Pat's Ebay Turbo Compound Boost Build

#1301

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Delayed again, but now it's supposed to ship out today. So hopefully that happens, and I'll receive the diff sometime next week. Supposed to have tracking info later today. Can't wait to get the hanger and see if it will work.

#1302

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

4 month bump! Been busy, haven't had time to work on car.

So, about that 8.8 diff swap. Finally started working on that today. Pulled the exhaust/boost pipes/rear turbo/driveshaft/ppf/diff out of the car. Unbolted C4 to PPF adapter from transmission. Put poly bushings in diff hanger, test fitted to car. Didn't fit, hit subframe. Cut subframe, now it fits. Then test fitted diff hanger to diff. Didn't fit, cut ears off diff cover, retested, hit more stuff. Cut more stuff, got late and I was making a lot of noise cutting/grinding metal off the cover so I stopped for the night. Tomorrow I continue cutting cover for clearance for diff hanger. Once that fits, clean and test fit hanger/cover/diff as an assembly into the car and see if this hanger (which is for a FC RX7) will locate the diff in the car and not hit anything I can't fix. If it works, then I build diff mounts to hold front of diff. Need to fab a new crossmember to hold transmission too. And other stuff, like buy parts for a driveshaft. And install new hubs into uprights.

Ordered new wheel bearings as I got new hubs to use with the new axles, those should arrive Saturday.

Question. Who thinks this turbo would live at 40 PSI for at least 6 months? This is my front turbo on the car now, wondering if it can do 500whp and last for 6 months between rebuilds. If it would do that, I'm tempted to try it.

360° thrust bearing GT30 GT3076 Universal performance Turbo charger 0.82 A/R T3 | eBay

So, about that 8.8 diff swap. Finally started working on that today. Pulled the exhaust/boost pipes/rear turbo/driveshaft/ppf/diff out of the car. Unbolted C4 to PPF adapter from transmission. Put poly bushings in diff hanger, test fitted to car. Didn't fit, hit subframe. Cut subframe, now it fits. Then test fitted diff hanger to diff. Didn't fit, cut ears off diff cover, retested, hit more stuff. Cut more stuff, got late and I was making a lot of noise cutting/grinding metal off the cover so I stopped for the night. Tomorrow I continue cutting cover for clearance for diff hanger. Once that fits, clean and test fit hanger/cover/diff as an assembly into the car and see if this hanger (which is for a FC RX7) will locate the diff in the car and not hit anything I can't fix. If it works, then I build diff mounts to hold front of diff. Need to fab a new crossmember to hold transmission too. And other stuff, like buy parts for a driveshaft. And install new hubs into uprights.

Ordered new wheel bearings as I got new hubs to use with the new axles, those should arrive Saturday.

Question. Who thinks this turbo would live at 40 PSI for at least 6 months? This is my front turbo on the car now, wondering if it can do 500whp and last for 6 months between rebuilds. If it would do that, I'm tempted to try it.

360° thrust bearing GT30 GT3076 Universal performance Turbo charger 0.82 A/R T3 | eBay

#1303

Elite Member

iTrader: (1)

Join Date: Apr 2014

Location: SF Bay Area, CA

Posts: 3,078

Total Cats: 553

Good to see you making progress, I hope you can get it all to fit and work as easily as possible. I was expecting someone else to have an opinion here. I remember 18 once saying something like they don't last long at 30psi, like weeks.

That being said, I ran 20psi on my current turbo for a long time and even ran it up to 29psi a few times. It still feels like it's brand new.

Makes me want to look for an internal wastegate version of that turbo.

That being said, I ran 20psi on my current turbo for a long time and even ran it up to 29psi a few times. It still feels like it's brand new.

Makes me want to look for an internal wastegate version of that turbo.

#1304

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Diff is so far playing hard to get. To continue the fight from yesterday, after sawing and grinding on the diff cover for a couple hours, it now fits the housing. I bolted it all together, tried to install it, and the diff is hitting the gas tank before it goes in all the way. Great. Gonna see if I can grind enough clearance to fix that, but it's not looking great. This kit locates the diff higher than the others, looks like a bit too high.

I've ran this turbo at 30 before, and it pulled hard to redline, so I don't think it was choking, but I dunno how much it had left in it.

I've ran this turbo at 30 before, and it pulled hard to redline, so I don't think it was choking, but I dunno how much it had left in it.

#1305

Good to see you making progress, I hope you can get it all to fit and work as easily as possible. I was expecting someone else to have an opinion here. I remember 18 once saying something like they don't last long at 30psi, like weeks.

That being said, I ran 20psi on my current turbo for a long time and even ran it up to 29psi a few times. It still feels like it's brand new.

Makes me want to look for an internal wastegate version of that turbo.

That being said, I ran 20psi on my current turbo for a long time and even ran it up to 29psi a few times. It still feels like it's brand new.

Makes me want to look for an internal wastegate version of that turbo.

#1307

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Ok so I think I'm done for today, but none the less made some progress. What happened today can be summarized as: try to install diff, note what it's hitting, remove, grind/cut whatever is interfering, then reinstall, and do that again. 11 times installed/removed, it now goes in and doesn't hit anything. Ok, it's not hitting anything, but there is nothing back there right now for it to hit. This diff hanger jams the diff way high in the subframe, which is awesome for ground clearance, halfshaft angles, and exhaust clearance, but it made it a nightmare to install. Anyways it needs front diff mounts next. There are a couple ways to do them, but I think I'm just gonna pull the diff, grind the paint off the front of subframe, weld a piece of plate to the subframe, then reinstall the diff and essentially replicate the factory mazda diff mount wing system- studs poking down from the subframe, and the diff has cups/bushings that connect to it. That will make for a fairly simple, clean, easy to remove/install setup, plus diff already has bushings in the front so that makes it even easier.

Plan is to do that tomorrow. Looks like the driveshaft is going to be a tight fit. I took a few pics, I need to take more and post some. Is there a good alternative to photobucket I should use? Imgur?

Plan is to do that tomorrow. Looks like the driveshaft is going to be a tight fit. I took a few pics, I need to take more and post some. Is there a good alternative to photobucket I should use? Imgur?

#1311

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Not much progress today, but hope to build the front diff mounts tomorrow. I did manage to stare at the diff and subframe for a while, and this is the best I could come up with for a design for diff mounts. Plan is to make the part that touches the diff from 3/16" steel, and the two sides that go up to the subframe 1/8", or maybe just use 3/16" there too for stiffness. And a nut/bolt interface to hold it to the landing pad, which is how these were designed to be installed from the factory.

#1312

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Front diff mounts are made of metal, fitted, and tach'd into place. Ran out of wire for the welder. Pulled diff already, tomorrow I buy more wire, finish welding out the mounts, then reinstall diff and verify it still fits and bolts up to the mounts. Then the diff will be in. After that, start on a transmission cross member.

#1315

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

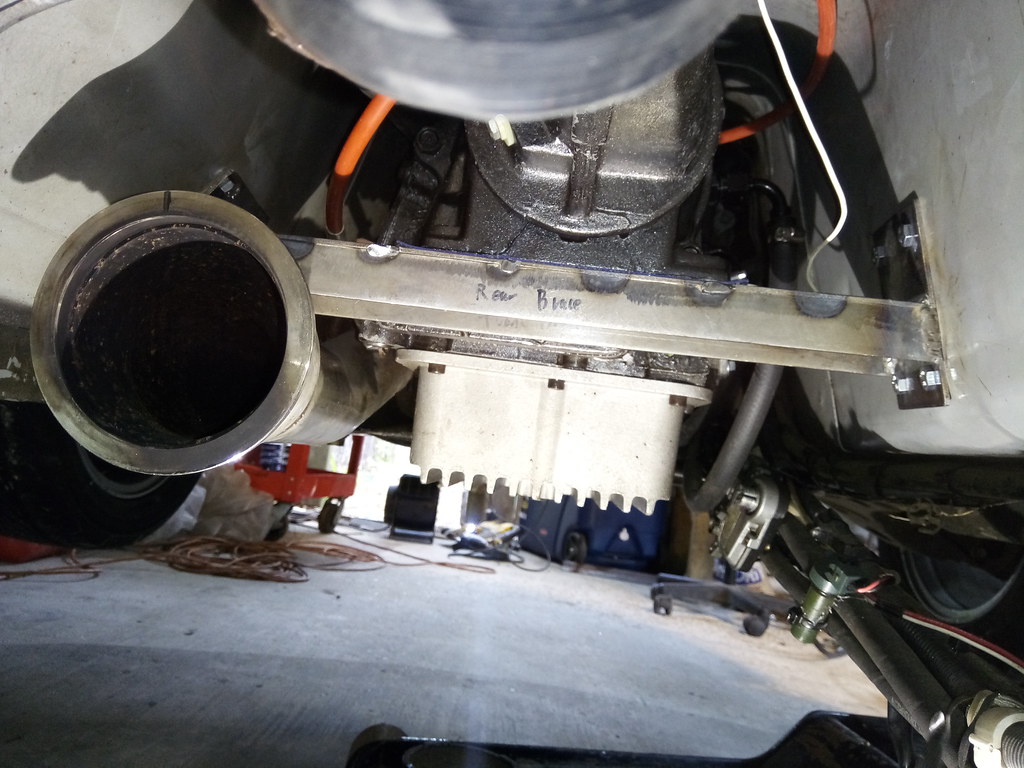

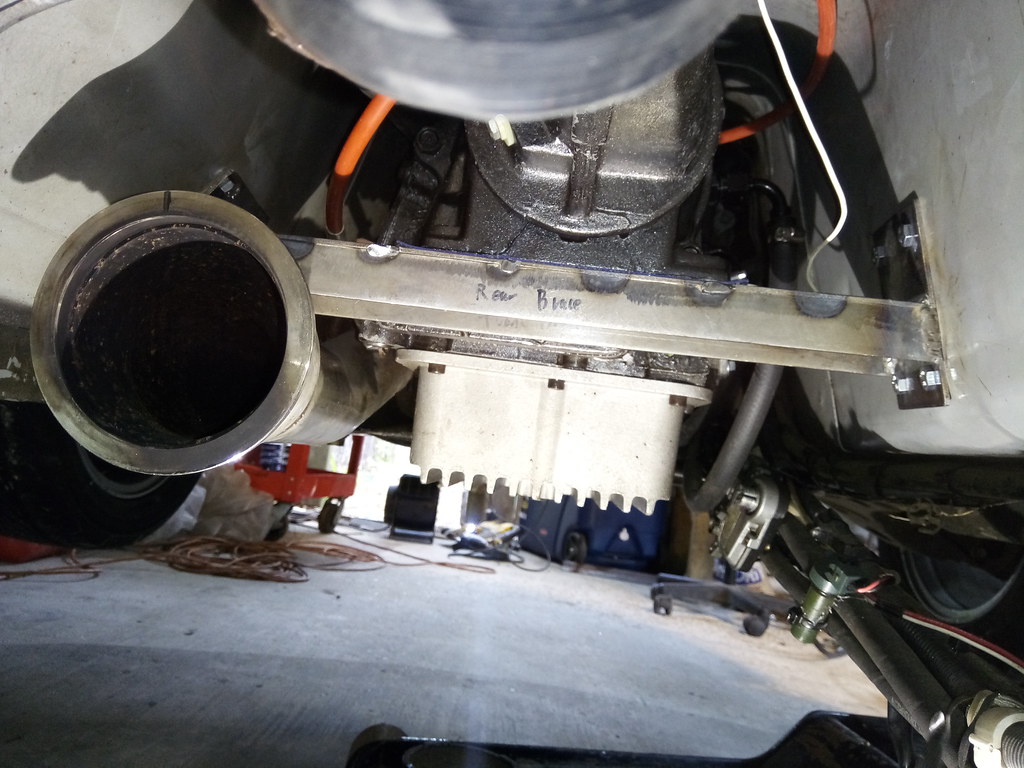

Diff is in! Front subframe mounts are finished, and the 8.8 is securely bolted into the car!

I reinstalled the rear turbo, the turbo itself still fits. The old 3" exhaust pipe that used to go into it does not fit though as the diff takes up a lot of space now. I don't think it's possible to run a 3" pipe to the back of the car anymore, unless you go under the diff which would hurt ground clearance. I'm not really sure what would fit, probably a 2" or 2.25" would fit?

Anyways, this presents an opportunity and I'm going to change things up a bit. The rear turbo is a T4, 1.05 A/R Twin scroll, with a 77mm turbine. So, it's friggin huge and laggy. I have searched online and some folks have tested this exact turbo (bolted to a chevy V8, usually a 5.3L or 5.7L) by blocking off one of the scrolls on the turbine to effectively make it smaller and spool a lot quicker. And of course, it works and the thing spools like mad but chokes up top, which makes sense. Most guys report 900-1500 RPM improvement in spoolup on a 5.7L V8! I can't imagine what the difference would be on my car. They make these things called quick spool valves, basically a valve that can block one scroll on a twin scroll turbo for fast spoolup, and then the valve opens once you reach your boost level so it can breathe and make high RPM power. But these valves are expensive, and I've seen questionable reliability on them.

So I'm going to not make a quick spool valve. Instead, I'm just going to use a spare wastegate I have to act as the valve. These of course are reliable in exhaust systems, and I already have it so it's free too. Exhaust layout will be as follows:

Downpipe from front turbo, catalytic converter, 3" pipe, 60mm wastegate T'dd into this pipe, 3" pipe continues to the rear, 3" splits into a pair of 1.75" pipes, one of these pipes has a wastegate plumbed inline, pair of 1.75" pipes snakes around the 8.8 and into the twin scroll turbine on the rear turbo.

The idea is that the 60mm gate will dump to regulate boost pressure of rear turbo at say, 20 PSI, and the smaller inline gate on one of the 1.75" pipes will open at say, 18 PSI. Thus when crusing, both gates are shut. When you floor it, the turbo spools very quickly to 18psi quickly, then it will stabilize at 18 PSI while the small gate transitions the turbine from ~0.6 A/R into a 1.05 A/R. Once that's done, it climbs up to 20 PSI and the large gate then regulates boost as normal. The only real addition to the car is the split pipes to the twin scroll and the inline valve for fast spooling. It is possible this will also improve rear ground clearance too, so if that happens, awesome as the 3" exhaust before was the lowest thing in the rear. I hope I'm right, but I expect this to result in the car making around 500wtq at 5K and much much better time to boost on the rear turbo, with no loss in top end power. I'm also swapping the front turbo A/R from a 0.86, to a 0.63 so that should help it out a bit as well.

Parts are ordered to do the above. For now, I need to build a crossmember for the trans. I also ordered some driveshaft parts, and once they get here I will take some measurements with these parts, and order the rest needed to assemble a strong driveshaft. It will be 3" tubing with 1350 U-joints aka bombproof.

I reinstalled the rear turbo, the turbo itself still fits. The old 3" exhaust pipe that used to go into it does not fit though as the diff takes up a lot of space now. I don't think it's possible to run a 3" pipe to the back of the car anymore, unless you go under the diff which would hurt ground clearance. I'm not really sure what would fit, probably a 2" or 2.25" would fit?

Anyways, this presents an opportunity and I'm going to change things up a bit. The rear turbo is a T4, 1.05 A/R Twin scroll, with a 77mm turbine. So, it's friggin huge and laggy. I have searched online and some folks have tested this exact turbo (bolted to a chevy V8, usually a 5.3L or 5.7L) by blocking off one of the scrolls on the turbine to effectively make it smaller and spool a lot quicker. And of course, it works and the thing spools like mad but chokes up top, which makes sense. Most guys report 900-1500 RPM improvement in spoolup on a 5.7L V8! I can't imagine what the difference would be on my car. They make these things called quick spool valves, basically a valve that can block one scroll on a twin scroll turbo for fast spoolup, and then the valve opens once you reach your boost level so it can breathe and make high RPM power. But these valves are expensive, and I've seen questionable reliability on them.

So I'm going to not make a quick spool valve. Instead, I'm just going to use a spare wastegate I have to act as the valve. These of course are reliable in exhaust systems, and I already have it so it's free too. Exhaust layout will be as follows:

Downpipe from front turbo, catalytic converter, 3" pipe, 60mm wastegate T'dd into this pipe, 3" pipe continues to the rear, 3" splits into a pair of 1.75" pipes, one of these pipes has a wastegate plumbed inline, pair of 1.75" pipes snakes around the 8.8 and into the twin scroll turbine on the rear turbo.

The idea is that the 60mm gate will dump to regulate boost pressure of rear turbo at say, 20 PSI, and the smaller inline gate on one of the 1.75" pipes will open at say, 18 PSI. Thus when crusing, both gates are shut. When you floor it, the turbo spools very quickly to 18psi quickly, then it will stabilize at 18 PSI while the small gate transitions the turbine from ~0.6 A/R into a 1.05 A/R. Once that's done, it climbs up to 20 PSI and the large gate then regulates boost as normal. The only real addition to the car is the split pipes to the twin scroll and the inline valve for fast spooling. It is possible this will also improve rear ground clearance too, so if that happens, awesome as the 3" exhaust before was the lowest thing in the rear. I hope I'm right, but I expect this to result in the car making around 500wtq at 5K and much much better time to boost on the rear turbo, with no loss in top end power. I'm also swapping the front turbo A/R from a 0.86, to a 0.63 so that should help it out a bit as well.

Parts are ordered to do the above. For now, I need to build a crossmember for the trans. I also ordered some driveshaft parts, and once they get here I will take some measurements with these parts, and order the rest needed to assemble a strong driveshaft. It will be 3" tubing with 1350 U-joints aka bombproof.

Last edited by patsmx5; 09-26-2017 at 10:05 PM.

#1316

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Diff mounts made from metal

Subframe prepped for welding

[url=https://flic.kr/p/XUv7LP]

Welded. Welds are not super great, flux core and overhead while car is on jackstands. A wire brush would make them look better, but regardless they are solid. Welded on both sides at all junctions and all 3/16" plate, so they aren't going anywhere I hope!

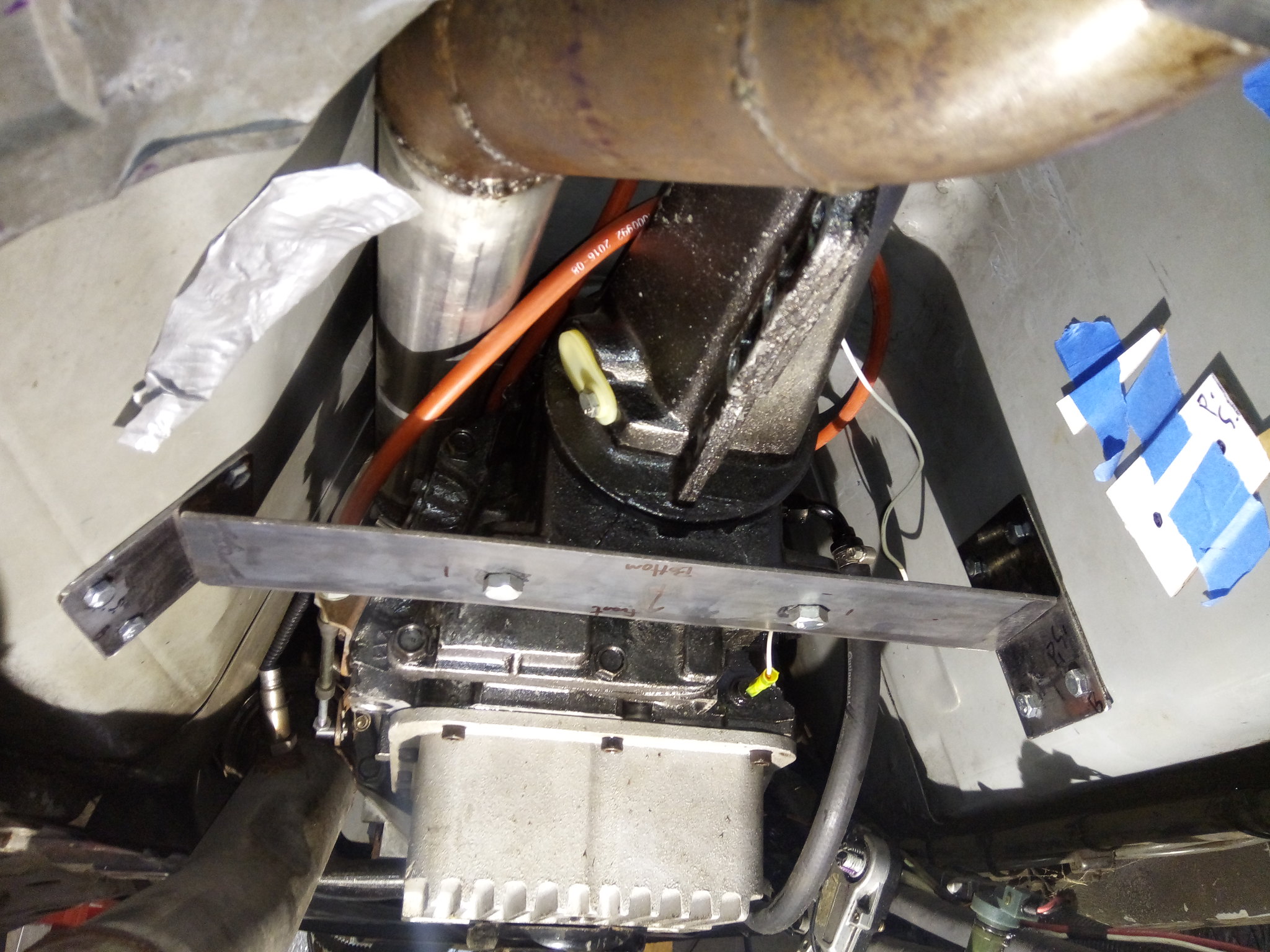

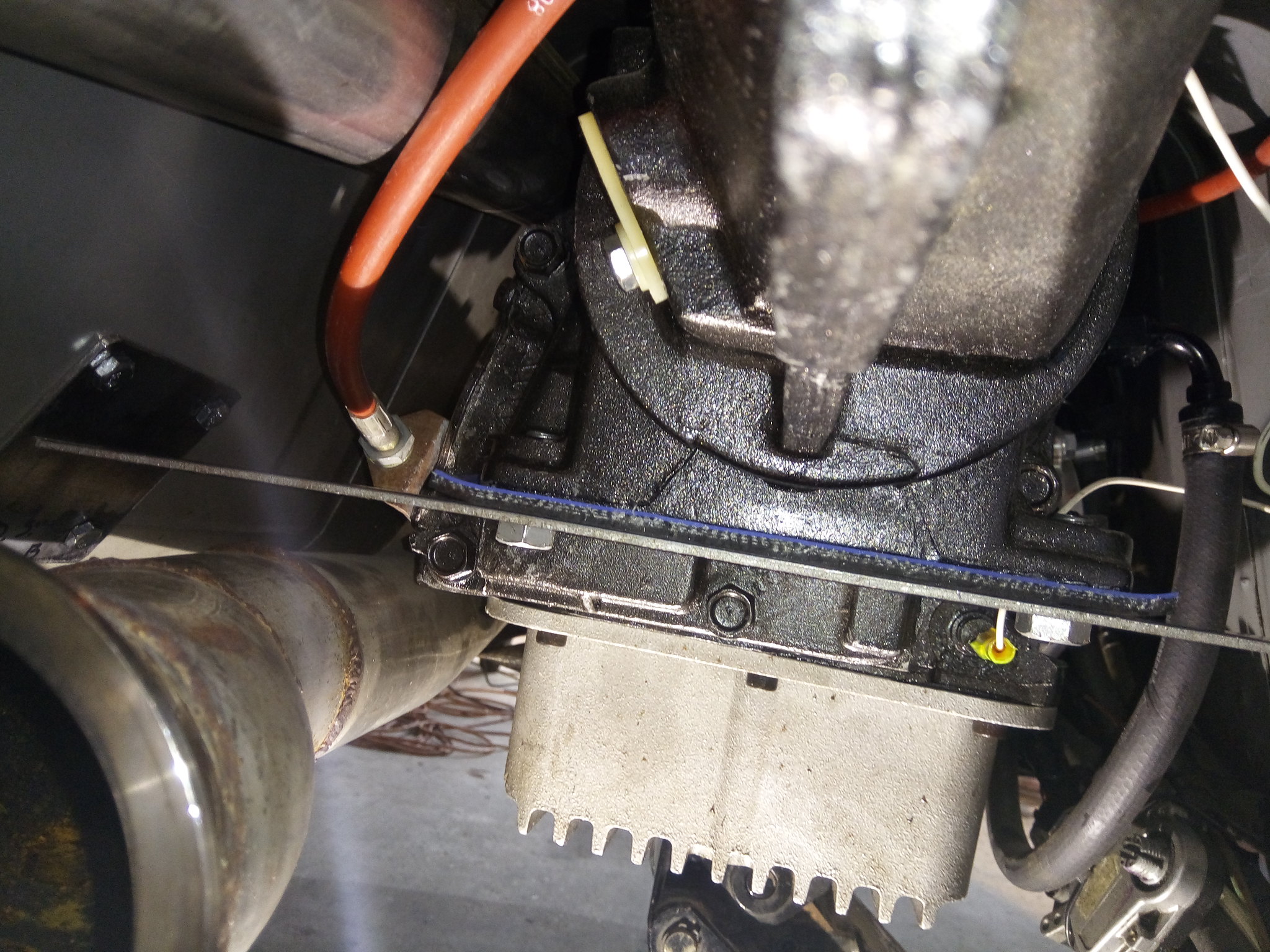

Ford 8.8 bolted into a miata subframe!

[url=https://flic.kr/p/XUv8Fp]

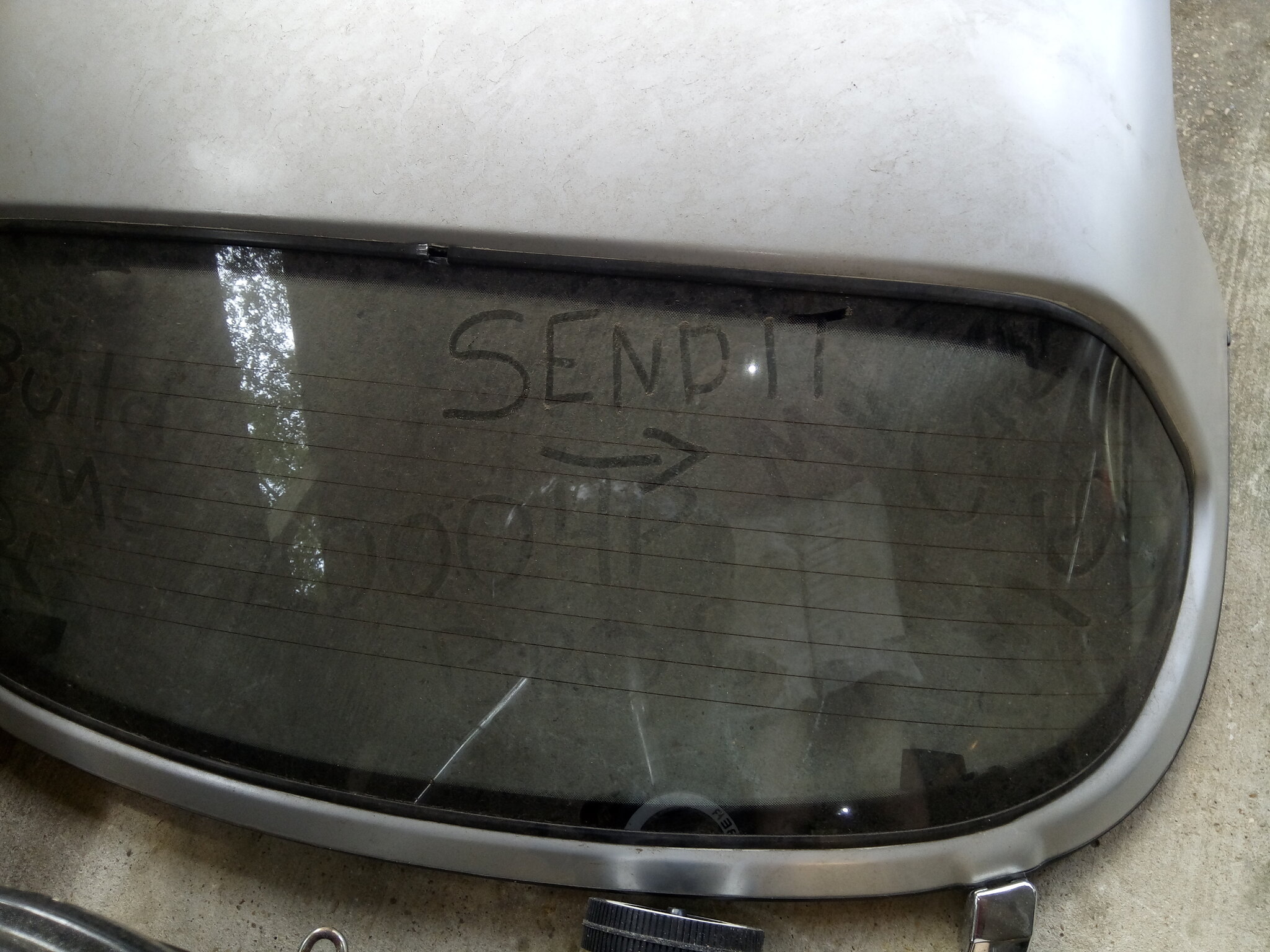

My friend contributions to my build

[url=https://flic.kr/p/XUv94P]

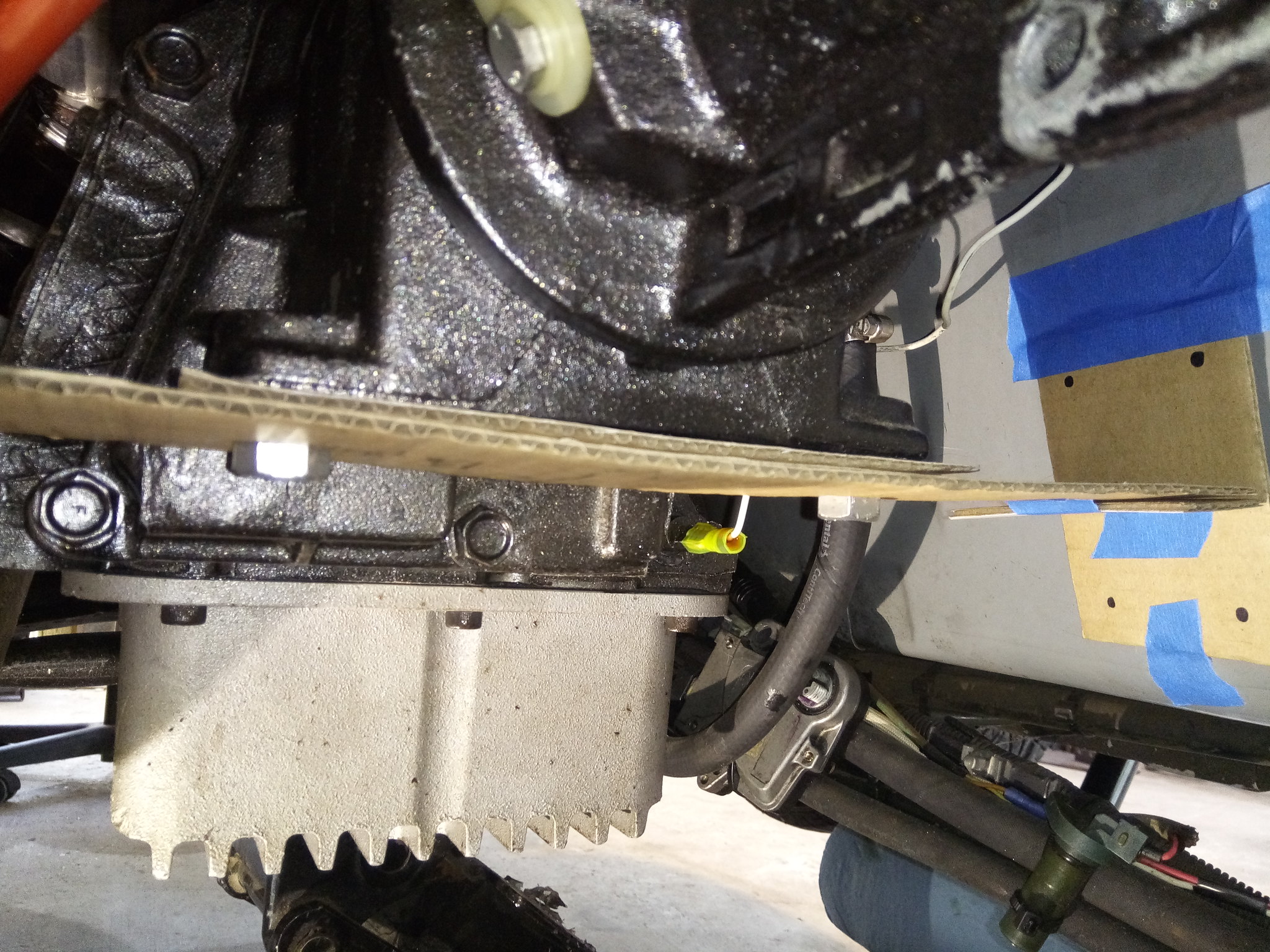

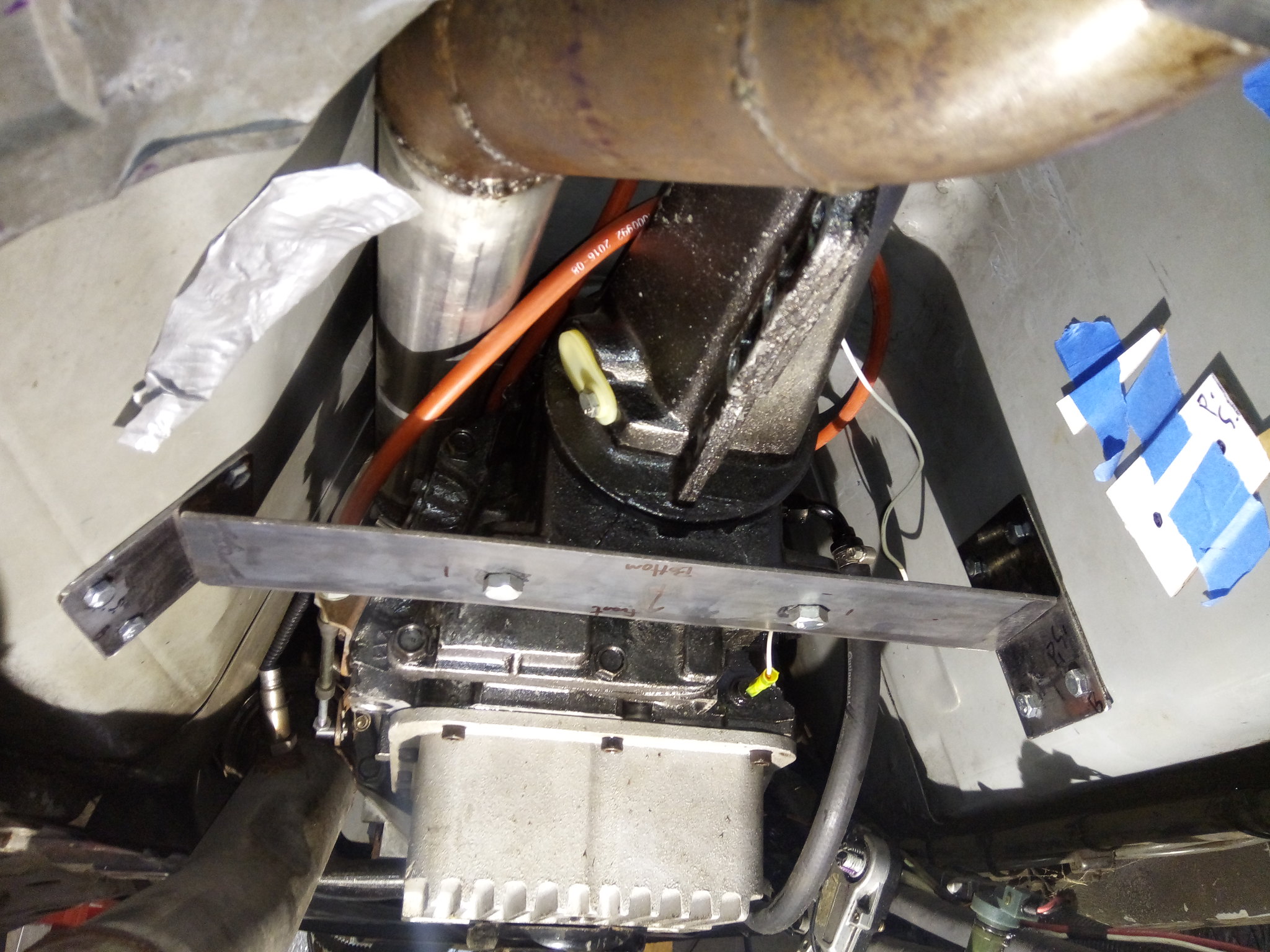

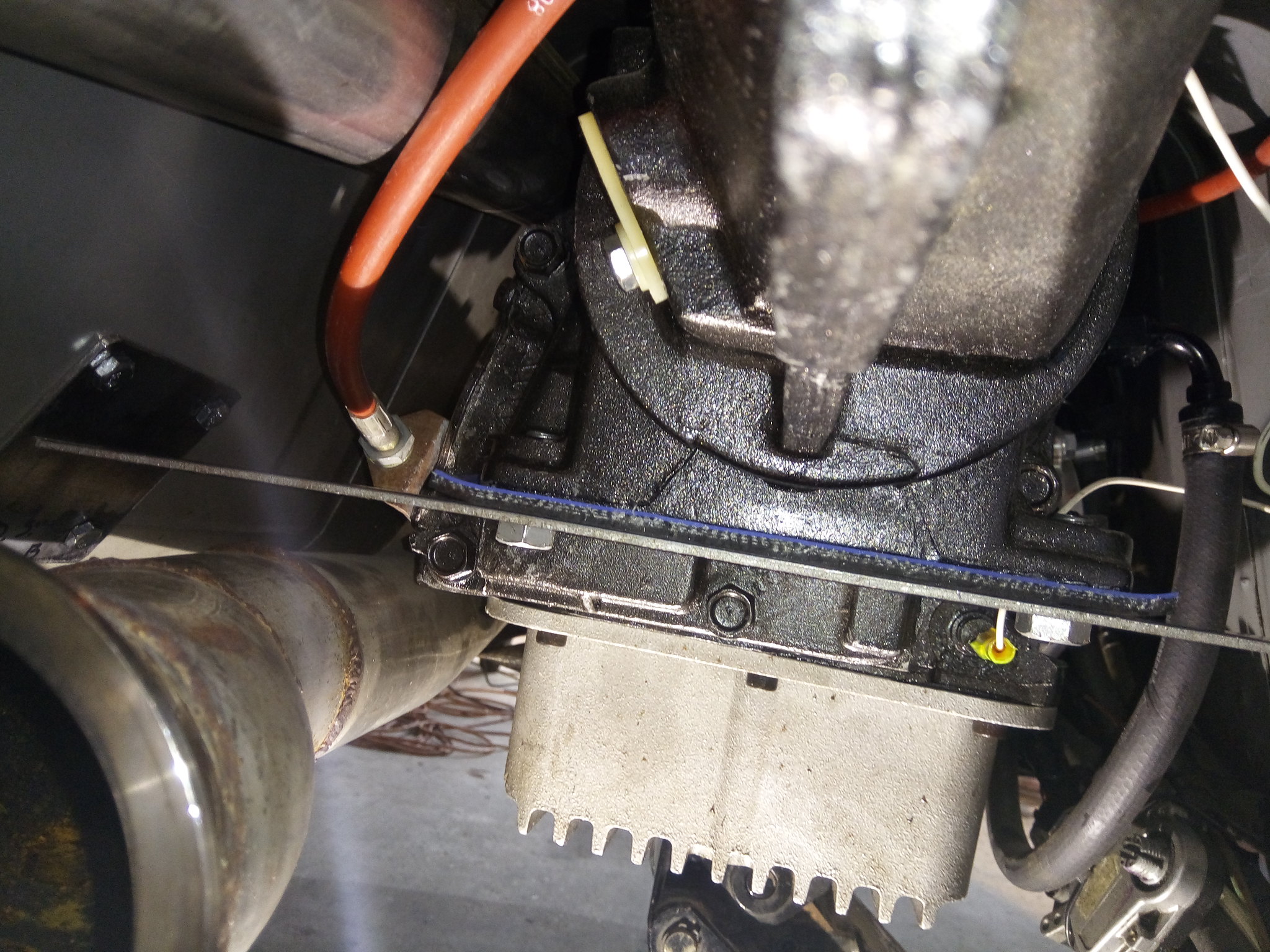

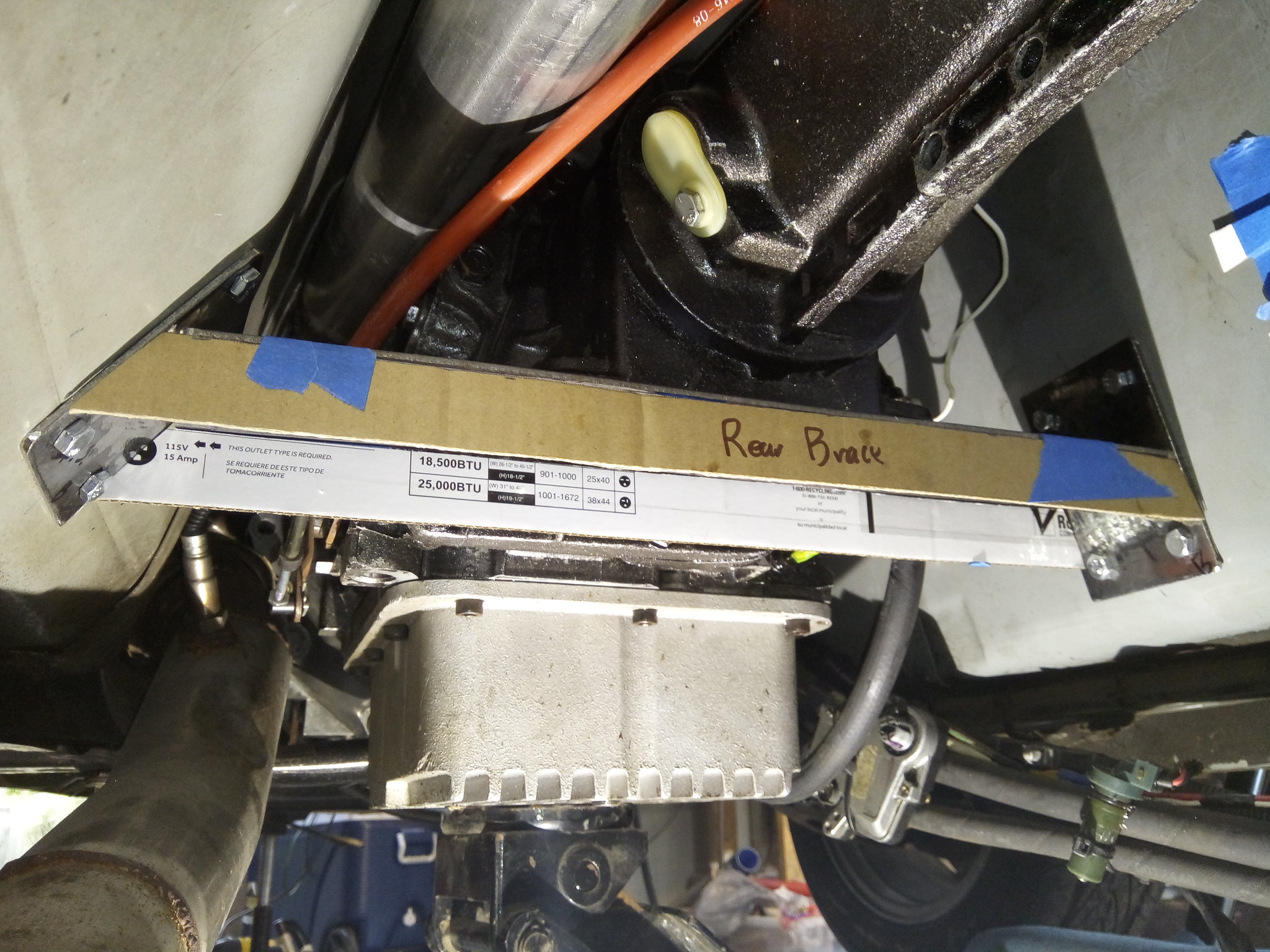

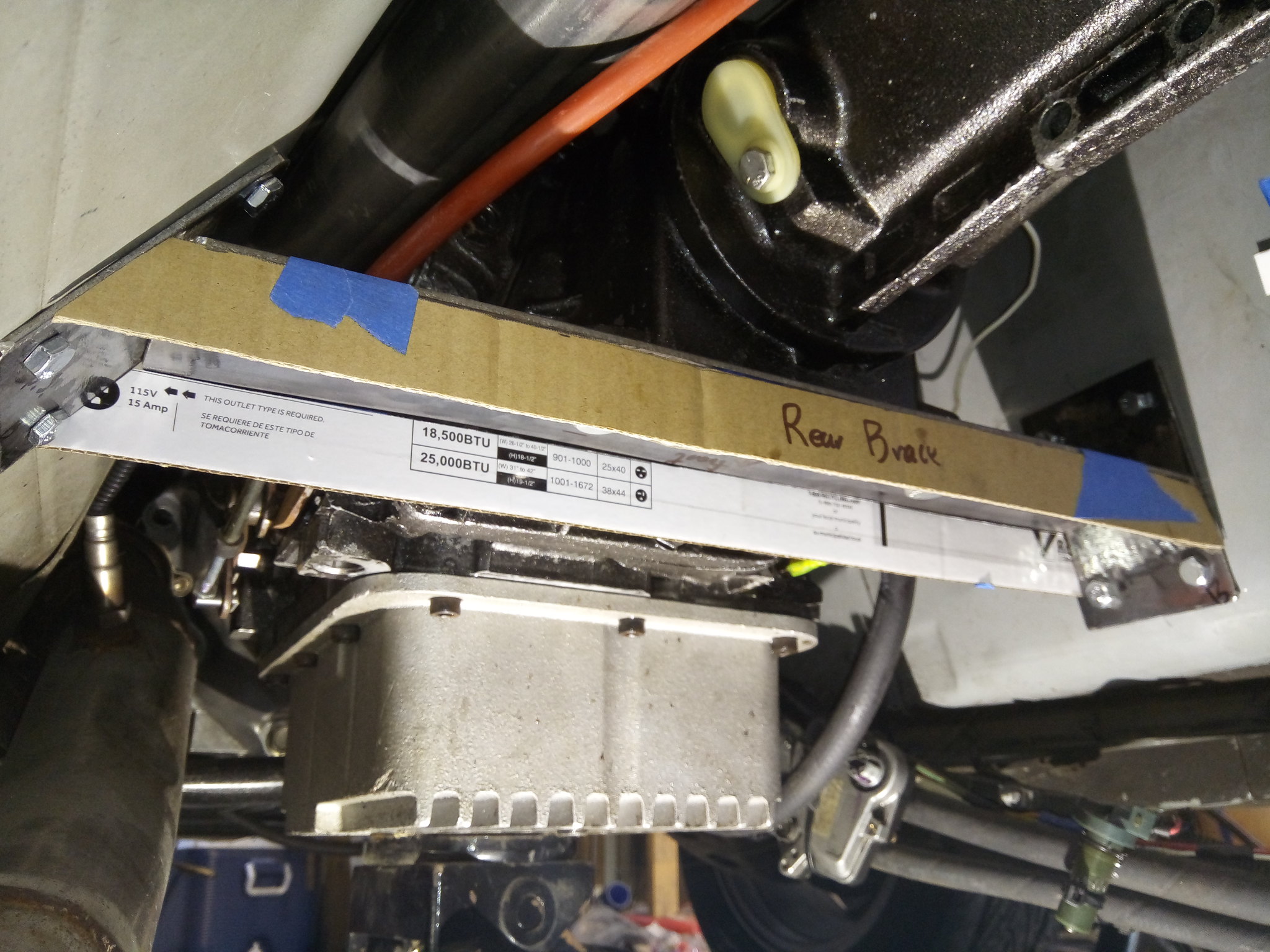

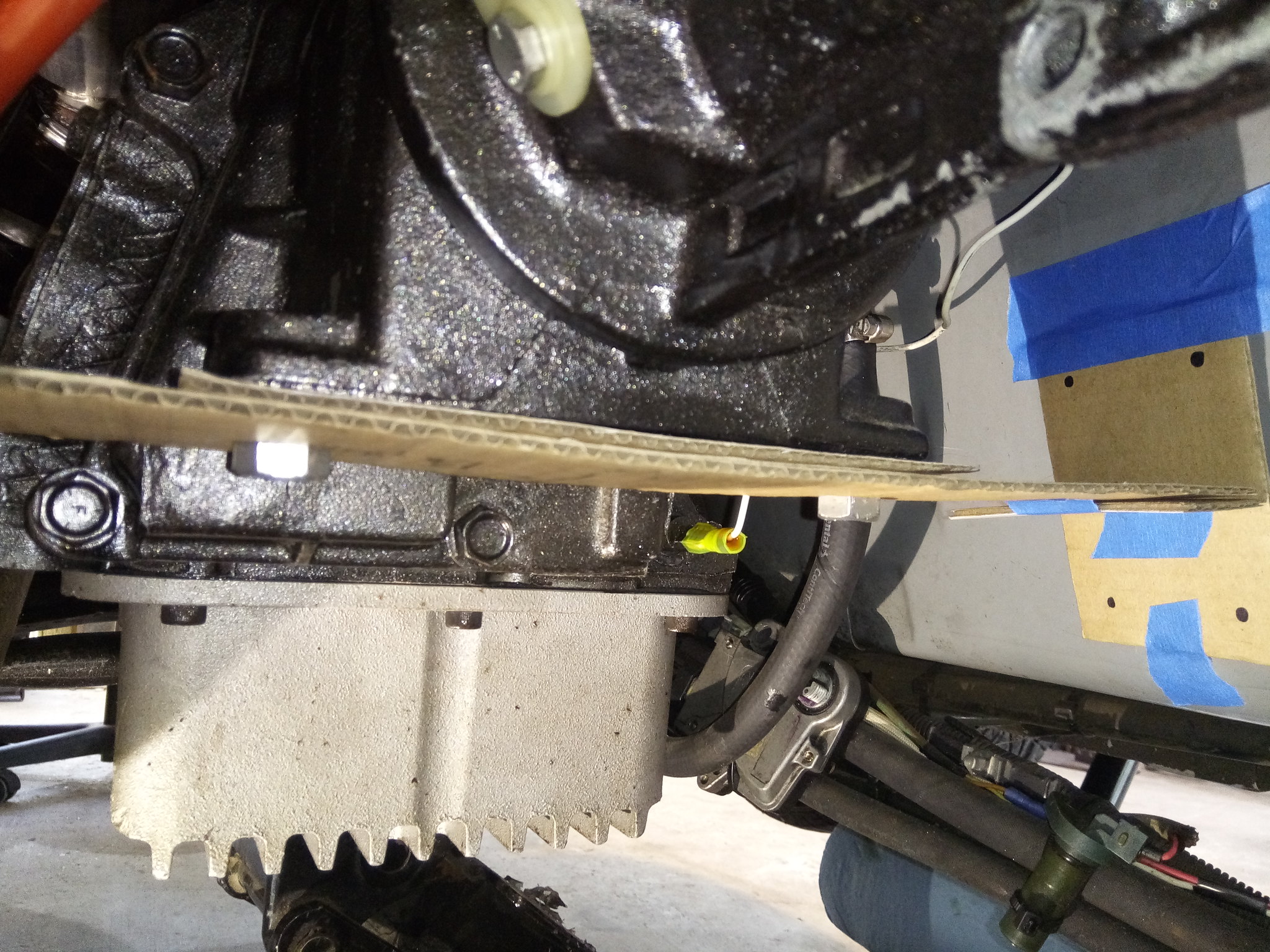

Diff is in, time to start on transmission crossmember. I set the angle of the tailshaft with a floor jack, checked it several times, then began fab work.

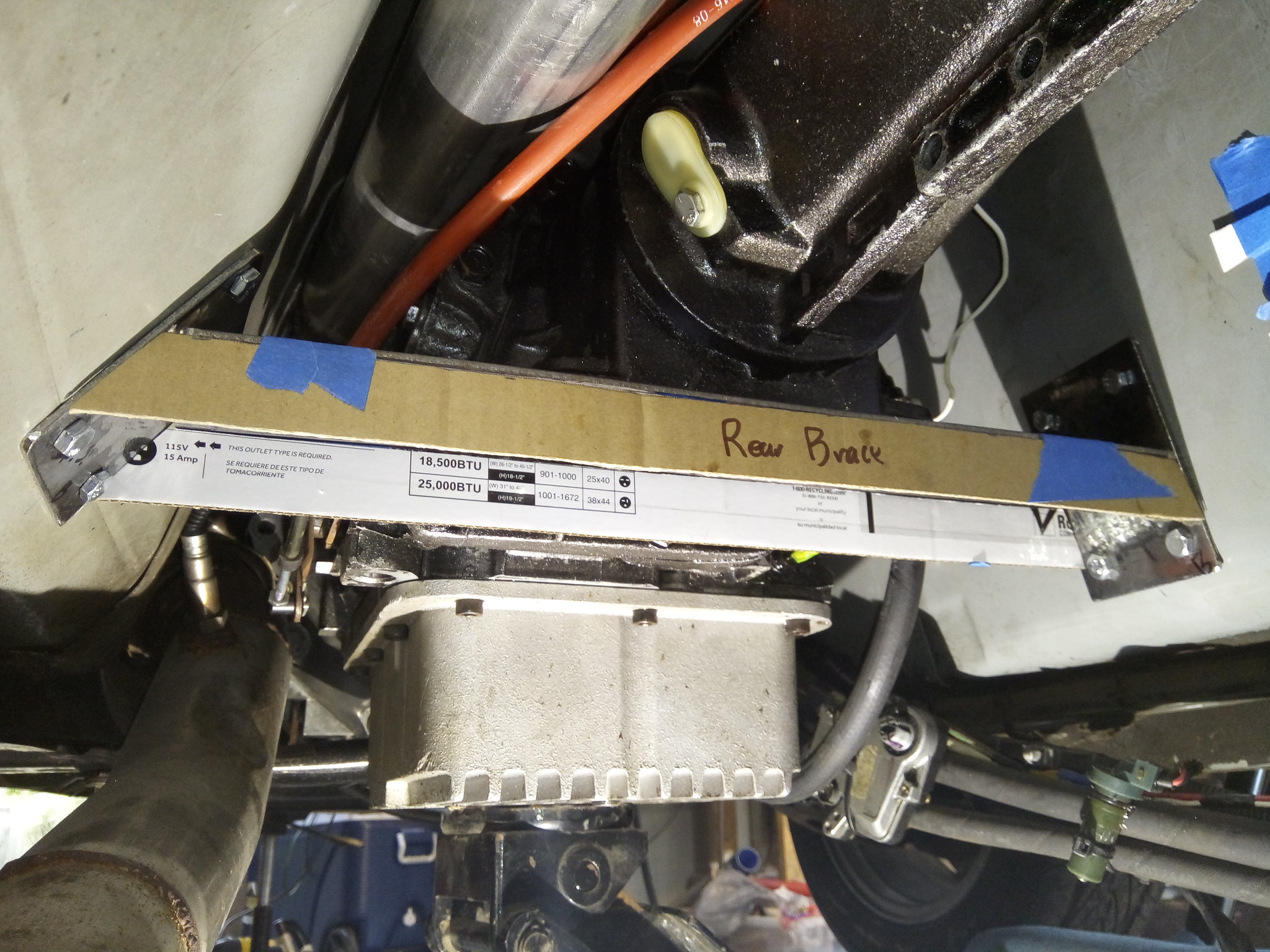

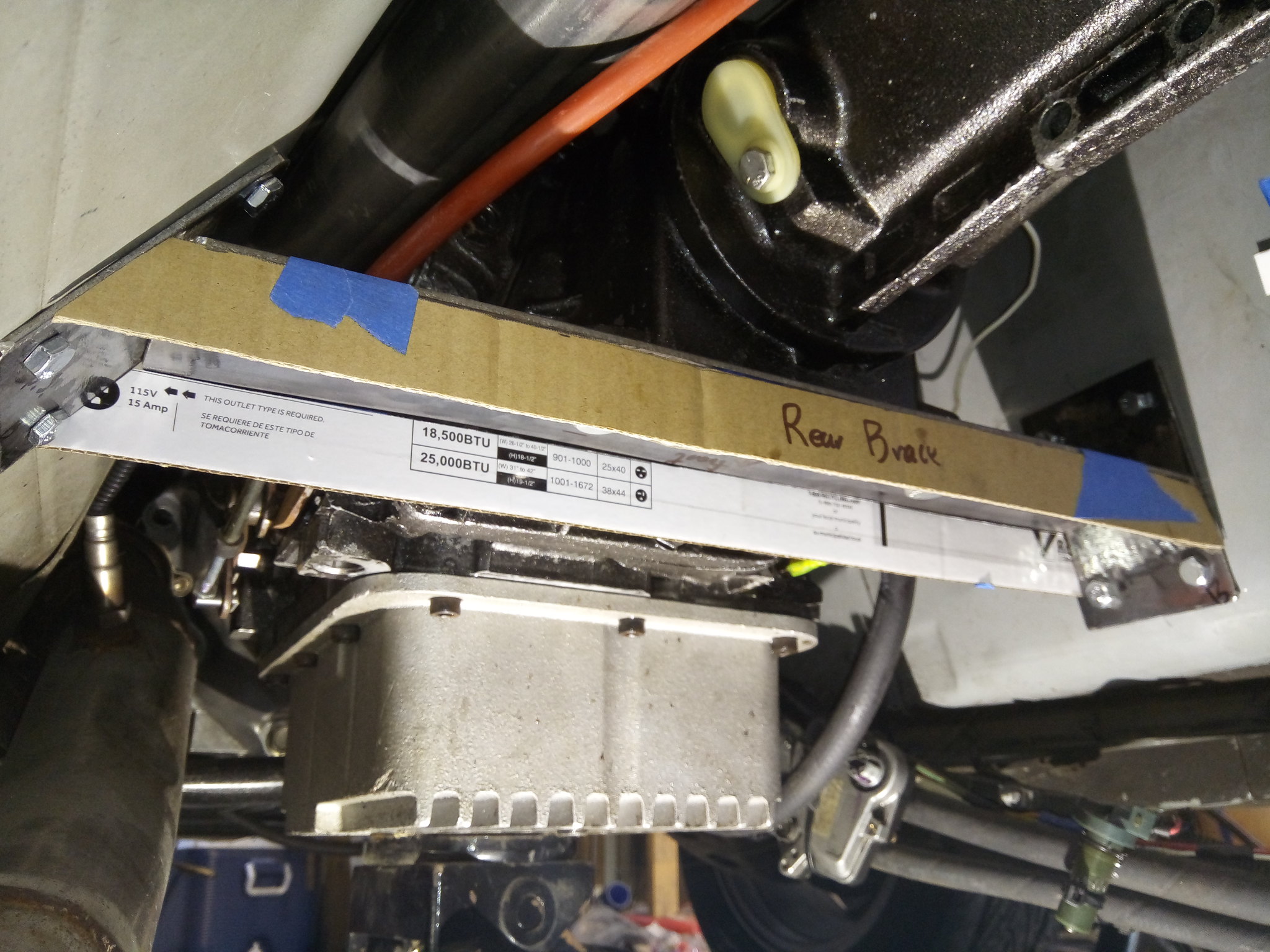

In this pick, you can see a spacer of cardboard between trans and flat piece, this represents the spacing of a vibration isolating piece of silicone. Will swap for rubber sheet probably one day for better damping. Also in this pick, I had landing pads on each end and planned to bolt these parts together, but later decided to weld all this and make it one piece.

Cardboard to metal conversion

Bolted to car and trans

Vibration isolating piece here. Because the damper is here and not on ends, this is also now a brace for the car so should help chassis stiffness a bit, can't hurt.

Cardboard mock-up for bracing to stiffen this member

I ran out of steel, had to buy some and then had other obligations this evening, but will continue building the crossmember tomorrow. Plan is for this to be one piece that bolts into the car, and can be removed completely if the trans needs to come out. Right now its just bolts/washers/nuts holding these pieces, so you gotta remove seats and a few things to lift carpet to access the nuts in the cabin. I may make backing plates or weld the nuts so I don't have to mess with interior to pull trans, we will see.

I weighed the mazdaspeed diff (torsen, 7" Ring and pinion, cast iron front with aluminum cover(also for sale in classifieds!)) and the ford 8.8 (torsen locking diff, 8.8" Ring and pinion, cast aluminum case and cover, with steel mounting frame bolted to it). Mazda diff, 64lbs, Ford diff, 84lbs. So +20 lbs/ +31% more than mazda diff. But it should be 3x stronger than the mazda diff. So worth it! Crossmember will probably weight more than PPF since it's all steel, but it support the transmission much much better than the PPF did, same for the new diff mounts too.

Pretty excited to see this come together!

Subframe prepped for welding

[url=https://flic.kr/p/XUv7LP]

Welded. Welds are not super great, flux core and overhead while car is on jackstands. A wire brush would make them look better, but regardless they are solid. Welded on both sides at all junctions and all 3/16" plate, so they aren't going anywhere I hope!

Ford 8.8 bolted into a miata subframe!

[url=https://flic.kr/p/XUv8Fp]

My friend contributions to my build

[url=https://flic.kr/p/XUv94P]

Diff is in, time to start on transmission crossmember. I set the angle of the tailshaft with a floor jack, checked it several times, then began fab work.

In this pick, you can see a spacer of cardboard between trans and flat piece, this represents the spacing of a vibration isolating piece of silicone. Will swap for rubber sheet probably one day for better damping. Also in this pick, I had landing pads on each end and planned to bolt these parts together, but later decided to weld all this and make it one piece.

Cardboard to metal conversion

Bolted to car and trans

Vibration isolating piece here. Because the damper is here and not on ends, this is also now a brace for the car so should help chassis stiffness a bit, can't hurt.

Cardboard mock-up for bracing to stiffen this member

I ran out of steel, had to buy some and then had other obligations this evening, but will continue building the crossmember tomorrow. Plan is for this to be one piece that bolts into the car, and can be removed completely if the trans needs to come out. Right now its just bolts/washers/nuts holding these pieces, so you gotta remove seats and a few things to lift carpet to access the nuts in the cabin. I may make backing plates or weld the nuts so I don't have to mess with interior to pull trans, we will see.

I weighed the mazdaspeed diff (torsen, 7" Ring and pinion, cast iron front with aluminum cover(also for sale in classifieds!)) and the ford 8.8 (torsen locking diff, 8.8" Ring and pinion, cast aluminum case and cover, with steel mounting frame bolted to it). Mazda diff, 64lbs, Ford diff, 84lbs. So +20 lbs/ +31% more than mazda diff. But it should be 3x stronger than the mazda diff. So worth it! Crossmember will probably weight more than PPF since it's all steel, but it support the transmission much much better than the PPF did, same for the new diff mounts too.

Pretty excited to see this come together!

#1318

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Some pics from todays progress. Got the transmission crossmember finished.

Then I figured I should press the studs into the hubs, press the hubs into the upgrights, and test fit the axles to make sure nothing crazy is going on. You know, like the outboard cv boot hitting the shock body. Guess what I found???

And they hit. Fantastic, 1800 dollar axles that are specifically sold to fit my car, hit the shocks. Uh. Not sure what I'm going to do about this yet, but I'm guessing they need new smaller boots from a quick search. Makes me wonder why they sell them with boots that don't work, that makes no sense.

Then I figured I should press the studs into the hubs, press the hubs into the upgrights, and test fit the axles to make sure nothing crazy is going on. You know, like the outboard cv boot hitting the shock body. Guess what I found???

And they hit. Fantastic, 1800 dollar axles that are specifically sold to fit my car, hit the shocks. Uh. Not sure what I'm going to do about this yet, but I'm guessing they need new smaller boots from a quick search. Makes me wonder why they sell them with boots that don't work, that makes no sense.