Se7en Turbo Build (Was: Thermostat Rerouting)

#43

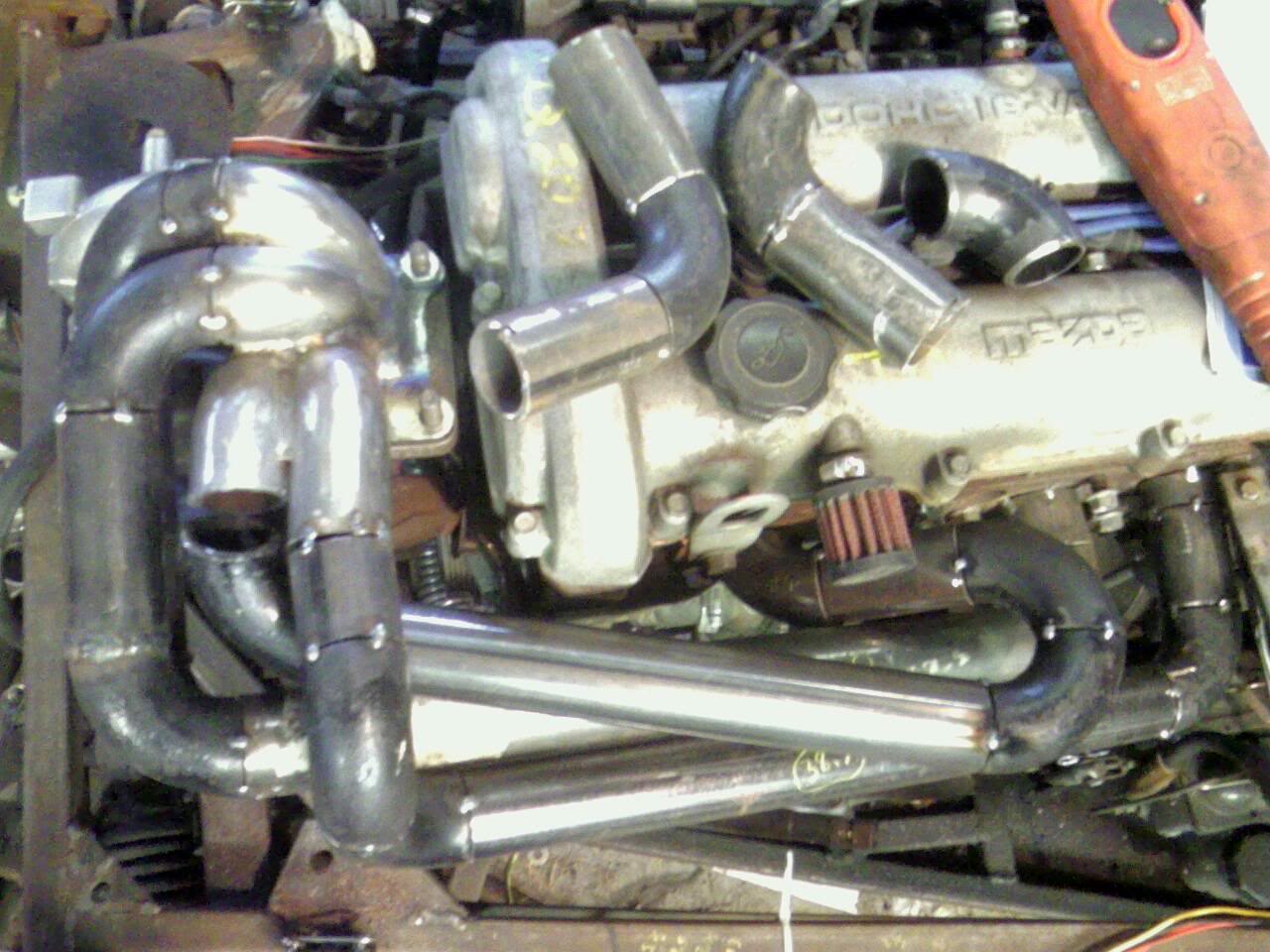

Well, I had some time to get out in the garage twice this last week, and I was able to finish the second primary on the turbo manifold (after many trials and re-cuts).

I originally started with the fourth primary, expecting that to be the longest, but, due to the turbo flange setup, three is actually the longest, at 38.5" long. I now have number two completed, within .25" of the third primary. From the turbo to the fourth port is roughly about 32", and from the first, only about 14". Number four should be relatively easy to come up with 6" extra, whereas number one is going to be a challenge. I expect to do a loop around the other three primaries at some point.

I realize the long primaries are going to cost me some spool-up time, but I am not overly concerned, as the equal-length manifold and the twin-scroll features should bring results in the higher RPM area.

http://i39.photobucket.com/albums/e1...TMPAUG/148.jpg

http://i39.photobucket.com/albums/e1...TMPAUG/149.jpg

http://i39.photobucket.com/albums/e1...TMPAUG/150.jpg

I originally started with the fourth primary, expecting that to be the longest, but, due to the turbo flange setup, three is actually the longest, at 38.5" long. I now have number two completed, within .25" of the third primary. From the turbo to the fourth port is roughly about 32", and from the first, only about 14". Number four should be relatively easy to come up with 6" extra, whereas number one is going to be a challenge. I expect to do a loop around the other three primaries at some point.

I realize the long primaries are going to cost me some spool-up time, but I am not overly concerned, as the equal-length manifold and the twin-scroll features should bring results in the higher RPM area.

http://i39.photobucket.com/albums/e1...TMPAUG/148.jpg

http://i39.photobucket.com/albums/e1...TMPAUG/149.jpg

http://i39.photobucket.com/albums/e1...TMPAUG/150.jpg

#44

I finally got an hour or so to work on my car... What little time I've had recently, I've worked on Other Dave's seven.

Today I stopped by the garage on the way home from work, and worked out the last primary. All four are now within a quarter inch of 38.5". I have to cut and tack in one small slice to the last primary, then I will remove the manifold from the car, and after marking the primaries relation to the flanges, break each one free and tig weld each individully. Finally, I will fit and weld each back onto the flanges.

Today I stopped by the garage on the way home from work, and worked out the last primary. All four are now within a quarter inch of 38.5". I have to cut and tack in one small slice to the last primary, then I will remove the manifold from the car, and after marking the primaries relation to the flanges, break each one free and tig weld each individully. Finally, I will fit and weld each back onto the flanges.

#46

well, this is my second header--the first being an N/A equal-length manifold, with 28" primaries. The main reason for the long primaries on this one, obviously, is because of the front-mounted turbo. That is there because theres no way of cramming it in the traditional location.

And, while I've heard plenty of questions, I have yet to hear anyone explain why it wouldn't work, so ill run with it.

were I to be able to get an affordable, more streamlined turbine housing, I would have probably have located it elseware... but.......

And, while I've heard plenty of questions, I have yet to hear anyone explain why it wouldn't work, so ill run with it.

were I to be able to get an affordable, more streamlined turbine housing, I would have probably have located it elseware... but.......

#49

I wast saying you were criticizing... I was referring to a diferent forum.

jfor the turbo out of 3/8 plate and bolted that up to the old cast A/C bracket. that shouldn't be going anywhere.

could one of the moderators please change the title of this post to something like "Now: Turbo Build Was: Thermostat Rerouting" or something of that nature?

jfor the turbo out of 3/8 plate and bolted that up to the old cast A/C bracket. that shouldn't be going anywhere.

could one of the moderators please change the title of this post to something like "Now: Turbo Build Was: Thermostat Rerouting" or something of that nature?

#51

thanks.

yes, once I tig everything upn ig am going to brush everything and then spray it with hi-temp paint, and then eventually hope to wrap it with cf wrap.

I may make one or two naca ducts to allow some internal airflow other than the nosecone. im going to do just about whatever it takes to refrain from burning off the outside paint.

as for schedule 40, I was going to usual aluminized exhaust piping, but one forum mentioned that would destroy pretty quickly under boost. as I eventually intend on applying some serious boost, I might as well prepare for it.

yes, once I tig everything upn ig am going to brush everything and then spray it with hi-temp paint, and then eventually hope to wrap it with cf wrap.

I may make one or two naca ducts to allow some internal airflow other than the nosecone. im going to do just about whatever it takes to refrain from burning off the outside paint.

as for schedule 40, I was going to usual aluminized exhaust piping, but one forum mentioned that would destroy pretty quickly under boost. as I eventually intend on applying some serious boost, I might as well prepare for it.

#53

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,201

Total Cats: 1,138

I believe he was refering to the turbo, hanging off the end of the manifold. And you still have the weight of the downpipe to go. BTW, what's the routing plan for that? And you may have mentioned it, but click "user CP" in the top left of the page and put in your location.

#54

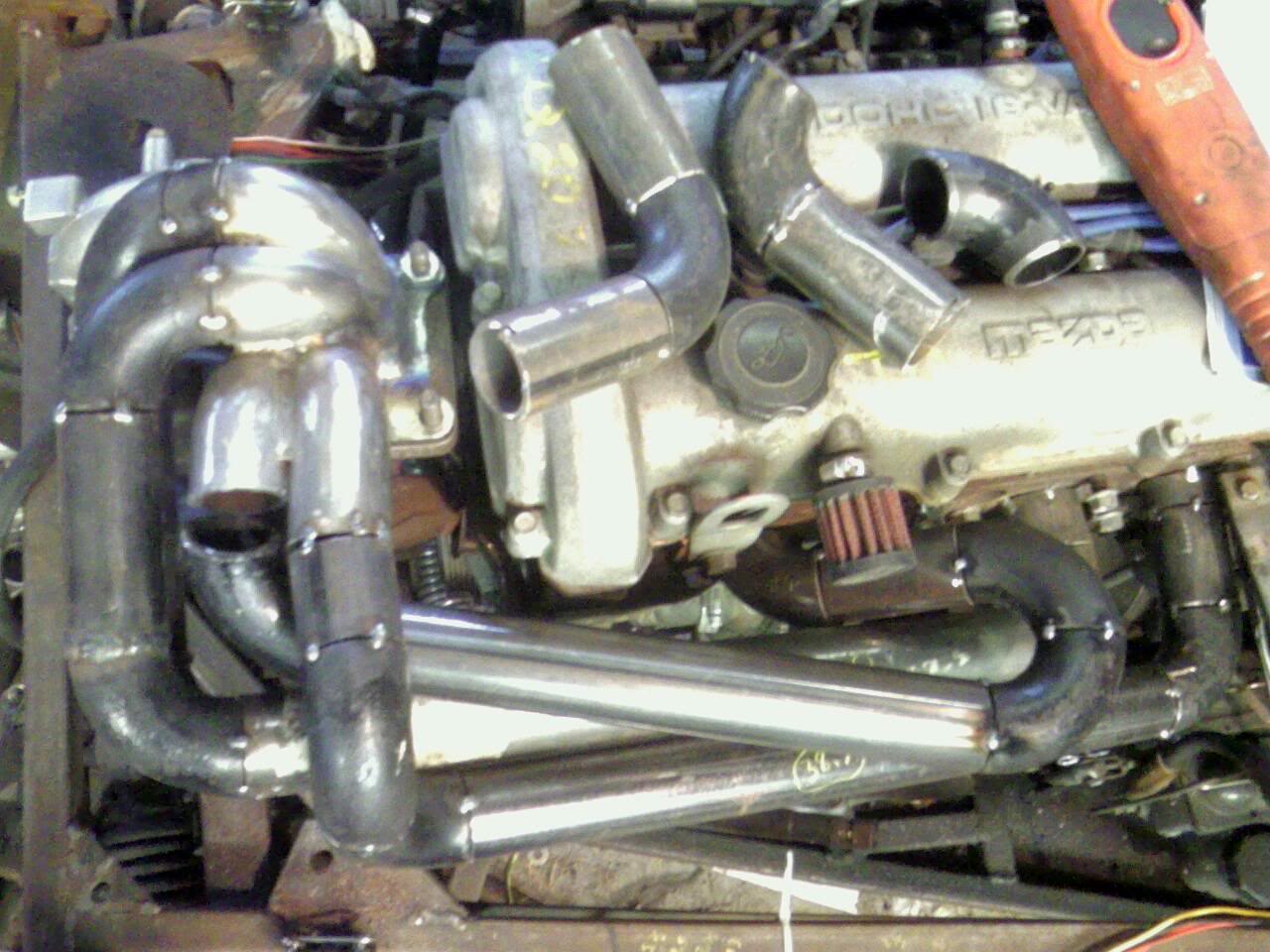

The turbo's not hanging off the manifold. And as for the downpipe, it is only going to be about 25" of stainless 2.5 -- I am going to have side exhaust right behind the left fro bet wheel. I will still try to make some sort of hanger/bracket, but weight-wise, it should be efficient.

Here are a couple of pics of the turbo bracket. Im not very concerned of it going anywhere. Between the 3/8" bracket and the A/C bracket, it should be good.

Here are a couple of pics of the turbo bracket. Im not very concerned of it going anywhere. Between the 3/8" bracket and the A/C bracket, it should be good.