Annealed aluminum line + miata engine

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2005

Location: Mass.

Posts: 811

Total Cats: 43

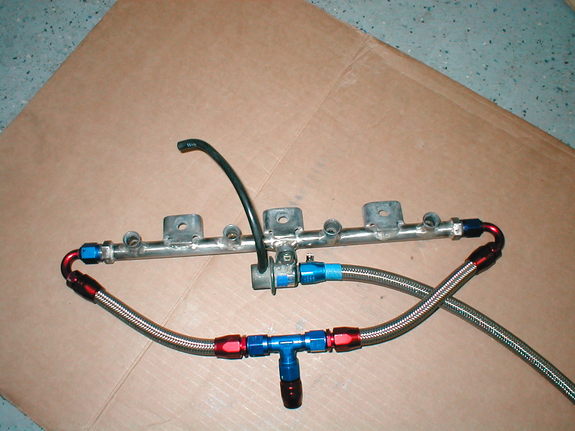

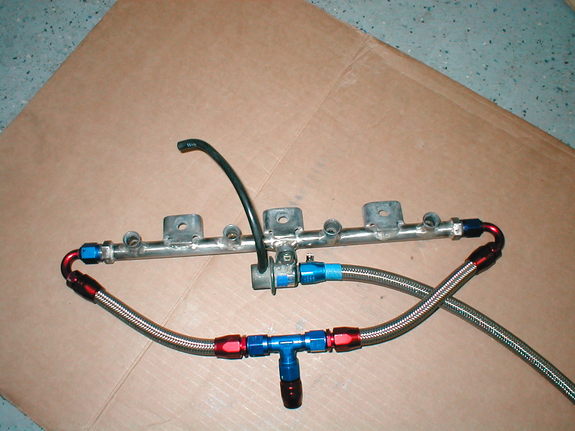

On a scale of 1 to 10, how f--king stupid am I for trying to do this:

on a balance shaftless vibrating turd that is the Mazda 1.6?

I see annealed aluminum used all the time on local cars for EFI, however, with people on here claiming their hard coolant lines have failed, I'm concerned I maybe building the car up only to have it burn to the ground.

I convinced myself it would be fine since the line is very short and rigidly mounted at both ends - flex isn't an issue.

-Zach

on a balance shaftless vibrating turd that is the Mazda 1.6?

I see annealed aluminum used all the time on local cars for EFI, however, with people on here claiming their hard coolant lines have failed, I'm concerned I maybe building the car up only to have it burn to the ground.

I convinced myself it would be fine since the line is very short and rigidly mounted at both ends - flex isn't an issue.

-Zach

#2

On a scale of 1 to 10, how f--king stupid am I for trying to do this:

on a balance shaftless vibrating turd that is the Mazda 1.6?

I see annealed aluminum used all the time on local cars for EFI, however, with people on here claiming their hard coolant lines have failed, I'm concerned I maybe building the car up only to have it burn to the ground.

I convinced myself it would be fine since the line is very short and rigidly mounted at both ends - flex isn't an issue.

-Zach

on a balance shaftless vibrating turd that is the Mazda 1.6?

I see annealed aluminum used all the time on local cars for EFI, however, with people on here claiming their hard coolant lines have failed, I'm concerned I maybe building the car up only to have it burn to the ground.

I convinced myself it would be fine since the line is very short and rigidly mounted at both ends - flex isn't an issue.

-Zach

Or, instead of trying to engineer it, just go buy some SS braided hose along with some peace of mind.

#3

I have aluminum line running the full length of the car from fuel pump to regulator.

If you engineer it properly, protect it from damage, and inspect it regularly, I would say you will be fine.

There is nothing wrong with taking calculated risks when engineering a lighter, faster car. If it becomes a failure point, move up to stainless.

I know it is legal for the track use I am doing. Check to make sure it is legal for any track use you may do with the sanctioning body you participate in.

If you engineer it properly, protect it from damage, and inspect it regularly, I would say you will be fine.

There is nothing wrong with taking calculated risks when engineering a lighter, faster car. If it becomes a failure point, move up to stainless.

I know it is legal for the track use I am doing. Check to make sure it is legal for any track use you may do with the sanctioning body you participate in.

#5

Aluminum is weak and subject to fatigue cracking. Hard lines that carry combustibles (gasoline or oil) and are subject to vibration should be steel.

Flexible lines are always a safe option too. If a line is subject to movement, it must be flexible. Keep in mind that AN fittings are made in both anodized aluminum and steel. Engine-mounted fuel lines should use steel AN fittings.

A hard aluminum fuel line mounted to the chassis is OK as long as it's reasonably protected.

All of the above is approved aircraft practice. FAA AC43.13-1B can be downloaded here and has a wealth of readable, useful information:

http://www1.airweb.faa.gov/Regulator...E?OpenDocument

Flexible lines are always a safe option too. If a line is subject to movement, it must be flexible. Keep in mind that AN fittings are made in both anodized aluminum and steel. Engine-mounted fuel lines should use steel AN fittings.

A hard aluminum fuel line mounted to the chassis is OK as long as it's reasonably protected.

All of the above is approved aircraft practice. FAA AC43.13-1B can be downloaded here and has a wealth of readable, useful information:

http://www1.airweb.faa.gov/Regulator...E?OpenDocument

Last edited by hornetball; 07-27-2012 at 10:02 AM.

#8

Aluminum is weak and subject to fatigue cracking. Hard lines that carry combustibles (gasoline or oil) and are subject to vibration should be steel.

Flexible lines are always a safe option too. If a line is subject to movement, it must be flexible. Keep in mind that AN fittings are made in both anodized aluminum and steel. Engine-mounted fuel lines should use steel AN fittings.

A hard aluminum fuel line mounted to the chassis is OK as long as it's reasonably protected.

All of the above is approved aircraft practice. FAA AC43.13-1B can be downloaded here and has a wealth of readable, useful information:

AC 43.13-1B CHG 1 [Large AC. This includes Change 1.] Acceptable Methods, Techniques, and Practices - Aircraft Inspection and Repair

Flexible lines are always a safe option too. If a line is subject to movement, it must be flexible. Keep in mind that AN fittings are made in both anodized aluminum and steel. Engine-mounted fuel lines should use steel AN fittings.

A hard aluminum fuel line mounted to the chassis is OK as long as it's reasonably protected.

All of the above is approved aircraft practice. FAA AC43.13-1B can be downloaded here and has a wealth of readable, useful information:

AC 43.13-1B CHG 1 [Large AC. This includes Change 1.] Acceptable Methods, Techniques, and Practices - Aircraft Inspection and Repair

#9

Steel fittings are over kill, they dont see much bending loads so they wont see much fatigue loading except from the cycling of the fuel pressure. That line might have an issue but my gut doesnt say so, if it worries you, support it in the middle with a little bracket and a proper tube clamp support for that size. Yes aluminum fatigues, but if you limit the the fatigue stress you can achieve essentially infinite life, do you know how long it takes to reach 10^8 cycles for most cyclic loading scenarios?

And its annealed so its fatigue properties should be better than normal aluminum though to be honest, I'm not sure if you can even get non-annealed Al tubing.

And its annealed so its fatigue properties should be better than normal aluminum though to be honest, I'm not sure if you can even get non-annealed Al tubing.

Last edited by Leafy; 07-27-2012 at 12:48 PM.

#12

Flex isnít an issue but vibration is very bad and aluminum not very fatigue resistant to high frequency vibration. I have cracked seemed steel hard lines used for turbo oil with similar length to that. Also interesting that one of my current work projects is measuring strain on fuel hard lines on a diesel engine and trying to come up with a mass damper system to keep them from cracking due to vibration.

FWIW my setup below.

FWIW my setup below.

#14

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2005

Location: Mass.

Posts: 811

Total Cats: 43

Thanks for the input guys. Its one of those situations where I think I could get away with it - for a while. This being said, I've gone out of my way to throw reliable parts at the car (minus the manifold, derk) so with that mindset, I should probably just switch it over to braided line and worry about other things.

It does look purty though

-Zach

It does look purty though

-Zach

Thread

Thread Starter

Forum

Replies

Last Post

elesjuan

Build Threads

9

11-14-2018 12:18 PM

Rudes333

Miata parts for sale/trade

17

11-05-2015 01:16 PM

SuperSneakySecretSquirrel

Meet and Greet

5

09-06-2015 08:30 PM