Boost creepin' like a mofo

#1

Senior Member

Thread Starter

iTrader: (8)

Join Date: Jun 2010

Location: Florida

Posts: 1,116

Total Cats: 43

Scroll down to last line for short version of this thread... sorry for the long drawn out post.

Boost creeping pretty bad on my miata... hoping to get some ideas/advice to fix the issue. First let me lay down exactly what my setup is, what it is doing, and what I have done so far to troubleshoot.

Setup:

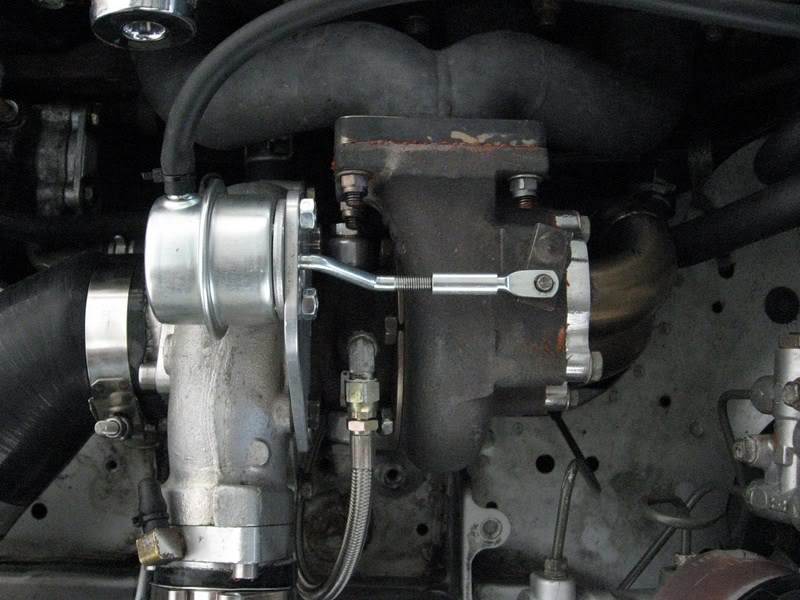

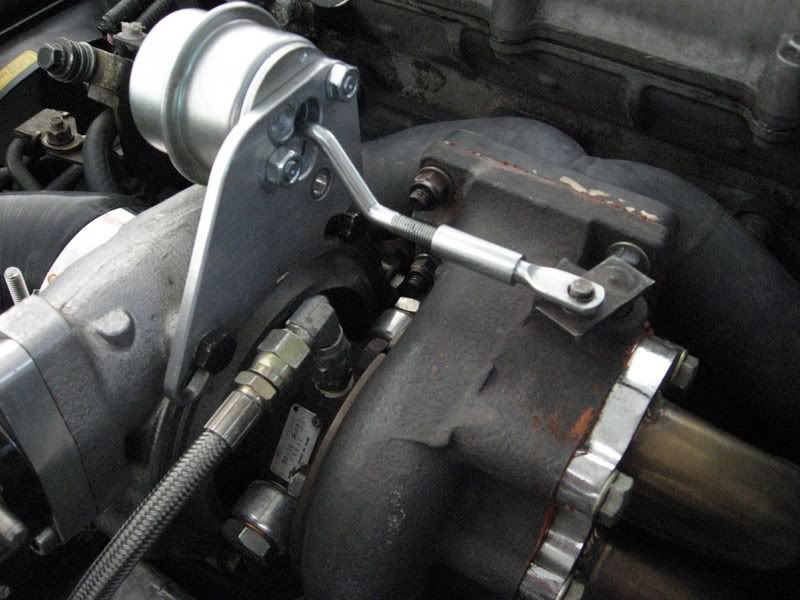

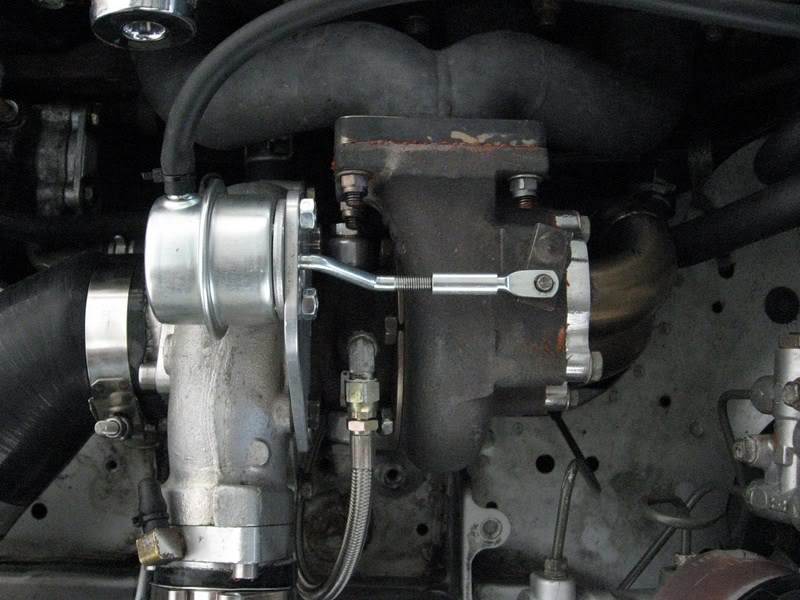

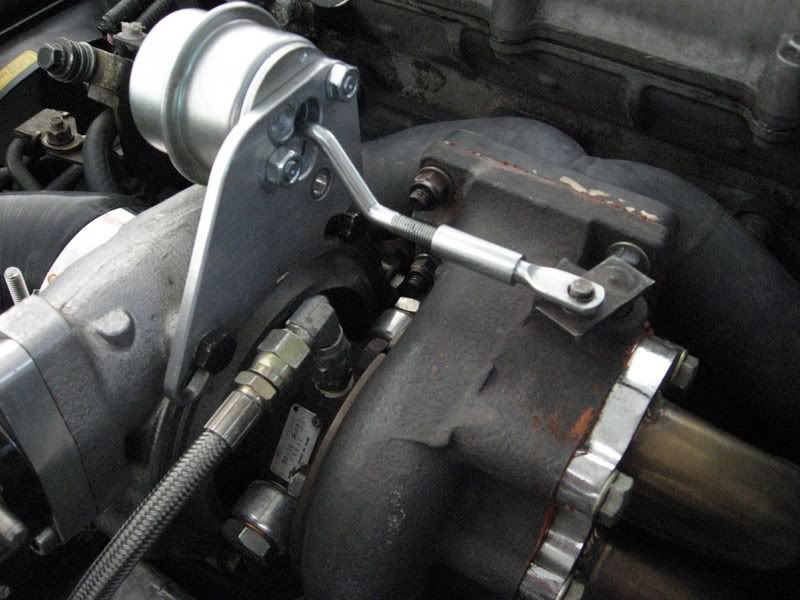

Garrett GT2560R, internal wastegate (one on Begi's website)- adjustable preload, anywhere from 6-11 psi advertised. I am running no preload, just enough to keep the flapper shut at rest. As far as the turbine/downpipe design... it's a split downpipe (ARTech). Main pipe is 3", no cats, exhaust is 3" as well, single magnaflow straight thru muffler. The wastegate gasses run in a separate pipe and dump to atmosphere. There is a "divider plate" of sorts welded into the turbine housing to keep the flows separate and not allow leaking either way (see pics later). Manifold is a short tubular manifold from ARTech as well.

What I am seeing:

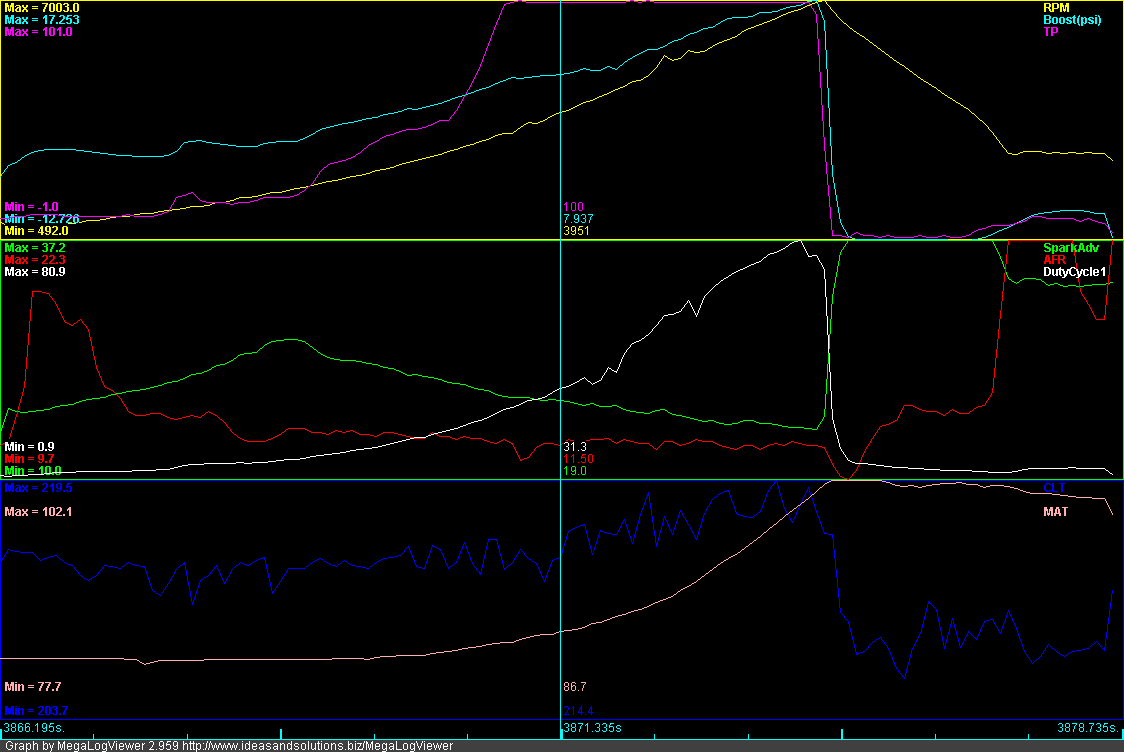

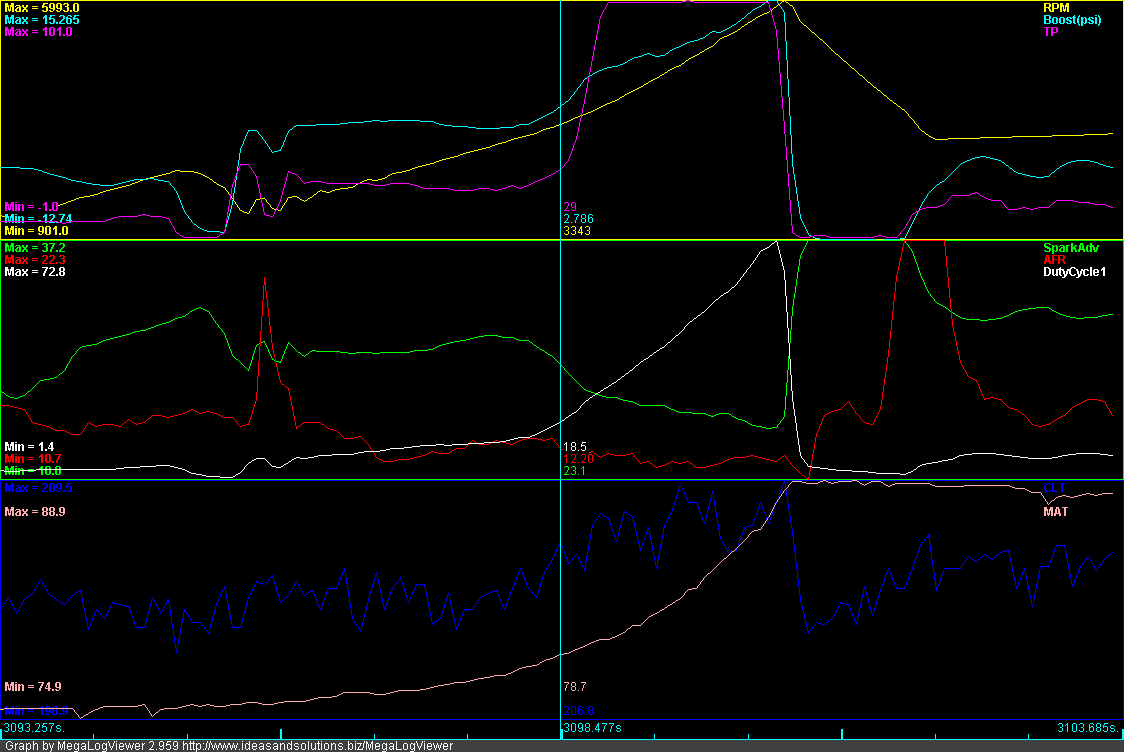

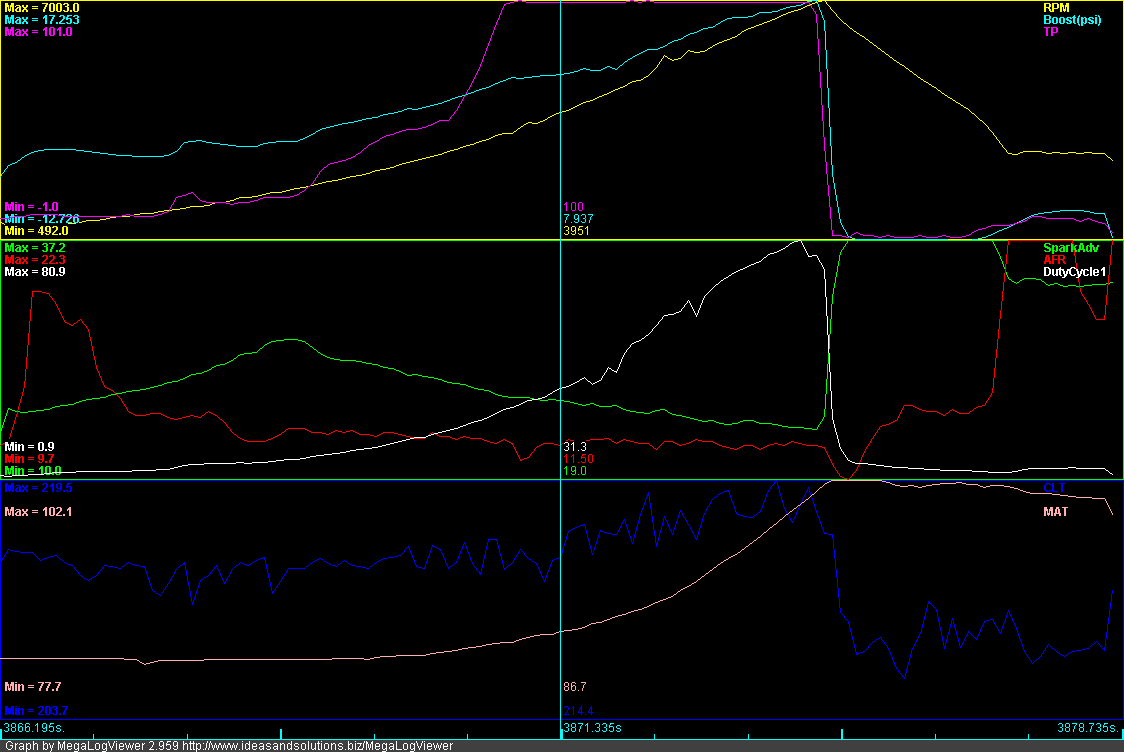

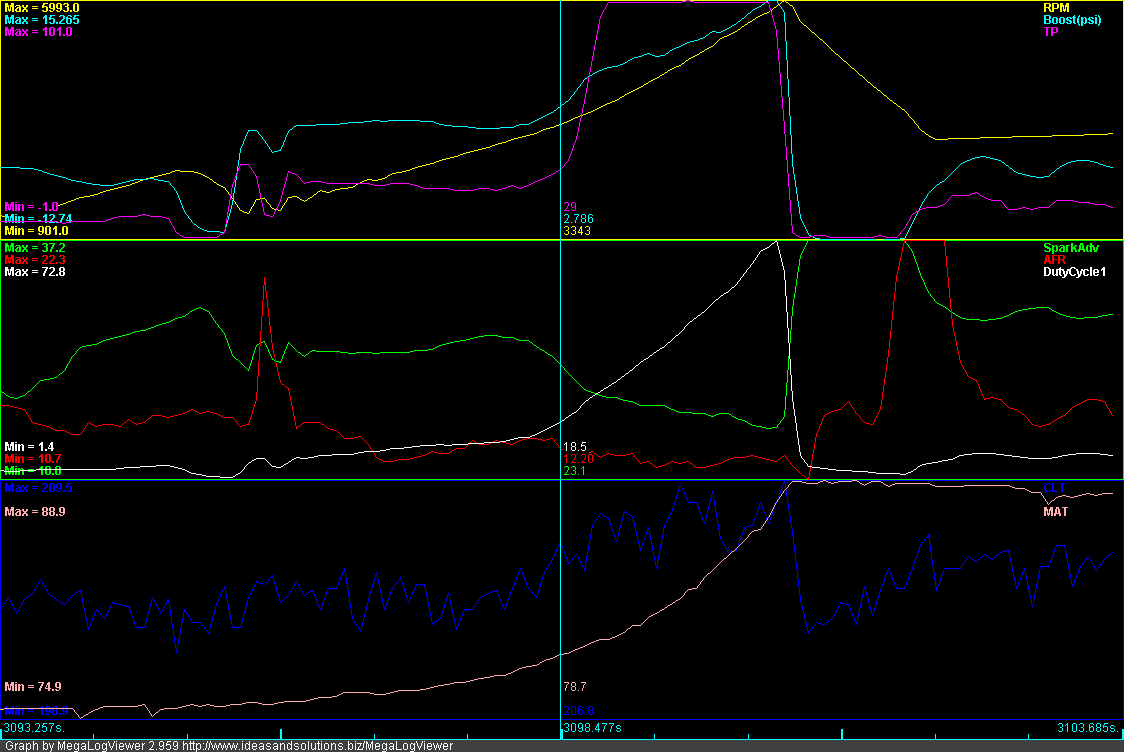

Boost creep entire rpm range. Once I put my foot down, boost always steadily increases. I've done all my pulls in 2nd gear (lower load...but I do have pretty long gearing, I can go around 65mph in 2nd). I saw 15psi around 5500 and 17psi by 7000 (redline).

What I've done:

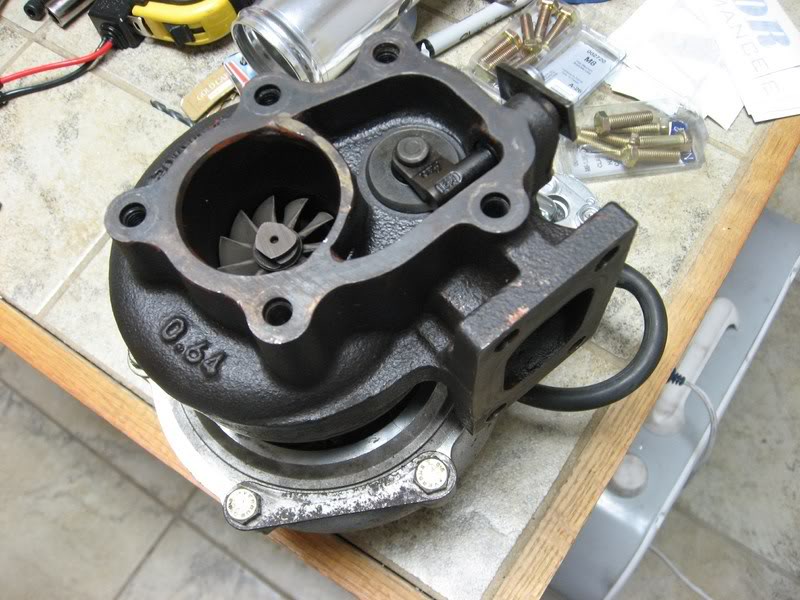

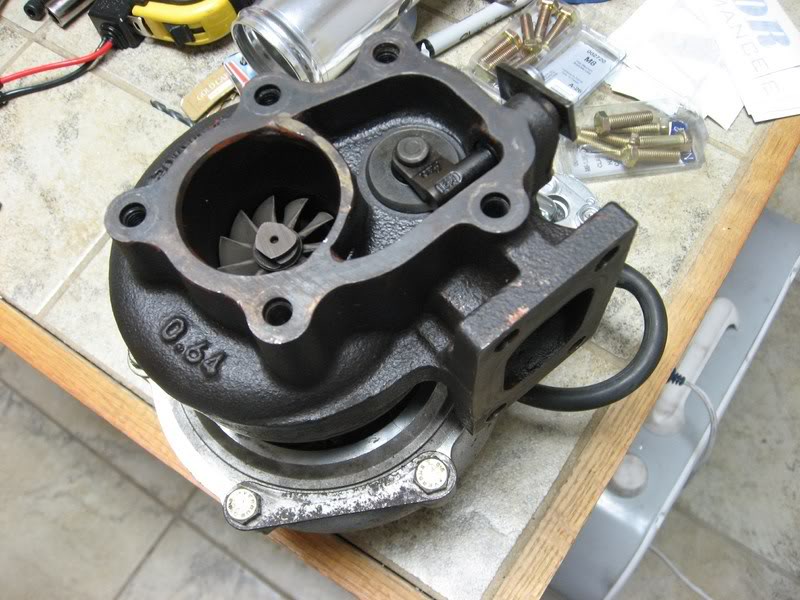

First thing I did was send my turbo off to Begi to get the wastegate ported. When they got it, they said it had already been ported a little, but they would do all they could, in addition to adding in a 'tunnel' (see pics). Well, that didn't help one bit. Of the two datalogs below.. first one is Pre porting, and 2nd is post-porting- they are basically identical.

I tried two different boost sources: compressor outlet and 'out' side of the intercooler end-tank...same results.

I have checked the wastegate flapper and actuator movement, to make sure the flapper is not hitting something and it's range of motion being affected, as well as making sure nothing is binding when pressure is applied to the wastegate with the flapped connected (video below). Everything seems fine... it cracks open around 7 psi, it takes something like 20-30psi to get full actuation, but of course this isn't a 'realistic' test by any means, as in this state there's no exhaust gas pressure on the flapper as well. My ears tell me the wastegate starts opening around 2-3 psi.

So basically as I see it, my options are now:

a.) EWG

b.) High flow cat in downpipe

c.) New/different turbo (good excuse to upgrade to something bigger?)

Option B is the quickest and easiest and may very well fix it, but there's no real way to know until I do it...also it's really more of a bandaid than fixing the issue. Option A seems pretty logical too, but at this point I'd have to send the manifold, downpipe and at least the turbine housing off most likely to get it all modded and done.... some extra money, that's not a huge deal but who knows how long... I want to get this car running right now!!! Option C... well I know there's really no point going bigger for my power goals etc, but it's still always tempting haha.

Anyways, just looking for some ideas/thoughts/advic...anything I might have overlooked or if something you see in here doesn't look right.

Sorry for the long drawn out post lol!

Short Version

Car is boost creeping even after wastegate ported....what now???

Boost creeping pretty bad on my miata... hoping to get some ideas/advice to fix the issue. First let me lay down exactly what my setup is, what it is doing, and what I have done so far to troubleshoot.

Setup:

Garrett GT2560R, internal wastegate (one on Begi's website)- adjustable preload, anywhere from 6-11 psi advertised. I am running no preload, just enough to keep the flapper shut at rest. As far as the turbine/downpipe design... it's a split downpipe (ARTech). Main pipe is 3", no cats, exhaust is 3" as well, single magnaflow straight thru muffler. The wastegate gasses run in a separate pipe and dump to atmosphere. There is a "divider plate" of sorts welded into the turbine housing to keep the flows separate and not allow leaking either way (see pics later). Manifold is a short tubular manifold from ARTech as well.

What I am seeing:

Boost creep entire rpm range. Once I put my foot down, boost always steadily increases. I've done all my pulls in 2nd gear (lower load...but I do have pretty long gearing, I can go around 65mph in 2nd). I saw 15psi around 5500 and 17psi by 7000 (redline).

What I've done:

First thing I did was send my turbo off to Begi to get the wastegate ported. When they got it, they said it had already been ported a little, but they would do all they could, in addition to adding in a 'tunnel' (see pics). Well, that didn't help one bit. Of the two datalogs below.. first one is Pre porting, and 2nd is post-porting- they are basically identical.

I tried two different boost sources: compressor outlet and 'out' side of the intercooler end-tank...same results.

I have checked the wastegate flapper and actuator movement, to make sure the flapper is not hitting something and it's range of motion being affected, as well as making sure nothing is binding when pressure is applied to the wastegate with the flapped connected (video below). Everything seems fine... it cracks open around 7 psi, it takes something like 20-30psi to get full actuation, but of course this isn't a 'realistic' test by any means, as in this state there's no exhaust gas pressure on the flapper as well. My ears tell me the wastegate starts opening around 2-3 psi.

So basically as I see it, my options are now:

a.) EWG

b.) High flow cat in downpipe

c.) New/different turbo (good excuse to upgrade to something bigger?)

Option B is the quickest and easiest and may very well fix it, but there's no real way to know until I do it...also it's really more of a bandaid than fixing the issue. Option A seems pretty logical too, but at this point I'd have to send the manifold, downpipe and at least the turbine housing off most likely to get it all modded and done.... some extra money, that's not a huge deal but who knows how long... I want to get this car running right now!!! Option C... well I know there's really no point going bigger for my power goals etc, but it's still always tempting haha.

Anyways, just looking for some ideas/thoughts/advic...anything I might have overlooked or if something you see in here doesn't look right.

Sorry for the long drawn out post lol!

Short Version

Car is boost creeping even after wastegate ported....what now???

#2

Senior Member

Thread Starter

iTrader: (8)

Join Date: Jun 2010

Location: Florida

Posts: 1,116

Total Cats: 43

Just want to add, seems like I'm the only one who got it ported and still having issues... saw that thread Doppelgänger made, where he got a new CHRA, boost crept, then the issue went away when he got a new turbine housing and got it ported. As far as I know this one never got a new CHRA or anything?

#6

There's no reason an internal wastegate shouldn't be able to handle what you need, so I wouldn't go EWG with your setup. If your wastegate is a 7psi wastegate, it should fully actuate with 7psi of pressure. I would probably try to loosten the wastegate by backing off the adjustable arm (to the point that the flapper is loose), and then see what happens with boost. Another option is to just disconnect your wastegate and see if you still make boost while driving. If you start making pressure when your wastegate is completely open, then there's something wrong either with the downpipe design or the turbo itself. Your wastegate actuator could just be screwed as well. It might be worth while putting it on a dyno and watching the engine while a run is done, so you can see where it is actually opening up.

#7

So let me get this straight . . .

Your turbine gets a luxuriously sized 3" exhaust.

Your wastegate gets a smaller exhaust (you didn't mention size, but visibly smaller). You've taken pains to make sure your wastegate can't share that luxurious 3" exhaust.

As you increase RPM, you increase flow through the engine. The flow follows the path of least resistance, whether that be through the turbine or through the wastegate. Boost creep means that the exhaust is choosing the turbine when you don't want it to.

So, your path through the wastegate is restricted. You've already addressed the obvious by porting and ensuring the wastegate can fully open. I wonder if you're outsmarting yourself with the separate exhaust pipes. Most that I've seen will rejoin the main exhaust. This allows the flow on the turbine side to "venturi" additional flow from the separated wastegate side. You don't have that setup -- might be worth a look -- although I don't know of a way to prove it without tearing up your downpipe.

Your turbine gets a luxuriously sized 3" exhaust.

Your wastegate gets a smaller exhaust (you didn't mention size, but visibly smaller). You've taken pains to make sure your wastegate can't share that luxurious 3" exhaust.

As you increase RPM, you increase flow through the engine. The flow follows the path of least resistance, whether that be through the turbine or through the wastegate. Boost creep means that the exhaust is choosing the turbine when you don't want it to.

So, your path through the wastegate is restricted. You've already addressed the obvious by porting and ensuring the wastegate can fully open. I wonder if you're outsmarting yourself with the separate exhaust pipes. Most that I've seen will rejoin the main exhaust. This allows the flow on the turbine side to "venturi" additional flow from the separated wastegate side. You don't have that setup -- might be worth a look -- although I don't know of a way to prove it without tearing up your downpipe.

#8

So let me get this straight . . .

Your turbine gets a luxuriously sized 3" exhaust.

Your wastegate gets a smaller exhaust (you didn't mention size, but visibly smaller). You've taken pains to make sure your wastegate can't share that luxurious 3" exhaust.

As you increase RPM, you increase flow through the engine. The flow follows the path of least resistance, whether that be through the turbine or through the wastegate. Boost creep means that the exhaust is choosing the turbine when you don't want it to.

So, your path through the wastegate is restricted. You've already addressed the obvious by porting and ensuring the wastegate can fully open. I wonder if you're outsmarting yourself with the separate exhaust pipes. Most that I've seen will rejoin the main exhaust. This allows the flow on the turbine side to "venturi" additional flow from the separated wastegate side. You don't have that setup -- might be worth a look -- although I don't know of a way to prove it without tearing up your downpipe.

Your turbine gets a luxuriously sized 3" exhaust.

Your wastegate gets a smaller exhaust (you didn't mention size, but visibly smaller). You've taken pains to make sure your wastegate can't share that luxurious 3" exhaust.

As you increase RPM, you increase flow through the engine. The flow follows the path of least resistance, whether that be through the turbine or through the wastegate. Boost creep means that the exhaust is choosing the turbine when you don't want it to.

So, your path through the wastegate is restricted. You've already addressed the obvious by porting and ensuring the wastegate can fully open. I wonder if you're outsmarting yourself with the separate exhaust pipes. Most that I've seen will rejoin the main exhaust. This allows the flow on the turbine side to "venturi" additional flow from the separated wastegate side. You don't have that setup -- might be worth a look -- although I don't know of a way to prove it without tearing up your downpipe.

#9

There's one flaw to your logic though. When the wastage opens there is NO restriction for the air to hit, there is a restriction through the turbine the wheel is a restriction. If this was always a problem with open dump tubes, nobody would use them. I think the problem is in the wastegate actuator. I'd take the above advice, and run with the wastegate stuck open and see if you make boost. When I did this i would make 1-2 psi at 6000-6500 wot in 5th gear.

#11

Senior Member

Thread Starter

iTrader: (8)

Join Date: Jun 2010

Location: Florida

Posts: 1,116

Total Cats: 43

Wastegate is brand new and actuates fine when pressure is applied thru a pump..but I agree, definitely worth unhooking it and seeing what happens. Ill try this weekend or tomorrow and report back!

#13

There's one flaw to your logic though. When the wastage opens there is NO restriction for the air to hit, there is a restriction through the turbine the wheel is a restriction. If this was always a problem with open dump tubes, nobody would use them. I think the problem is in the wastegate actuator. I'd take the above advice, and run with the wastegate stuck open and see if you make boost. When I did this i would make 1-2 psi at 6000-6500 wot in 5th gear.

The trick is to balance the restrictions to achieve the turbine work extraction you're after. Turbos are designed with a balance between the path through the turbine and the path through the wastegate. If you have the exact setup used in the lab, then you'll get nearly perfect design boost control. Anything off-design changes that balance. We can change the balance with things like EBC, separated gasses downpipes, porting, etc.

It is helpful sometimes to take a step back and think of the underlying physics involved.

As bad as this creep is, I would have guessed wastegate as well. However, the OP seems to have already checked this out. I wonder if there is any binding going on when components come up to temperature.

#15

Of course there's a restriction. The wastegate only opens so far. That's a restriction. Flow forced through a tube is a restriction -- the narrower and longer the tube and the higher the pressure at the end of the tube, the more the restriction. As you noted, being forced through a turbine is a restriction.

The trick is to balance the restrictions to achieve the turbine work extraction you're after. Turbos are designed with a balance between the path through the turbine and the path through the wastegate. If you have the exact setup used in the lab, then you'll get nearly perfect design boost control. Anything off-design changes that balance. We can change the balance with things like EBC, separated gasses downpipes, porting, etc.

It is helpful sometimes to take a step back and think of the underlying physics involved.

As bad as this creep is, I would have guessed wastegate as well. However, the OP seems to have already checked this out. I wonder if there is any binding going on when components come up to temperature.

The trick is to balance the restrictions to achieve the turbine work extraction you're after. Turbos are designed with a balance between the path through the turbine and the path through the wastegate. If you have the exact setup used in the lab, then you'll get nearly perfect design boost control. Anything off-design changes that balance. We can change the balance with things like EBC, separated gasses downpipes, porting, etc.

It is helpful sometimes to take a step back and think of the underlying physics involved.

As bad as this creep is, I would have guessed wastegate as well. However, the OP seems to have already checked this out. I wonder if there is any binding going on when components come up to temperature.

I'm thinking along the same lines as why a larger downpipe is beneficial, pressure differential. Are you saying it better because the exhaust is "pulling" out wastegate gasses? In the catch can thread, it has been researched that the exhaust pulls only 1-2 psi at wot on the track cars. Also, some guys have had power losses from switching from dump to recirculated, don't know which thread that was off the top of my head.

All in all, I dont think the dump tube is the cause

#16

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,499

Total Cats: 4,080

The problem is more that the increase of flow is so great through the main exhaust tube, it's hard to get the exhaust gasses to divert and turn 90° out the wastegate. That's why BEGi adds the "tunnel" into the housing to help divert gasses and point them in the right direciton and this typically works well.

When the dump tube is connected into the main tube, it creates turbulence and slows the gasses coming from the turbine, creating some backpressure. This effectively helps, using pressure differentials, to allow the gasses to bypass into the wastegate tube.

When you removed the wastegate tube from the main, you removed that from the formula. While there is zero pressure behind the dump tube, there's also nothing really helping scavenge or force the exhaust to change directions. Both tubes have little restricition, and it's simple too easy for the exhaust gasses to keep moving forward instead of dumping off before the turbine.

When the dump tube is connected into the main tube, it creates turbulence and slows the gasses coming from the turbine, creating some backpressure. This effectively helps, using pressure differentials, to allow the gasses to bypass into the wastegate tube.

When you removed the wastegate tube from the main, you removed that from the formula. While there is zero pressure behind the dump tube, there's also nothing really helping scavenge or force the exhaust to change directions. Both tubes have little restricition, and it's simple too easy for the exhaust gasses to keep moving forward instead of dumping off before the turbine.

#17

Senior Member

Thread Starter

iTrader: (8)

Join Date: Jun 2010

Location: Florida

Posts: 1,116

Total Cats: 43

I still need to do the wired open flapper test, just to rule out the possibility of the wastegate being bad..but yeah its hard to know if open dump or recirculated would help promote boost creep more. Open dump allows better, smoother flow for each tube separately, but if the turbine flow is too efficient...that's not good I guess either when working with a small IWG. I went this route for better efficiency...anyways here's a pic of the porting, its just like how they show on their site.

Also to note is, dsm and evo guys have done IWG dump for quite awhile, and I've never heard of it being a big issue. Bottom line I don't think open dump alone is going to make it creep as bad as it is....probably more like the sum of a few things....but this all assumes my wastegate checks out. I'm running one from begi's site, don't know if its legit garrett or what...what is everyone else using?

Also to note is, dsm and evo guys have done IWG dump for quite awhile, and I've never heard of it being a big issue. Bottom line I don't think open dump alone is going to make it creep as bad as it is....probably more like the sum of a few things....but this all assumes my wastegate checks out. I'm running one from begi's site, don't know if its legit garrett or what...what is everyone else using?