How To: Change Valve Stem Seals With Head On

#1

TheCarPassionChannel

Thread Starter

Join Date: Mar 2013

Location: San Diego, Ca

Posts: 188

Total Cats: 136

Valve Stem Seal Replacement

Let me preface this article by informing you that I am not a professional mechanic. Cars are my hobby and Iíve been doing all of my own work on them since I got my first car 10 years ago. If you see something that could be done differently or better than how I have it laid out here, let me know about it! Iím all about putting out good information. Okay onto the fun stuff!

Before the actual seal replacement begins, you need to be able to get this far. Front covers off, cams and lifters out. If youíre uncomfortable with removing your camshafts or setting up the cam timing on your engine, you may want to bring your car to a professional to have the seals done. For the record this car is a 1.6L, but Iím sure 99% of the procedures found here will apply to the 1.8L engine as well.

Hereís the complete list of tools I used for the entire procedure (including cam removal, etc):

3/8Ē Drive Ratchet & 6Ē extension

(2) Torque wrenches, in-lbs & ft-lbs

10mm (deep), 12mm, 14mm, 21mm sockets

5/8Ē Spark plug socket

Long tipped needle nose pliers

Straight pick

(2) Shoelaces OR nylon rope

Long flat head screwdriver

Neiko valve spring compressor (AmazonDOTcom, $60)

Zip ties & diagonals to cut them

(16) OEM Mazda valve stem seals

High temp silicone sealant (for the cam caps)

While Iím at it, hereís a list of ďWhile youíre in thereĒ items that could be easily done if your car is due:

Spark plugs

Spark plug wires

Valve cover gasket

Timing belt / tensioner / idler

Alternator belt

AC / power steering belt (if equipped)

Lifter rebuild or replacement

CAS O-Ring

Cam seals

Once youíve got your lifters out youíre ready for business. Remove all of the spark plugs and drop your long screwdriver into the #3 cylinder spark plug hole (FIG 1). Crank the engine by hand with your 21mm socket on the crank pulley until the screwdriver starts to rise and stop when it reaches its peak. Piston #2 and piston #3 are now at top dead center (TDC) which means piston #1 and piston #4 are at bottom dead center (BDC).

Next up start feeding your shoelaces (I used two tied together and it worked perfectly) or nylon rope into the spark plug hole for cylinder #1. You want to get it pretty full, then crank the engine by hand again, bringing cylinder #1 back to TDC (or as close as you can, the rope will probably stop it from going all the way up, which is perfect).

Now itís time to set your tool up. This tool has many different options when it comes to setup, it really is a versatile, quality unit. You may still have to get a little creative like I did for your mounting.

After you get that all figured out, youíre ready for the real fun! I try to set the tool up to be at the same angle as the valve Iím working with so itís pushing directly downwards. You may have to play with a couple of combinations on the tool to get the right angle and the right amount of stroke (especially on the intake side where the manifold tends to stop the tool from compressing the spring enough). Hereís why I prefer using rope in the cylinders over the compressed air method: Most write-ups say to fill the cylinder with 100psi to hold the valves in place while you compress the spring. I believe the stock intake valve diameter on a 1.6L is 31mm. A quick calculation tells me that the 100psi in the cylinder is putting about 117lbs of upward force on that valve. I can tell you on at least half of the valves it took over 100lbs of force to crack the retainer loose from the keeper. I certainly donít want to break the seal of the cylinder and have my valve go plowing into the top of the piston with my weight behind it. At any rate, to each his own.

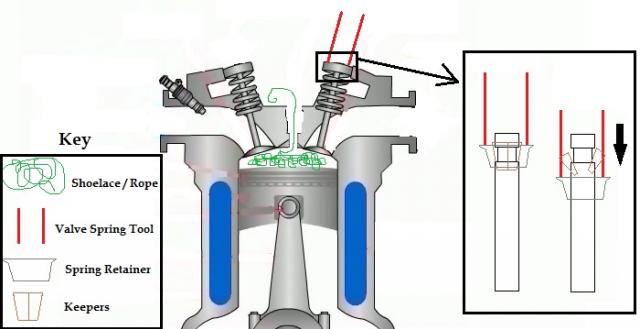

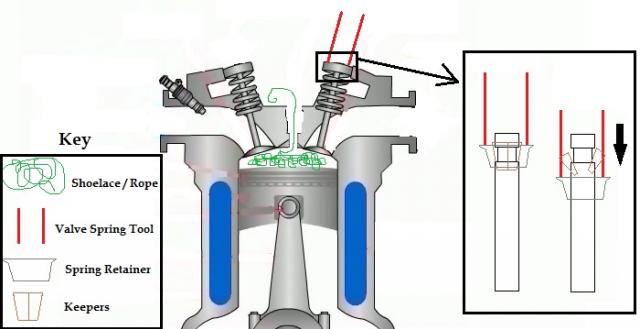

What you want to do is pry downwards on the tool, pushing the retainer down the valve stem and freeing the keepers. The keepers will probably stick to the valve stem, so you want to have a pick handy to flick them off. Once they are free, slowly release the tool until the spring is fully uncompressed. Iíve included a rudimentary drawing as well. (Base picture from TheAutoPartsShopDOTcom modified with my mind blowing MS Paint skill)

Use your magnet to carefully remove the keepers, retainer, and spring. If you drop a keeper, you may never find it, so be careful!

Look at that old seal. Who knew such a tiny culprit could generate smoke screens that would have James Bond looking to use a high mileage Miata in his next movie.

Now youíre going to grab the seal by its metal sleeve. Be very careful not to scratch the lifter bucket or valve stem! Twist a bit while pulling straight off the valve, they took a little muscle. As long as you pull straight up, you wonít contact anything else on the way up, except maybe your elbow on the hood. (Possibly several times).

Hereís what most of them looked like after removal, Iím guessing these are the original 22-year-old, 189,000 mile seals in this head.

After removing the seal, you can see the groove that you will feel the new seals ďpopĒ into. I always like to check things like that out so I can get an idea of how much pressure to use / how far to go when installing the new units.

Thatís a fresh looking seal! I opted for the more expensive OEM Mazda seals. For things like this, I believe nobody does it better than the manufacturer. And if I have to replace them in another 150,000 miles, I wonít be bummed.

Hereís a little trick that makes it easy to drop the seal where you want it. Hold the seal on your pick, line it up with the top of the valve and drop the seal. Pictures describe it better:

Now take your 10mm deep socket on an extension and place it lightly on top of the seal. I moved it in a circular motion to eased it over the top of the valve stem, pushed it to the bottom, and felt it ďpopĒ into place. Iíd say it takes around 10lbs of force. Now all you have to do now is reverse your steps. Thatís easier said than done, so I have some more pictures for you!

Drop your spring back in, followed by the retainer with the keepers. FIG A shows one keeper facing each way. Notice how one side is fatter? The fat parts go up. You can now drop the retainer on top of the spring with the keepers in it.

Are you ready for the trickiest part of the whole job? There are a couple of different techniques I used when getting these things back in place. One is to place your finger on top of the keepers, compress the spring, and sometimes they go right into place and lock in the retainer upon releasing the tool. Probably 25% chance, at least the way I was doing it. Make sure the keepers are in place before fully releasing the spring! Go slow and make sure they arenít getting crazy on you. If that method doesnít work you can also use your pick to move the keepers into place. This takes patience and the stability of a surgeonís hand. The keepers will be flipping all over inside the bucket, basically doing the Hokey Pokey in the most taunting fashion possible while you sweat trying to keep the spring compressed. They will go in, trust me. Be patient. In the picture below, the keepers are in position and youíre ready to release the spring compressor.

Once everything is back in place, it will look something like this. Donít worry about the keepers being perfectly centered, it doesnít matter. That wasnít so bad, right? Only 15 more to go!

Side note: A round nylon rope may work better than the shoelace method for one reason. First time I went to pull the shoelace out it was stuck and I about had a heart attack. It was just pinched under the valve. I just took a large socket and pressed each valve down by hand until I found the one it was pinched under and it came right out. I did like the shoelace because it was super easy to get into the cylinder using my TDC tool (long screwdriver).

The test drive: always the best part! I coasted down a long hill, probably about Ĺ mile, off throttle the whole way. At the bottom I punched it, and where before it would generate more smoke than a Bob Marley concert, there was none to be found! Operation successful!

Let me preface this article by informing you that I am not a professional mechanic. Cars are my hobby and Iíve been doing all of my own work on them since I got my first car 10 years ago. If you see something that could be done differently or better than how I have it laid out here, let me know about it! Iím all about putting out good information. Okay onto the fun stuff!

Before the actual seal replacement begins, you need to be able to get this far. Front covers off, cams and lifters out. If youíre uncomfortable with removing your camshafts or setting up the cam timing on your engine, you may want to bring your car to a professional to have the seals done. For the record this car is a 1.6L, but Iím sure 99% of the procedures found here will apply to the 1.8L engine as well.

Hereís the complete list of tools I used for the entire procedure (including cam removal, etc):

3/8Ē Drive Ratchet & 6Ē extension

(2) Torque wrenches, in-lbs & ft-lbs

10mm (deep), 12mm, 14mm, 21mm sockets

5/8Ē Spark plug socket

Long tipped needle nose pliers

Straight pick

(2) Shoelaces OR nylon rope

Long flat head screwdriver

Neiko valve spring compressor (AmazonDOTcom, $60)

Zip ties & diagonals to cut them

(16) OEM Mazda valve stem seals

High temp silicone sealant (for the cam caps)

While Iím at it, hereís a list of ďWhile youíre in thereĒ items that could be easily done if your car is due:

Spark plugs

Spark plug wires

Valve cover gasket

Timing belt / tensioner / idler

Alternator belt

AC / power steering belt (if equipped)

Lifter rebuild or replacement

CAS O-Ring

Cam seals

Once youíve got your lifters out youíre ready for business. Remove all of the spark plugs and drop your long screwdriver into the #3 cylinder spark plug hole (FIG 1). Crank the engine by hand with your 21mm socket on the crank pulley until the screwdriver starts to rise and stop when it reaches its peak. Piston #2 and piston #3 are now at top dead center (TDC) which means piston #1 and piston #4 are at bottom dead center (BDC).

Next up start feeding your shoelaces (I used two tied together and it worked perfectly) or nylon rope into the spark plug hole for cylinder #1. You want to get it pretty full, then crank the engine by hand again, bringing cylinder #1 back to TDC (or as close as you can, the rope will probably stop it from going all the way up, which is perfect).

Now itís time to set your tool up. This tool has many different options when it comes to setup, it really is a versatile, quality unit. You may still have to get a little creative like I did for your mounting.

After you get that all figured out, youíre ready for the real fun! I try to set the tool up to be at the same angle as the valve Iím working with so itís pushing directly downwards. You may have to play with a couple of combinations on the tool to get the right angle and the right amount of stroke (especially on the intake side where the manifold tends to stop the tool from compressing the spring enough). Hereís why I prefer using rope in the cylinders over the compressed air method: Most write-ups say to fill the cylinder with 100psi to hold the valves in place while you compress the spring. I believe the stock intake valve diameter on a 1.6L is 31mm. A quick calculation tells me that the 100psi in the cylinder is putting about 117lbs of upward force on that valve. I can tell you on at least half of the valves it took over 100lbs of force to crack the retainer loose from the keeper. I certainly donít want to break the seal of the cylinder and have my valve go plowing into the top of the piston with my weight behind it. At any rate, to each his own.

What you want to do is pry downwards on the tool, pushing the retainer down the valve stem and freeing the keepers. The keepers will probably stick to the valve stem, so you want to have a pick handy to flick them off. Once they are free, slowly release the tool until the spring is fully uncompressed. Iíve included a rudimentary drawing as well. (Base picture from TheAutoPartsShopDOTcom modified with my mind blowing MS Paint skill)

Use your magnet to carefully remove the keepers, retainer, and spring. If you drop a keeper, you may never find it, so be careful!

Look at that old seal. Who knew such a tiny culprit could generate smoke screens that would have James Bond looking to use a high mileage Miata in his next movie.

Now youíre going to grab the seal by its metal sleeve. Be very careful not to scratch the lifter bucket or valve stem! Twist a bit while pulling straight off the valve, they took a little muscle. As long as you pull straight up, you wonít contact anything else on the way up, except maybe your elbow on the hood. (Possibly several times).

Hereís what most of them looked like after removal, Iím guessing these are the original 22-year-old, 189,000 mile seals in this head.

After removing the seal, you can see the groove that you will feel the new seals ďpopĒ into. I always like to check things like that out so I can get an idea of how much pressure to use / how far to go when installing the new units.

Thatís a fresh looking seal! I opted for the more expensive OEM Mazda seals. For things like this, I believe nobody does it better than the manufacturer. And if I have to replace them in another 150,000 miles, I wonít be bummed.

Hereís a little trick that makes it easy to drop the seal where you want it. Hold the seal on your pick, line it up with the top of the valve and drop the seal. Pictures describe it better:

Now take your 10mm deep socket on an extension and place it lightly on top of the seal. I moved it in a circular motion to eased it over the top of the valve stem, pushed it to the bottom, and felt it ďpopĒ into place. Iíd say it takes around 10lbs of force. Now all you have to do now is reverse your steps. Thatís easier said than done, so I have some more pictures for you!

Drop your spring back in, followed by the retainer with the keepers. FIG A shows one keeper facing each way. Notice how one side is fatter? The fat parts go up. You can now drop the retainer on top of the spring with the keepers in it.

Are you ready for the trickiest part of the whole job? There are a couple of different techniques I used when getting these things back in place. One is to place your finger on top of the keepers, compress the spring, and sometimes they go right into place and lock in the retainer upon releasing the tool. Probably 25% chance, at least the way I was doing it. Make sure the keepers are in place before fully releasing the spring! Go slow and make sure they arenít getting crazy on you. If that method doesnít work you can also use your pick to move the keepers into place. This takes patience and the stability of a surgeonís hand. The keepers will be flipping all over inside the bucket, basically doing the Hokey Pokey in the most taunting fashion possible while you sweat trying to keep the spring compressed. They will go in, trust me. Be patient. In the picture below, the keepers are in position and youíre ready to release the spring compressor.

Once everything is back in place, it will look something like this. Donít worry about the keepers being perfectly centered, it doesnít matter. That wasnít so bad, right? Only 15 more to go!

Side note: A round nylon rope may work better than the shoelace method for one reason. First time I went to pull the shoelace out it was stuck and I about had a heart attack. It was just pinched under the valve. I just took a large socket and pressed each valve down by hand until I found the one it was pinched under and it came right out. I did like the shoelace because it was super easy to get into the cylinder using my TDC tool (long screwdriver).

The test drive: always the best part! I coasted down a long hill, probably about Ĺ mile, off throttle the whole way. At the bottom I punched it, and where before it would generate more smoke than a Bob Marley concert, there was none to be found! Operation successful!

#4

Supporting Vendor

iTrader: (33)

Join Date: Jul 2006

Location: atlanta-ish

Posts: 12,659

Total Cats: 134

This is a pretty good write up. I've never tried your shoelace method before. I just wanted to note that snapon/bluepoint has an amazing valve keeper tool that makes removing and installing the keepers much easier. Well worth the money IMO, and I'm cheap! It was $80 new off the truck IIRC.

#5

Supporting Vendor

iTrader: (33)

Join Date: Jul 2006

Location: atlanta-ish

Posts: 12,659

Total Cats: 134

Make it easy on yourself. Use this toolset:

Amazon.com: KD Tools Gearwrench Valve Service Kit: Home Improvement

...

It's magic.

Amazon.com: KD Tools Gearwrench Valve Service Kit: Home Improvement

...

It's magic.

#6

TheCarPassionChannel

Thread Starter

Join Date: Mar 2013

Location: San Diego, Ca

Posts: 188

Total Cats: 136

Thanks

I saw that tool as well and opted for the Neiko. I was a little worried about that tool not working as well as the video demonstration shows it, and I had already done springs with a hook and handle style compressor before, so I knew it would work out fine. Would definitely try that tool in the future though! Also did not know about the seal pliers prior to the procedure.

I saw that tool as well and opted for the Neiko. I was a little worried about that tool not working as well as the video demonstration shows it, and I had already done springs with a hook and handle style compressor before, so I knew it would work out fine. Would definitely try that tool in the future though! Also did not know about the seal pliers prior to the procedure.

#7

I used compressed air to keep the valves in place. That was easy too -- assuming you have an air compressor. Nothing wrong with the rope trick though.

#12

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Definitely use a magnetic keeper tool. The tool I used to do this exact job also had a magnetic installer which slipped the retainers into place as you pressed down. Easy-peasy, no chance of dropping a retainer down an oil drain into the oil pan.

Also +1 to valve seal pliers, I did it with needlenose and it was a little nerve-wracking.

Flawless writeup otherwise.

Also +1 to valve seal pliers, I did it with needlenose and it was a little nerve-wracking.

Flawless writeup otherwise.

Thread

Thread Starter

Forum

Replies

Last Post

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM