TSE EFR NB2 Build Thread

#1222

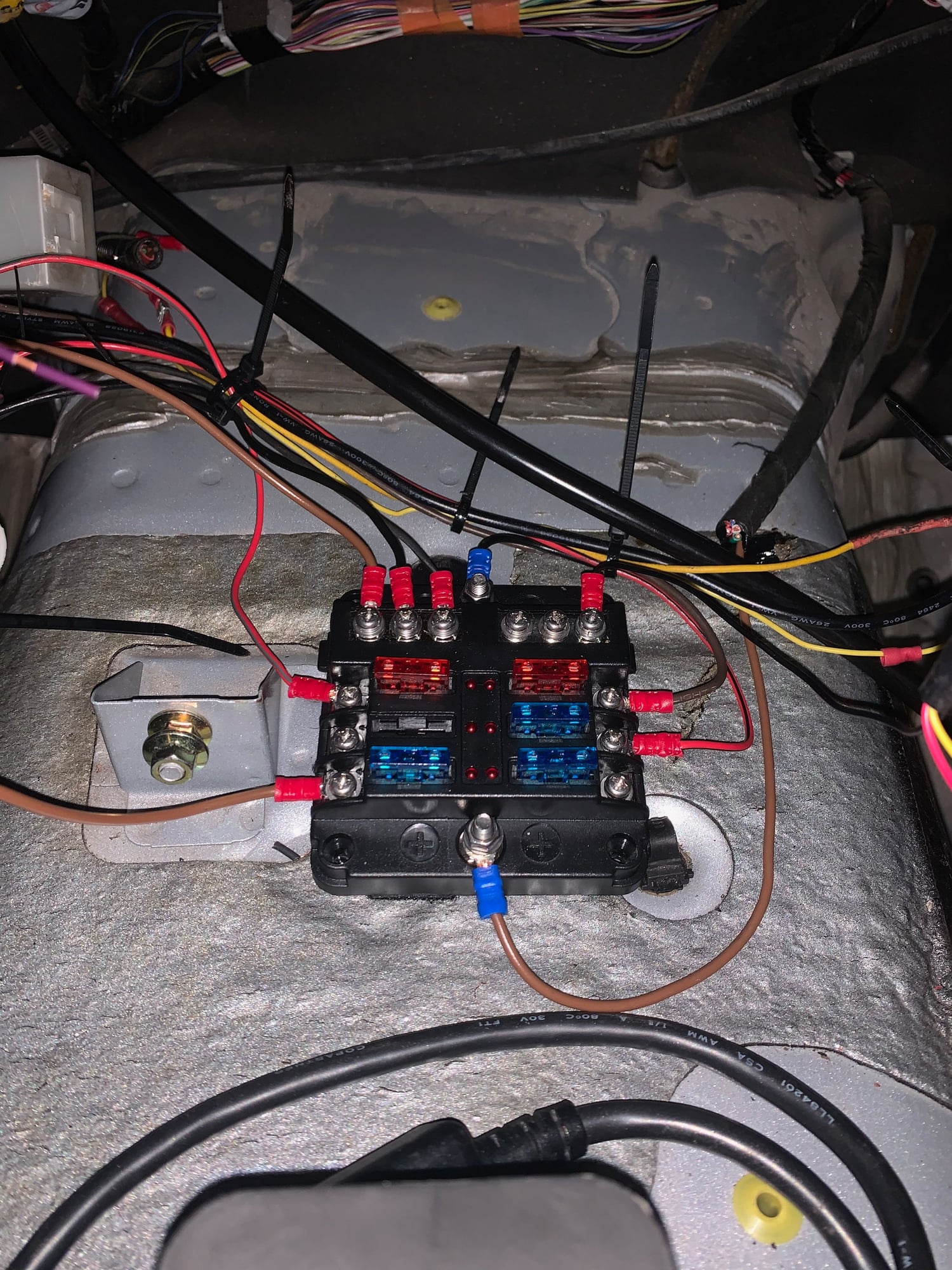

okay so note the "donishnotreally". I electrical taped the connectors for each wire so contact wouldn't happen. Otherwise, I used a double crimper. I can tug on the ends pretty hard and they dont budge.

way too much $ for what I need.

Again, the likelihood of a failure from a connector sperating is pretty low I would imagine. its not a high NVH environment. I took care of the uninsulated part as I said earlier.

I dont see the advantage of that box.

I know all this looks bad and ugly, but you have to remember, these were pics that were taken "along the way". Ive been poking around making small changes here and there. I would like to point out that I DID think about the possibility of the pigtails failing (adding more failure points). However the strength of the double crimps is pretty good, so im just not confident it will be a thing.

Now, here is what I will say. In all of my years of tracking, iv'e never had an electrical failure (knock on wood). So are the "quick disconnects" really necessary? Probably not. So just for the sake of simplicity, I might delete them.

Just buy dis?

https://www.aim-sportline.com/en/pro...dm08/index.htm

https://www.aim-sportline.com/en/pro...dm08/index.htm

Each pigtail is adding at least 3 extra joints that could fail. On top of that some of them are so short that they can't flex properly. On top of that you now have a bunch of uninsulated connections floating around. It should also be pretty uncommon to have to disconnect any of those connections. If you want to remove power from a circuit just pull the fuse. Does the same thing as unplugging your pigtail.

You should at least run a bussman fuse box.

I know all this looks bad and ugly, but you have to remember, these were pics that were taken "along the way". Ive been poking around making small changes here and there. I would like to point out that I DID think about the possibility of the pigtails failing (adding more failure points). However the strength of the double crimps is pretty good, so im just not confident it will be a thing.

Now, here is what I will say. In all of my years of tracking, iv'e never had an electrical failure (knock on wood). So are the "quick disconnects" really necessary? Probably not. So just for the sake of simplicity, I might delete them.

#1225

--Ian

#1232

So i'm not an expert, more closer to a beginner than not but here's what i'd do differently.

- I'm not sure if exposed live terminals are bad but i'd prefer to avoid them.

- Label the wiring so I have an idea of what fuse powers what.

- Larger gauge power wire (depending on total amperage of what you're powering)

- Move it an inch away from the mount on the left so the wire is less kinked (you mentioned you already did this)

- Use a proper fuse box/pdm. Lights that come up when a fuse blows isn't a high priority to me.

- If I wanted a quick disconnect to separate fusebox from wiring harness, a DT/DTM connector would be use

- Bundle the wires together for a cleaner look

#1233

See thats a constructive post. Not whatever bull **** was going on above.

1. They are gone now.

2. I need to figure out a system for labeling. But I know what goes where for the most part.

3. I'm not sure how to figure out what the total amperage is, so unless my current power source poses an issue, i'll probably just leave it alone.

4. Already done

5. What is the advantage to a different PDM/fuse box? What is this one lacking that is necessary? I agree the lights on this one are not necessary, I just pointed it out as a neat feature.

6. I have cloth tape en-route to take care of this.

To everyone else:

I don't get why its so hard for people to be informative rather than just **** on others. This is my first time tackling a big wiring project. I don't know squat about wiring (clearly) so i'm learning as I go. You cant expect someone to be perfect at everything, especially the first attempt. Im a 20yr old kid trying to build this car by myself, i'm sorry I dont have tons of experience with this stuff so if you see jank ****, point it out with solid reasoning/explanation and I will change it. Don't just sit there and laugh.

1. They are gone now.

2. I need to figure out a system for labeling. But I know what goes where for the most part.

3. I'm not sure how to figure out what the total amperage is, so unless my current power source poses an issue, i'll probably just leave it alone.

4. Already done

5. What is the advantage to a different PDM/fuse box? What is this one lacking that is necessary? I agree the lights on this one are not necessary, I just pointed it out as a neat feature.

6. I have cloth tape en-route to take care of this.

To everyone else:

I don't get why its so hard for people to be informative rather than just **** on others. This is my first time tackling a big wiring project. I don't know squat about wiring (clearly) so i'm learning as I go. You cant expect someone to be perfect at everything, especially the first attempt. Im a 20yr old kid trying to build this car by myself, i'm sorry I dont have tons of experience with this stuff so if you see jank ****, point it out with solid reasoning/explanation and I will change it. Don't just sit there and laugh.

Last edited by icantlearn; 07-11-2020 at 02:44 AM.

#1234

This is what i'm using for labeling.... It's not officially support and it took a couple trial and error tries but it's cheap enough to where I didn't mind.

Cloth tape, im using Tesa Tape 51036...People love this but I hate the sticky residue it leaves. Rather, I use the much more hated split loom with tape placed every 5-6 inches on the outside. It's not in the engine bay where heat is an issue so I figured why not. No nasty residue if I have to make any modifications and easy to remove.

The fuse box is just my personal preference, it's a cleaner look since you can bundle the wires together a lot easier.

For amperage, it's more of an educated guess for me. I'd check what's going on each line and google what people estimated the amperage for the devices would be. If it's just a handful of gauge lights, I wouldn't care. If you were powering the fuel pump or fans, i'd want much thicker wiring.

Wirebarn makes an excellent calculator for wire gauge and its support amperage for the length of wire.

https://www.wirebarn.com/Wire-Calculator-_ep_41.html

Cloth tape, im using Tesa Tape 51036...People love this but I hate the sticky residue it leaves. Rather, I use the much more hated split loom with tape placed every 5-6 inches on the outside. It's not in the engine bay where heat is an issue so I figured why not. No nasty residue if I have to make any modifications and easy to remove.

The fuse box is just my personal preference, it's a cleaner look since you can bundle the wires together a lot easier.

For amperage, it's more of an educated guess for me. I'd check what's going on each line and google what people estimated the amperage for the devices would be. If it's just a handful of gauge lights, I wouldn't care. If you were powering the fuel pump or fans, i'd want much thicker wiring.

Wirebarn makes an excellent calculator for wire gauge and its support amperage for the length of wire.

https://www.wirebarn.com/Wire-Calculator-_ep_41.html

#1236

No, I use the cheap generic split loom off amazon (not this exact one but same concept)

https://www.amazon.com/Split-Tubing-Conduit-Flexible-Cover/dp/B07KDFD3WP/ref=sr_1_3?dchild=1&keywords=split+loom&qid=1594351297&sr=8-3

and then I use tesa tape every 5-6 inches so that the conduit holds close, which is probably excessive since this split loom coils itself shut on its own. Measure how thick the bundle of wire is and order the appropriate size. It's not professional but it's more than good enough.

https://www.amazon.com/Split-Tubing-Conduit-Flexible-Cover/dp/B07KDFD3WP/ref=sr_1_3?dchild=1&keywords=split+loom&qid=1594351297&sr=8-3

and then I use tesa tape every 5-6 inches so that the conduit holds close, which is probably excessive since this split loom coils itself shut on its own. Measure how thick the bundle of wire is and order the appropriate size. It's not professional but it's more than good enough.

I heard tesa tape doesn't leave a residue as well so maybe others have had better experience...But my 4 feet of wiring that I originally taped up is now all sticky so i'd say otherwise.

I heard tesa tape doesn't leave a residue as well so maybe others have had better experience...But my 4 feet of wiring that I originally taped up is now all sticky so i'd say otherwise.

#1238

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

My recommendation for those ring terminals is to pull the plastic piece off, ensure a good crimp, then use glue lined heat shrink to secure the connection. That'll take the vibration strain off the crimp joint. Plus, it looks 1000x better.

#1240

Dude, chill the **** out. You posted shoddy wiring and got shat on for posting shoddy wiring, as is the norm around here for badly done jobs.

Looks like others have started to chime in with fixes, so your covered there. Only thing I'd add is that inside the cabin your don't *need* wire covering(obviously heatshrink solder joints and do basic strain relief/standoffs). Using the plastic pipe covering isn't going to hurt anything, and if you wanted to be extra fancy and milspec you could do snakeskin, but this would require pulling apart wiring and pre-planning your wiring layout. Adel clamps will both provide vibration protection and form your wires into bundles instead of floating around chafeing on the chassis.

Looks like others have started to chime in with fixes, so your covered there. Only thing I'd add is that inside the cabin your don't *need* wire covering(obviously heatshrink solder joints and do basic strain relief/standoffs). Using the plastic pipe covering isn't going to hurt anything, and if you wanted to be extra fancy and milspec you could do snakeskin, but this would require pulling apart wiring and pre-planning your wiring layout. Adel clamps will both provide vibration protection and form your wires into bundles instead of floating around chafeing on the chassis.