Inconsistent fuel pressure & Radium pulse damper

#1

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

OK, so as documented in my build thread (https://www.miataturbo.net/build-thr...5/#post1242401), I've recently converted my 99 from the stock NB pressure regulator setup to use an FM "BFK". AEM regulator mounted where the filter normally goes, -6 AN lines, deleting the fender-mounted pulse damper. Walbro pump, older FM dual-port rail, ID1000s, MS3.

With the stock regulator & pulse damper, the Walbro was overwhelming the FPR at idle, but under boost the injectors leaked enough that it worked well. Logging the fuel pressure, the stock system kept it between 60 and 61 psi.

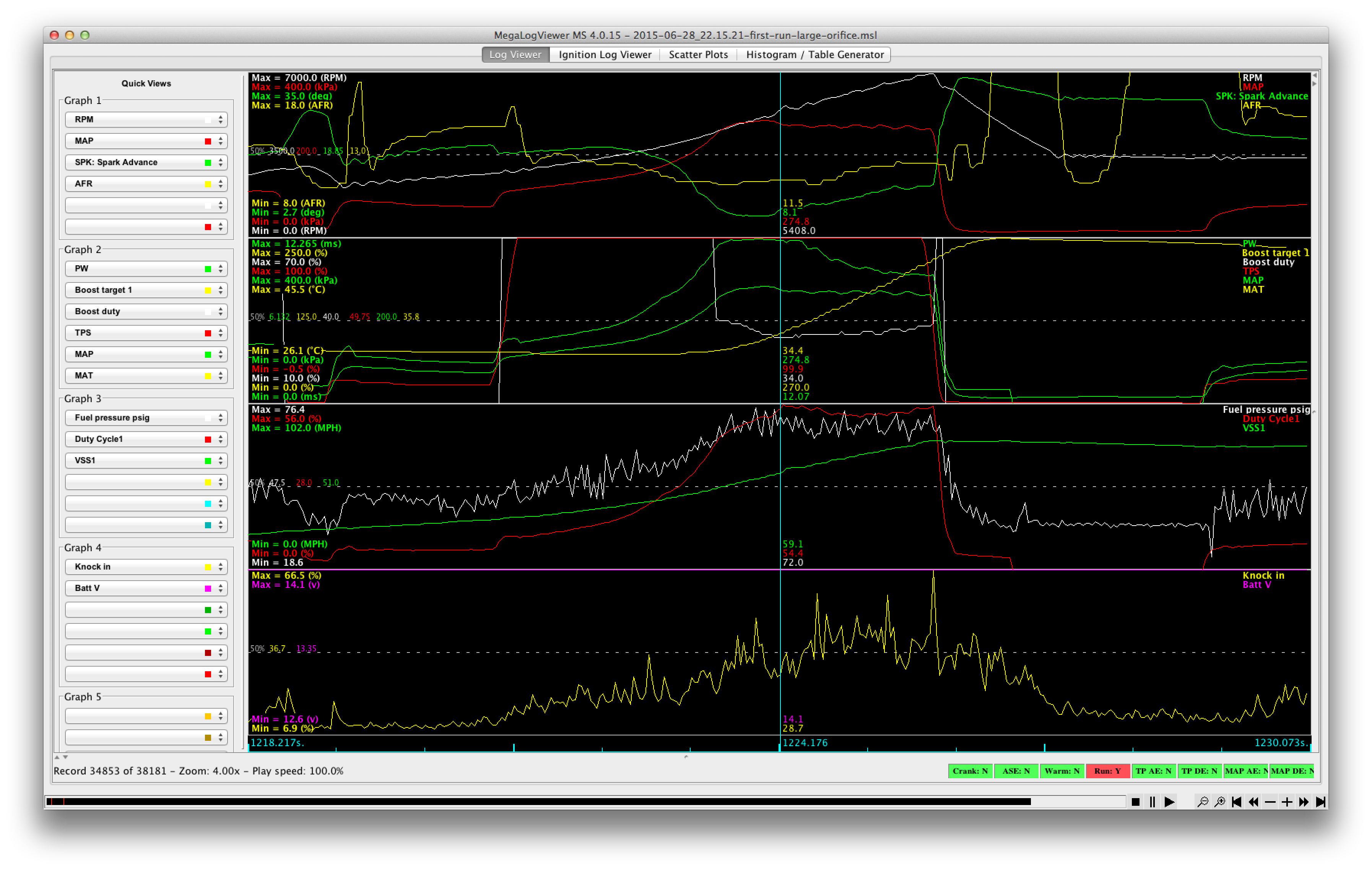

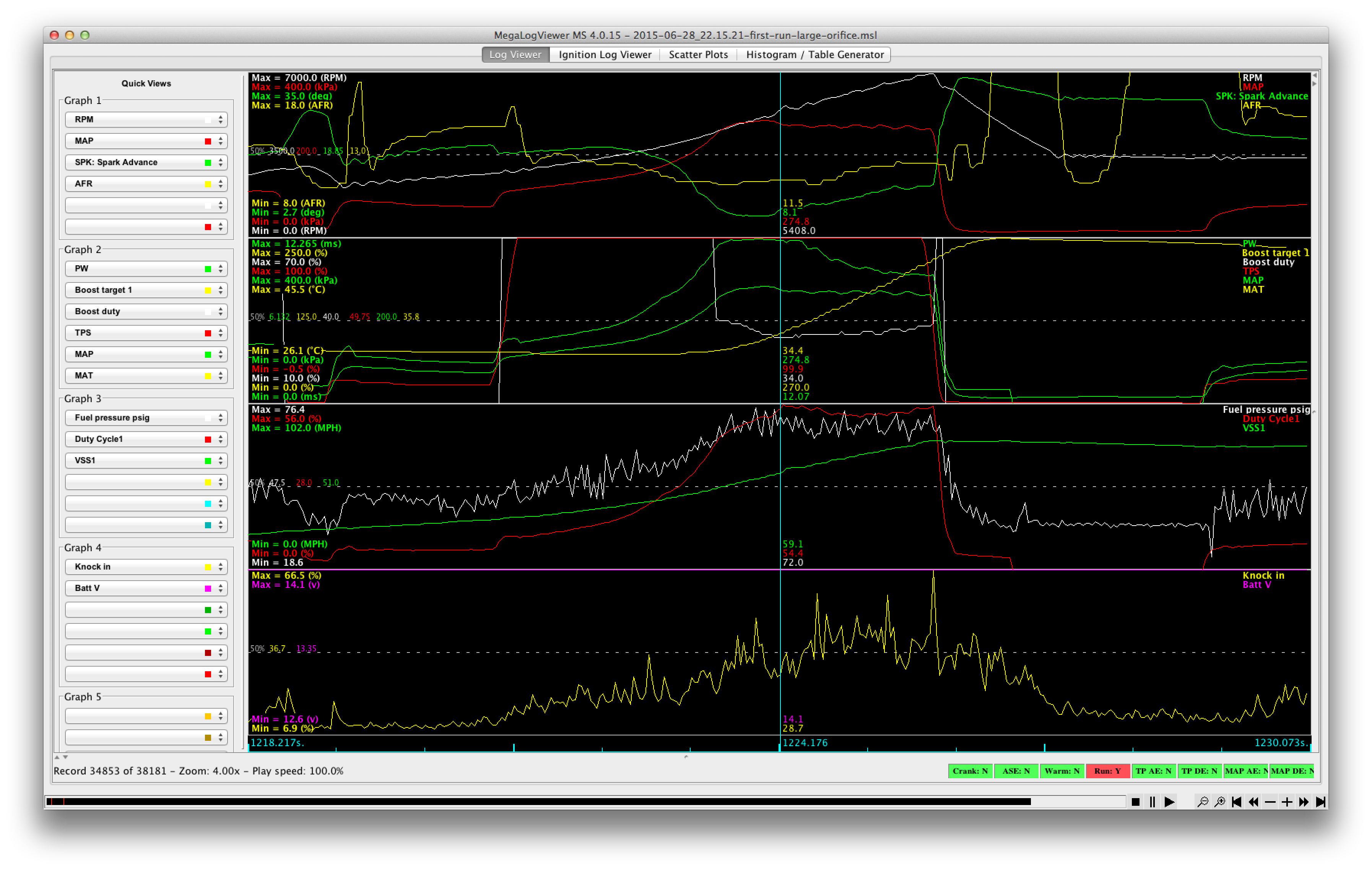

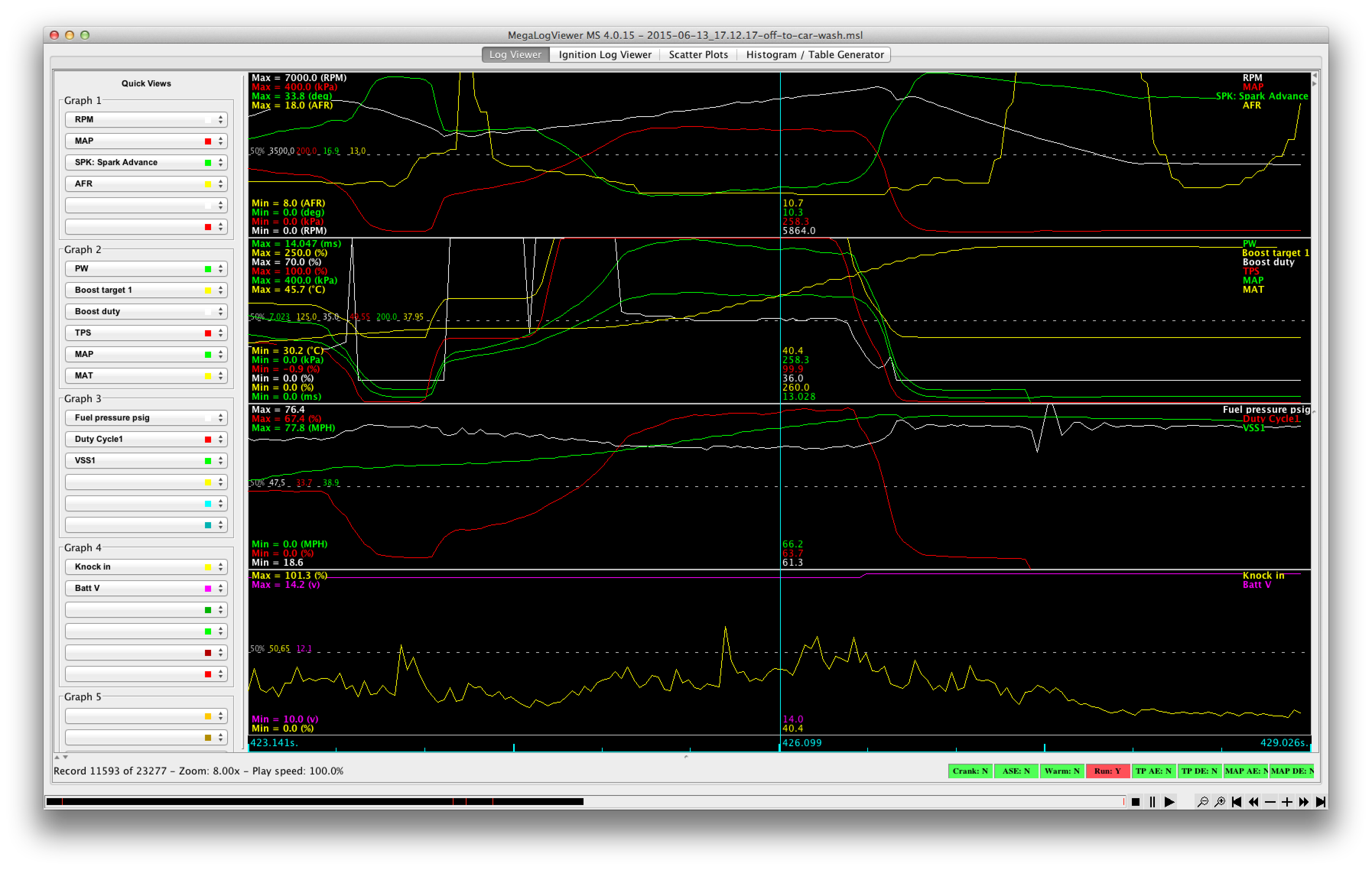

With the AEM, I now have a reasonable idle fuel pressure (plus I can vacuum reference it), but it's giving me very noisy fuel under boost, wavering by 15 psi at 270 kpa MAP (white trace in graph #3):

So I'm thinking I need a pulse damper again. I've still got the rail mounted one, but the fender mounted one would need a bunch of fittings and adapters to go into the AN lines, plus it's 5/16 rather than the -6 AN lines. So poking around on the net I found this:

https://www.radiumauto.com/Blog/Post...lse-Dampers-90

Anyone know anything about it?

--Ian

With the stock regulator & pulse damper, the Walbro was overwhelming the FPR at idle, but under boost the injectors leaked enough that it worked well. Logging the fuel pressure, the stock system kept it between 60 and 61 psi.

With the AEM, I now have a reasonable idle fuel pressure (plus I can vacuum reference it), but it's giving me very noisy fuel under boost, wavering by 15 psi at 270 kpa MAP (white trace in graph #3):

So I'm thinking I need a pulse damper again. I've still got the rail mounted one, but the fender mounted one would need a bunch of fittings and adapters to go into the AN lines, plus it's 5/16 rather than the -6 AN lines. So poking around on the net I found this:

https://www.radiumauto.com/Blog/Post...lse-Dampers-90

Anyone know anything about it?

--Ian

#4

NBs have *two* dampers, one on the rail, one on the fender. The regulator has to sense the drop in pressure and mechanically adjust for it, the more volume there is after it, the larger the lag introduced before it can do that. Putting the regulator on the rail gives it very little lag, so it can respond to injector events more quickly.

AIUI, wideband O2 sensors don't have the response time of a lot of other sensors. The fuel pressure sensor I'm using will do 1KHz, widebands aren't anything like that. That's part of the reason it appears more solid, but yeah, I'm concerned about pressure drop for individual injectors making individual cylinders go lean.

--Ian

AIUI, wideband O2 sensors don't have the response time of a lot of other sensors. The fuel pressure sensor I'm using will do 1KHz, widebands aren't anything like that. That's part of the reason it appears more solid, but yeah, I'm concerned about pressure drop for individual injectors making individual cylinders go lean.

--Ian

Also given the fact that you're running 1,000 cc injectors, I'm sure some pressure drop is going to be unavoidable but I guess the damper would still help.

Are you using the dual port functionality of the rail? I run a stock rail and it's single feed. I wonder if your experience would change by feeding it only from one end? I dunno how easy or difficult that would be for your to test.

#5

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Hmmm. Now I'm gonna go look, I don't remember seeing a damper on my fuel rail, it's a 2003 fuel rail though, let me check. I know I had a fender one and it's gone now.

Also given the fact that you're running 1,000 cc injectors, I'm sure some pressure drop is going to be unavoidable but I guess the damper would still help.

Are you using the dual port functionality of the rail? I run a stock rail and it's single feed. I wonder if your experience would change by feeding it only from one end? I dunno how easy or difficult that would be for your to test.

Also given the fact that you're running 1,000 cc injectors, I'm sure some pressure drop is going to be unavoidable but I guess the damper would still help.

Are you using the dual port functionality of the rail? I run a stock rail and it's single feed. I wonder if your experience would change by feeding it only from one end? I dunno how easy or difficult that would be for your to test.

I'm "using" the dual port functionality in the sense that it's hooked up at both ends. There's a -6 AN line coming forward from the tank, and in the vicinity of the intake manifold it goes into a tee with a line that feeds the pressure sensor. The other outlet of the tee is attached to a second tee that then has lines feeding each end of the rail.

The rail looks like this:

The elbows on each end are the two feed lines. The pulse damper is mounted underneath, in the center, and isn't visible.

The tee fittings look like this:

The feed line is the one with the straight, blue hose end and the the plastic ribbing covering up the braided line. The right-angle fitting at the top of the photo goes to the sensor. The silver tee at the bottom goes to the two feed lines which branch off right and left.

--Ian

#6

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>

</p><p>On the 2003 fuel rail the damper is where the regulator is on NA cars.</p>

Hmmm. Now I'm gonna go look, I don't remember seeing a damper on my fuel rail, it's a 2003 fuel rail though, let me check. I know I had a fender one and it's gone now. Also given the fact that you're running 1,000 cc injectors, I'm sure some pressure drop is going to be unavoidable but I guess the damper would still help. Are you using the dual port functionality of the rail? I run a stock rail and it's single feed. I wonder if your experience would change by feeding it only from one end? I dunno how easy or difficult that would be for your to test.

#7

The AEM regulator has known issues in the Honda community, I'm sure the form and function of your regulator is similar. I have never owned an AEM regulator so I cannot comment on the quality or issues.

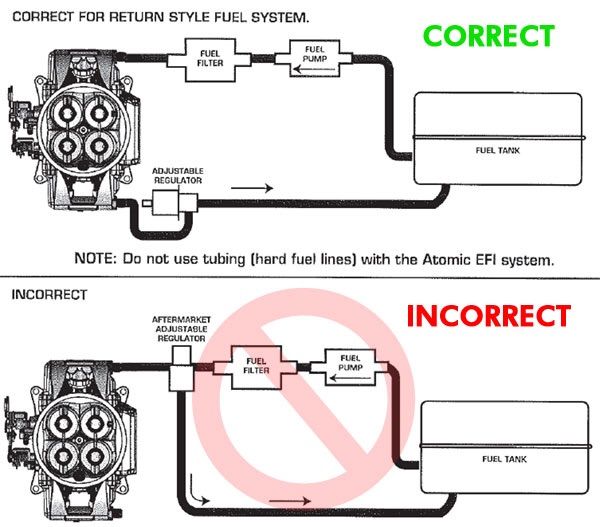

In an idealsystem you would have the regulator plumbed AFTER the fuel rail, I believe the dual feed rails is a step down and still acts as a dead end rather than a true regulated system.

In an idealsystem you would have the regulator plumbed AFTER the fuel rail, I believe the dual feed rails is a step down and still acts as a dead end rather than a true regulated system.

#13

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

As for the routing, yes, the FPR could be used as a 2-port regulator if desired, but it is specifically designed to be capable of being used as a 3-port regulator as well.

--Ian

#15

He does have a point- the regulator that regulates pressure WOULD work better the closer you can get it to the fuel injectors. I'm not saying it's the cause of your spikes, it's probably not, but it would regulate and dampen better being closer. I never liked where FM put the regulator in their fuel kit. I guess it makes for an easy install but not ideal.

#17

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

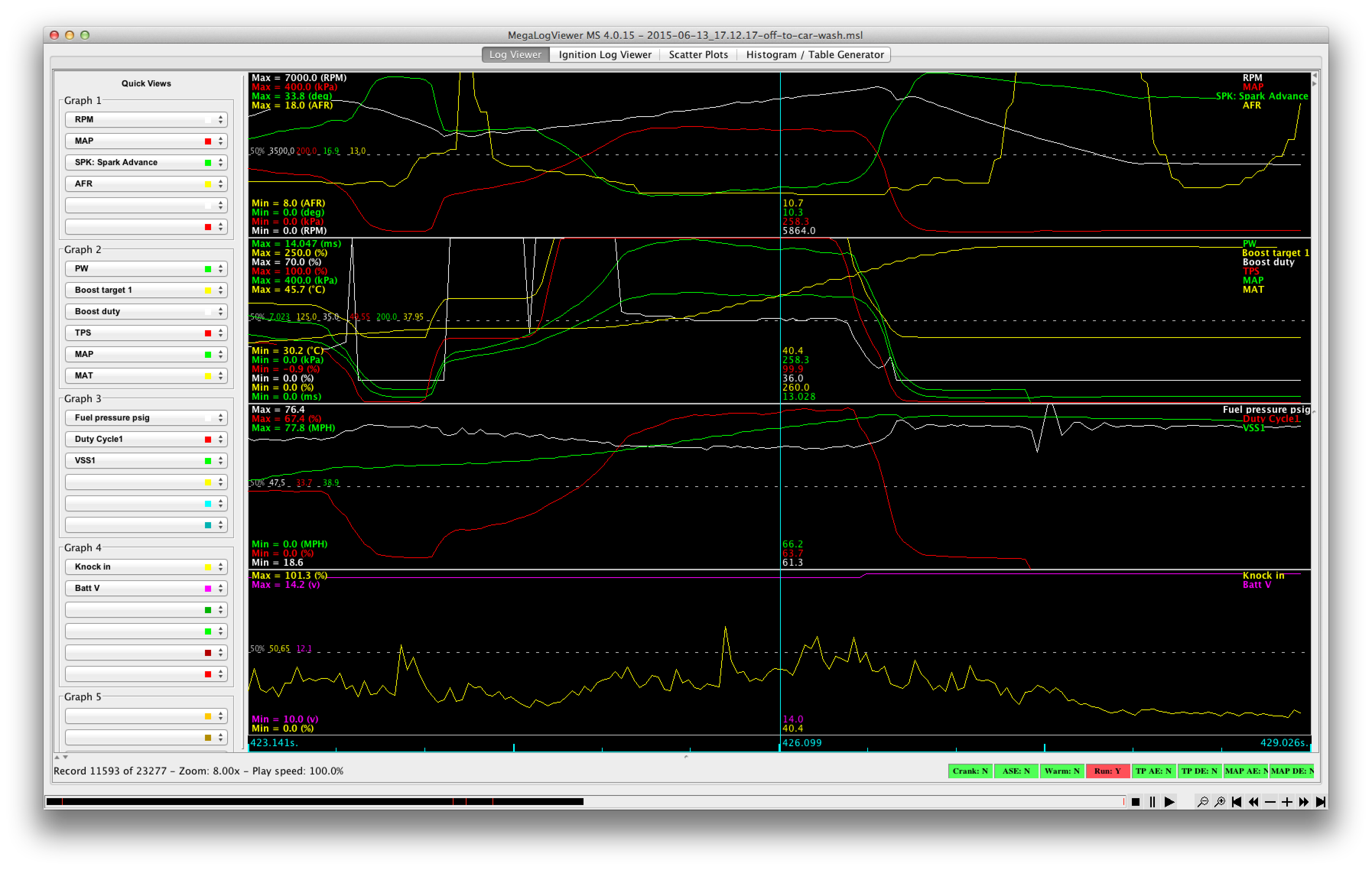

Here's a datalog of the factory regulator, with the range on the fuel pressure forced to the same delimiters as the ones in the previous image. Once again it's the white line in the 3rd graph, look at the part where it's in boost, in the center under the plateau of the duty cycle.

Yes, it's moving around outside of that range, that's because the Walbro pump is overwhelming the factory regulator, which is the whole reason I put in the AEM.

--Ian

Yes, it's moving around outside of that range, that's because the Walbro pump is overwhelming the factory regulator, which is the whole reason I put in the AEM.

--Ian

#18

I would at least try moving the regulator to the correct spot. That's absolutely not how that's supposed to be used, and that's definitely not how the Mazda return systems works.

I don't use a pulsation damper on the MX6 and don't have these problems. My regulator is mounted "after" the rail, though. I do run upwards of 80psi rail pressure at full boost.

I don't use a pulsation damper on the MX6 and don't have these problems. My regulator is mounted "after" the rail, though. I do run upwards of 80psi rail pressure at full boost.

Last edited by concealer404; 06-30-2015 at 09:03 AM.

#20

It looks to me that the difference between the 2 is that the "incorrect" version will regulate pressure at the outlet of the FPR; the pressure at the rail will be the pressure at the FPR minus the pressure drop in the line from the FPR to the rail.

This pressure drop will be proportional to flow (power) and inversely with the size of the line. If the line is big, then the pressure drop will be small. This pressure drop characteristic will be consistent for a given line, and will be baked into the fuel table during tuning.

I don't see how the "correct" version will reduce pressure spikes in the line, unless the FPR can absorb them (i.e. act like a damper), and is mounted close to the fuel rail (in either the "correct" or "incorrect" version).

This pressure drop will be proportional to flow (power) and inversely with the size of the line. If the line is big, then the pressure drop will be small. This pressure drop characteristic will be consistent for a given line, and will be baked into the fuel table during tuning.

I don't see how the "correct" version will reduce pressure spikes in the line, unless the FPR can absorb them (i.e. act like a damper), and is mounted close to the fuel rail (in either the "correct" or "incorrect" version).