An idea for decreased spool times (out there but possible)

#1

Junior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Palm Harbor FL

Posts: 328

Total Cats: 4

Well i was sitting in the shop one day about a year ago and i had a 16g turbo in my hand, i was spraying the air from the compressor through the exhaust side of it (dont worry it was a junk turbo). i had an air chuck that was like an 8th inch opening so it wasnt a really high pressure but it was very high volume, i then grabbed a standard spray nozzle with just a pin hole size outlet and noticed a very high increase in wheel acceleration even though i was putting the same amount of air through it.

So i did some looking around on the internet and realized that increasing the velocity of exhaust gas by restricting the flow pre turbo would result in very very fast spool time, however this would also decrease maximum output. So i thought what if you could restrict the flow only until the engine was flowing enough exhaust gasses to keep the turbo spooled. What i came up with was the idea to scale down the "exhaust control tube funnel blades" (only definition i could find) off a jet engine and place them inside the merge collector, you could easily use an electric solenoid to control them or even something similar to a wategate.

My doubts come from the fact that im an uneducated 20 year old dreaming of doing 200mph in the standing mile in a miata, im sure that if it worked some of the engineers working for these billion dollar race teams would have thought of this. Either way tell me what you think.

So i did some looking around on the internet and realized that increasing the velocity of exhaust gas by restricting the flow pre turbo would result in very very fast spool time, however this would also decrease maximum output. So i thought what if you could restrict the flow only until the engine was flowing enough exhaust gasses to keep the turbo spooled. What i came up with was the idea to scale down the "exhaust control tube funnel blades" (only definition i could find) off a jet engine and place them inside the merge collector, you could easily use an electric solenoid to control them or even something similar to a wategate.

My doubts come from the fact that im an uneducated 20 year old dreaming of doing 200mph in the standing mile in a miata, im sure that if it worked some of the engineers working for these billion dollar race teams would have thought of this. Either way tell me what you think.

#3

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

it has been shown that running a small runner tubular manifold helps spool, for exactly the reason you decribe, exhaust velocity, but the increase is negligible compared to the loss in top end power.

Im not so sure a 'restriction' in the collector would have this same effect though, there would be higher velocity at the collector but the velocity would still be low throuout the runners.

Also, There is already something more effective at doing this

Im not so sure a 'restriction' in the collector would have this same effect though, there would be higher velocity at the collector but the velocity would still be low throuout the runners.

Also, There is already something more effective at doing this

#4

Junior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Palm Harbor FL

Posts: 328

Total Cats: 4

^ wow very similar to my idea.

i think the idea behind higher spool due to smaller runners is that when you have say 20psi back pressure before the turbo and 5psi after it the gasses will not flow through the turbine housing as fast as they will if you have 50psi before the turbo and 5 after. (numbers are just thrown out there nothing that would necessarily be actual.

Either way that shows me that its been considered, it always boggled my why i had not seen it on some hill climb car or something, maybe one of these days i will have the rescorces to find out for myself.

i think the idea behind higher spool due to smaller runners is that when you have say 20psi back pressure before the turbo and 5psi after it the gasses will not flow through the turbine housing as fast as they will if you have 50psi before the turbo and 5 after. (numbers are just thrown out there nothing that would necessarily be actual.

Either way that shows me that its been considered, it always boggled my why i had not seen it on some hill climb car or something, maybe one of these days i will have the rescorces to find out for myself.

#5

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

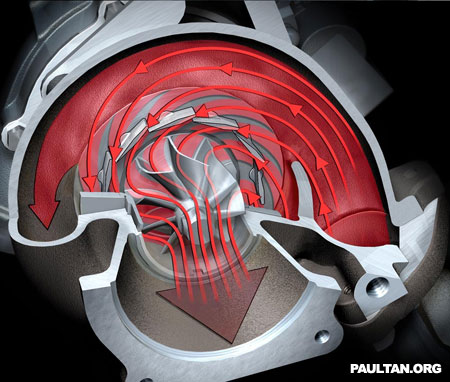

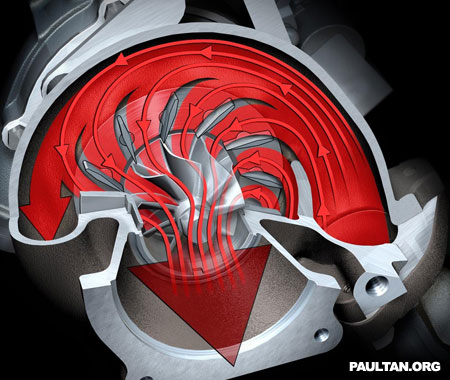

I just realize i didnt explain that picture I posted at all, I think youll like this idea.

Basically you use that butterfly deal on a twin scroll turbo, so that instead of trying to change the aspects of the manifold flow, your basically changing the a/r of the turbine.

So when the butterlfy is closed the turbo has effectively half the A/R that it would normally, then the butterlfy opens and it has its full A/R and makes good top end.

Basically you use that butterfly deal on a twin scroll turbo, so that instead of trying to change the aspects of the manifold flow, your basically changing the a/r of the turbine.

So when the butterlfy is closed the turbo has effectively half the A/R that it would normally, then the butterlfy opens and it has its full A/R and makes good top end.

#6

I need some posts...

I dont know where to begin to explain the faults in your invention... You seem to have a genuine interest in physics, which is great, but start with the basics man. In so many words by spraying a higher velocity stream of air into a turbo you didnt figure out something "the billion dollar engineering teams" didnt. Be careful man, I dont have many posts here but Ive read enough to know these guys will eat you alive.

I dont know where to begin to explain the faults in your invention... You seem to have a genuine interest in physics, which is great, but start with the basics man. In so many words by spraying a higher velocity stream of air into a turbo you didnt figure out something "the billion dollar engineering teams" didnt. Be careful man, I dont have many posts here but Ive read enough to know these guys will eat you alive.

#7

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

So i did some looking around on the internet and realized that increasing the velocity of exhaust gas by restricting the flow pre turbo would result in very very fast spool time, however this would also decrease maximum output. So i thought what if you could restrict the flow only until the engine was flowing enough exhaust gasses to keep the turbo spooled. What i came up with was the idea to scale down the "exhaust control tube funnel blades" (only definition i could find) off a jet engine and place them inside the merge collector, you could easily use an electric solenoid to control them or even something similar to a wategate.

more restrictive:

Less restrictive:

#11

Junior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Palm Harbor FL

Posts: 328

Total Cats: 4

Variable-vein turbos can survive gasoline engines, hence the Peugeot 405 T16, Porsche 911 Turbo, and optional turbo v6 jeep grand Cherokee in the Australia (or at least that's the only place iv seen one). A lil more research turned up a variable nozzle turbo, essentially identical to what i was thinking. Only 500 were produced and used on a shelby csx-vnt which was released as a limited production vehicle in 89. Must not have worked too well.

#13

Junior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Palm Harbor FL

Posts: 328

Total Cats: 4

^ I did a brief search and found nothing on the failing due to heat, alot about them failing due to carbon buildup. However this is a lil off topic and i feel like this thread has run its course, it provides no useful information to anyone.

#14

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

the aerocharger 2.0 is supposed to have moved past it's failures:

AEROCHARGER Turbocharger is the most advanced form of forced induction, giving you the edge over the competition. First to Boost, First to Win.

AEROCHARGER Turbocharger is the most advanced form of forced induction, giving you the edge over the competition. First to Boost, First to Win.

#16

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

Corky would be the best source, as his first turbo kit was built around the aerocharger. It seemed they ran great at 5psi, but as soon as you added more boost they'd straight up die.

I was witness to an original begi aerocharger setup last dyno day:

I was witness to an original begi aerocharger setup last dyno day: