BackYard Straight Edge

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

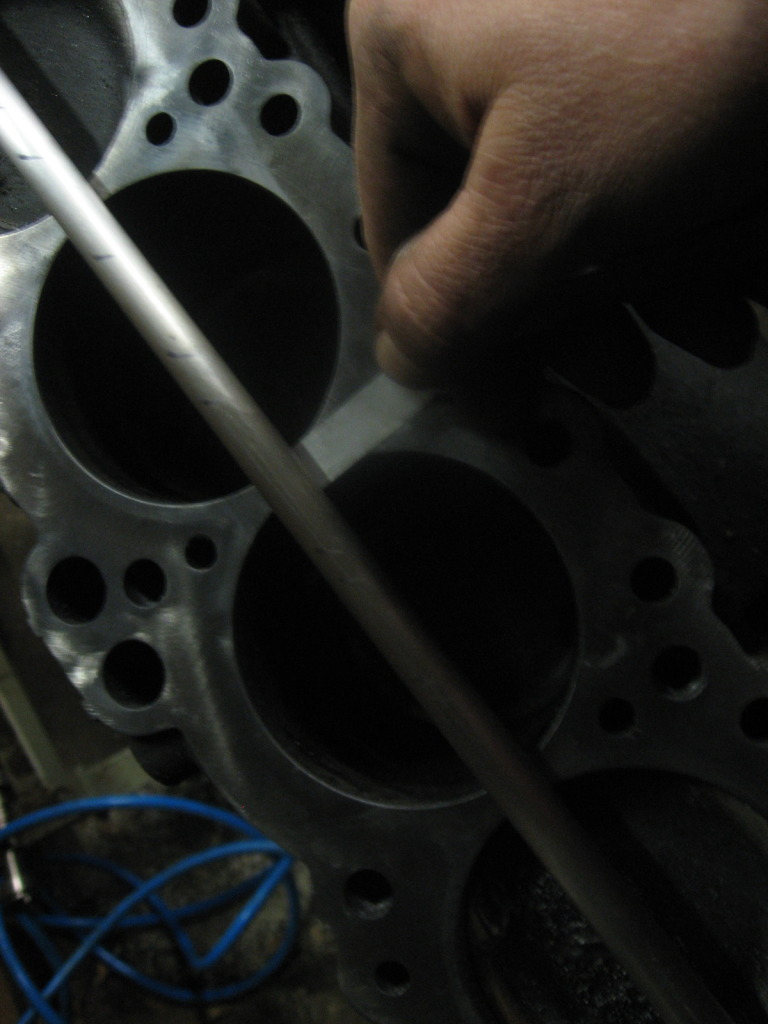

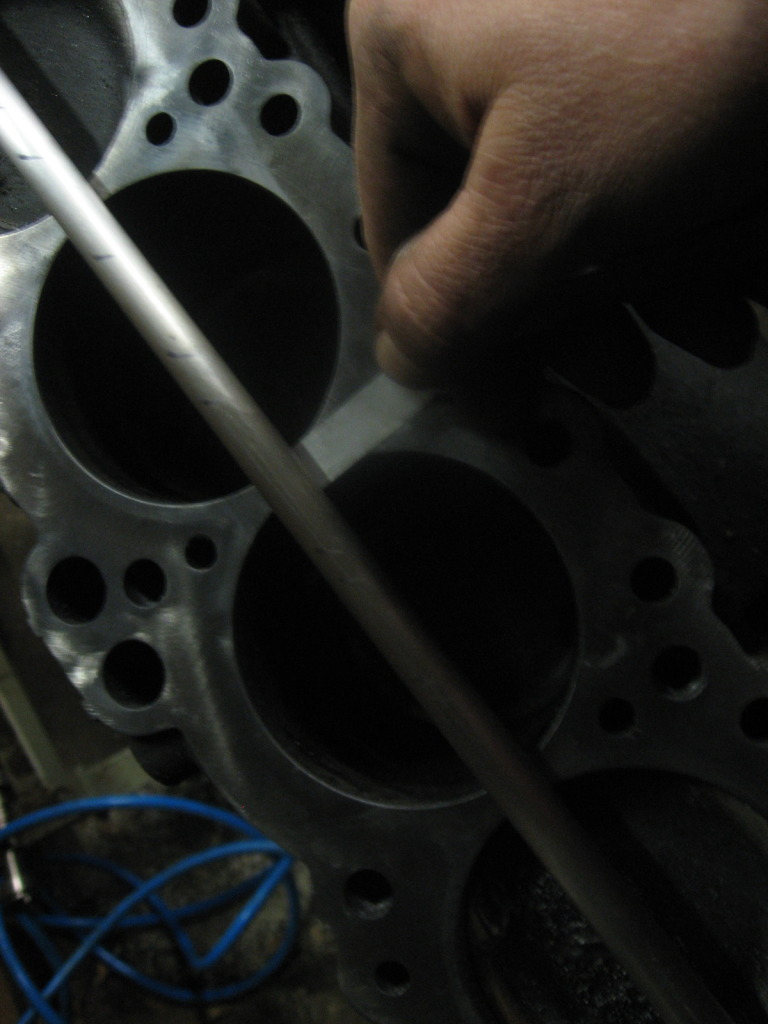

I know not everyone has a machinist straight edge in with the tools they own.

This is not the most accuate check But it should be close enough to help you decide if a MLS will seal or the block needs to come out and me milled flat.

Tools needed

20" or longer extention, 1/2 perfered.

Decent set of feeler gauges

.0015, .002, .0025, .003

Sharpie marker

A good know flat item, a piece of glass or mom's glass top table work best.

Pull out the .0015 feeler gauge.

Lay the extention on the glass, make sure the square drive end hangs off the edge.

Take the feeler gauge, and check the extention for bow.

Spin the extention untill you can not get the .0015 feeler gauge under it.

Once the feeler gauge will not go under the extention, take the sharpie marker and mark the top.

You are now read to check your block, head, intake mani or anything else you need for warp.

For Head gaskets

MLS if the .0015/.002 slides under, get the part milled, or go to a composite

Composite, if a .003 or more slides under, get part milled.

About any flange with a warp of .005 or more, needs closer inspection, and a good chance of being milled

This is not the most accuate check But it should be close enough to help you decide if a MLS will seal or the block needs to come out and me milled flat.

Tools needed

20" or longer extention, 1/2 perfered.

Decent set of feeler gauges

.0015, .002, .0025, .003

Sharpie marker

A good know flat item, a piece of glass or mom's glass top table work best.

Pull out the .0015 feeler gauge.

Lay the extention on the glass, make sure the square drive end hangs off the edge.

Take the feeler gauge, and check the extention for bow.

Spin the extention untill you can not get the .0015 feeler gauge under it.

Once the feeler gauge will not go under the extention, take the sharpie marker and mark the top.

You are now read to check your block, head, intake mani or anything else you need for warp.

For Head gaskets

MLS if the .0015/.002 slides under, get the part milled, or go to a composite

Composite, if a .003 or more slides under, get part milled.

About any flange with a warp of .005 or more, needs closer inspection, and a good chance of being milled

#3

Bogus... I don't know you, and I'm new here, but I want to say thanks for sharing your knowledge and tips/tricks with us. Not only are you sharing, but you're taking quite a bit of time to take pictures and write explanations... For free! I'd go out of my way to support your business just because of this, and I'm sure others feel the same!

#4

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Maiter, Frumby Thanks!

I been wrenching on cars for 25 years or so, and doing machine shop work for 20.

I have seen some horrid things, and many WTF was that shop doing.

This write up is so a guy can decide if he can bolt a head back down on a weekend, or hold off and get it machined.

I been wrenching on cars for 25 years or so, and doing machine shop work for 20.

I have seen some horrid things, and many WTF was that shop doing.

This write up is so a guy can decide if he can bolt a head back down on a weekend, or hold off and get it machined.

#5

Can I ask a stupid question? You'll have to forgive me since I'm a degree'd engineer, ie dumber than a bag of rocks...

I've read this a few times and it didn't make any sense to me until just now.

The point of marking the extension is to show the areas that are flat enough to use to judge a head? Is that correct. ie only use the areas "marked" to measure against your head (or whatever other surface)?

Sorry, i dumb

I've read this a few times and it didn't make any sense to me until just now.

The point of marking the extension is to show the areas that are flat enough to use to judge a head? Is that correct. ie only use the areas "marked" to measure against your head (or whatever other surface)?

Sorry, i dumb

#6

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

The mark is to show 180* from the area that will be used for the straight edge.

After it is checked and you find the least distorted part of the extention, the marks will be up, so the down surface is used for checking.

After it is checked and you find the least distorted part of the extention, the marks will be up, so the down surface is used for checking.

#7

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,189

Total Cats: 1,135

I don't particularly like this concept, as it assumes that you're marking the point under an arch that is .001" above the surface. However that arch, and therefore the gap, changes depending on how much or how little of the arch is hanging off each edge.

Am I completely off base? I know this is a "backyard machinist" method, but still.

Am I completely off base? I know this is a "backyard machinist" method, but still.

#8

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Curly, that is correct, if there is an arch to the extention, the top of the arch can be less if the contact points are close, or more the further they are apart.

This method, is crude at best.

It is ment to let you know something more than a guess.

If you check the extention on glass, and can not get a .0015 feeler under it along the length of it.

Then go check a head, and can slip a .006 under it. That lets you know to shop and get it surfaced.

But if you go to the head, and a .0015 will not slip under, then AT your own risk can choose to bolt it down.

This method, is crude at best.

It is ment to let you know something more than a guess.

If you check the extention on glass, and can not get a .0015 feeler under it along the length of it.

Then go check a head, and can slip a .006 under it. That lets you know to shop and get it surfaced.

But if you go to the head, and a .0015 will not slip under, then AT your own risk can choose to bolt it down.

Thread

Thread Starter

Forum

Replies

Last Post

JesseTheNoob

DIY Turbo Discussion

15

09-30-2015 02:44 PM