Honda intake manifold

#663

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

I would wager the welds were the culprit. Proper prep is key for welding Al. Not to mention the possibility that there wasnt enough penetration, especially if the welder was trying to make the welds "pretty".

#666

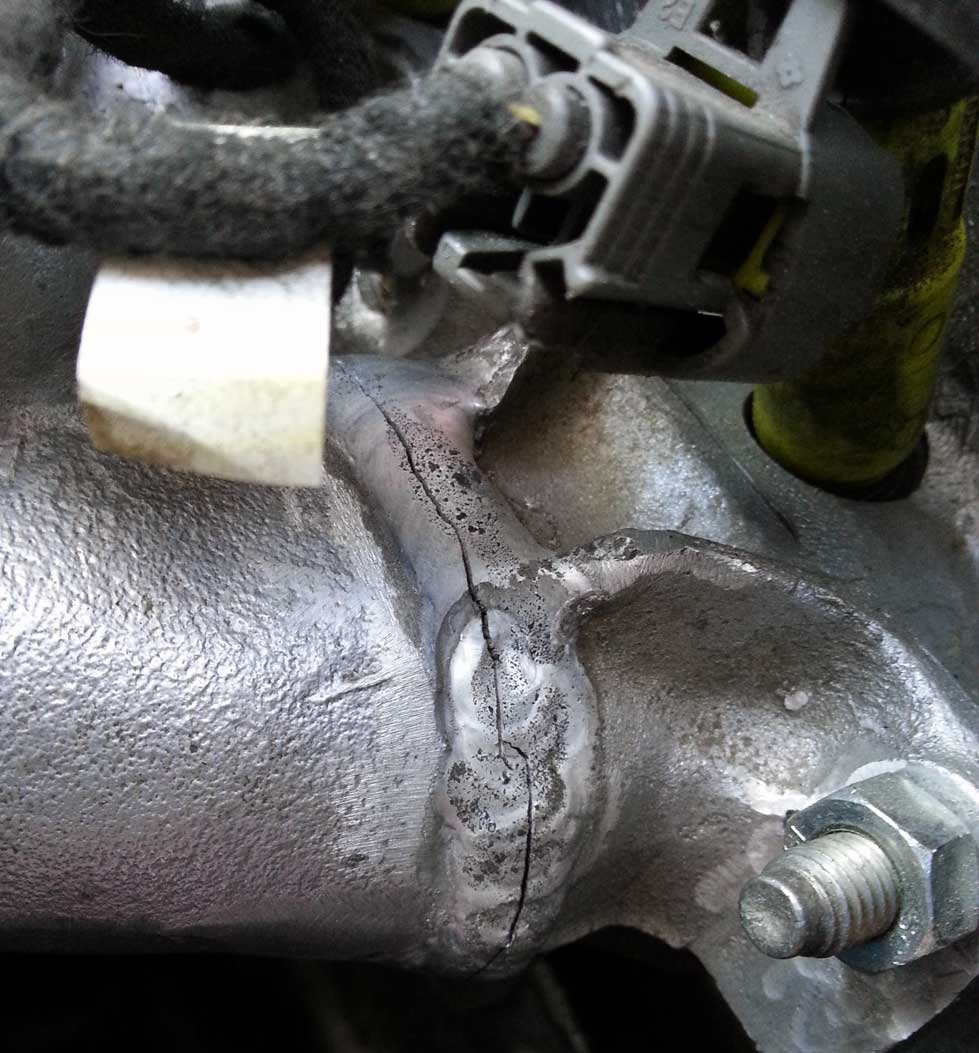

The welds cracked right down the middle. They had great penetration. There is just to much weight hanging and leverage on them.

Maybe the delrin mounts played a role.

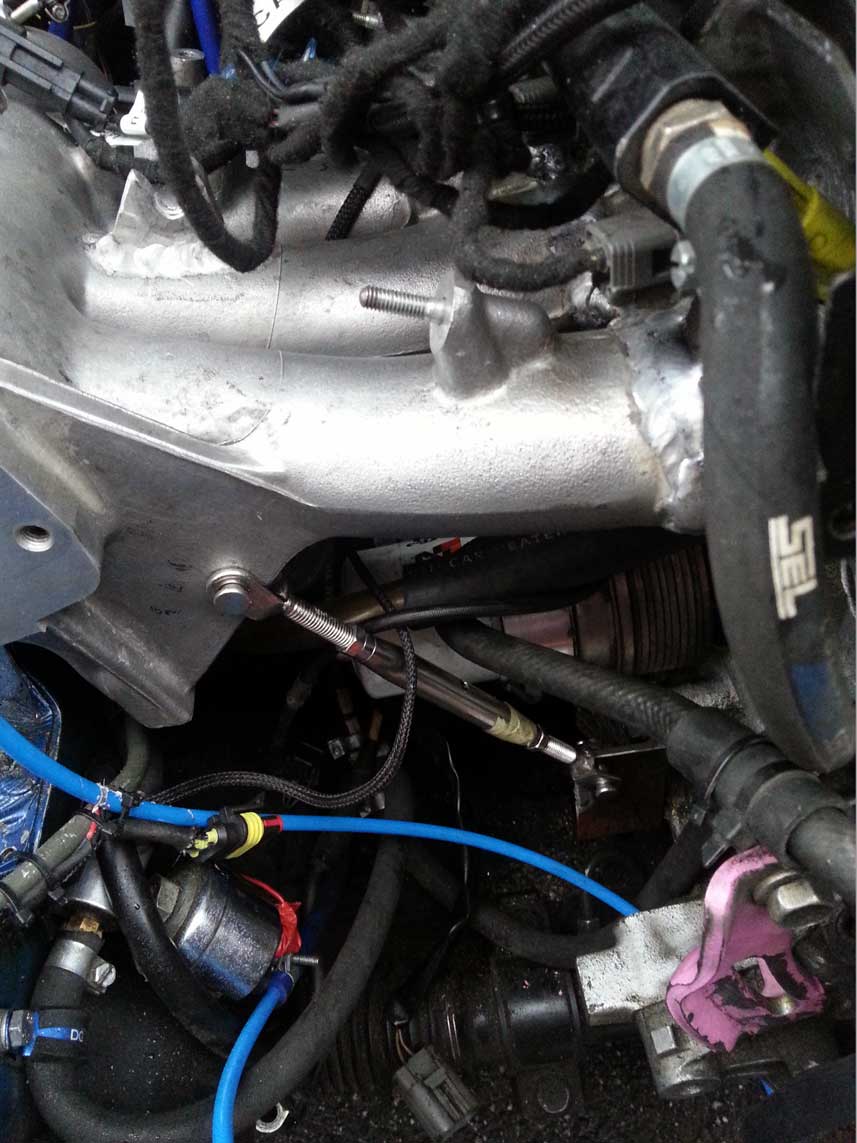

We will also be supporting it from underneath with a brace. Gonna make sure we have zero problems going forward.

Maybe the delrin mounts played a role.

We will also be supporting it from underneath with a brace. Gonna make sure we have zero problems going forward.

#670

No one til now has braced these things, and so far we have 2 documented failures: 1 for sure was crappy welding, the other apparently not but who would know for sure?

That said I don't have anything against bracing them either.

Last edited by 18psi; 05-20-2013 at 09:58 AM.

#674

To be honest I was not surprised it cracked. I just expected it too take longer.

Those that question the quality of the welds or weld material just need to look at how the rest of the car is built to get a reference for the work we do.

Heed the warnings or ignor them. It's up to you.

FWIW V2.0 is being done by the head fabricator at a race shop that services million dollar plus vintage formula one cars. It was his recommendation for the bracing etc.

Those that question the quality of the welds or weld material just need to look at how the rest of the car is built to get a reference for the work we do.

Heed the warnings or ignor them. It's up to you.

FWIW V2.0 is being done by the head fabricator at a race shop that services million dollar plus vintage formula one cars. It was his recommendation for the bracing etc.