Drilling block for oil feed?

#21

Elite Member

iTrader: (11)

Join Date: Jun 2007

Location: Overland Park, Kansas

Posts: 5,360

Total Cats: 43

I never considered the sandwich plate offered unfiltered oil but you're absolutely right Joe. In light of that, I believe this would be the best solution to your conundrum:

Eaton 1/8"BNPSTWIERHJK to -4AN fitting then attach your pressure sending unit to sandwich plate and hope it doesn't leak all over the place.

Eaton 1/8"BNPSTWIERHJK to -4AN fitting then attach your pressure sending unit to sandwich plate and hope it doesn't leak all over the place.

#24

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,050

Total Cats: 6,615

Indeed. 1/8 BSPT.

The specs two are *really* close. 1/8 NPT is 27 TPI with a major diameter of 0.405", whereas 1/8 BSP is 28 TPI with a 0.383" major diameter.

Some folks report that the two can be interchanged, provided that one exercises caution and is liberal in the use of sealant.

Others prefer to use the correct adapters.

https://www.pegasusautoracing.com/gr...D=PLUMADAPTBSP

The specs two are *really* close. 1/8 NPT is 27 TPI with a major diameter of 0.405", whereas 1/8 BSP is 28 TPI with a 0.383" major diameter.

Some folks report that the two can be interchanged, provided that one exercises caution and is liberal in the use of sealant.

Others prefer to use the correct adapters.

https://www.pegasusautoracing.com/gr...D=PLUMADAPTBSP

#25

Elite Member

iTrader: (11)

Join Date: Jun 2007

Location: Overland Park, Kansas

Posts: 5,360

Total Cats: 43

Use an oil safe sealant (Rectorseal5 for example) on the OEM sending unit, it will thread into a 1/8NPT standard port perfectly, you just can't install 1/8NPT into a 1/BSPT hole. Ask me how I know. Didn't even know such a thing as "BSPT" existed until Husty and some others clued me in on my thread, not that I'm a pipe fitter or anything . . .

#27

Senior Member

iTrader: (2)

Join Date: Sep 2009

Location: Edmonton, AB, Canada

Posts: 1,193

Total Cats: 29

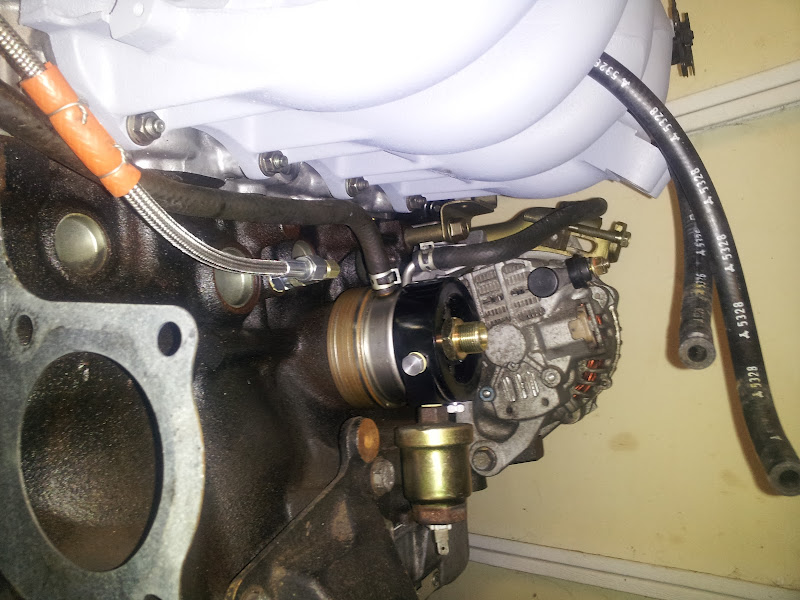

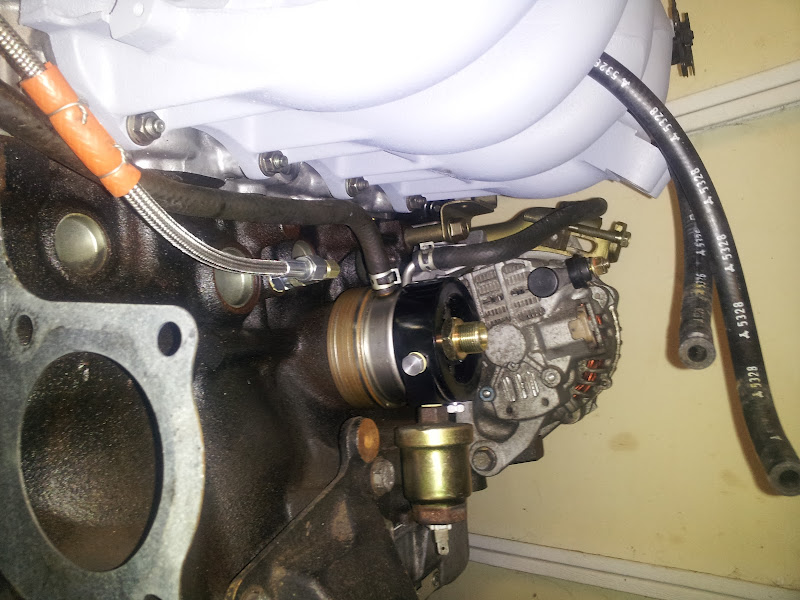

Speaking of oil feeding.

I have an NBB so I want to run a mechanical oil guage in the car, any idea what length I need of 4AN braided going from block port through firewall to guage near steering wheel. I could measure myself but then what good is that gonna do?

I have an NBB so I want to run a mechanical oil guage in the car, any idea what length I need of 4AN braided going from block port through firewall to guage near steering wheel. I could measure myself but then what good is that gonna do?

#29

Senior Member

iTrader: (2)

Join Date: Sep 2009

Location: Edmonton, AB, Canada

Posts: 1,193

Total Cats: 29

Hmm food for thought.

You know I had a nylon line in my VW for years but never thought about the temperature of the oil. It never leaked after years of use so I never paid the "what ifs" much attention.

I know there are people that do it, is not braided line to brass gauge fittings very very reliable?

My mechanical fuel gauge with heater hose line in the cabin has never leaked, gets a bit of fumes going after a hard run but that's all. Since I'm so busy texting I get the kids to watch the dial when I'm full throttlin'.

You know I had a nylon line in my VW for years but never thought about the temperature of the oil. It never leaked after years of use so I never paid the "what ifs" much attention.

I know there are people that do it, is not braided line to brass gauge fittings very very reliable?

My mechanical fuel gauge with heater hose line in the cabin has never leaked, gets a bit of fumes going after a hard run but that's all. Since I'm so busy texting I get the kids to watch the dial when I'm full throttlin'.

Last edited by Landrew; 07-05-2012 at 10:20 PM.

#32

Senior Member

iTrader: (2)

Join Date: Sep 2009

Location: Edmonton, AB, Canada

Posts: 1,193

Total Cats: 29

Ha the fuel guage was a joke.

So then get an electrical guage and sender but run the braided line from the block out a few feet then connect to the sender so to avoid vibration damage to the sender unit??

So then get an electrical guage and sender but run the braided line from the block out a few feet then connect to the sender so to avoid vibration damage to the sender unit??

#34

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,050

Total Cats: 6,615

I've never seen it happen, but there are a few horror-stories floating around about hoses (or gauges themselves) failing, with the result of 250 degree oil being sprayed into the driver's compartment at 60+ PSI. I'd imagine that this is probably an unpleasant thing to experience.

They do make diaphragm-style isolators for use with mechanical fuel pressure gauges. Not sure if I've ever seen one rated for use with oil, but they may be out there.

On the other hand, as cheap and reliable as electric gauges are, coupled with the fact that it's a lot easier to run a wire than a braided line, I'd personally stick with the electric gauges across the board. Direct-reading mechanical gauges are so 19'th century.

#35

Elite Member

iTrader: (11)

Join Date: Jun 2007

Location: Overland Park, Kansas

Posts: 5,360

Total Cats: 43

Prosport Gauges Oil Pressure Gauge 52mm

$43 bux and some change for shipping. Don't cheap out when it comes to something safety related...

$43 bux and some change for shipping. Don't cheap out when it comes to something safety related...

#36

Senior Member

iTrader: (2)

Join Date: Sep 2009

Location: Edmonton, AB, Canada

Posts: 1,193

Total Cats: 29

Going with electric unit.

Isn't there a reasonable amount of vibration failures associated with attaching the electric sending unit directly to the block. I had heard running some hose/line from block then the sender unit will isolate it from quite a bit of vibration and ensure a longer life.

Paranoid or overkill ?

Wait did I just go from borderline unsafe to oversafe?

Isn't there a reasonable amount of vibration failures associated with attaching the electric sending unit directly to the block. I had heard running some hose/line from block then the sender unit will isolate it from quite a bit of vibration and ensure a longer life.

Paranoid or overkill ?

Wait did I just go from borderline unsafe to oversafe?

#37

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,050

Total Cats: 6,615

What I have heard (but never seen first-hand) is that putting the heavy analog sender on the end of a tee-adapter combination can lead to stress-induced fracturing of the mechanical fittings between the sensor and the block. This would argue for a remote fitting if your application requires intermediate hardware, such as when using the oil pressure hole for a turbo oil feed on a later-model engine.

#38

Senior Member

iTrader: (2)

Join Date: Sep 2009

Location: Edmonton, AB, Canada

Posts: 1,193

Total Cats: 29

Thanks for the tip on the blackout gauges, good point, and the leverage on the fittings when piggybacking the block port.

If a sandwich plate is used as well as the block port what is the best spot for the turbo line and pressure gauge when choosing from either feed?

If a sandwich plate is used as well as the block port what is the best spot for the turbo line and pressure gauge when choosing from either feed?