Moving that coolant pipe

#22

Senior Member

iTrader: (10)

Join Date: Aug 2007

Location: Fredericton, NB

Posts: 1,186

Total Cats: 4

I run the begi piece....water comes out of heater core and goes into long pipe tucked in fender. Eventually tees off with the water inlet rad hose.

Besides a rather complicated looking inlet hose with a few bends, it's a very clean install.

Besides a rather complicated looking inlet hose with a few bends, it's a very clean install.

#26

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Heater core flow bypasses the thermostat entirely, which results in long warmup times and more cold engine wear as a result. It has nothing to do with living in Texas or other warm climates. The way BEGi does that reroute is simply wrong.

#28

Former Vendor

iTrader: (8)

Join Date: Mar 2005

Location: Broken Arrow,Ok

Posts: 1,185

Total Cats: 57

It was indeed a billet piece that took a few evenings to carve out. There just wasn't a nice option out there. The tube portion is a reasonably priced off the shelf part from CSR.

#30

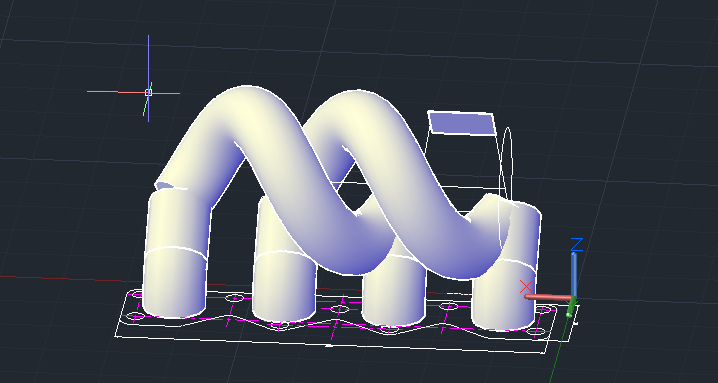

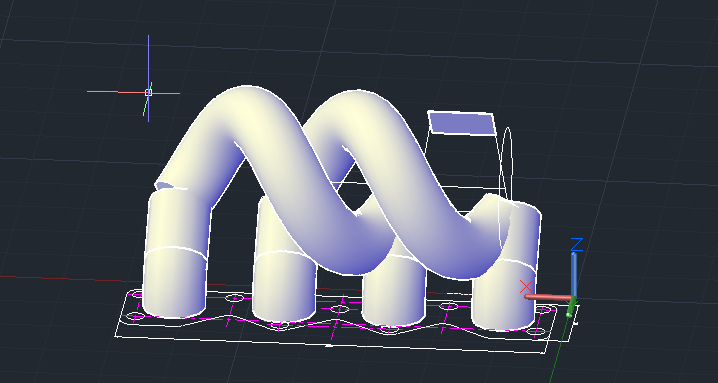

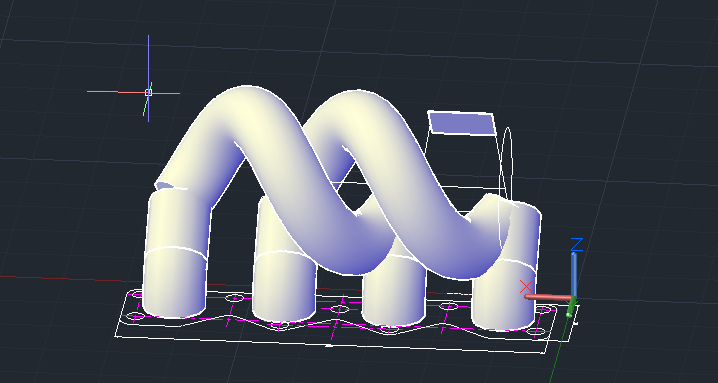

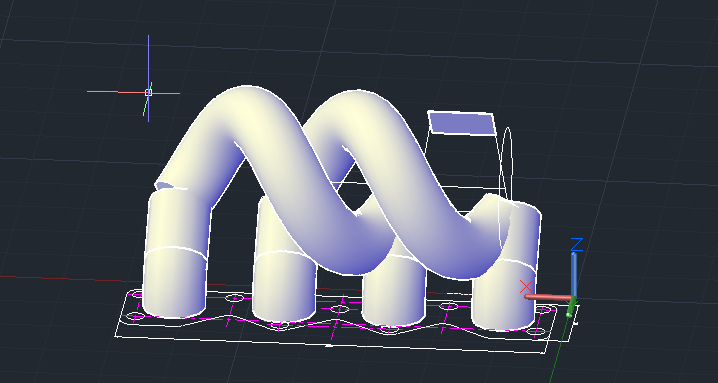

I'll need at least 20 45*elbows, but I really like the little runners and the double helix.

Am I just going to have to wait until I have the turbo in hand to figure out how to make it all fit in there? It would be nice if this was high enough to not need the whole relocation in the first place

Am I just going to have to wait until I have the turbo in hand to figure out how to make it all fit in there? It would be nice if this was high enough to not need the whole relocation in the first place

#32

yeaaaa I should just wait. It's not like my welding is up to par yet. I've seen dog turds smoother than my beads.

The measurements I've used are based on schedule 10 long radius bends. I did mess up and the radius of the helix portions though. They are the same radius as if you made a circle with the elbows, but if you stretch it out the length of the helix, the radius shrinks in. That's a fun bit of math I'll have to figure out.

I thought I'd ask about manifold design since this IS the DIY forum. I guess I have lots of time to figure out turbo placement and collector design

The measurements I've used are based on schedule 10 long radius bends. I did mess up and the radius of the helix portions though. They are the same radius as if you made a circle with the elbows, but if you stretch it out the length of the helix, the radius shrinks in. That's a fun bit of math I'll have to figure out.

I thought I'd ask about manifold design since this IS the DIY forum. I guess I have lots of time to figure out turbo placement and collector design

#33

Here's how I moved the heater core pipe. Flipped and welded the mixing manifold, added a -10 male 90* fitting. Attached a pushlock -10 to that and ran a hose up to the hard pipe. The hard pipe I welded up from 2 of the oem lines that normally run under the manifold. On the other end I also did a -10 fitting to pushlock, but I had converted the heater core to AN fittings as well after fighting with 3 different units and it still leaking. The little -6 line was for the turbo return fitting.

#34

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

I'll need at least 20 45*elbows, but I really like the little runners and the double helix.

Am I just going to have to wait until I have the turbo in hand to figure out how to make it all fit in there? It would be nice if this was high enough to not need the whole relocation in the first place

Am I just going to have to wait until I have the turbo in hand to figure out how to make it all fit in there? It would be nice if this was high enough to not need the whole relocation in the first place

Look at how simple barons or my manifold is, and you get it down low and a really good flowing downpipe.

#35

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

https://www.miataturbo.net/miata-par...-plates-85529/

im looking into possibly producing these in the future

im looking into possibly producing these in the future

#36

Do I have a reason? Not exactly. I've always been a fan of race pipes, and while this isn't actually as optimal as other designs, it sure looks that way. Call me crazy, but it's just too cool not to do. My philosophy with this car is that it's about fun, not being optimal (Like why the BRZ comes with the same tires as the Prius). Plus, it's refreshing to actually use some of this math I've spent years learning.

Thread

Thread Starter

Forum

Replies

Last Post

Schuyler

Miata parts for sale/trade

8

12-01-2016 04:45 PM