is equal to combustion chamber volume plus swept volume divided by combustion chamber volume:

CR = ( Vc + Vs ) / Vc

Every cc of volume in the hose is added to Vc. A 1/4" diameter hose that's 12 inches long has 0.6 cubic inches of volume inside it, or 10ccs. Add 10ccs to the 50cc combustion chamber volume and you change the compression ratio by quite a bit.

Assuming a stock 99 motor, Vs is 460 cc and CR is 9.5 (spec), so Vc is 54 cc. Bump that up to 64 cc by adding that hose and now your compression ratio is only 8.2:1. Double the length of hose to 2 feet and it's only 7.2:1.

--Ian

Compression ratio is equal to combustion chamber volume plus swept volume divided by combustion chamber volume:

CR = ( Vc + Vs ) / Vc

Every cc of volume in the hose is added to Vc. A 1/4" diameter hose that's 12 inches long has 0.6 cubic inches of volume inside it, or 10ccs. Add 10ccs to the 50cc combustion chamber volume and you change the compression ratio by quite a bit.

Assuming a stock 99 motor, Vs is 460 cc and CR is 9.5 (spec), so Vc is 54 cc. Bump that up to 64 cc by adding that hose and now your compression ratio is only 8.2:1. Double the length of hose to 2 feet and it's only 7.2:1.

--Ian

Actually, just measured it and the adapter is .89cc extra, so my 9.0:1 motor would be 8.85:1 with the adapter screwed in. So small change, not huge though. Between the adapter, and the ported/unshrouded combustion chambers which must be more cc than before, I'm ok with the compression results.

#1131

Most cams close at around 50 degrees after BDC regardless of duration which means they are getting a bit less than half the stroke in compression when cranking. Different cams will vary a few degrees but not much. So really it's just compression ratio plus whatever air is in the gauge as to how much compression you read. On cranking, my high compression engine (around 13.5:1 CR) reads around 250PSI and that is with the standard cheap compression gauge. The one way valve is generally at the end of the hose so it's only the internal volume of the hose affecting the compression reading.

Also, because of the massive cam overlap I basically only get a compression reading on every second stroke, whilst on a stock engine you'll get a small pulse then a larger pulse on each alternate stroke. This means it takes a decent amount of cranking to generate compression and I normally see the battery starting to slow cranking speed by the time I've done 4 cylinders.... So the 4th cylinder is always 5 PSI or so lower than 1.

Also, because of the massive cam overlap I basically only get a compression reading on every second stroke, whilst on a stock engine you'll get a small pulse then a larger pulse on each alternate stroke. This means it takes a decent amount of cranking to generate compression and I normally see the battery starting to slow cranking speed by the time I've done 4 cylinders.... So the 4th cylinder is always 5 PSI or so lower than 1.

#1132

Originally Posted by Leafy

Not really surpising. Stock miata diff is really strong. there really isnt a need to replace it even with v8 swaps as long as you dont boost the v8. I think all the v8 swaps replacing it is why everyone thinks its weak. Just dont wheel hop and it wont break.

But mostly drag racing the car so i m pretty sure i m gonna go with the rx7 t2 diff or go all the way with a cobra rear end

#1134

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

So here's a bigger update of what all was fixed/changed/upgraded while under the knife the last few days.

One of my extreme performance SPAL fans was damaged. I built a fancy PWM fan controller a few months back, and discovered one of the fans was weaker than the other. So I happen to have two spare high performance spal fans (one step below the extreme series) so I swapped that fan out for a high performance. No surprise it's not as strong as the extreme, but it only pulls 13A instead of 40. And it moves more air than the damaged fan.

A lot of the hose clamps in the engine bay were too big, and had a large piece hanging out when tightened. I marked and shortened every clamp for the cooling system and intercooler pipes to fix that. Some were actually a cut hazard because they run behind and beside the motor and were sharp. After shortening them I ground them all smooth and rounded the corners.

Cylinder head had new bronze valve guides installed, new mazda valve stem seals, 3 new exhaust valves, and a complete rebuild with multi angle valve job.

I swapped from a 180 thermostat to a mazda style 192*F thermostat. That should be good for something, at least the heater will work a bit better. Technically might make more power from better ring sealing, dunno but should help motor life at least.

Fan controller was adjusted to 0% duty up to 199*F, 20% fan duty at 200*F, taper to 85% at 210*F, 100% above 210*F. Might add 3-5 degrees to all those numbers, not sure yet.

I installed a new oil pump in the rear of the car for the rear turbo. It's about 10x quieter than the old one and pulls 1/2 the current. No louder than typical fuel pump. I also made a current monitoring device for it, I just need to install it. It will turn a LED on for 5 sec if it ever sees the current go lower than 1 Amp. Will use one of my warning lights for it.

New spark plugs installed and gaped at 30 thousandths.

Was extremely careful installing the timing belt to make sure there was no piston/valve contact. There was none. I spun the motor over by hand (no tools) after setting the belt to make sure it spun freely with no problems.

Installed larger ARP head stud washers. ARP-200-8747

Is the part number. They are .12" thick, and .875" OD, ground flat. They are larger OD and thicker than the factory mazda washers. And they FIT! I torqued the head to 72 ft*lbs with these washers with a calibrated torque wrench.

Pulled the front wastegate apart and added some springs to it. It now has 3 springs in it, and wastegate pressure is 22-24 PSI on the front turbo. The rear is 4 PSI on wastegate. So total wastegate is now 26-28 psi.

The car has more power everywhere with the new cylinder head. I'm convinced now I bent those valves on assembly 2 years ago. It's got more torque, more power from cranking and idle, to midrange, to boost. Turbo spools faster too, like considerably faster. It starts better, idles better, idles with more vacuum.

For only 26 psi, it rips fairly well. If by some miracle it's dry tomorrow, I will race it on wastegate to see how it does. It pulls great in 1st and good in 2nd, 3rd is slow and needs a lot more boost.

Currently 26 PSI is hitting 75% duty cycle on the ID1300s. Looks like they will max out at 35 PSI. Compared to previous turbo setup, datalogs show this is burning 14% more fuel than the old setup at the same boost level.

Trans is doing great so far.

Plan is to drive it like this for a while just to make sure everything is working right, then bring it up to 35 psi and max out these injectors. Will try to get the current monitor installed soon so I don't have to worry about that pump ever again.

One of my extreme performance SPAL fans was damaged. I built a fancy PWM fan controller a few months back, and discovered one of the fans was weaker than the other. So I happen to have two spare high performance spal fans (one step below the extreme series) so I swapped that fan out for a high performance. No surprise it's not as strong as the extreme, but it only pulls 13A instead of 40. And it moves more air than the damaged fan.

A lot of the hose clamps in the engine bay were too big, and had a large piece hanging out when tightened. I marked and shortened every clamp for the cooling system and intercooler pipes to fix that. Some were actually a cut hazard because they run behind and beside the motor and were sharp. After shortening them I ground them all smooth and rounded the corners.

Cylinder head had new bronze valve guides installed, new mazda valve stem seals, 3 new exhaust valves, and a complete rebuild with multi angle valve job.

I swapped from a 180 thermostat to a mazda style 192*F thermostat. That should be good for something, at least the heater will work a bit better. Technically might make more power from better ring sealing, dunno but should help motor life at least.

Fan controller was adjusted to 0% duty up to 199*F, 20% fan duty at 200*F, taper to 85% at 210*F, 100% above 210*F. Might add 3-5 degrees to all those numbers, not sure yet.

I installed a new oil pump in the rear of the car for the rear turbo. It's about 10x quieter than the old one and pulls 1/2 the current. No louder than typical fuel pump. I also made a current monitoring device for it, I just need to install it. It will turn a LED on for 5 sec if it ever sees the current go lower than 1 Amp. Will use one of my warning lights for it.

New spark plugs installed and gaped at 30 thousandths.

Was extremely careful installing the timing belt to make sure there was no piston/valve contact. There was none. I spun the motor over by hand (no tools) after setting the belt to make sure it spun freely with no problems.

Installed larger ARP head stud washers. ARP-200-8747

Is the part number. They are .12" thick, and .875" OD, ground flat. They are larger OD and thicker than the factory mazda washers. And they FIT! I torqued the head to 72 ft*lbs with these washers with a calibrated torque wrench.

Pulled the front wastegate apart and added some springs to it. It now has 3 springs in it, and wastegate pressure is 22-24 PSI on the front turbo. The rear is 4 PSI on wastegate. So total wastegate is now 26-28 psi.

The car has more power everywhere with the new cylinder head. I'm convinced now I bent those valves on assembly 2 years ago. It's got more torque, more power from cranking and idle, to midrange, to boost. Turbo spools faster too, like considerably faster. It starts better, idles better, idles with more vacuum.

For only 26 psi, it rips fairly well. If by some miracle it's dry tomorrow, I will race it on wastegate to see how it does. It pulls great in 1st and good in 2nd, 3rd is slow and needs a lot more boost.

Currently 26 PSI is hitting 75% duty cycle on the ID1300s. Looks like they will max out at 35 PSI. Compared to previous turbo setup, datalogs show this is burning 14% more fuel than the old setup at the same boost level.

Trans is doing great so far.

Plan is to drive it like this for a while just to make sure everything is working right, then bring it up to 35 psi and max out these injectors. Will try to get the current monitor installed soon so I don't have to worry about that pump ever again.

#1138

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Engines are designed to run at a certain temperature. The stock BP that was 192 or 195 (not sure which). So at those temps, the rings/pistons/cylinder walls are at what mazda deemed the correct piston/wall clearance. If you run the motor hotter, it will reduce this clearance, and if you run it colder, that will increase it.

My stuff is loose, so I figured run it at 195 since that will likely tighten it up a bit and actually help the rings/pistons seal better. Which if so, would make more power.

My stuff is loose, so I figured run it at 195 since that will likely tighten it up a bit and actually help the rings/pistons seal better. Which if so, would make more power.

#1139

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

It rained all last week, but I'm hoping to take it to the track on friday and get some runs in. Been driving it on the street and so far it's working well. Plan is to run wastegate at the track and just have fun. If the mph proves to be consistent with the auto, then I'd like to try adding say, 2* of timing to the map and then make a pass, see if more timing = more mph, as mph = power in the drag racing world. Also need to wire up the trans brake, maybe I'll do that before friday!

#1140

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Then turned up back turbo 5 psi higher than before. Now total boost is 31psi.

New pass was a LOT faster. I foot braked the car more to help it launch. I cut a 1.81 60'. Not very good but better than last run. Need to hook up trans brake. Looking at datalogs, I launched with 5 psi boost! Uh. Transbrake will help but truth is the converter is just way too tight.

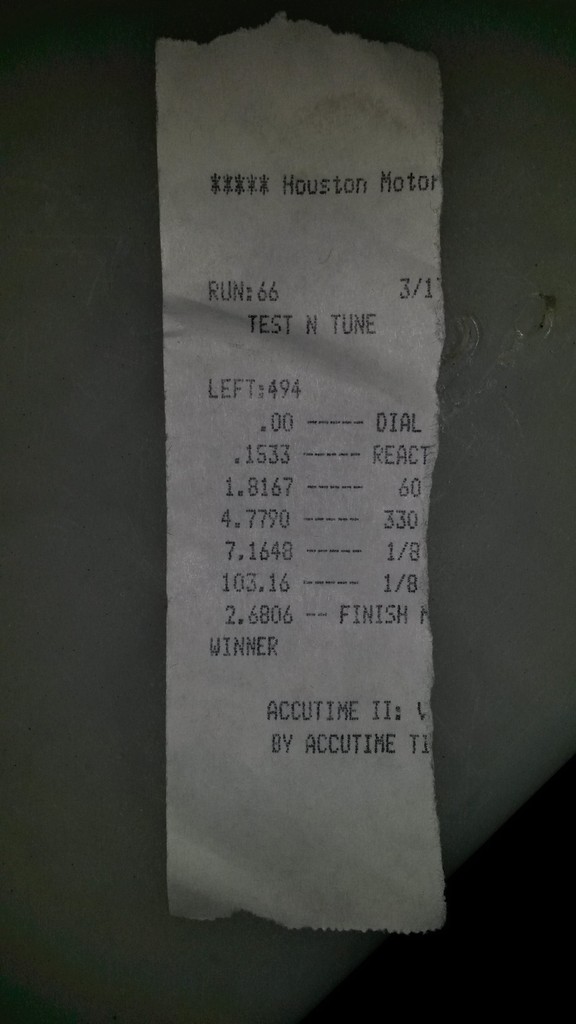

BUT OMG I SET A NEW PERSONAL RECORD, 7.16 @ 103.16 mph!!!!!!!!!!! It was about 70*F outside.

After looking at the datalogs, I launched at 5 psi, didn't hit full boost till after shifting into 2nd gear, I pedaled it a bit in 2nd (will get to that in a minute), and I short shifted from 2nd to 3rd.

The logs show that in 1st gear, my average acceleration was 15mph/second. 2nd gear? 20 mph/second! Funny stuff, cause first gear is a 2.45:1 reduction vs a 1.45 reduction in second gear. So from gearing alone, if I can accelerate at 20mph/second in 2nd gear, I should be able to hit 20* (2.45/1.45) = 33.8mph/sec in first! And with the converter multiplying torque on the launch, it should actually be even better in 1st. Ignoring traction and whatnot but obviously getting the boost to build before launching is going to make a BIG difference in ET and mph. I can more than DOUBLE my first gear acceleration with this power level just by launching with more boost out of the hole.

Also hit 75% duty cycle, so got more power left on the table too. 33% more.

Ok, so there is one problem. I think I broke the subframe again, or something in the suspension on the passengers side. I was in the left lane. When I hit 2nd gear, the car just steered itself into the right lane! I countersteered to try to catch it, and pedaled it, and still barely stayed out of the other lane. It was not wheel spin, it's like someone just kicked the back end of the car when I shifted. Like rear wheel steering.

Upon inspection, the passenger rear tire is rubbing the plastic that's over 1" in front of the tire. So somehow, I'm bending the suspension enough to let a tire contact something that's over 1" in front of it! Not good. Obviously something is broken, or these bushings are completely shot. Will investigate tomorrow or Sunday and try to figure out what needs to happen to fix this.

Drove it home, inspected spark plugs and checked everything over. All looks good, just need to figure out why the car jumps right under high acceleration.

Plan is to diagnose and fix what I think is a suspension problem. Wire up and test trans brake, also connect launch control to antilag. Once I get it working right at this power level, it's going up the rest of the way.