Impossible bolt- need tricks and suggestions

#1

trans bellhousing bolt (14mm with nut on front). Stripped threads. Yesterday I Tightened a new nut on the good threads and jb welded the two together. Tried to spin both off by the good nut and the jb weld just broke. Iím thinking 18 hours wasnít enough cure time so I cleaned everything up and applied some more. But I need other suggestions in case that fails again.

#4

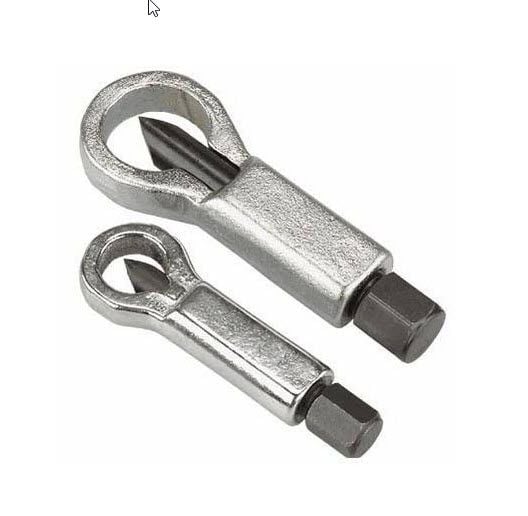

I don't think you're going to fit a nut splitter over the nut because it's too close to the block.

It's time to remove one end of the bolt -- the head is probably easier to get to, so I'd try that. Drill, dremel, cutoff wheel, something like that. You might need to pull the motor + tranny together and do it out of the car.

--ian

It's time to remove one end of the bolt -- the head is probably easier to get to, so I'd try that. Drill, dremel, cutoff wheel, something like that. You might need to pull the motor + tranny together and do it out of the car.

--ian

#10

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,593

I've had the same corded multi-speed dremel tool for about the past 15 years. If their quality has gone downhill in recent years, then I'll retract this comment. But I have beat the absolute hell out of that tool, and it's never let me down. I wish I could post a photo and the model number, but I left it at work this weekend, as I've been using it to modify a set of 30 year old Vinten Fulmar camera pedestals to accept a modern robotic head, and also to lock their leaky pneumatic columns in place.

Would I spec this tool for use on an assembly line where it'll be in service for two shifts every day? Hell no. It's a consumer-grade product. But for my needs, it does the job well.

#11

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

For small items and small jobs, they are fine. The problem is that nothing on a car is small enough to justify its size and corresponding lack of power. I owned one and threw it away after the collet lock snapped off, dooming it to a lifelong marriage with a broken router bit.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

#12

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,593

#13

Elite Member

iTrader: (21)

Join Date: Jun 2007

Location: Rochester, NY

Posts: 6,593

Total Cats: 1,259

For small items and small jobs, they are fine. The problem is that nothing on a car is small enough to justify its size and corresponding lack of power. I owned one and threw it away after the collet lock snapped off, dooming it to a lifelong marriage with a broken router bit.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

#15

For small items and small jobs, they are fine. The problem is that nothing on a car is small enough to justify its size and corresponding lack of power. I owned one and threw it away after the collet lock snapped off, dooming it to a lifelong marriage with a broken router bit.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

For cutting through the nut and shaft of an M12 bolt, I would not suggest one.

--Ian

#16

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

When i crack my boat (wood) i use a dremel to router out the crack before applying filler. Dremel is good for light, delicate work, even if it's a big job. In the scenario in which i need to grind down a half inch bolt head, a dremel isn't my first thought. It just doesn't have the *****.

For that i use this:

For that i use this:

#17

When i crack my boat (wood) i use a dremel to router out the crack before applying filler. Dremel is good for light, delicate work, even if it's a big job. In the scenario in which i need to grind down a half inch bolt head, a dremel isn't my first thought. It just doesn't have the *****.

For that i use this: https://www.amazon.com/Makita-GD0601.../dp/B001ASC73E

For that i use this: https://www.amazon.com/Makita-GD0601.../dp/B001ASC73E

--Ian

#20

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I just don't know guys. I'm probably doing something completely wrong with my dremel. Don't get me wrong, i absolutely love it and i know it has it's place. But man i just don't remember it cutting through metal, specifically a bolt head that easily.