Need Some Manifold Suggestions.

#1

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

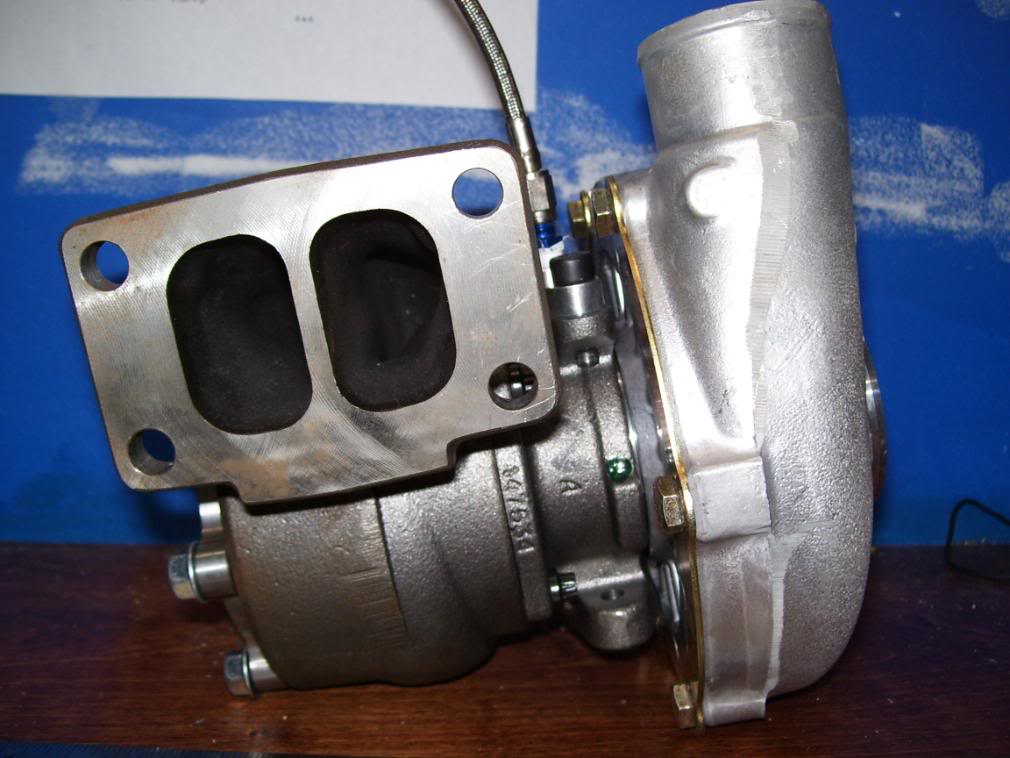

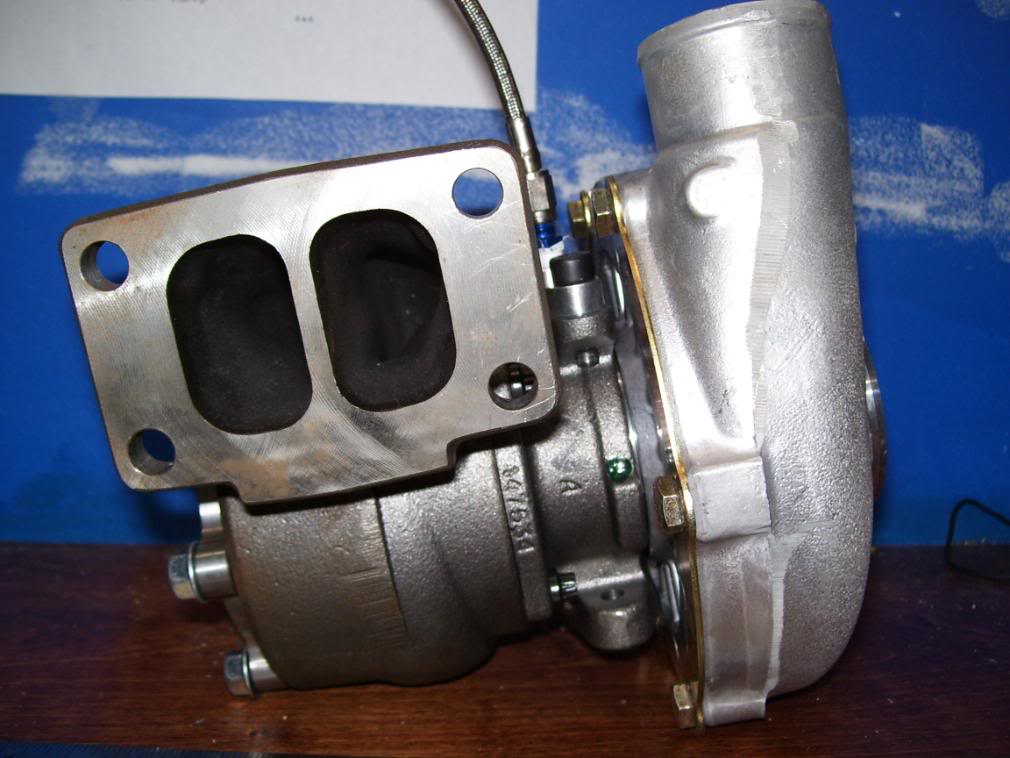

I can't decide what to do for a manifold for my turbo setup on my 99'. This is pretty much the last hurdle to get through though, thankfully. I have a new Garret GT3271 turbo I will be using. It's a T3 based turbo. I also have an old FM T2 based manifold in good shape. Problem is, T2  T3. Plus, it has no port for an external wastegate and my turbo is setup for external gate. I bought a new external gate and it should be here tomorrow.

T3. Plus, it has no port for an external wastegate and my turbo is setup for external gate. I bought a new external gate and it should be here tomorrow.

There are several options:

1) Buy a Begi S5 manifold for 519 bucks. It's externally gated, but they do so by welding on a port to the bottom. It's not actually cast into the manifold. So more likely to crack. Plus, I don't have the money for that manifold. And then there's dealing with Begi and waiting, etc. $519

2) Build a T2/T3 adapter plate to allow me to bolt my turbo to this manifold. I could also incorporate the external wastegate port into the adapter. Problems here are there are now more failure points. It puts the turbo hanging out at least 2" more than if it bolted right to the mani. But the good is I could use the manifold I got, and I've already ordered a T2 and T3 flange, so it would only take time to build it. Another plus is I wouldn't have to modify the FM manifold. $50

3) Modify the FM manifold and make it a T3 manifold. Looks doable to me. I'd have to fill the four M8 threaded holes in it somehow, and then redrill the manifold for a T3 flange, and then open up the port for it. There's plenty of metal to do so, but the 4 holes already being there is what makes this idea hard. No easy way to fill them. (suggestions?) And then I'd also have to cut it and add a port for the external gate. Probably copy how BEGI does it on the S5 manifold. But I can't weld to cast (tried and failed before... long story) so I'd have to take it to a welder. I know a welder that would do it, but it would probably cost 100 bucks if I made the adapter piece and handed it and the manifold to him to weld out. $130ish

4) Put my T2 manifold up for trade for a T3 w/external gate manifold. Kinda doubt anyone that had one would trade, and they seem rare to me. Probably never happen.

5) Sell the FM manifold and make my own. I could, and then there are several possibilities there as well. (log mani, absurdflow style, begi S4 style, fancy divided gases mani to accommodate the twin scroll turbo) But honestly I'm looking at this from a "get er done" perspective. I don't want to build a manifold right now if I don't have to. I'd just want to turbo this thing finally. If I sell the FM manifold, I could buy some weld ells and a header flange and make me a ghetto log manifold easy enough. But that would take a lot of work. Odds are, it would be easier to modify the FM manifold for T3 and external gate and the FM one would probably be better and more reliable. So if I build one, I should probably build a fancy one. But that goes against the get er done idea. I'd like to make turboing my car a weekend affair if at all possible. $200 ,but then sell the FM mani, so not too expensive.

I'm open for suggestions. I don't know what I'm gonna do.

Will post pics in a few.

T3. Plus, it has no port for an external wastegate and my turbo is setup for external gate. I bought a new external gate and it should be here tomorrow.

T3. Plus, it has no port for an external wastegate and my turbo is setup for external gate. I bought a new external gate and it should be here tomorrow.There are several options:

1) Buy a Begi S5 manifold for 519 bucks. It's externally gated, but they do so by welding on a port to the bottom. It's not actually cast into the manifold. So more likely to crack. Plus, I don't have the money for that manifold. And then there's dealing with Begi and waiting, etc. $519

2) Build a T2/T3 adapter plate to allow me to bolt my turbo to this manifold. I could also incorporate the external wastegate port into the adapter. Problems here are there are now more failure points. It puts the turbo hanging out at least 2" more than if it bolted right to the mani. But the good is I could use the manifold I got, and I've already ordered a T2 and T3 flange, so it would only take time to build it. Another plus is I wouldn't have to modify the FM manifold. $50

3) Modify the FM manifold and make it a T3 manifold. Looks doable to me. I'd have to fill the four M8 threaded holes in it somehow, and then redrill the manifold for a T3 flange, and then open up the port for it. There's plenty of metal to do so, but the 4 holes already being there is what makes this idea hard. No easy way to fill them. (suggestions?) And then I'd also have to cut it and add a port for the external gate. Probably copy how BEGI does it on the S5 manifold. But I can't weld to cast (tried and failed before... long story) so I'd have to take it to a welder. I know a welder that would do it, but it would probably cost 100 bucks if I made the adapter piece and handed it and the manifold to him to weld out. $130ish

4) Put my T2 manifold up for trade for a T3 w/external gate manifold. Kinda doubt anyone that had one would trade, and they seem rare to me. Probably never happen.

5) Sell the FM manifold and make my own. I could, and then there are several possibilities there as well. (log mani, absurdflow style, begi S4 style, fancy divided gases mani to accommodate the twin scroll turbo) But honestly I'm looking at this from a "get er done" perspective. I don't want to build a manifold right now if I don't have to. I'd just want to turbo this thing finally. If I sell the FM manifold, I could buy some weld ells and a header flange and make me a ghetto log manifold easy enough. But that would take a lot of work. Odds are, it would be easier to modify the FM manifold for T3 and external gate and the FM one would probably be better and more reliable. So if I build one, I should probably build a fancy one. But that goes against the get er done idea. I'd like to make turboing my car a weekend affair if at all possible. $200 ,but then sell the FM mani, so not too expensive.

I'm open for suggestions. I don't know what I'm gonna do.

Will post pics in a few.

#4

I don't suggest making an adapter for your FM manifold to adapt it to a T3 mostly because once you do I have a feeling the turbo will be sticking out so far you will have to more than substantially trim the shelf to clear the turbo.

JGS Precision Turbo

That is a good solid manifold, not optimal for flow but it is for a T3, it places the turbo forward which is good for building a downpipe, and the wastegate flange is integrated.

JGS Precision Turbo

That is a good solid manifold, not optimal for flow but it is for a T3, it places the turbo forward which is good for building a downpipe, and the wastegate flange is integrated.

#5

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Here's what I got right now.

Yeah, it is a divided gas turbine, .78 A/R. This summer when I have time and money I'll build a nice manifold that puts cylinders 1&4 combining into one side of the turbine, 2&3 into the other. But for now, I just want to turbo it and be boosted.

So that JGS manifold would be a kit manifold. Hmm. Not bad I guess. Something to consider. But that's about 220 shipped, then I gotta weld it all out. But I could sell the FM manifold to recoup some of the cost.

Chad, i think you're right. By the time I made the adapter and all, it would put the turbo in a bad place and make everything harder then it needs to be.

Yeah, it is a divided gas turbine, .78 A/R. This summer when I have time and money I'll build a nice manifold that puts cylinders 1&4 combining into one side of the turbine, 2&3 into the other. But for now, I just want to turbo it and be boosted.

So that JGS manifold would be a kit manifold. Hmm. Not bad I guess. Something to consider. But that's about 220 shipped, then I gotta weld it all out. But I could sell the FM manifold to recoup some of the cost.

Chad, i think you're right. By the time I made the adapter and all, it would put the turbo in a bad place and make everything harder then it needs to be.

#7

Well, I bought flanges from wiertech to build my own. Got a nice Miller TIG at home. I'm going to build a T2 for myself. Maybe you just ship me yours for dimensions and your T3 flange and I will build you a T3 instead of a T2 for me. I'll supply the weld els and the flange and labor. Swap you for the T2 cast unit. That way you can get exactly what you want, esternal WG where you want it, etc. Well, not the 1-4 2-3 thing but everything where you want it.

#14

Elite Member

iTrader: (5)

Join Date: Jul 2006

Location: Central California

Posts: 2,536

Total Cats: 4

since you already have a downpipe, you are going to need to make sure that the manifold you buy will be compatable. I know the discharge flange of that turbo can be rotated around which should help, but some manifolds have the turbo sit up higher than others and that is something you need to consider.

#15

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Ok, so now I've come up with option 6.

Right now the manifold has four threaded holes in it for a T2 turbo to bolt up. But there's enough flange there to accommodate a T3 layout. I'm guessing the manifold was cast so that it could be drilled and tapped for T2 or T3. Only it was tapped for T2.

Only it was tapped for T2.

Two problems. One, I can't just drill and tap four new holes. Almost can, but can't. The new ones wouldn't quite be far enough away to not interfere with the old ones, which would make drilling and taping very hard. Plus it wouldn't be as strong if part of the threads had no metal around them.

Option 6) I have access to a bunch drill bits and reamers. I'm thinking I could drill out the old threaded bolt holes and then ream it to say half a thousandth undersize of 3/8". Then, press in some 3/8 round stock with lock-tite to help secure it. Now I got metal everywhere. Give it a day for the lock-tite to cure, and now I can drill and tap the area for the new T3 flanged turbo. I think this part would be pretty straight forward and very reliable once it's done. I think this is the answer. Does anyone see any pitfalls I'm overlooking?

Second problem is I would have to account for an external wastegate somehow. I could just copy what BEGI does on their S5 manifold. Drill a big hole in the bottom of the manifold and have some Godblessed welder weld it to the cast manifold. I know a few badass welders.

This would give me a cast iron manifold that would allow my T3 to bolt right up as if it was originally a t3 manifold. In fact, nobody would ever know it wasn't once the turbo's bolted up. Clean and simple installation just like normal. Only weld to fail would be the pipe to cast iron weld for the external W/G, and this I'll have done by some expert welder. I think this is the thing to do. Seems it would flow better and be more reliable then a log manifold. And look better too.

This could all be done with a drill, drill bits, and a 3/8 tap. I have everything I'll need except the 3/8 round stock and 1/2 thousandth under 3/8" reamer, both which my machinist has that he would loan me. I can't see this taking too long. Overall very little fabrication involved. Just a little machine work.

Any reason not to do it this way? Am I overlooking anything?

Right now the manifold has four threaded holes in it for a T2 turbo to bolt up. But there's enough flange there to accommodate a T3 layout. I'm guessing the manifold was cast so that it could be drilled and tapped for T2 or T3.

Only it was tapped for T2.

Only it was tapped for T2. Two problems. One, I can't just drill and tap four new holes. Almost can, but can't. The new ones wouldn't quite be far enough away to not interfere with the old ones, which would make drilling and taping very hard. Plus it wouldn't be as strong if part of the threads had no metal around them.

Option 6) I have access to a bunch drill bits and reamers. I'm thinking I could drill out the old threaded bolt holes and then ream it to say half a thousandth undersize of 3/8". Then, press in some 3/8 round stock with lock-tite to help secure it. Now I got metal everywhere. Give it a day for the lock-tite to cure, and now I can drill and tap the area for the new T3 flanged turbo. I think this part would be pretty straight forward and very reliable once it's done. I think this is the answer. Does anyone see any pitfalls I'm overlooking?

Second problem is I would have to account for an external wastegate somehow. I could just copy what BEGI does on their S5 manifold. Drill a big hole in the bottom of the manifold and have some Godblessed welder weld it to the cast manifold. I know a few badass welders.

This would give me a cast iron manifold that would allow my T3 to bolt right up as if it was originally a t3 manifold. In fact, nobody would ever know it wasn't once the turbo's bolted up. Clean and simple installation just like normal. Only weld to fail would be the pipe to cast iron weld for the external W/G, and this I'll have done by some expert welder. I think this is the thing to do. Seems it would flow better and be more reliable then a log manifold. And look better too.

This could all be done with a drill, drill bits, and a 3/8 tap. I have everything I'll need except the 3/8 round stock and 1/2 thousandth under 3/8" reamer, both which my machinist has that he would loan me. I can't see this taking too long. Overall very little fabrication involved. Just a little machine work.

Any reason not to do it this way? Am I overlooking anything?

#17

I think the loctite will fail under heat. If you are going to go this route, drill out the holes, have some cast plugs welded in by the badass welders so you don't have to deal with drilling and tapping dissimilar metals and then retap the holes where you want them.

If you want to go cheap, take some cheap grade 2 bolts, run them into the threaded holes as hard as you can so they bind up in the holes where the thread ran out. This will help them resist spinning when you drill and tap the overlapping holes. Cut them off flush, have the welder tack them if you want some extra security and then redrill. If you don't want to do any welding on the studs, you can drill and ream a small dowel hole that overlaps the threads of the plug to the mani and drive in a dowel or roll pin. That would also keep the plugs from turning. Normally on steel to steel you can just center punch around the plug to peen it in but I woudn't do that on cast. I wouldn't use grade 5 because they would be too hard when you try to drill and tap the new holes. They could cause your drill to walk and your pattern may be off. The grade 2 should cut and tap OK where they overlap.

Or sell me your mani.

If you want to go cheap, take some cheap grade 2 bolts, run them into the threaded holes as hard as you can so they bind up in the holes where the thread ran out. This will help them resist spinning when you drill and tap the overlapping holes. Cut them off flush, have the welder tack them if you want some extra security and then redrill. If you don't want to do any welding on the studs, you can drill and ream a small dowel hole that overlaps the threads of the plug to the mani and drive in a dowel or roll pin. That would also keep the plugs from turning. Normally on steel to steel you can just center punch around the plug to peen it in but I woudn't do that on cast. I wouldn't use grade 5 because they would be too hard when you try to drill and tap the new holes. They could cause your drill to walk and your pattern may be off. The grade 2 should cut and tap OK where they overlap.

Or sell me your mani.

Last edited by Stein; 11-06-2008 at 05:42 PM. Reason: Edited for even more awesome info.

#18

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Well the idea was that a 1/2 thousandth press fit would permanently anchor the rod into the manifold, filling the hole. Using lock-tite is probably pointless but i figured it could only help. The new "filling" only needs to stay put long enough to drill and tap the new holes. I'm sure the lock-tite will be defeated once the manifold is heat cycled, but then it won't be doing anything anyway.

FWIW, I'm not gonna press in oil hardened drill rod. Just some regular, hot roll steel. Yeah, it will be a little bit harder to machine then cast, but they are pretty similar.

FWIW, I'm not gonna press in oil hardened drill rod. Just some regular, hot roll steel. Yeah, it will be a little bit harder to machine then cast, but they are pretty similar.