The new "definitive catch can" thread

#81

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,656

Total Cats: 3,011

With the setup where both vents are connected to a vented catch can.

Do you have to change the PCV one way valve into a normal fitting instead? (and you have to tap a new AN fitting to it?)

Since without manifold vacuum,the one way valve could act differently?

But I guess if the pcv is vented to the atmosphere(catch can), it would be similar to WOT, where intake manifold would be at almost atmospheric? and the PCV valve would open fully?

Do you have to change the PCV one way valve into a normal fitting instead? (and you have to tap a new AN fitting to it?)

Since without manifold vacuum,the one way valve could act differently?

But I guess if the pcv is vented to the atmosphere(catch can), it would be similar to WOT, where intake manifold would be at almost atmospheric? and the PCV valve would open fully?

#83

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,656

Total Cats: 3,011

I tapped it for a NPT thread and screwed in a fitting with a hose barb on the outside. It won't be under any pressure so unless you are a fan of ridiculously overpriced AN gear or just like the way they look there's no concrete need.

#86

Junior Member

Join Date: Dec 2015

Location: Brisbane, Queensland, Australia

Posts: 213

Total Cats: 67

I'm about to drop all my bits to the engine builder for assembly, and I have three -10AN weldon fittings in the box of bits. One is for the oil drain for the turbo, and the other two are ear-marked for the valve cover. I plan to leave the PCV side as is, and run a small air-oil separator in line.

For the hotside, I am considering placing the two other fittings on top at either end of the internal baffle plate, each of which will run to a vented catch can.

The 'tiny hole mod' seems to be the most commonly done thing to increase flow through the factory baffling in the valve cover, Sometimes a second 'tiny hole' is added.

The alternative is to simply cut a suitable hole in the middle of the hotside baffle plate in the middle, essentially bypassing the VC baffles and turning that plate into a simple splash guard.

I read in another thread that Shuiend had done this, and he'd posted a link to the post where he made this modification. I was in for results, but what I got instead was five destroyed engines and nothing (that I could find) about the effectiveness of a holey baffle plate.

So - does anyone have real world experience with the effectiveness of converting the hotside baffle to a splash guard and two -10an/large vents from this?

For context, the engine will have a EFR6758 and will be producing around 400hp give or take a gearbox or so.

For the hotside, I am considering placing the two other fittings on top at either end of the internal baffle plate, each of which will run to a vented catch can.

The 'tiny hole mod' seems to be the most commonly done thing to increase flow through the factory baffling in the valve cover, Sometimes a second 'tiny hole' is added.

The alternative is to simply cut a suitable hole in the middle of the hotside baffle plate in the middle, essentially bypassing the VC baffles and turning that plate into a simple splash guard.

I read in another thread that Shuiend had done this, and he'd posted a link to the post where he made this modification. I was in for results, but what I got instead was five destroyed engines and nothing (that I could find) about the effectiveness of a holey baffle plate.

So - does anyone have real world experience with the effectiveness of converting the hotside baffle to a splash guard and two -10an/large vents from this?

For context, the engine will have a EFR6758 and will be producing around 400hp give or take a gearbox or so.

#87

Motivated by @George Jorge post on his build thread, I would like to have some experiences as it regards VVT catch can setup.

Basically stock engine, plus Rotrex C30-74, 90% street use.

My plan was to run the stock PCV on the passenger side, but intercept a sealed catch can between that and the IM. Stock size lines, as it will be effectively shut when in boost, and no significant blow-by is expected when in vacuum, so they should suffice. Remove baffles, add copper scrubbers, enlarge baffle holes/passages to 10mm or so, seal baffles again. I was also planning to enlarge the hot side vent and ran a 8AN line to a VTA catch can on this side; but according to the aforementioned thread (and @Savington ) that seems like a bad idea.

What do?

Basically stock engine, plus Rotrex C30-74, 90% street use.

What do?

#88

Elite Member

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,045

Total Cats: 265

Motivated by @George Jorge post on his build thread, I would like to have some experiences as it regards VVT catch can setup.

Basically stock engine, plus Rotrex C30-74, 90% street use.

My plan was to run the stock PCV on the passenger side, but intercept a sealed catch can between that and the IM. Stock size lines, as it will be effectively shut when in boost, and no significant blow-by is expected when in vacuum, so they should suffice. Remove baffles, add copper scrubbers, enlarge baffle holes/passages to 10mm or so, seal baffles again. I was also planning to enlarge the hot side vent and ran a 8AN line to a VTA catch can on this side; but according to the aforementioned thread (and @Savington ) that seems like a bad idea.

What do?

Basically stock engine, plus Rotrex C30-74, 90% street use.

My plan was to run the stock PCV on the passenger side, but intercept a sealed catch can between that and the IM. Stock size lines, as it will be effectively shut when in boost, and no significant blow-by is expected when in vacuum, so they should suffice. Remove baffles, add copper scrubbers, enlarge baffle holes/passages to 10mm or so, seal baffles again. I was also planning to enlarge the hot side vent and ran a 8AN line to a VTA catch can on this side; but according to the aforementioned thread (and @Savington ) that seems like a bad idea.

What do?

#89

I have a Mishimoto compact can hooked up between the valve and the IM. The exhaust side is connected via a -12 outlet to it's own large vented can. In a 20 minute session the PCV can is half full (1.5 fl oz.) and sucking oil through the brass filter inside the mishi can into the intake. Zero oil in the exhaust side. I just cap the PCV side for track work now. Sav has mentioned this before to cap the IM side but I like to keep the PCV hooked up just for street use.

That's running 13psi/270hp on track with a fresh built engine. I'm intrigued to play around with baffling (not just scouring pads) on the PCV side to limit the amount of oil that can get into the chamber which I believe is a combination of oil slosh and IM suction. Maybe weld in some cheese grater style walls or something inside the chamber but that's way down the to-do list

That's running 13psi/270hp on track with a fresh built engine. I'm intrigued to play around with baffling (not just scouring pads) on the PCV side to limit the amount of oil that can get into the chamber which I believe is a combination of oil slosh and IM suction. Maybe weld in some cheese grater style walls or something inside the chamber but that's way down the to-do list

#91

i just pull the hose off the IM barb and use a silicone cap on the barb.

The hose to the catch can just swings in the wind. Without vacuum to pull the PCV valve open itís not venting at all in this configuration and I just let the -12 exhaust vent do all the work.

The hose to the catch can just swings in the wind. Without vacuum to pull the PCV valve open itís not venting at all in this configuration and I just let the -12 exhaust vent do all the work.

Last edited by AussieMSM; 09-26-2020 at 05:20 AM.

#92

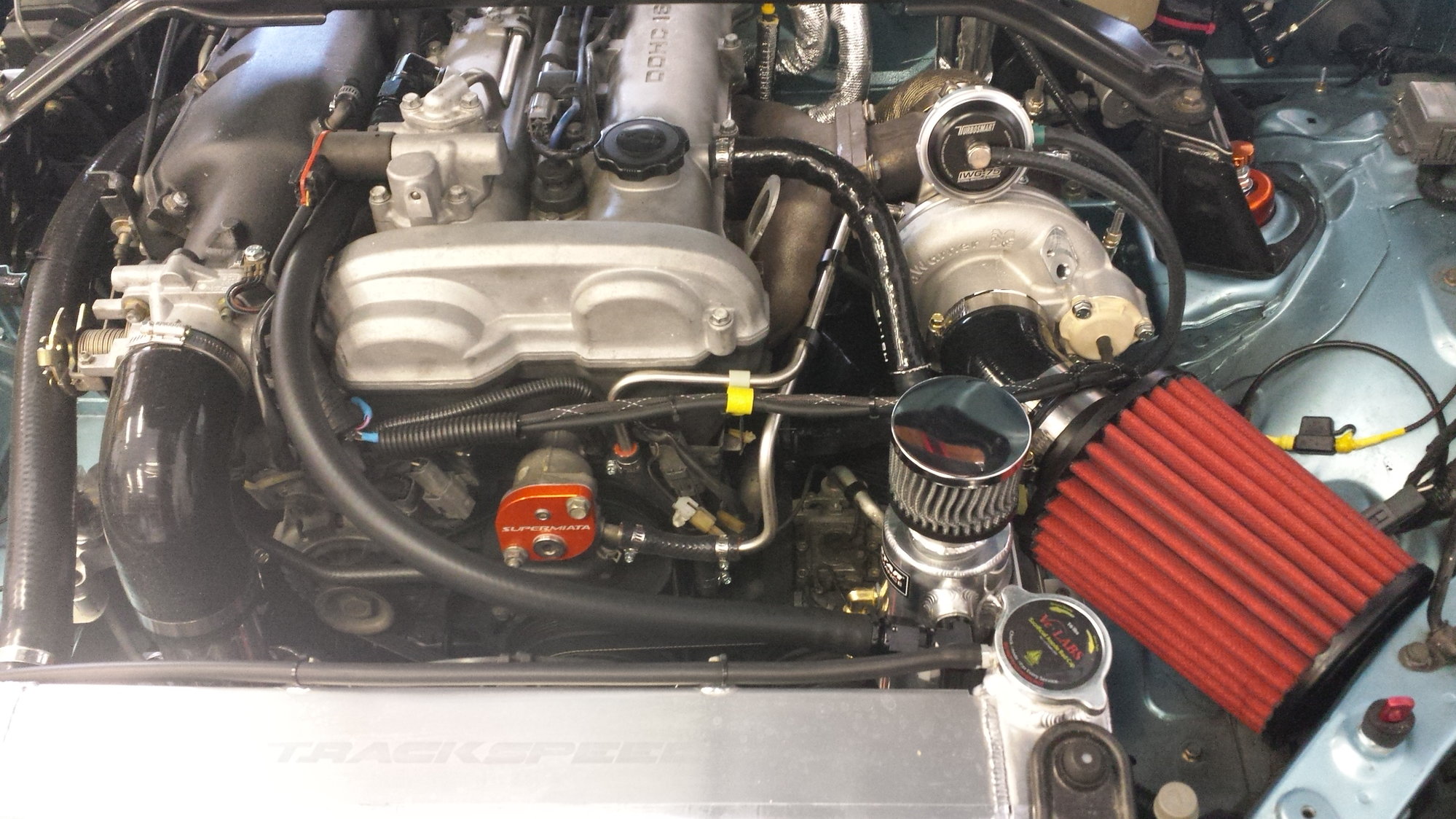

Savington has mentioned a few times that the VVT crank case venting is more troublesome than than the non-VVT. He also hasn't shared what he's learned on the forum. Not sure if its something he had in development for TSE or maybe someone else he worked with who offers a solution. Based on one of his customer car build threads from 2018 (https://www.miataturbo.net/build-thr...ad-95411/page4) it looks like he's only using the exhaust side vent to a AOS. Which leads me to think there is something propitiatory going on under the covers.

This isn't an issue with the non-VVT motors, so you would run a traditional catch can/AOS.

Last edited by icantlearn; 10-14-2020 at 12:58 PM.

#94

Nothing fancy going on under the valve cover/baffles. The reason you use a small line on the breather side is becase it simply limits the amount of oil escaping from the engine. VVT motors pump a lot of oil out that port so you can lose lot of oil if you don't have a catch can setup that has a drain back line an AOS. The 3/8"/6an line is enough for a pressure relief, while allowing oil to escape.

This isn't an issue with the non-VVT motors, so you would run a traditional catch can/AOS.

This isn't an issue with the non-VVT motors, so you would run a traditional catch can/AOS.

(99% street driven car, stock VVT engine, Rotrex'd at 14psi)

#95

If you do that, run a line from the "vent" port on the hotside can down under the car. You will still get lots of oil vapor out of there and it will get all over the engine bay.

That is the more traditional catch can setup.

I capped the cold side port on the VC and IM, then ran a 6an line from the hot side to an AOS, which has a drain back to the sump and a vent. Works very well.

That is the more traditional catch can setup.

I capped the cold side port on the VC and IM, then ran a 6an line from the hot side to an AOS, which has a drain back to the sump and a vent. Works very well.

#96

Gents,

Best wishes to everyone for a safe and prosperous 2021.

This was a very interesting read. Thanks, Joe, for the original post. I'm going back through the original thread, too.

Would one of you be so kind as to provide a link to a check valve that you've had good luck with.

Thanks much,

Best wishes to everyone for a safe and prosperous 2021.

This was a very interesting read. Thanks, Joe, for the original post. I'm going back through the original thread, too.

Would one of you be so kind as to provide a link to a check valve that you've had good luck with.

Thanks much,

#97

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

@poormxdad US Plastics P/N 64175. 3/8" Kynar check valve. Has the casing and diaphragm materials needed.

usplastics.com

Not a link, but all necessary information.

DNM

usplastics.com

Not a link, but all necessary information.

DNM

#99

Junior Member

iTrader: (2)

Join Date: Aug 2009

Location: Chaparral, New Mexico

Posts: 200

Total Cats: 9

Looking at what I'll be doing for my catch can setup and have been reading threads all the way back since 2010 and a lot has changed since then. Lots of contradictory info, wanted to ask if the general consensus still stands.

-Block pcv port on intake manifold.

-Tap and plug pcv port on valve cover.

-Enlarge passages between baffles in valve cover.

-Put brass scrubbers in valve cover baffles and seal well.

-Tap or weld fitting onto exhaust side outlet on valve cover and run directly to vta catch can.

The alternative I see recommended the most is to put a air to oil separator between the vc and intake with the gtx pcv valve and the exhaust side vented to atmosphere as explained above. One thing I don't understand though, is that if the exhaust side is vented to atmosphere. How could the tiny pcv pull enough vacuum to not just pull atmosphere making the valve worthless. Or is their something I'm missing.

I'm leaning towards the ladder anyhow to just eliminate the blow by going back into the combustion chamber all together.

-Block pcv port on intake manifold.

-Tap and plug pcv port on valve cover.

-Enlarge passages between baffles in valve cover.

-Put brass scrubbers in valve cover baffles and seal well.

-Tap or weld fitting onto exhaust side outlet on valve cover and run directly to vta catch can.

The alternative I see recommended the most is to put a air to oil separator between the vc and intake with the gtx pcv valve and the exhaust side vented to atmosphere as explained above. One thing I don't understand though, is that if the exhaust side is vented to atmosphere. How could the tiny pcv pull enough vacuum to not just pull atmosphere making the valve worthless. Or is their something I'm missing.

I'm leaning towards the ladder anyhow to just eliminate the blow by going back into the combustion chamber all together.

#100

I don't believe you want to use both VTA and the PCV. Perhaps it is fine if you are using manifold air pressure to control the fuel supply.

But if using vane air flow or mass air flow metering then you are sucking in unmetered air, sending you very lean.

In other words, the VTA becomes a vacuum leak when the PCV is open.

But if using vane air flow or mass air flow metering then you are sucking in unmetered air, sending you very lean.

In other words, the VTA becomes a vacuum leak when the PCV is open.