Fixing manifold crack and reinforcing

#1

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

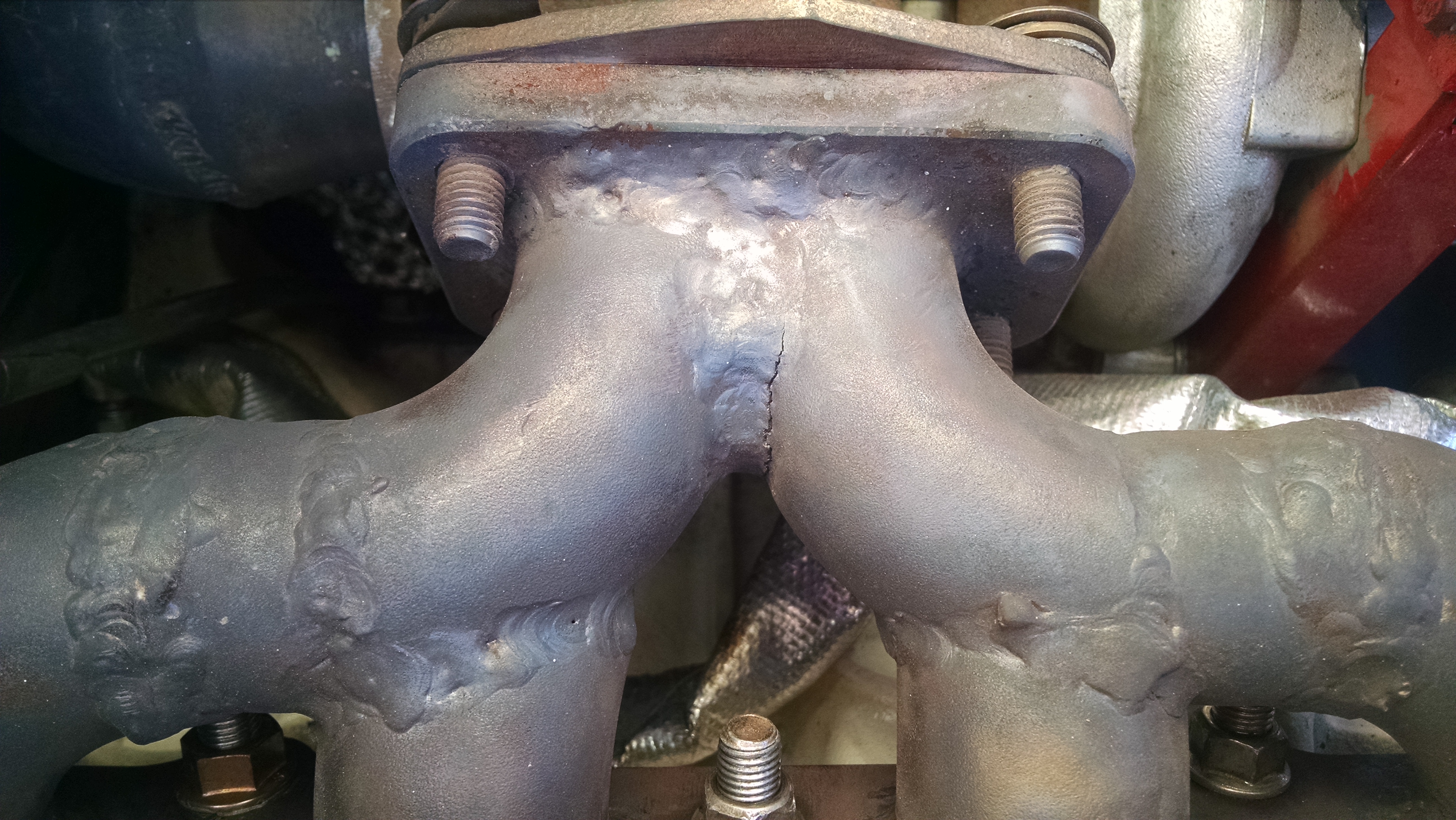

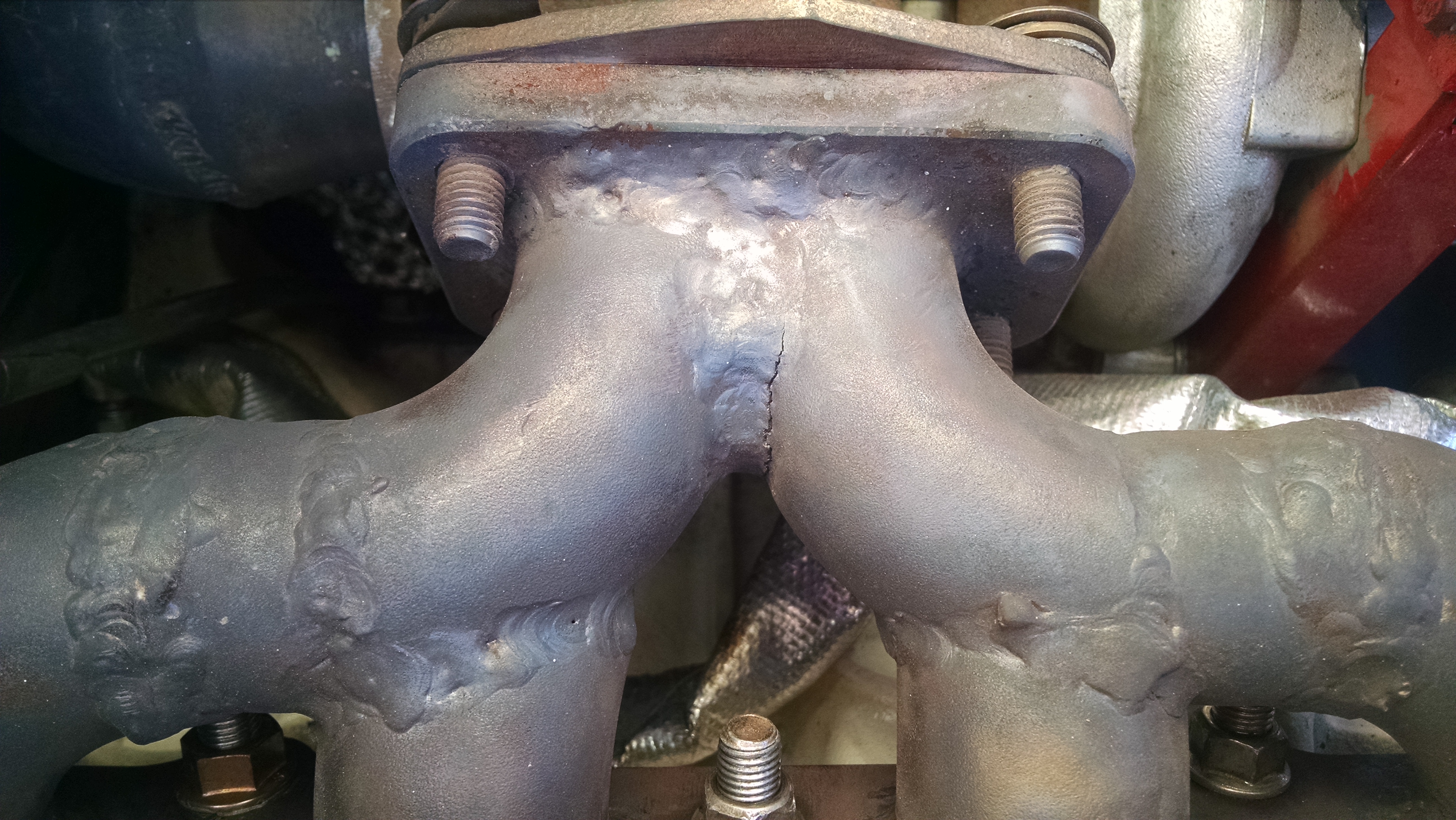

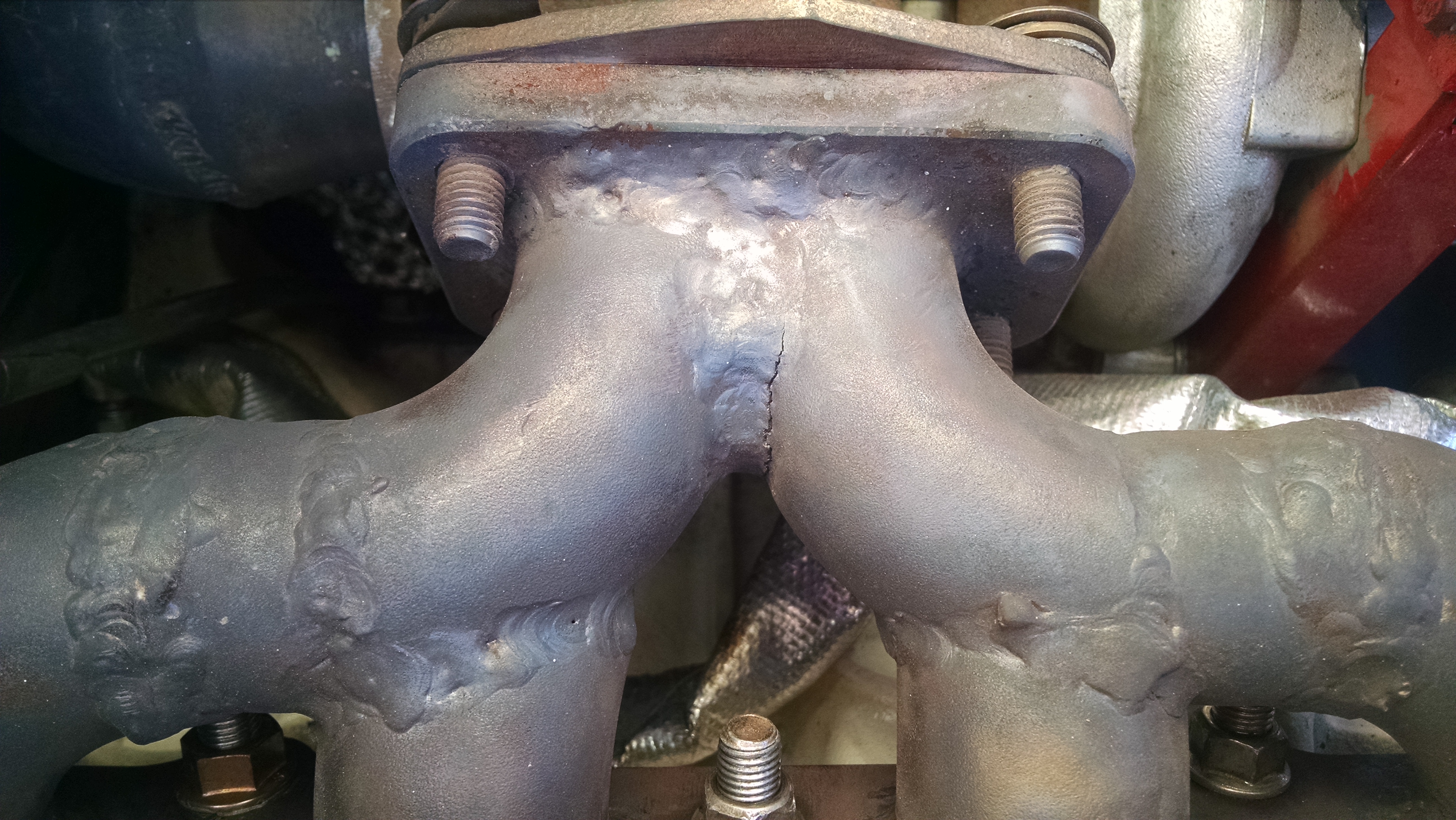

Built this manifold last winter. I have something like 15k on it, and 8 track days.

Just found this crack. Ran it for a whole track day, and an 800 mile trip home with no soot coming out at all. Must not leak much. I believe it is from thermal expansion.

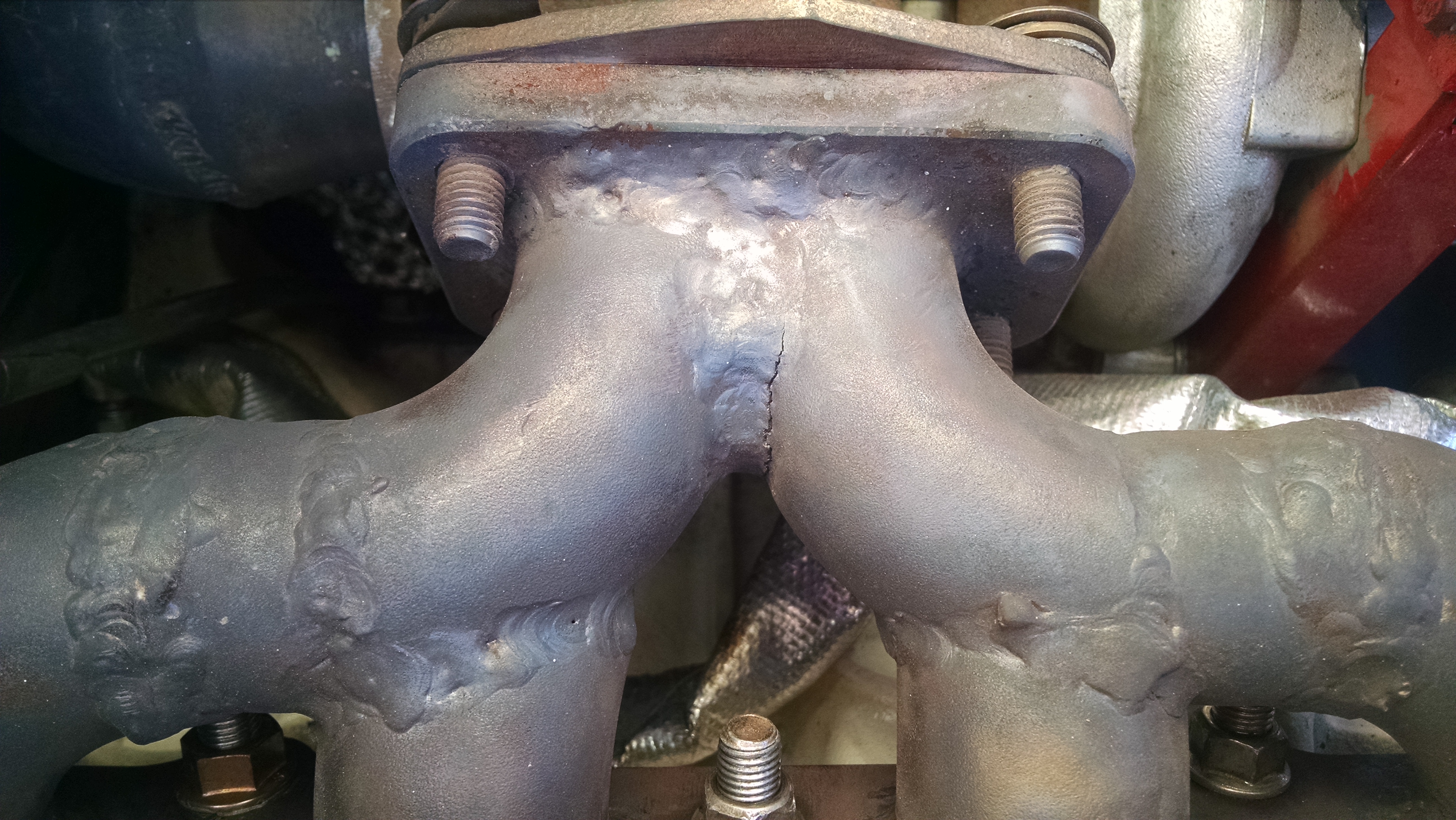

The plan

Drill out both ends of the crack to stop propagation.

Clean the inside very well and try and clean the actual crack (how?)

Backpurge and weld the crack.

Add a gusset between the 2.

Suggestions? What thickness plate should I use as a gusset.

Also thinking about cutting more relief cuts.

Just found this crack. Ran it for a whole track day, and an 800 mile trip home with no soot coming out at all. Must not leak much. I believe it is from thermal expansion.

The plan

Drill out both ends of the crack to stop propagation.

Clean the inside very well and try and clean the actual crack (how?)

Backpurge and weld the crack.

Add a gusset between the 2.

Suggestions? What thickness plate should I use as a gusset.

Also thinking about cutting more relief cuts.

#2

Get an air powered die grinder and some carbide burrs to clean out the crack. I'd skip drilling out the ends, and just weld it good once you've ground every bit of the old weld out. Consider welding on the inside as well if you can reach it easily. Clean the metal with acetone before welding, don't use brake cleaner or anything chlorinated unless you really want to die.

#3

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Every bit of old weld isn't coming out of that. Its a giant pile of filler. I can easily get to it from the inside. yank should be bringing over his die grinder.

I'll try and find an old picture of the weld.

I'll try and find an old picture of the weld.

#7

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Whole manifold welded without backpurging...oops.

This time I have a second regulator, and will just use my spare bottle to backpurge.

Wired the welder into 220v last night and got the full 200amps. Still waiting on the stainless gusset and time to pull the manifold.

This time I have a second regulator, and will just use my spare bottle to backpurge.

Wired the welder into 220v last night and got the full 200amps. Still waiting on the stainless gusset and time to pull the manifold.

#8

Also, preheating and post heating a weld can help stress relieve the material you are working with.

#9

Built this manifold last winter. I have something like 15k on it, and 8 track days.

Just found this crack. Ran it for a whole track day, and an 800 mile trip home with no soot coming out at all. Must not leak much. I believe it is from thermal expansion.

The plan

Drill out both ends of the crack to stop propagation.

Clean the inside very well and try and clean the actual crack (how?)

Backpurge and weld the crack.

Add a gusset between the 2.

Suggestions? What thickness plate should I use as a gusset.

Also thinking about cutting more relief cuts.

Just found this crack. Ran it for a whole track day, and an 800 mile trip home with no soot coming out at all. Must not leak much. I believe it is from thermal expansion.

The plan

Drill out both ends of the crack to stop propagation.

Clean the inside very well and try and clean the actual crack (how?)

Backpurge and weld the crack.

Add a gusset between the 2.

Suggestions? What thickness plate should I use as a gusset.

Also thinking about cutting more relief cuts.

Here's what I would do to fix it.

Clean, grind out, drill to stop crack.

Reweld. Then weld a gusset top and bottom to help spread the load out in that area. Then cut the flange to allow it to stretch a bit.

For gusset thickness, I would use 1/8" or so.

Thread

Thread Starter

Forum

Replies

Last Post

mgeoffriau

General Miata Chat

9

10-07-2015 11:11 AM