ARP Main stud install

#1

Elite Member

Thread Starter

iTrader: (4)

Join Date: Aug 2009

Location: Redwood City, CA

Posts: 1,784

Total Cats: 42

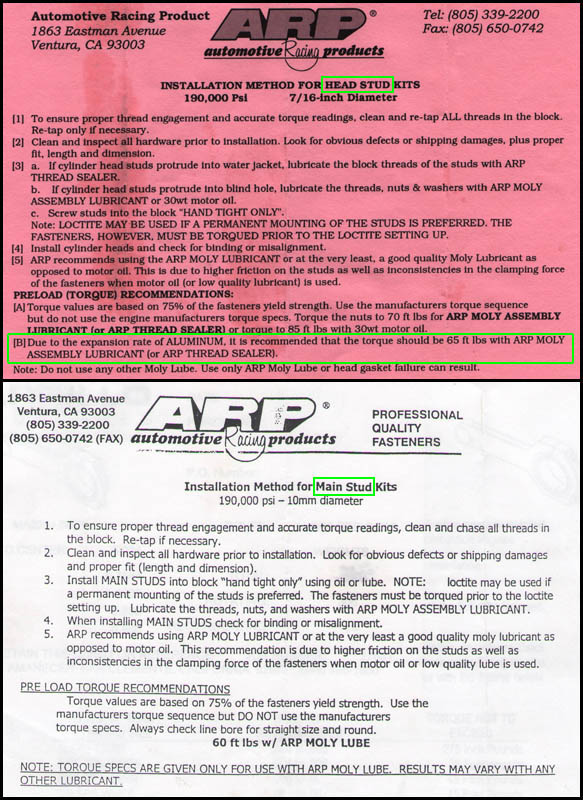

The instructions that come with the studs say to hand tighten the studs into the block, and then it says to torque the nuts to spec. Am I not supposed to torque the studs into the block to a certain torque spec? It has a hole for a hex key on one side of the stud so I'm assuming that it should be tightened to xx ft lbs, but figured I'd ask. I'm just paranoid that the studs would somehow loosen out of the block.

Opinions/suggestions?

Opinions/suggestions?

#4

It is like 5-10 ft/lbs

once the caps are installed, and the washer and nuts installed, then torqued to spec they will not just fall out the block.

The same tourque applied to the nut and stud, is applied to the thread engagement of the stud threads and the threads in the block.

Big thing is to make sure the bolt holes and threads are clean.

once the caps are installed, and the washer and nuts installed, then torqued to spec they will not just fall out the block.

The same tourque applied to the nut and stud, is applied to the thread engagement of the stud threads and the threads in the block.

Big thing is to make sure the bolt holes and threads are clean.

#5

Elite Member

Thread Starter

iTrader: (4)

Join Date: Aug 2009

Location: Redwood City, CA

Posts: 1,784

Total Cats: 42

It is like 5-10 ft/lbs

once the caps are installed, and the washer and nuts installed, then torqued to spec they will not just fall out the block.

The same tourque applied to the nut and stud, is applied to the thread engagement of the stud threads and the threads in the block.

Big thing is to make sure the bolt holes and threads are clean.

once the caps are installed, and the washer and nuts installed, then torqued to spec they will not just fall out the block.

The same tourque applied to the nut and stud, is applied to the thread engagement of the stud threads and the threads in the block.

Big thing is to make sure the bolt holes and threads are clean.

#9

I like that answer much better.

I sat in a seminar at PRI a few years back, and listened to Smoky say: "in no way should the end of the stud hit the bottom of the hole."

When the stud is bottomed out, the stud will **** over to one side, when you tighten the nut, you just bent the stud, side loaded the nut, and tried to move the device you are trying to clamp.

I sat in a seminar at PRI a few years back, and listened to Smoky say: "in no way should the end of the stud hit the bottom of the hole."

When the stud is bottomed out, the stud will **** over to one side, when you tighten the nut, you just bent the stud, side loaded the nut, and tried to move the device you are trying to clamp.

#10

Elite Member

Thread Starter

iTrader: (4)

Join Date: Aug 2009

Location: Redwood City, CA

Posts: 1,784

Total Cats: 42

So I'm supposed to leave the stud loose in its hole and tighten the nut with a loose stud? I have a copy of those instructions that came with the studs, but I think "handtight" is a little vague for such a critical component.

#11

ARP-bolts.com | ARP Quick Catalog Viewer

Page 49

Hand tight is all you need.

The allen socket on the top of the stud is for removing them.

Page 49

Hand tight is all you need.

The allen socket on the top of the stud is for removing them.

#12

Elite Member

Thread Starter

iTrader: (4)

Join Date: Aug 2009

Location: Redwood City, CA

Posts: 1,784

Total Cats: 42

Well then. Handtightened the studs with my fingers, used the lube provided, and torqued the nuts to 60 ftlbs. I guess I'll find out if I did it wrong when my crank goes through the oil pan.

#16

Senior Member

iTrader: (10)

Join Date: Aug 2007

Location: Fredericton, NB

Posts: 1,186

Total Cats: 4

I would like to add that a re-torque after a couple heat cycles is good added measure for brand new ARP head studs as well.

Loosen each stud a quarter to an eighth of a turn and re-torque one at a time in proper sequence (when engine has cooled of course).

This could be argued as not needed, but gives me added confidence.

Loosen each stud a quarter to an eighth of a turn and re-torque one at a time in proper sequence (when engine has cooled of course).

This could be argued as not needed, but gives me added confidence.

#17

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,224

Total Cats: 1,145

I've been told that with rod studs, as you want to torque to seat the spline in the rod, then release and torque again a final time.

However for head studs, you're not seating a spline, and with any torque spec, you're turning the fastener into a spring to hold itself in place.

Martinez, remember that although you're twisting the nut onto the stud, you're technically applying an upwards force on the block threads, so unless you there's some crap on your threads or they're damaged, it shouldn't tighten the studs into the block any more.

However for head studs, you're not seating a spline, and with any torque spec, you're turning the fastener into a spring to hold itself in place.

Martinez, remember that although you're twisting the nut onto the stud, you're technically applying an upwards force on the block threads, so unless you there's some crap on your threads or they're damaged, it shouldn't tighten the studs into the block any more.

Thread

Thread Starter

Forum

Replies

Last Post

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM

--Ferdi

--Ferdi